High precision optical fiber grating wave length demodulation system

A wavelength demodulation and fiber grating technology, applied to broadband demodulation, can solve the problems of low accuracy and signal-to-noise ratio, large bandwidth, and low cost, and achieve broad market prospects, fast response speed, and easy productization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

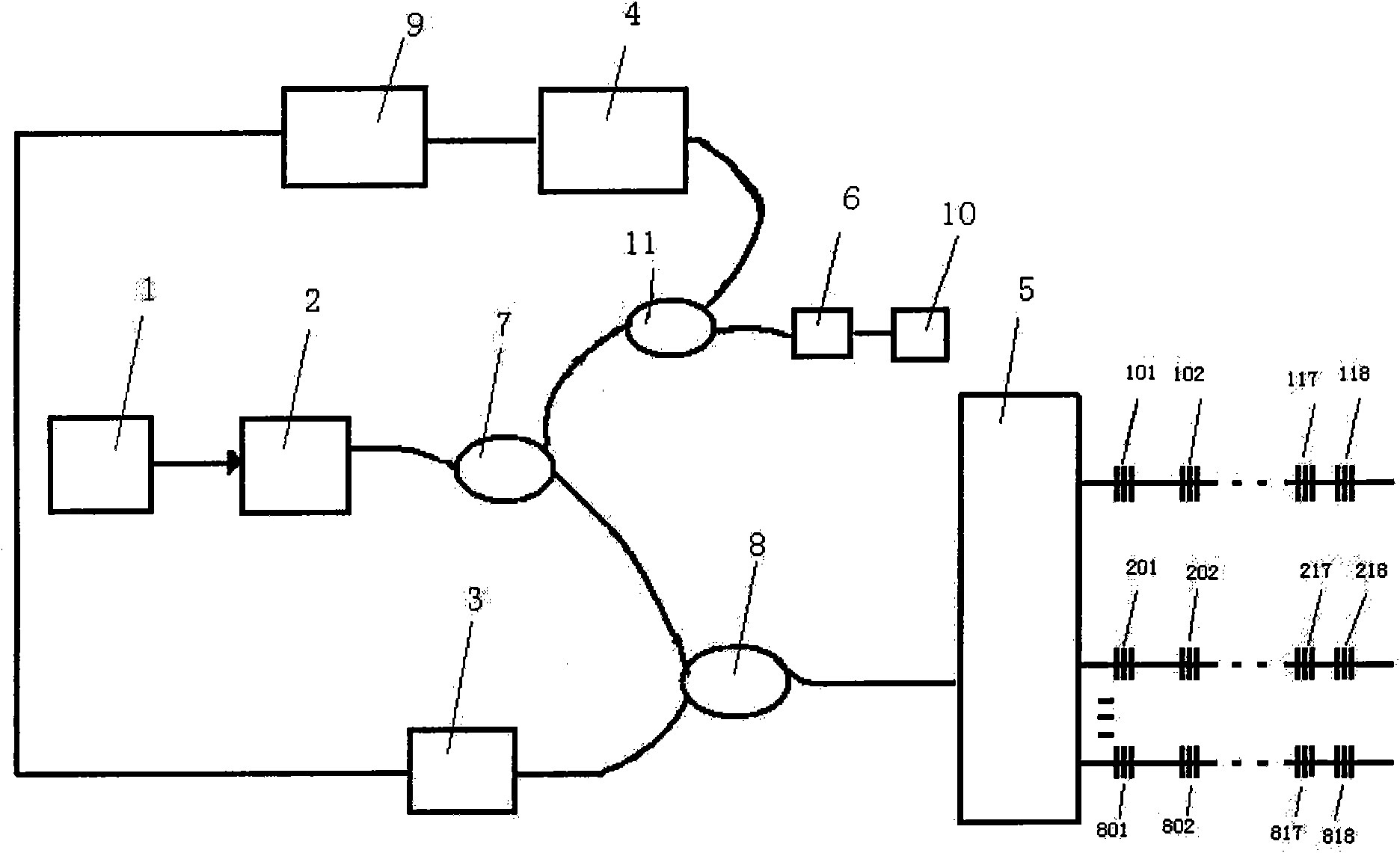

[0027] A fiber grating wavelength demodulation system, the demodulation system includes: a broadband light source 1, a tunable filter 2, a first 1×2 coupler 7, a 1×2 coupler 11, an etalon filter 6, a reference grating 10 and the wavelength calibration module composed of the second photodetector 4, the second 1×2 coupler 8, the first photodetector 3, the 1×N optical switch 5, and the signal processing system 9; the connection between the devices formed by it :

[0028] The output terminal of the broadband light source 1 is connected to the input terminal of the tunable filter 2, the output terminal of the tunable filter 2 is connected to the input terminal of the first 1×2 coupler 7, and the other output terminal of the first 1×2 coupler 7 is connected to the second An output end of the second 1×2 coupler 8; the other output end of the second 1×2 coupler 8 is connected to the signal processing system 9 through the first photodetector 3; the input end of the second 1×2 coupler 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com