Manufacture method of elliptical stressed zone type polarization maintaining fiber

A polarization-maintaining optical fiber and manufacturing method technology, applied in polarization optical fibers, cladding optical fibers, manufacturing tools, etc., can solve the problems of difficult operation, complex process, high cost, and achieve the effect of easy productization, simple process, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

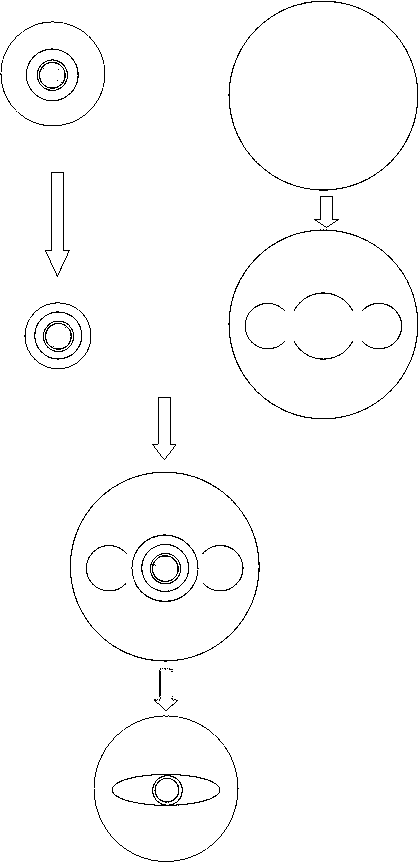

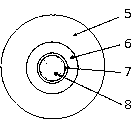

[0031] (1) Use an MCVD lathe to make an optical fiber preform to be processed with a stress zone, the outer diameter of the preform is 10mm, and the diameter of the stress zone is 5mm;

[0032] (2) Fix the optical fiber preform to be processed on the grinding machine, grind the outer diameter to 8mm, then polish it, and throw it to mm;

[0033] (3) Fix a quartz rod with an outer diameter of 20mm and a length of 200mm on a drill press, and drill a hole in the center with a size of mm round hole, drill a round hole with a size of 5±0.1mm on both sides;

[0034] (4) Insert the core rod of the preform into the center hole of the quartz sheath and fix it to obtain a formal preform;

[0035] (5) Fix the official preform on the drawing tower, and draw it into an elliptical stress zone type polarization-maintaining optical fiber at a temperature of 2000 ° C, with an outer diameter of 40 μm.

[0036]

no. 2 example

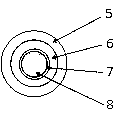

[0038] (1) Use an MCVD lathe to make an optical fiber preform with a stress zone to be processed. The outer diameter of the preform is 15mm, and the diameter of the stress zone is 8mm;

[0039] (2) Fix the optical fiber preform to be processed on the grinding machine, grind the outer diameter to 10mm, then polish it, and throw it to mm;

[0040] (3) Fix a quartz rod with an outer diameter of 30mm and a length of 200mm on a drill press, and drill a hole with a size of mm round hole, drill a round hole with a size of 7±0.1mm on both sides;

[0041] (4) Insert the core rod of the preform into the center hole of the quartz sheath and fix it to obtain a formal preform;

[0042] (5) Fix the official preform on the drawing tower, and draw it into an elliptical stress zone type polarization-maintaining optical fiber at a temperature of 2000 ° C, with an outer diameter of 40 μm.

[0043]

[0044] It can be seen from the above embodiments that the present invention adopts the perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com