Redundant seal pipeline connector

A sealed pipe, redundant technology, applied in the direction of pipe joints, pipes/pipe joints/fittings, fluid tightness testing, etc., can solve the problem of reduced sealing effect of pipeline sealing structure, complex detection devices and detection procedures, and impossibility of sealing Leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

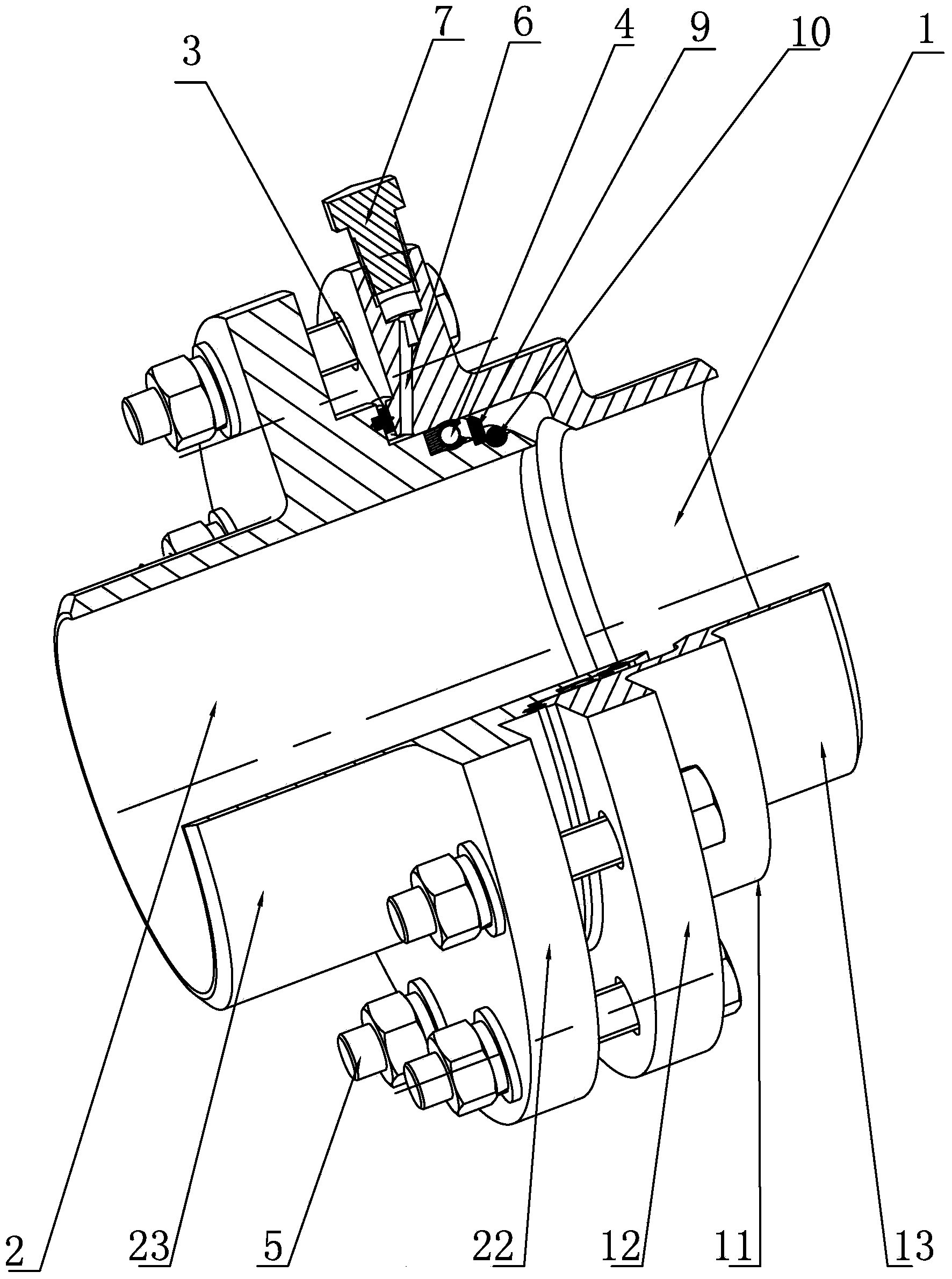

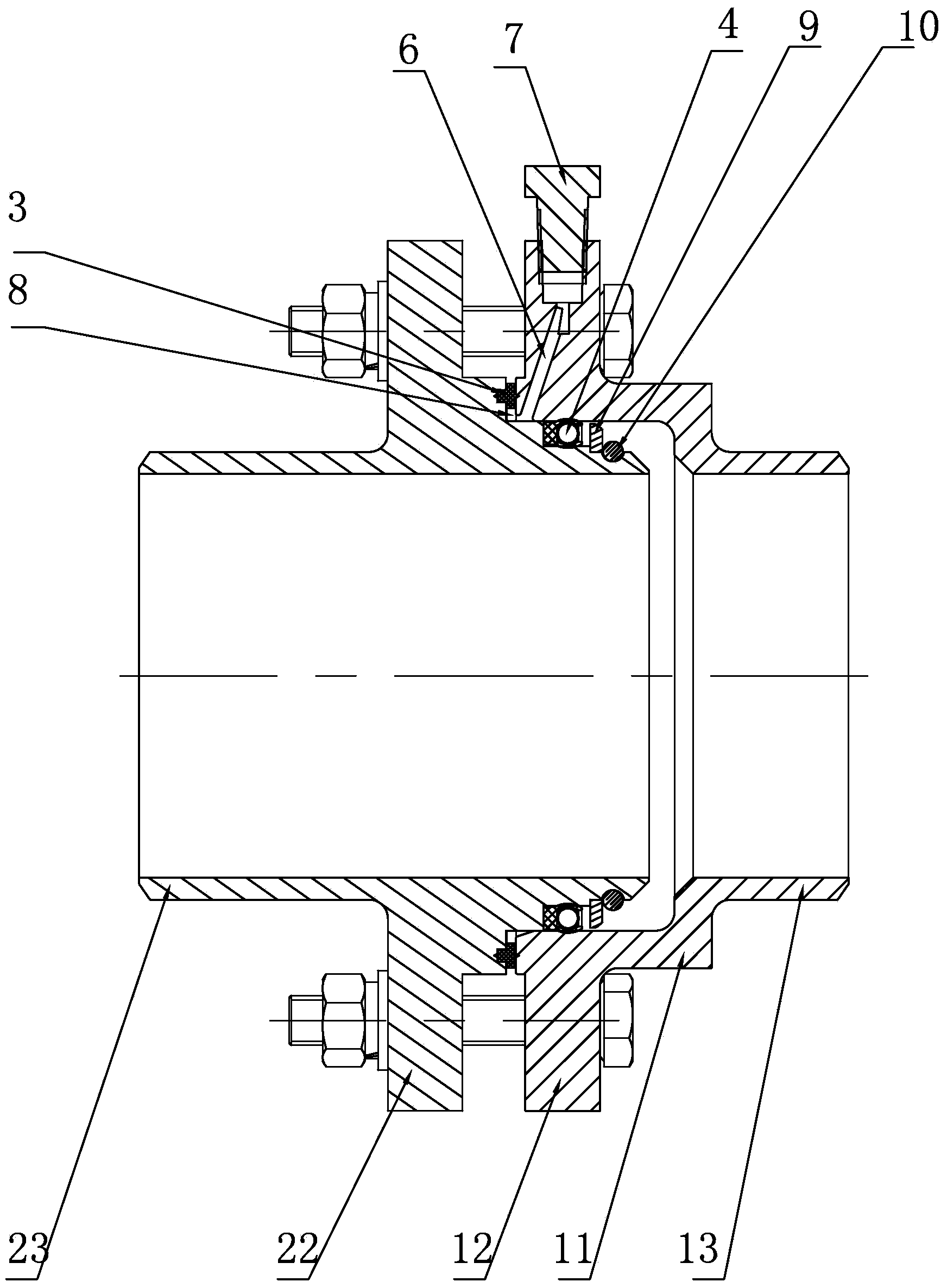

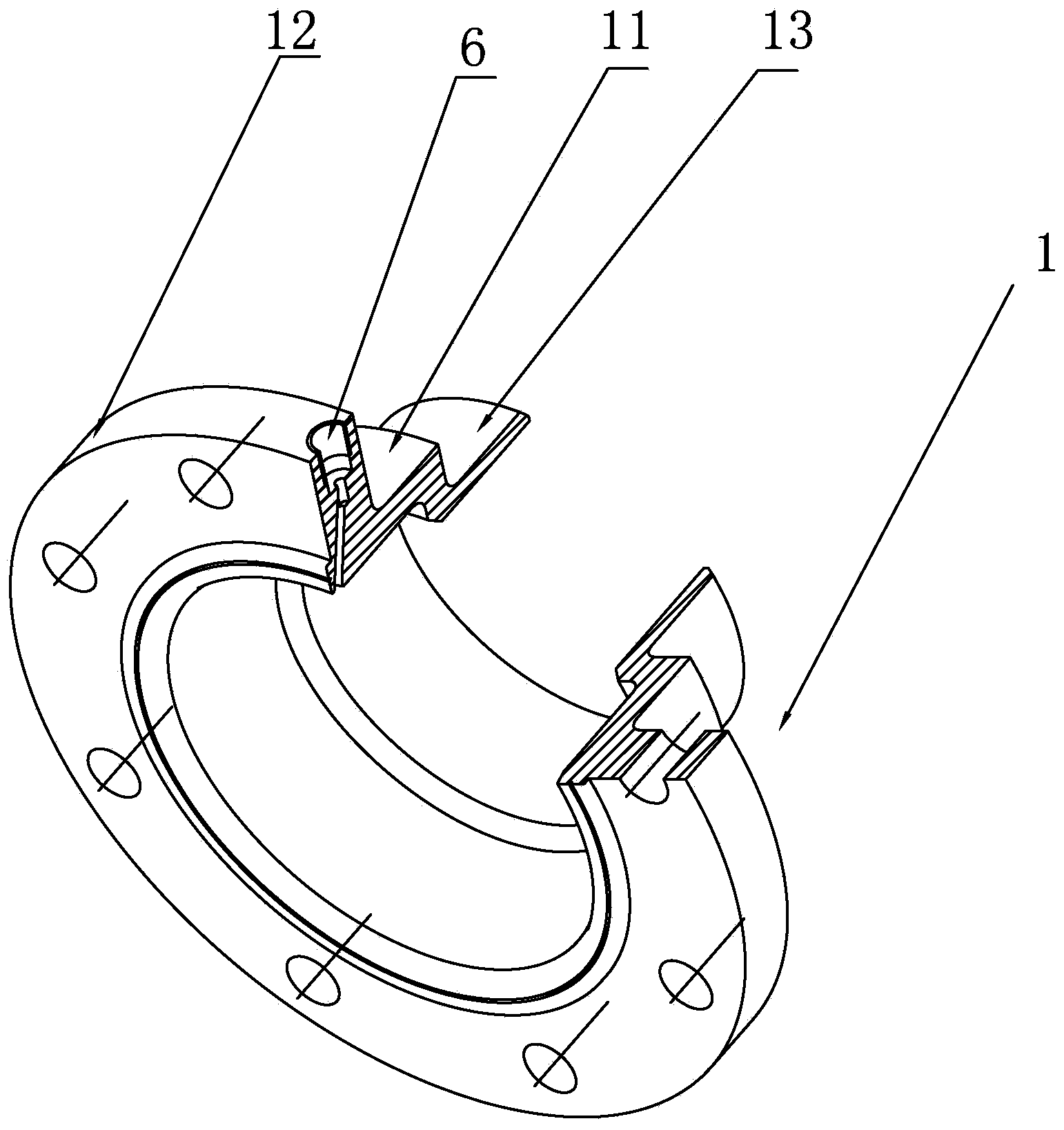

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the redundant sealing pipeline joint of the present invention includes a seal seat 1, a seal cone 2, an end face seal 3, a radial seal 4 and a fastener 5, and the seal seat 1 includes a first axial protrusion 11, a first The annular flange 12 and the first welding end 13, the first axial protrusion 11, the first annular flange 12 and the first welding end 13 are integrally made, and the sealing cone 2 includes the second axial protrusion 21, The second annular flange 22 and the second welding end 23, the second axial protrusion 21, the second annular flange 22 and the second welding end 23 are integrally made, and the fastener 5 is installed on the first annular On the flange 12 and the second annular flange 22, the sealing seat 1 and the sealing cone 2 are fixedly connected by fasteners 5, there are several fasteners 5, and the fasteners 5 are installed on the first annular flange 12 On the second ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com