Time gating angular displacement sensor

An angular displacement sensor and sensor technology, which is applied in the direction of converting sensor output, instruments, and measuring devices, can solve problems such as high price, poor anti-interference ability, and complex structure, and achieve low cost, strong anti-interference ability, and high resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

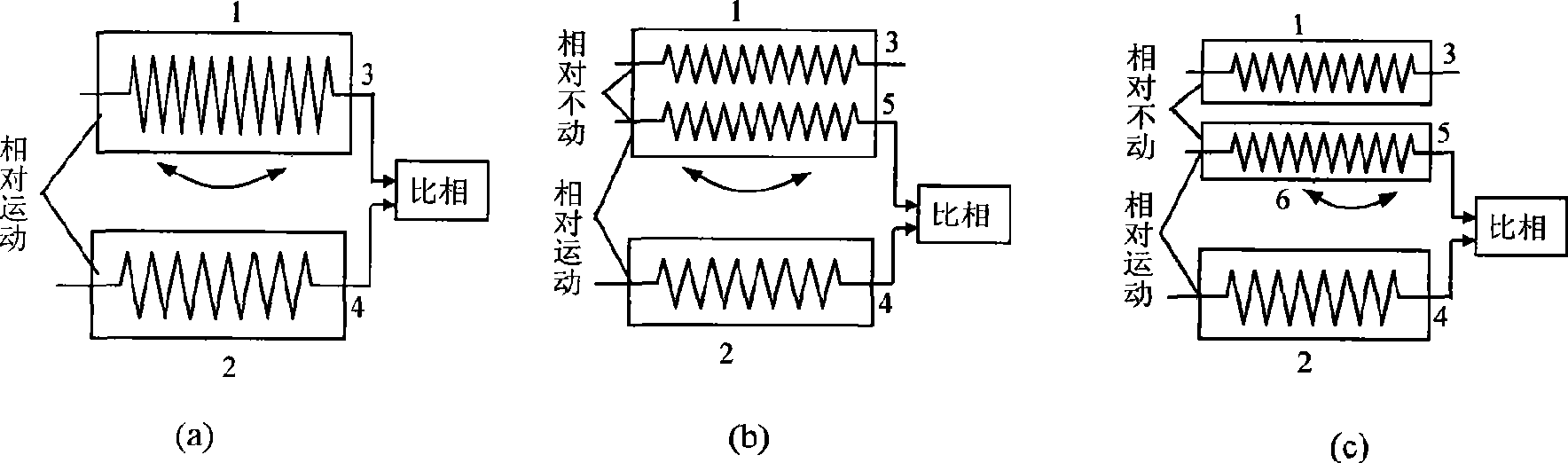

[0014] see figure 1 (a), this is the first structural principle of the sensor, which has a relatively moving outer circle base body 1 and inner circle base body 2 to form a skeleton for winding coils, the outer circle base body 1 is wound with an excitation coil 3, and the inner circle base body 2 is wound with a second induction coil 4, and the induction coil and the excitation coil also move relative to the substrate, and the excitation source directly generates a phase comparison signal, which is compared with the signal of the second induction coil 4.

[0015] see figure 1 (b), this is the second structural principle of the sensor, which has a relatively moving outer circle base body 1 and inner circle base body 2 to form a skeleton for winding coils, and the outer circle base body 1 is wound with an excitation coil 3 and a first induction coil. The coil 5 is wound with a second induction coil 4 on the inner circular substrate 2, and the excitation coil 3 is relatively st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com