Connecting rod fatigue test device with high reliability

A fatigue test and reliability technology, applied in the mechanical field, can solve the problems such as failure to design the reliability of the connecting rod fatigue test device, test failure, etc., to ensure continuity and effectiveness, eliminate the risk of damage, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

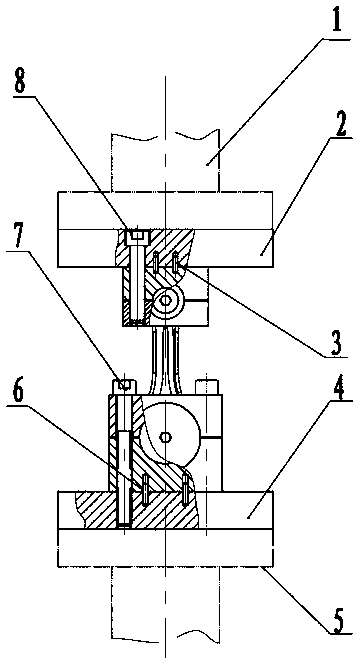

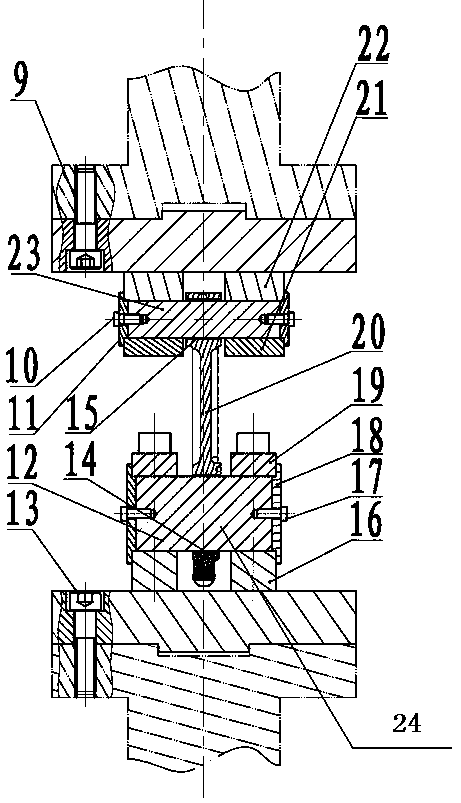

[0022] like figure 1 , 2 As shown, a highly reliable connecting rod fatigue test device, the connecting rod fatigue test device has an adapter flange I2 connected to the lower end of the main drive shaft I1 and an adapter flange connected to the upper end of the main drive shaft II5 II4; the adapter flange I1 and the main transmission shaft I2 are clearance-fitted and solidly connected together; the middle part of the lower end surface of the main transmission shaft I1 has a groove, and the adapter flange I2 is the upper end surface A cylinder with a boss in the middle, and the boss is in clearance fit with the groove on the main transmission shaft I1; there are eight stepped holes evenly distributed along the circumferential direction on the adapter flange I2, and these stepped holes are respectively connected with the main transmission shaft. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com