A vibrating device with an Oldham coupling and a membrane processing system using the same

A technology of cross coupling and vibration device, which is applied in the field of membrane separation, can solve the problems of broken motor shaft and transmission shaft, shortened service life of the motor, etc., and achieves the effect of improving the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

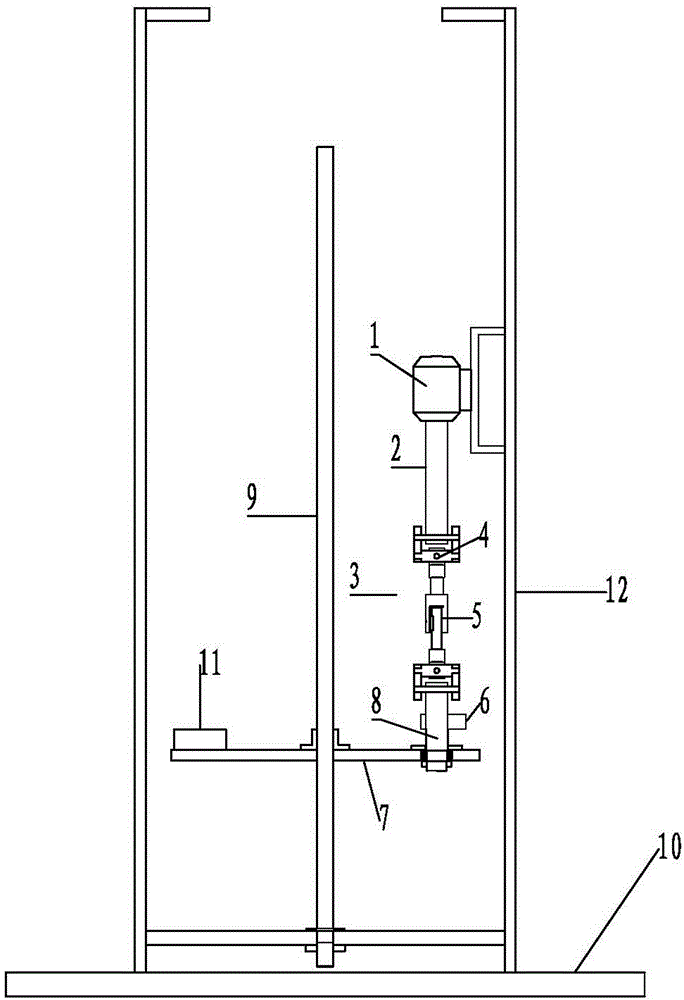

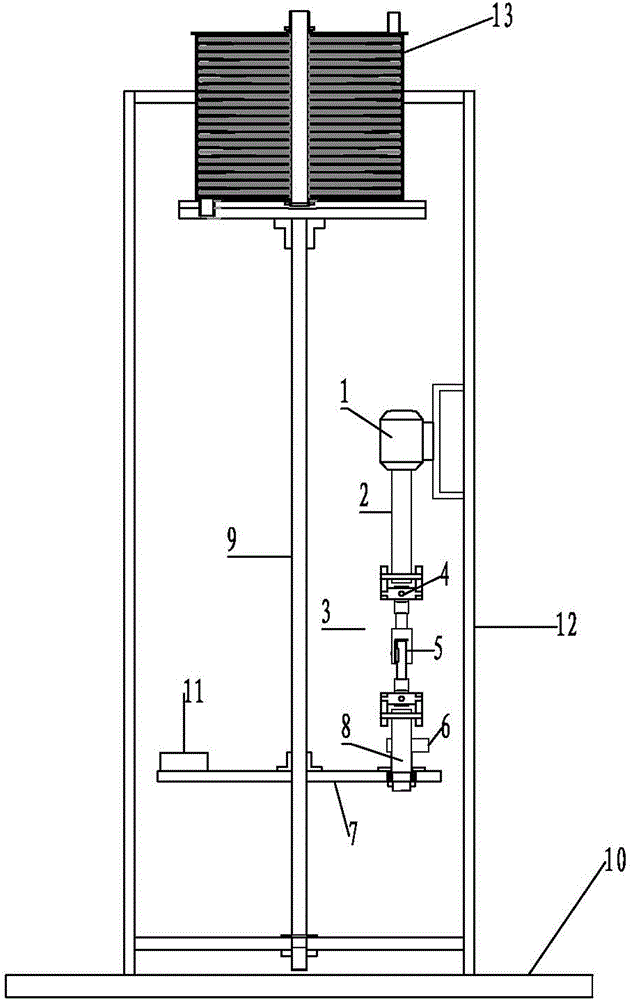

[0039] The vibrating device with the Oldham coupling of the present invention comprises, the motor 1 is provided with a rotatable output shaft 2; the Oldham coupling group 3 and the eccentric shaft 6 that vibrates the membrane assembly 13 through eccentric rotation, and the The Oldham coupling group 3 is composed of an even number of Oldham coupling joints 4, and the Oldham coupling group 3 in this embodiment is composed of two Oldham coupling joints 4; the cross at one end of the Oldham coupling group 3 The coupling 4 is connected to the output shaft 2, and the Oldham coupling 4 at the other end is connected to the eccentric shaft 6. The output shaft 2 is suitable for making the eccentric The shaft 6 rotates eccentrically; the adjacent Oldham couplings 4 are connected by key sleeves 5, and the adjacent Oldham couplings 4 are suitable for sliding relative to each other in the axial direction while being unable to rotate relatively. In this embodiment, the adjacent Oldham coupling...

Embodiment 2

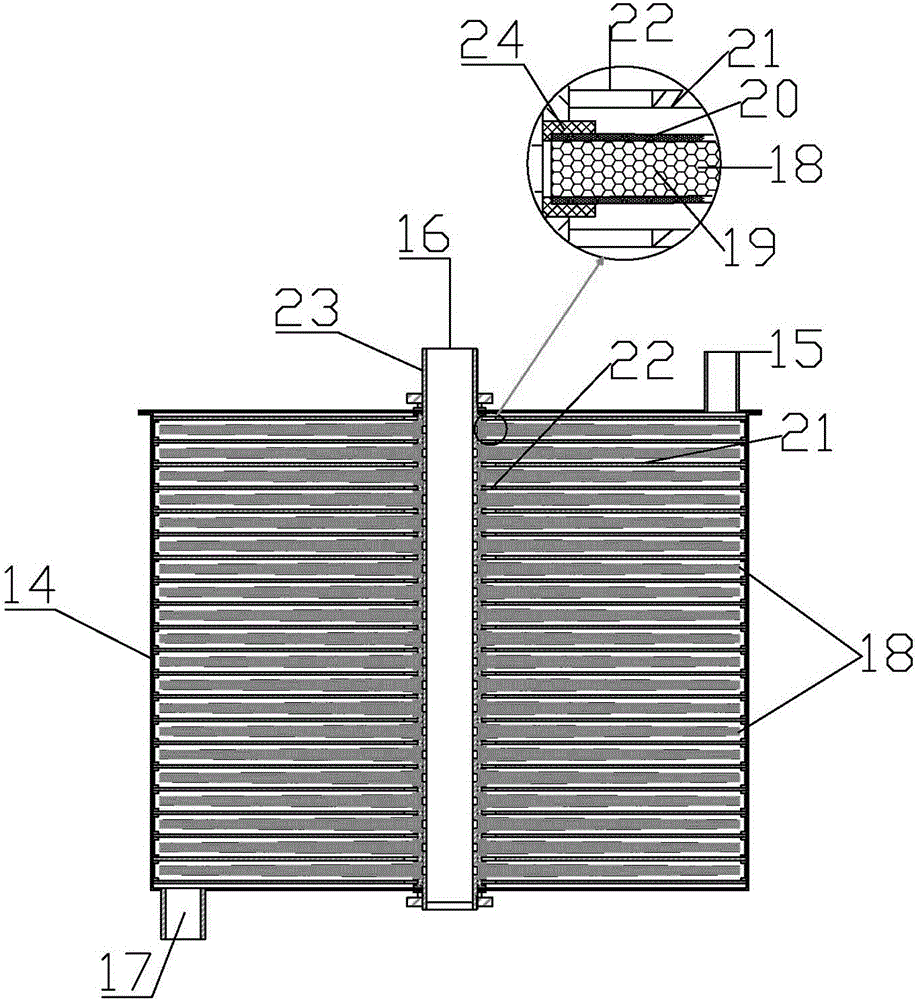

[0042] On the basis of the above, in order to further improve the removal effect of impurities on the surface of the membrane and in the pores, such as figure 1 As shown, the vibrating device also includes a wobble plate 7 for connecting with the membrane assembly 13 and a drive shaft 8 fixedly connected with the wobble plate 7, and the eccentric shaft 6 communicates with the wobble plate 7 through the drive shaft 8. connect. It also includes a vibration transmission rod 9 for connecting the membrane assembly 13 , and the vibration transmission rod 9 is connected with the shaking plate 7 . It also includes a base 10, the vibration transmission rod 9 is vertically arranged, the shaking plate 7 is horizontally connected to the vibration transmission rod 9, one end of the vibration transmission rod 9 is used to connect the membrane assembly 13, and the other end is connected to the vibration transmission rod 9. The base 10 is fixedly connected; the shaking plate 7 on one side of...

Embodiment 3

[0044] On this basis, as an alternative embodiment, the eccentric shaft 6 is movably embedded in the wobble plate 7, a bearing is provided between the embedded part of the eccentric shaft 6 and the inside of the wobble plate 7, and the eccentric The eccentric rotation of the shaft 6 drives the shaking plate 7 to vibrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com