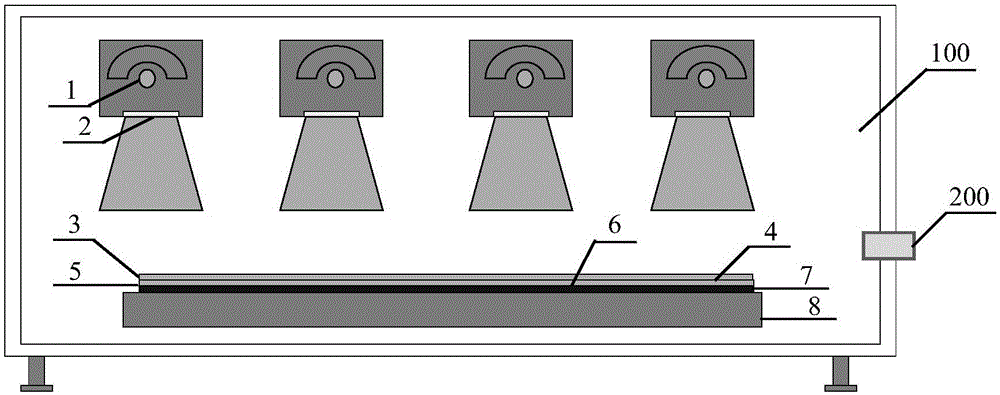

UV glue curing device and curing method

A curing device and curing machine technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of long process time and light source loss, reduce the process time and avoid the service life of the light source shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the present invention easier to understand, the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings, and these embodiments are for illustrative purposes only, and do not limit the scope of application of the present invention.

[0042] As mentioned above, when OLED is packaged, in order to achieve the cumulative light value required for UV glue curing, a long UV irradiation time is required. At this time, the temperature of the glass substrate will also rise significantly, which may affect the OLED organic material. . However, by controlling the UV irradiation time and intermittent irradiation, and then controlling the temperature rise of the glass substrate, the UV light source needs to be switched on and off frequently, which greatly consumes the service life of the light source, and the lighting is staged, and the process takes a long time. The inventors of the present invention found ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com