Electrode for all-solid-state battery, comprising solid electrolyte, and all-solid-state battery

A technology of all-solid-state batteries and solid electrolytes, applied in non-aqueous electrolyte battery electrodes, solid electrolytes, battery electrodes, etc., can solve the problems of increased electrode interface resistance, shortened battery life, etc., and achieve the effect of preventing resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

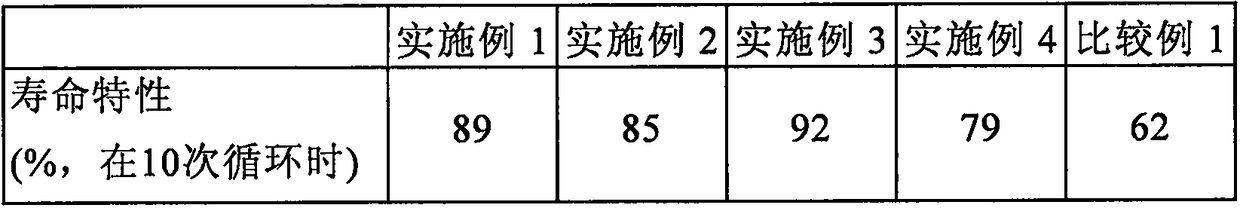

Embodiment 1

[0062] (1) Manufacture of negative electrode

[0063] will have an average particle size of 20 μm (D 50 ), carbon black as conductive material, polymer solid electrolyte (PEO+LiFSI (lithium bis(fluorosulfonyl)imide), 20:1 (molar ratio)) and vapor-grown carbon fiber (VGCF, 20 μm long ) were mixed in a weight ratio of 70:5:20:5 to obtain 5 g of the mixture. Acetonitrile (AN) was added to the mixture to prepare an anode slurry with a solid content of 30%.

[0064] Subsequently, the anode slurry was coated onto a 20 μm thick copper current collector and dried under vacuum at 120 °C for 24 h.

[0065] Subsequently, a rolling process was performed to form an 80 μm thick negative electrode.

[0066] (2) Manufacture of batteries

[0067] Use stamping into 1.4875cm 2 The circular negative electrode and the counter electrode are cut into 1.7671cm 2 circular lithium metal thin films to fabricate coin half-cells. Specifically, an electrode assembly was fabricated using lithium meta...

Embodiment 2

[0069] An electrode assembly was fabricated by the same method as that of Example 1, except that carbon nanotubes (CNTs, 15 μm long) were used instead of VGCF for the linear structure.

Embodiment 3

[0071] An electrode assembly was fabricated by the same method as that of Example 1, except that for the linear structure, carbon nanofibers (CNF, 50 μm long) were used instead of VGCF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com