Double-floor type structure dry-mixed mortar station and construction method thereof

A technology of dry-mixed mortar and construction method, which is applied in chemical instruments and methods, industrial construction, mixing operation control, etc., can solve the problems of uncompact structure and equipment, low production flexibility, and affecting work efficiency, etc. Improve coal efficiency, reduce manual labor intensity, and improve dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

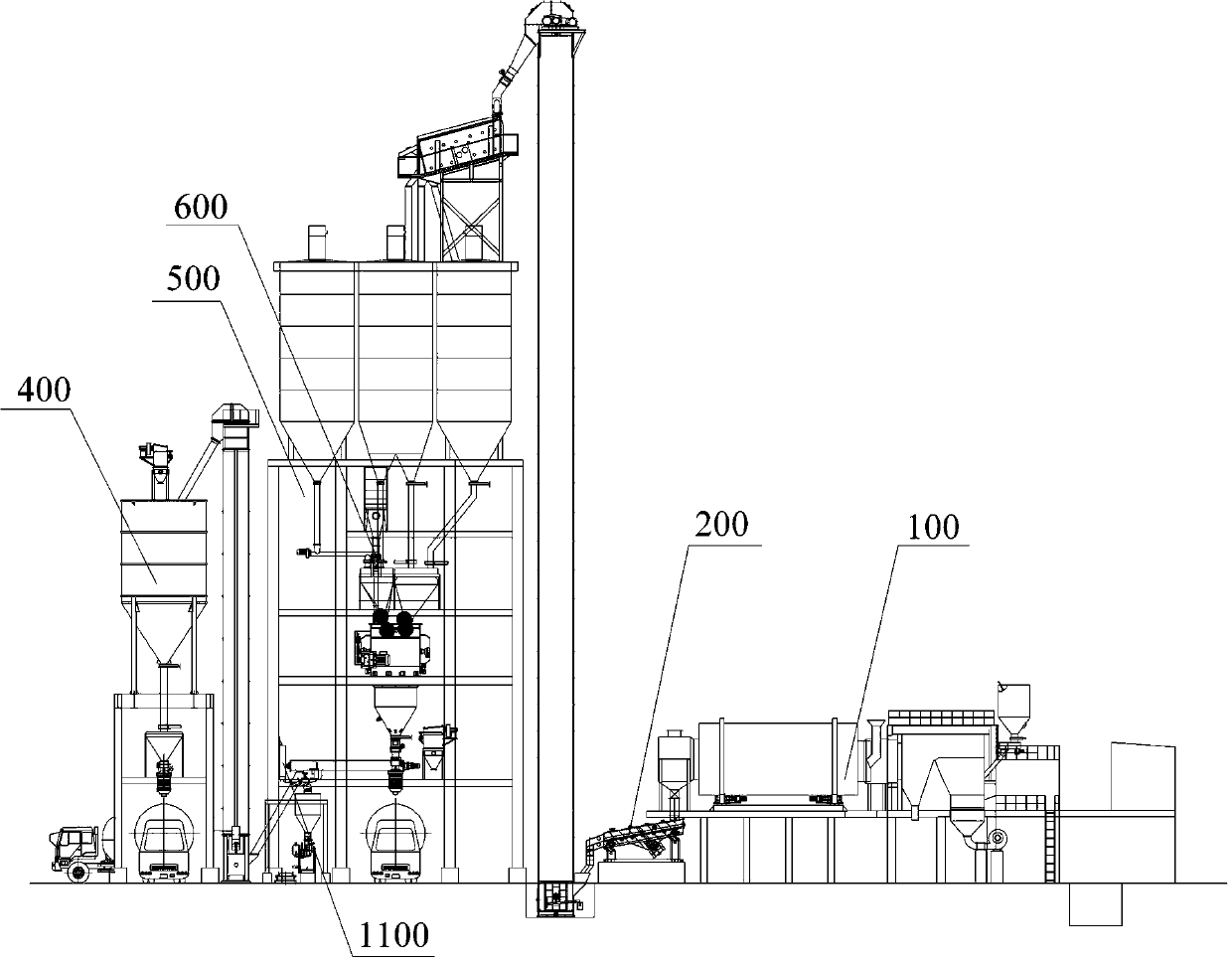

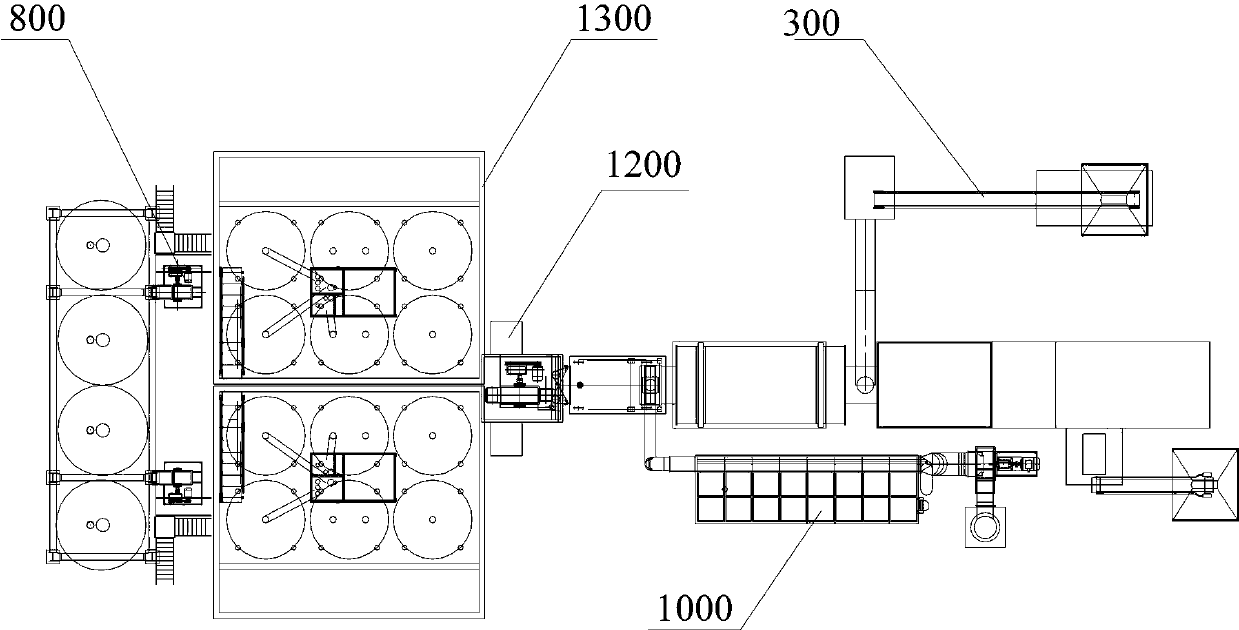

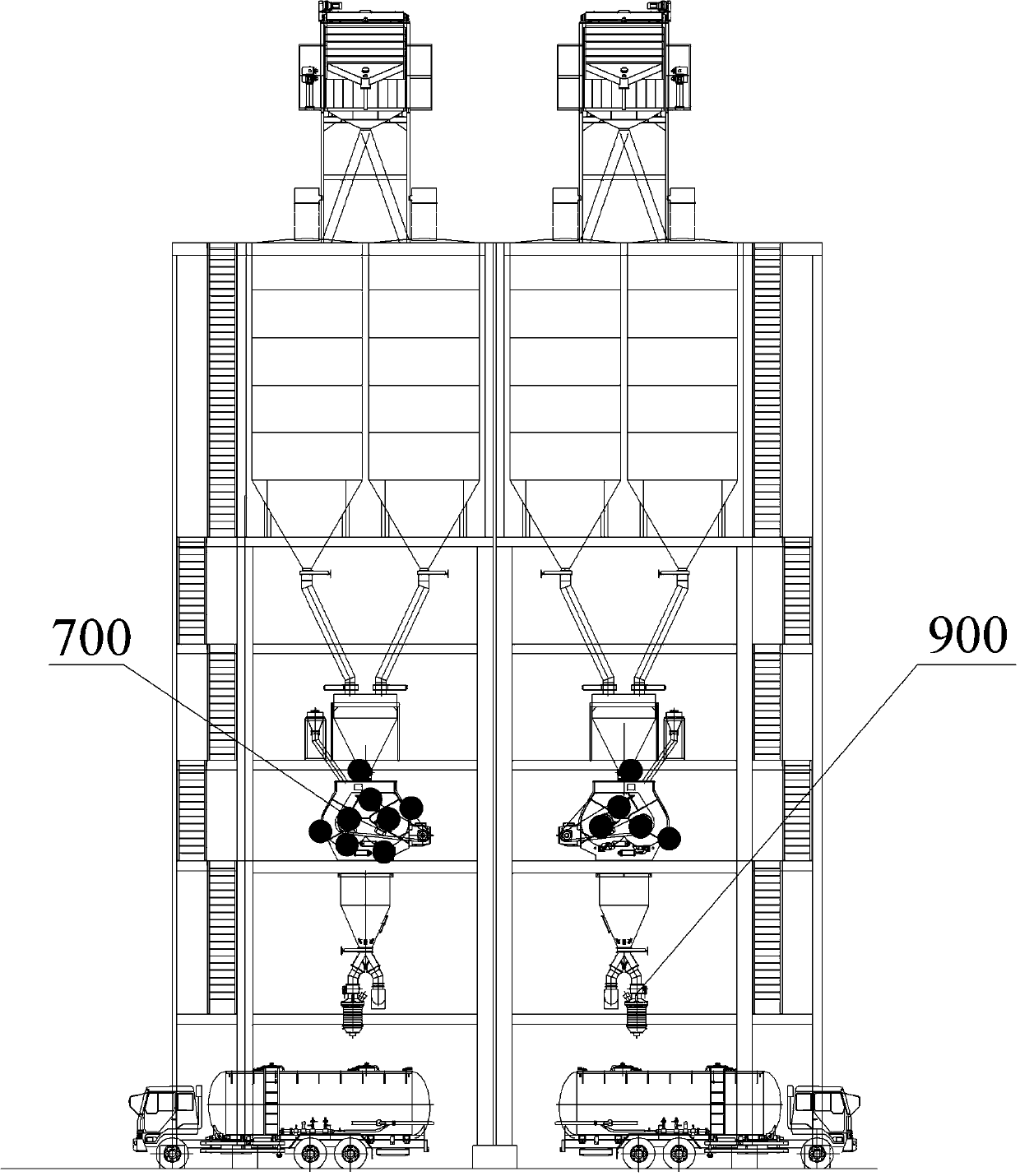

[0028] In terms of its structure and performance, the dry-mixed mortar plant with double-floor structure of the present invention is mainly divided into 13 parts: drying system, screening system, feeding system, storage system, main structure, metering system, mixing system, packaging system, bulk system, dust collection system, electrical system, pneumatic system and external packaging system.

[0029] The invention has a double-floor structure design, the equipment occupies a small area, shares one aggregate drying line, and has compact and reasonable process arrangement and high efficiency. The electrical system adopts a dual-machine synchronous control system and a man-machine interface control device, which makes the operation more reliable and safe, and prolongs the trouble-free working time. The pneumatic system has a two-way self-control and self-locking function, equipped with two cabinet-type screw air compressors, which has good vibration reduction effect, low noise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com