High-temperature high-pressure anti-vibration anti-scouring thermocouple outer sleeve and installation method thereof

A high-temperature, high-pressure, installation method technology, applied in the direction of the use of electrical devices, thermometers, measuring devices, etc., can solve problems such as the fracture of the weld between the outer sleeve and the steam pipe, the threat to the safe, stable and economical operation of the boiler, and the wear of the head of the outer sleeve of the thermocouple. , to achieve the effect of ensuring thickness, reducing scouring force and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

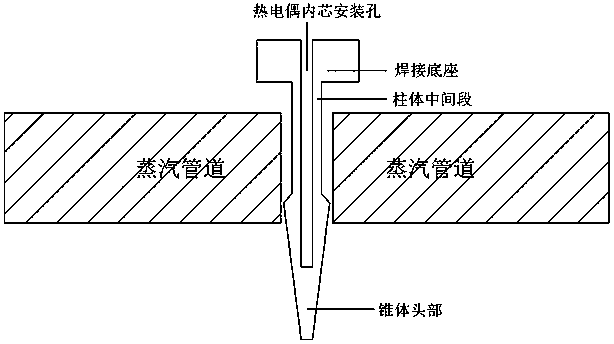

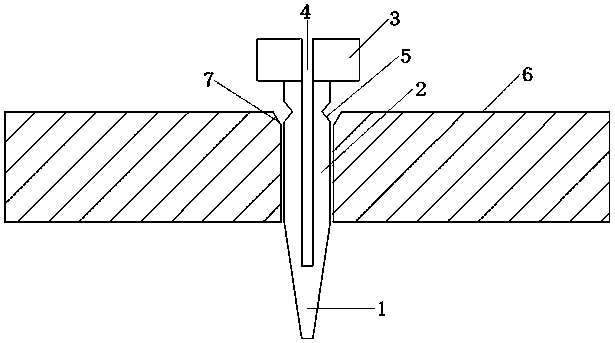

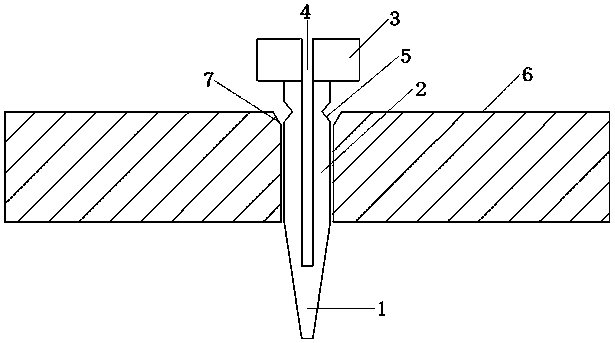

[0025] see figure 2 , in this embodiment, a high-temperature, high-pressure, anti-vibration, and anti-scouring thermocouple outer casing includes a conical head 1, a cylindrical middle section 2, and a base 3, and the above three parts are processed by a solid special round steel column of the same material The conical head 1 is connected with the cylindrical middle section 2, and the cylindrical middle section 2 is connected with the base 3. The materials of the conical head 1, the cylindrical middle section 2 and the base 3 are the same; There is a mounting hole 4 for installing the thermocouple inner core. The mounting hole 4 runs through the base 3 and the cylindrical middle section 2 in turn and extends into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com