Vibration motor

A vibration motor and drive mechanism technology, applied in the direction of connection with the control/drive circuit, electrical components, electromechanical devices, etc., can solve the problem that vibration cannot be transmitted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

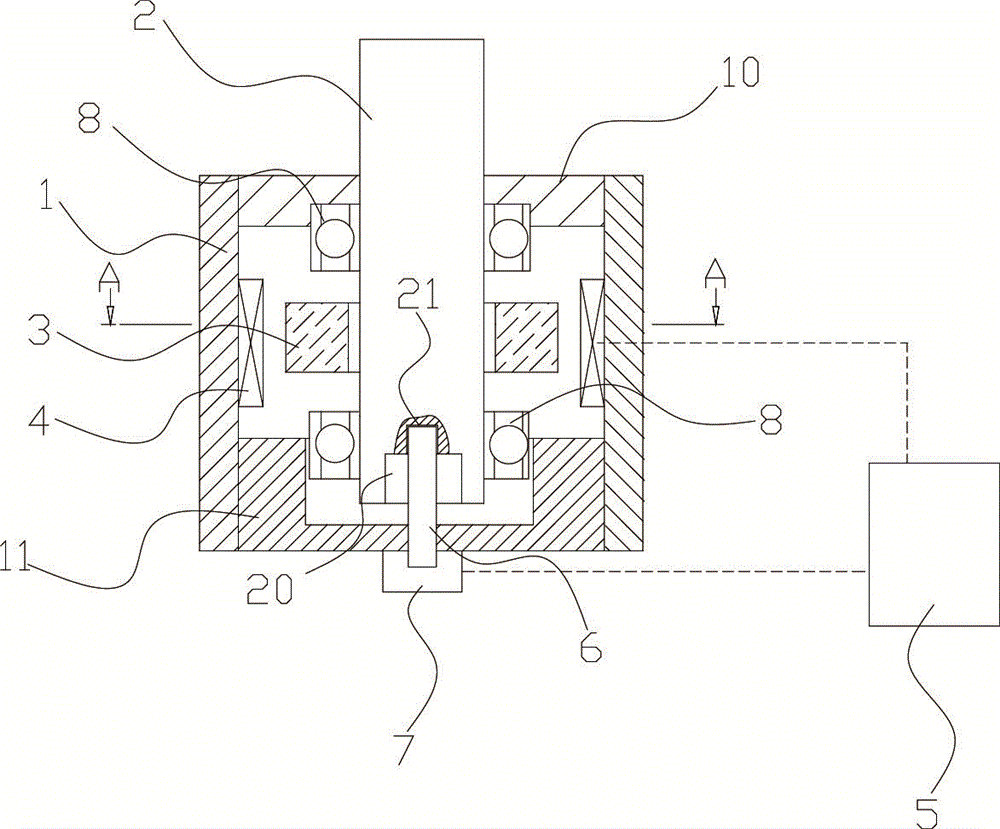

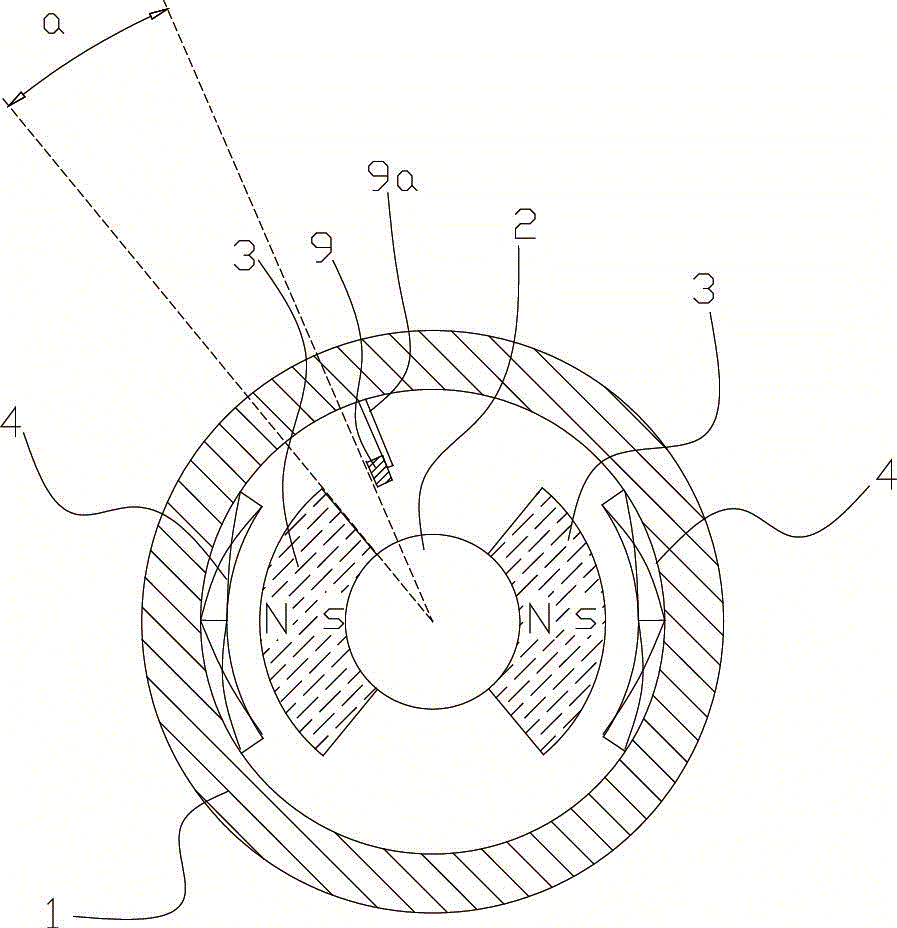

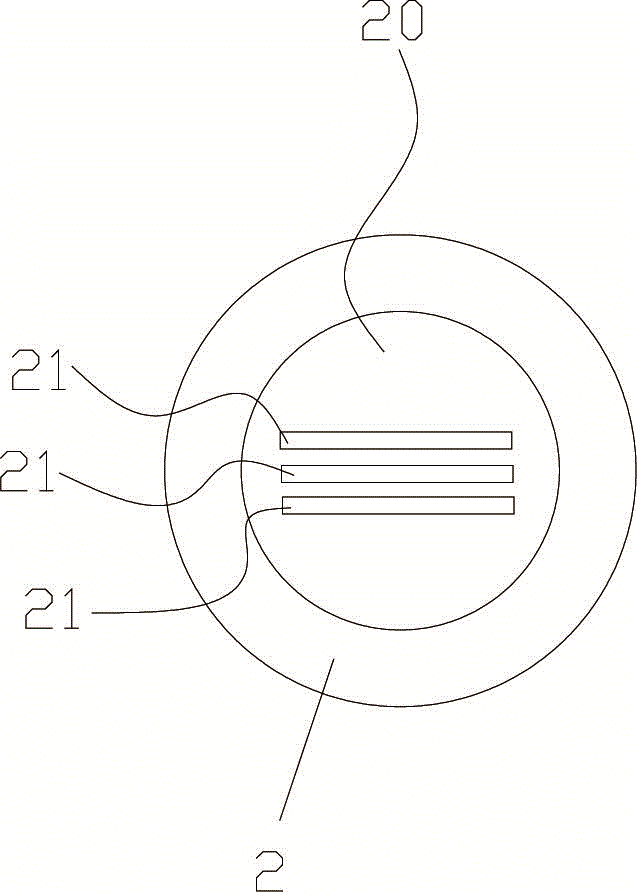

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 As shown, the vibration motor includes a housing 1, and the housing 1 includes an upper end cover 10 and a lower end cover 11, and an output shaft 2 is rotated in the housing 1, and in the upper end cover 10 and the lower end cover 11 A bearing 8 for supporting the output shaft 2 is provided, and two oppositely placed coils 4 are provided on the side wall of the housing 1, and AC power is passed through the coils 4 so that an alternating current is formed between the coils. The magnetic field also includes a gear switch 5 for controlling the frequency of the AC power supply, and an armature component 3 corresponding to the coil 4 is fixedly arranged on the output shaft 2 . There is a gap between the armature component 3 and the coil 4, so that the output shaft 2 can swing back and forth at a specific angle within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com