String vibration period experiment instrument with vibration motor and electric vibration tuning fork as double vibration wave sources

A technology of vibration motor and experimental instrument, applied in instruments, educational appliances, teaching models, etc., can solve problems such as the influence of experimental teaching quality, poor demonstration effect, complex equipment structure, etc., to achieve excellent experimental teaching quality, fast and accurate vibration frequency , the effect of high experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

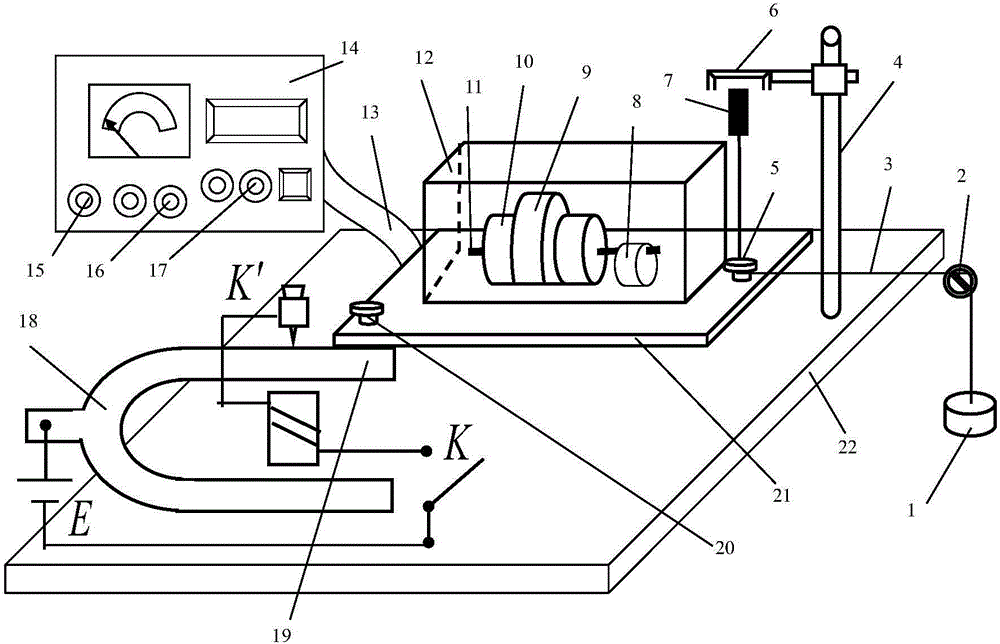

[0016] See figure 1 , The vibration motor and the electric vibration tuning fork are dual vibration wave sources. The string vibration period tester includes a main body of the tester. A base 22 is provided at the bottom of the main body of the tester. The base 22 and the vibration motor part fixing plate 21 pass through the electric vibration tuning fork. The head 19 of the electric vibration tuning fork of the string vibration tester 18 which is the wave source is supported and fixed. A vibration motor part 12 is installed on the main body of the tester. The vibration motor part 12 is installed above the fixed plate 21. The fixed plate 21 is installed above the head 19 of the electric vibration tuning fork. The head 19 of the electric vibration tuning fork supports the fixed plate 21 at a single point. The screw 20 is fixed. A vibration motor 10 is installed in the vibration motor component 12, and the vibration motor 10 is fixed on a fixed plate 21 by a vibration motor fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com