Granulated feed drying and sorting integrated device

A pellet feed drying technology, applied in feed, heating devices, non-progressive dryers, etc., can solve problems such as difficult to accurately control feed particle size, lack of feed drying function, and unfavorable working environment, etc., to achieve sorting effect Good, reduce installation complexity, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

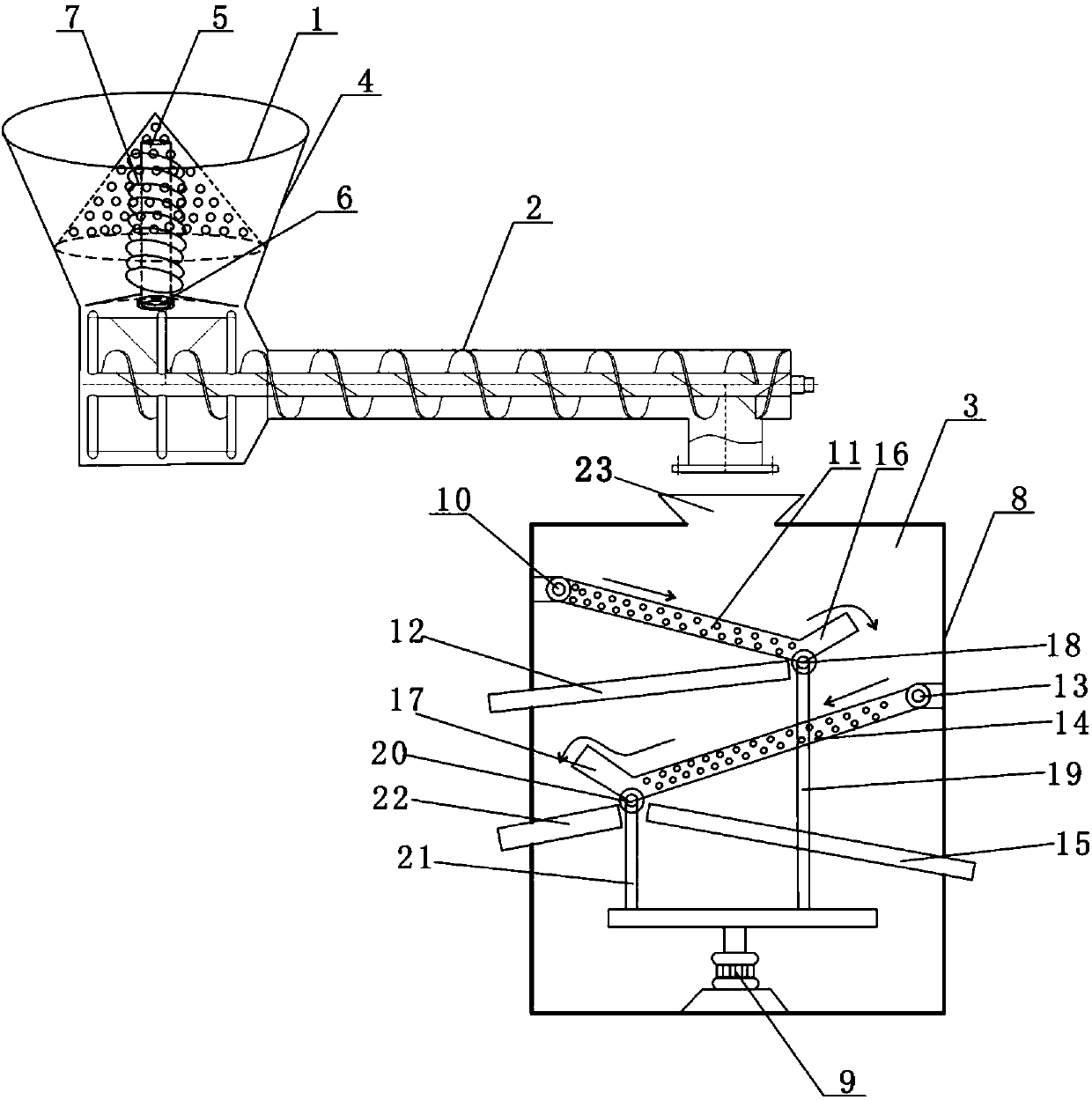

[0024] Such as figure 1 As shown, the granular feed drying and sorting integrated device includes a drying mechanism 1, a screw conveyor 2, and a sorting mechanism 3. The drying mechanism 1 is connected to the screw conveyor 2, and a separator is set under the discharge end of the screw conveyor 2. Select organization 3.

[0025] The drying mechanism 1 includes a drying bucket 4, and a cone-shaped bucket 5 with holes is sheathed inside the drying bucket 4, and the tip of the cone-shaped bucket 5 faces upward. The drying hopper 4 is provided with a vertical shaft 5, the bottom end of which is connected to the rotating disk 6, and the rotating disk 6 is connected to the drive motor through a belt. heated. A hollow spiral heating coil 7 is fixed on the vertical shaft 5, and heating steam is introduced into the hollow spiral heating coil 7, and the hollow spiral heating coil 7 adopts a copper hollow spiral tube, which has good heat conduction effect.

[0026] The vertical shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com