Numerical control sponges cutting machine

A technology of sponge cutting machine and frame, applied in metal processing, using vibrating fluid, etc., can solve the problems of difficult processing of sponges with complex shapes, and achieve the effects of great practical and popular value, consistent vibration frequency and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

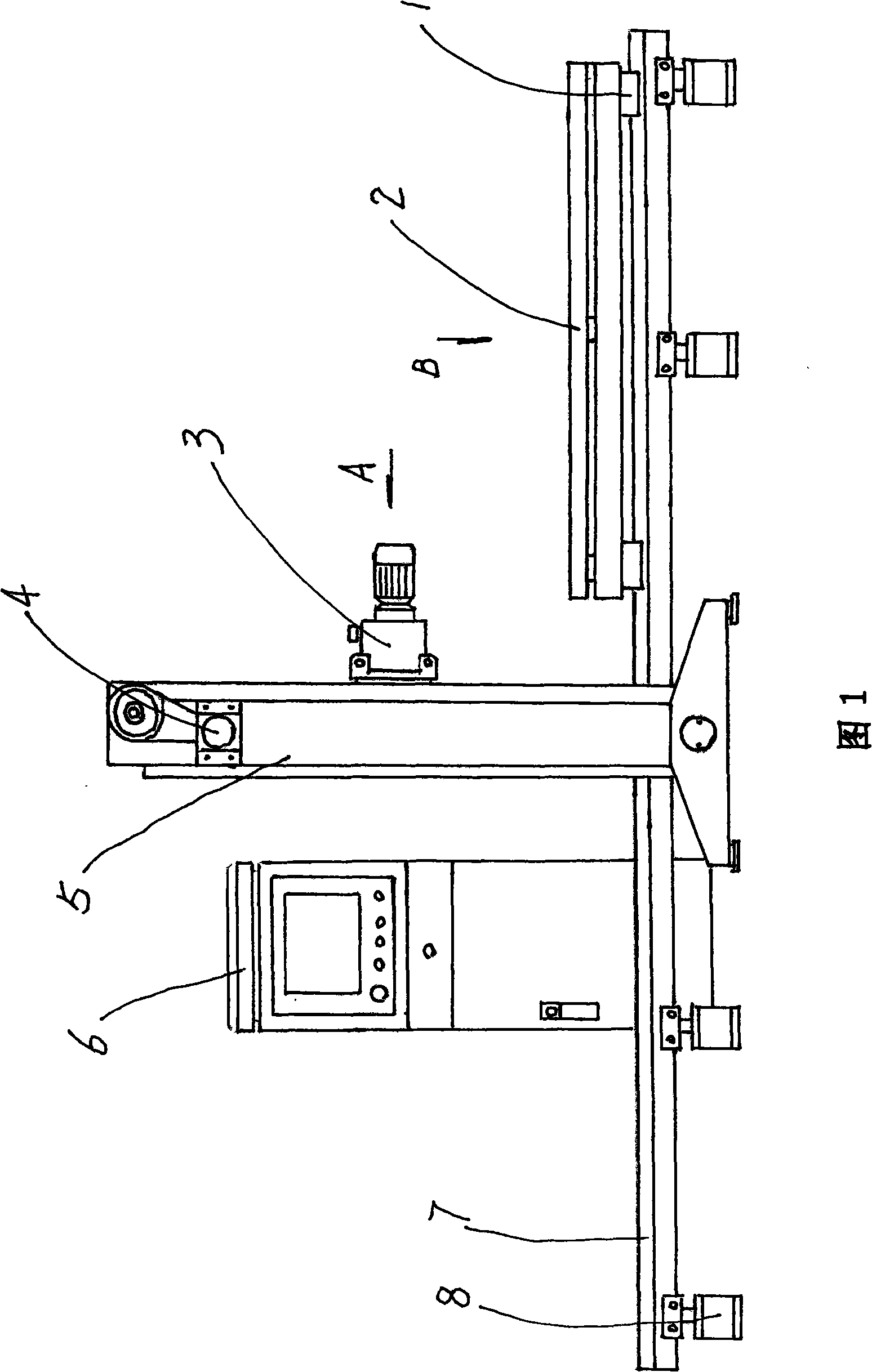

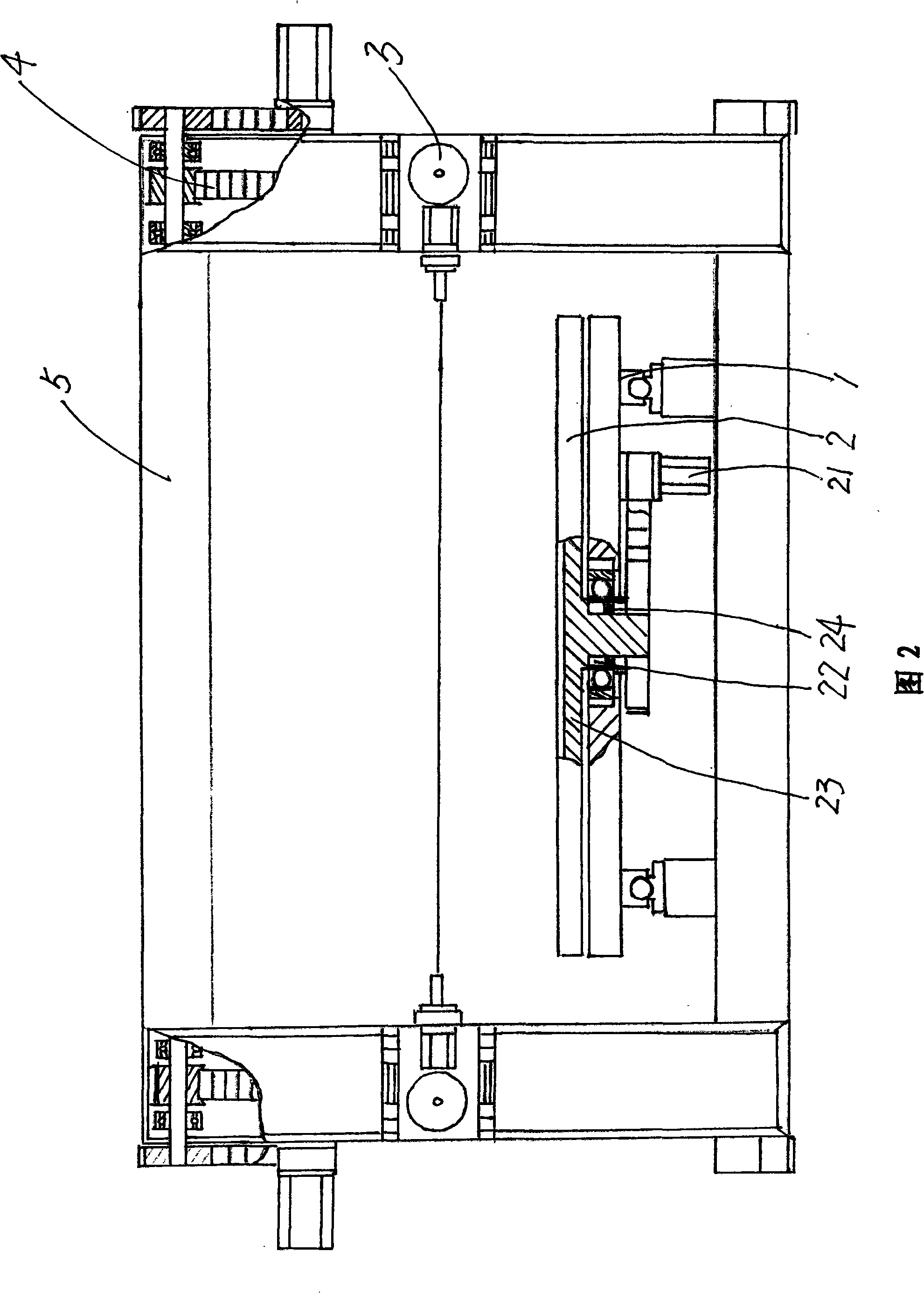

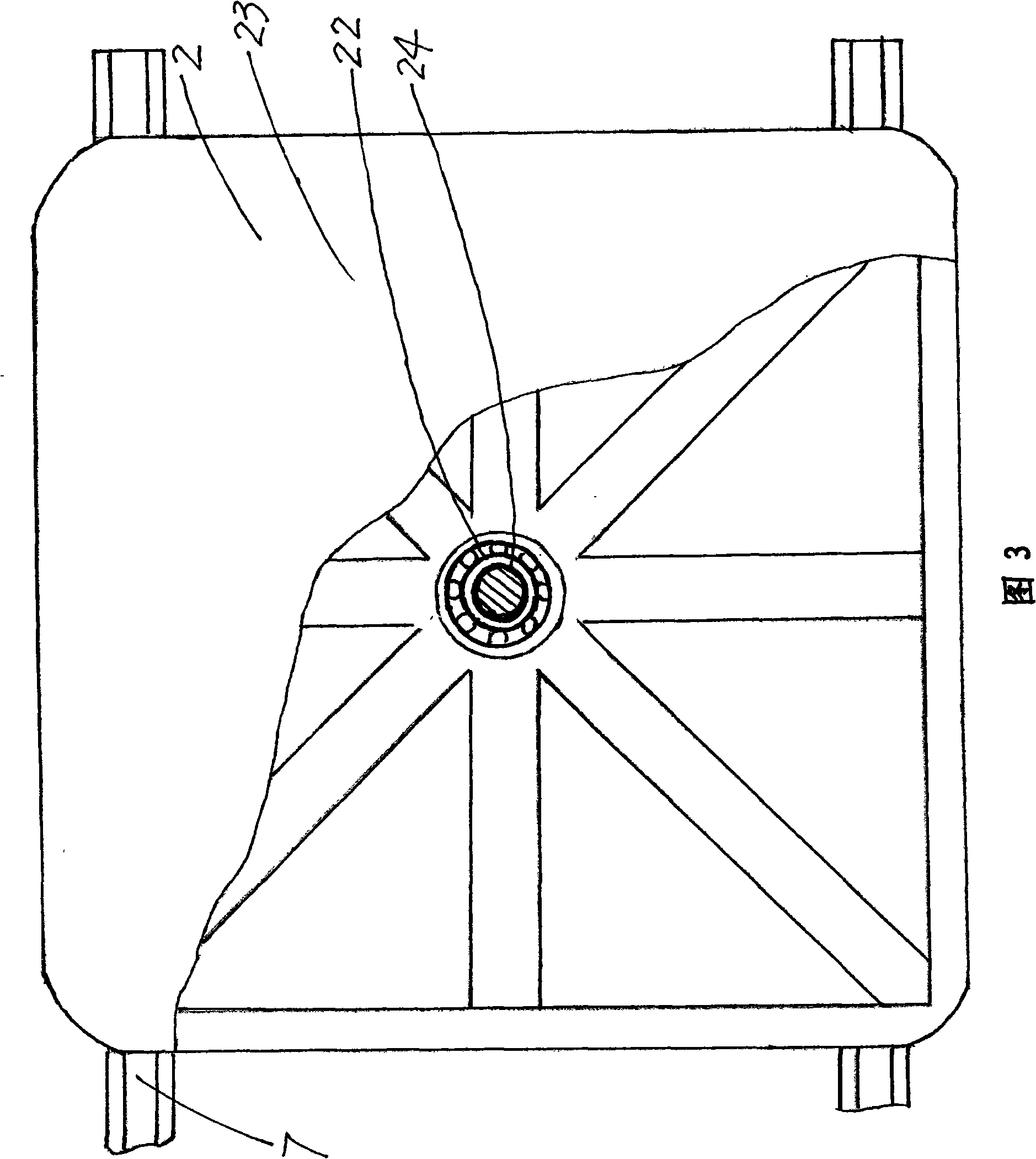

[0024] With reference to accompanying drawing 1, accompanying drawing 2, accompanying drawing 3, numerical control sponge cutting machine of the present invention, by workbench base 1, rotating workbench 2, vibration device 3, vertical traction device 4, door frame 5, control part 6, horizontal The guide rail 7 and the frame 8 are composed of a workbench base 1 arranged on the horizontal guide rail 7, and can move horizontally along the horizontal guide rail 7; The workbench 2 is a workbench that can be lifted and rotated on the workbench base 1. The rotary workbench 2 is composed of a rotary drive device 21, a lift cylinder part 22, a workbench 23, and a piston 24. The cylinder liner of the lift cylinder part 22 supports On the workbench base 1, the rotary drive device 21 is fixed on the workbench base 1, and the rotary drive device 21 drives the drive gear on the workbench 23 through the drive belt; The inlet and outlet of the liquid; the shaft of the workbench 23 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com