A method for processing a hyperbolic plate and a pyrotechnic tool used in the method

A processing method and hyperbolic technology, applied in the field of ships, can solve the problems of affecting the appearance and structural strength, the decrease of thermal deformation effect, and the carbonization of the surface of the plate, and achieve the appearance and structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

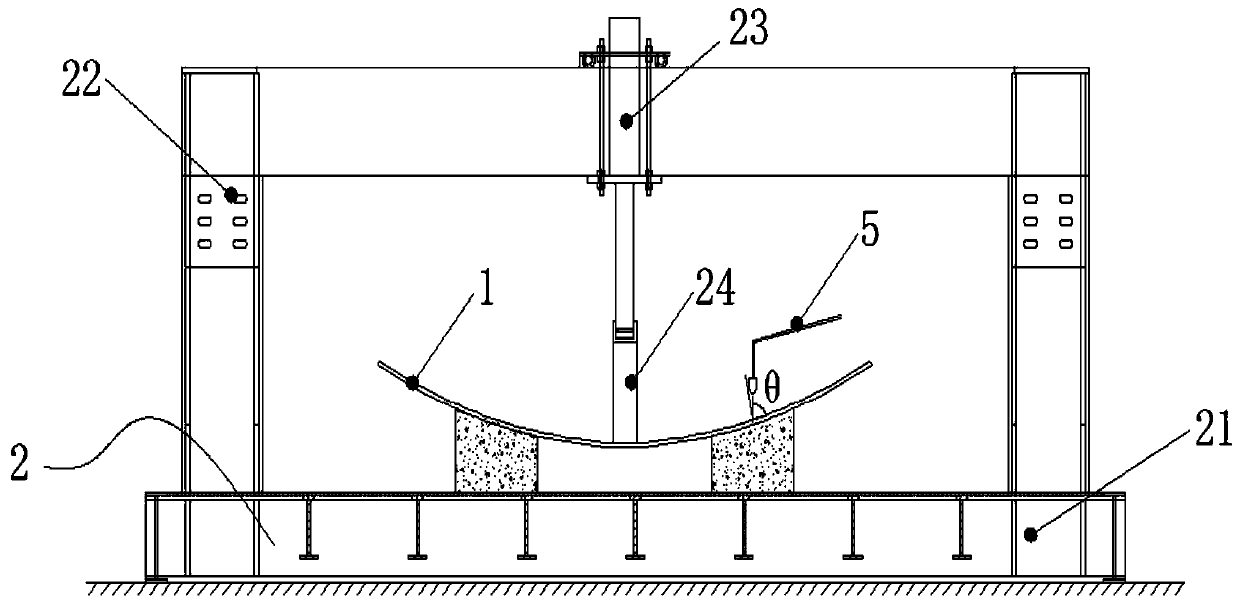

[0028] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

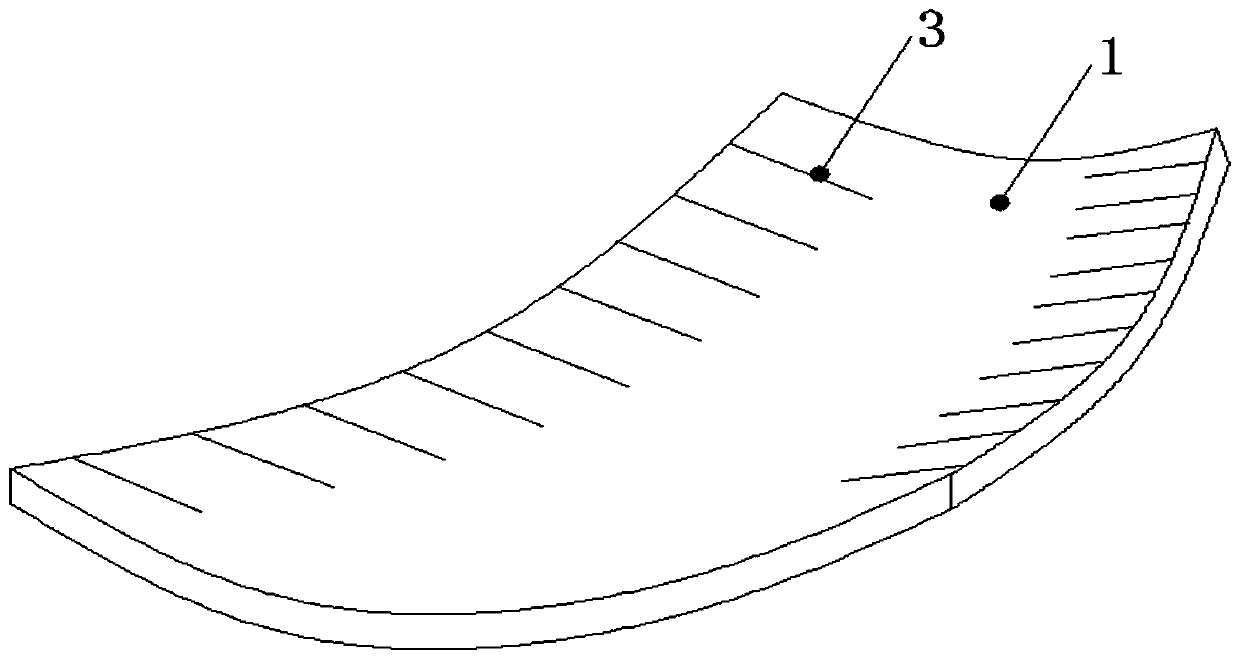

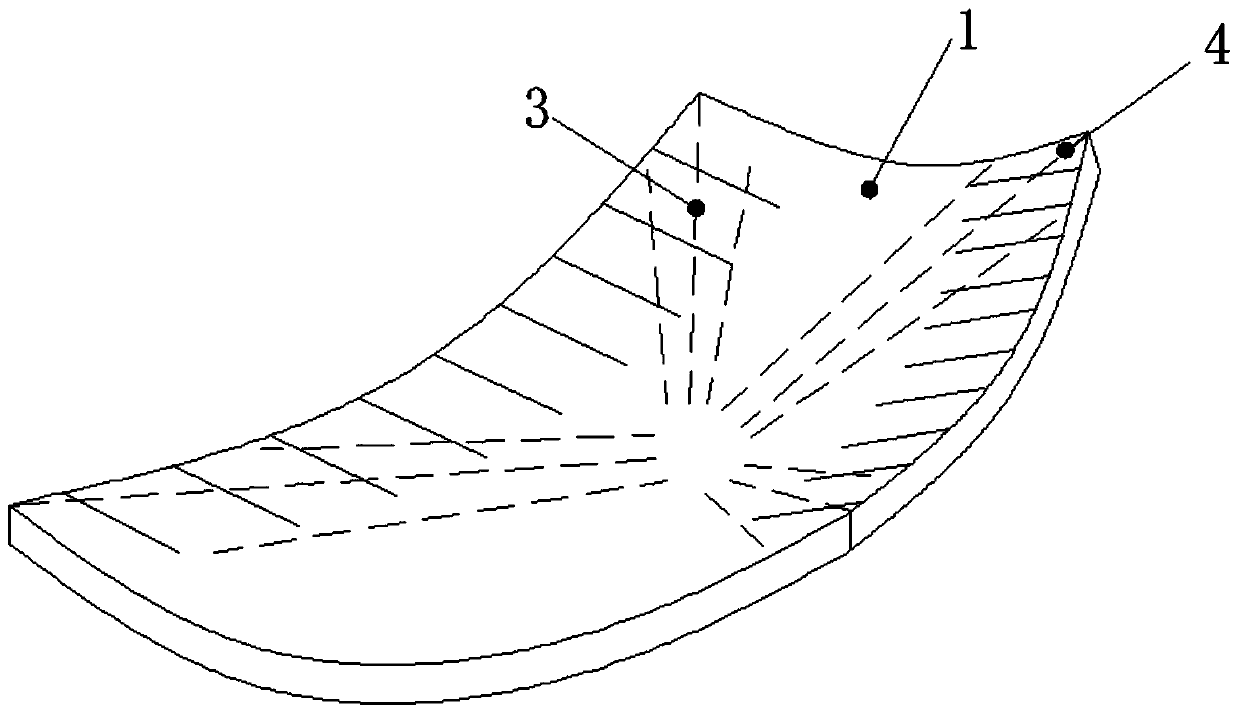

[0029] like Figure 1 to Figure 3 As shown, the double curvature plate 1 processing method in the present embodiment comprises the following steps:

[0030] 1) Draw a transverse heating line 3 on the surface of the double curvature plate 1 according to the amount of deformation required for the processing of the double curvature plate 1;

[0031] 2) Fix the hyperbolic plate 1 on the pyrotechnic tooling 2, heat the hyperbolic plate 1 along the transverse heating line 3, and apply pressure to the hyperbolic plate 1 through the ejector pin 24 of the pyrotechnic tooling 2, The ejector rod 24 in this embodiment is controlled by the driving device 23, and then the hyperbolic plate 1 is pressed and fastened. During the heating process, it is not necessary to adjust the jack to fasten the hyperbolic plate 1, so that the whole operation is simple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com