Patents

Literature

35results about How to "Realize the printing function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

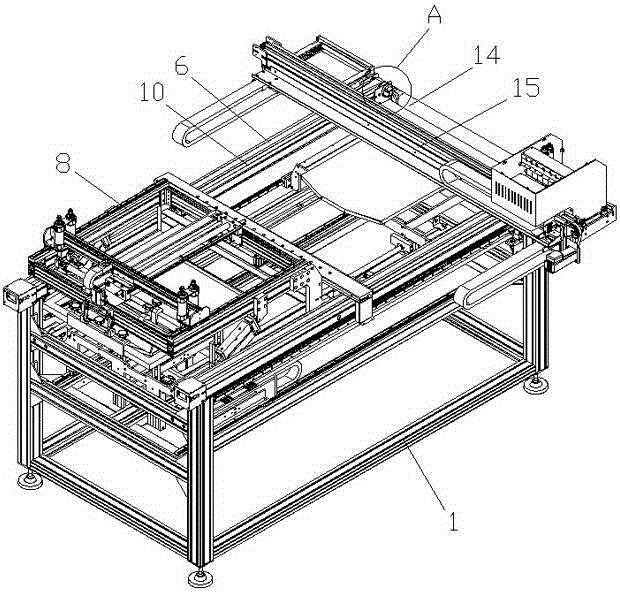

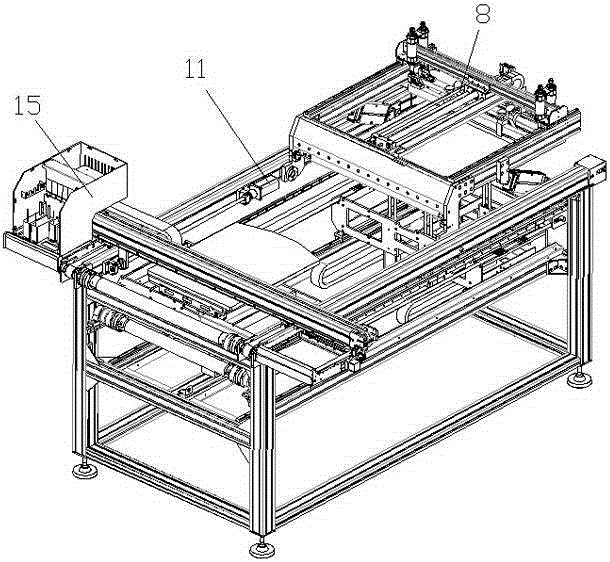

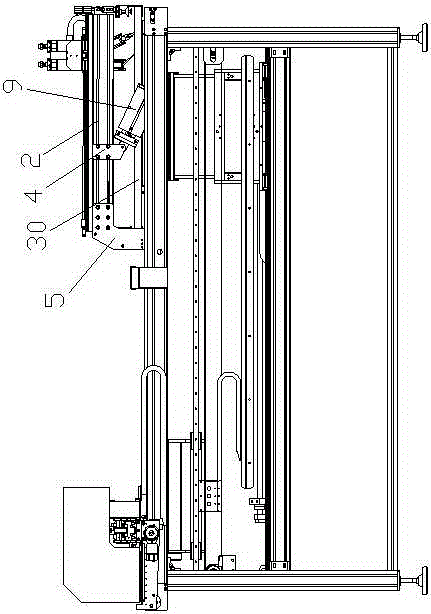

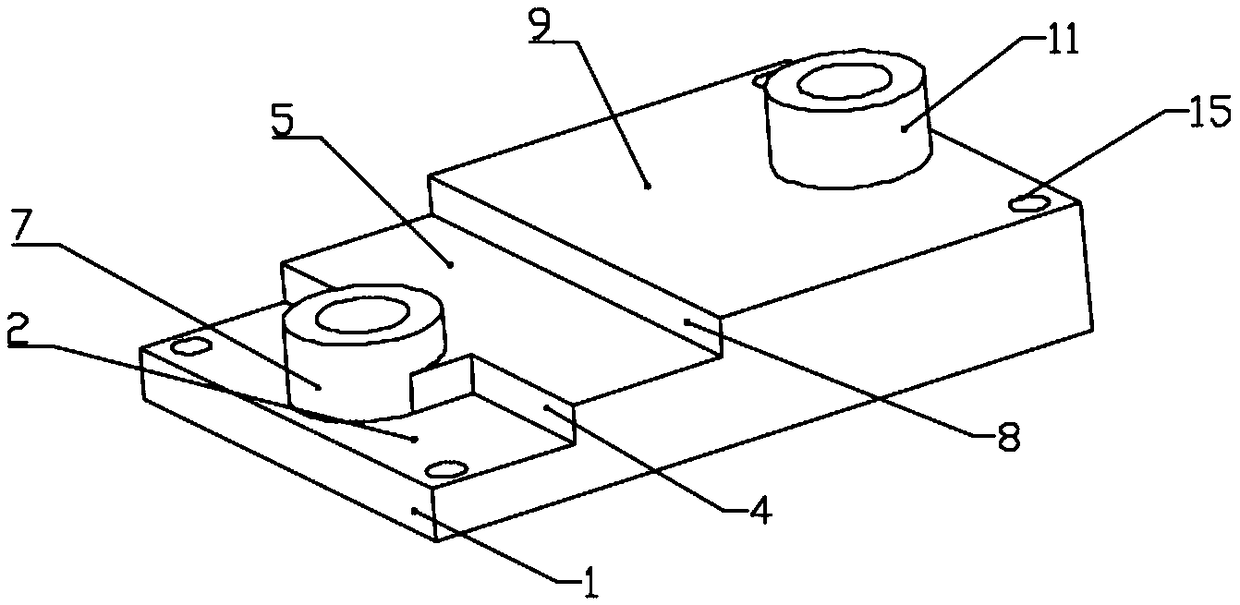

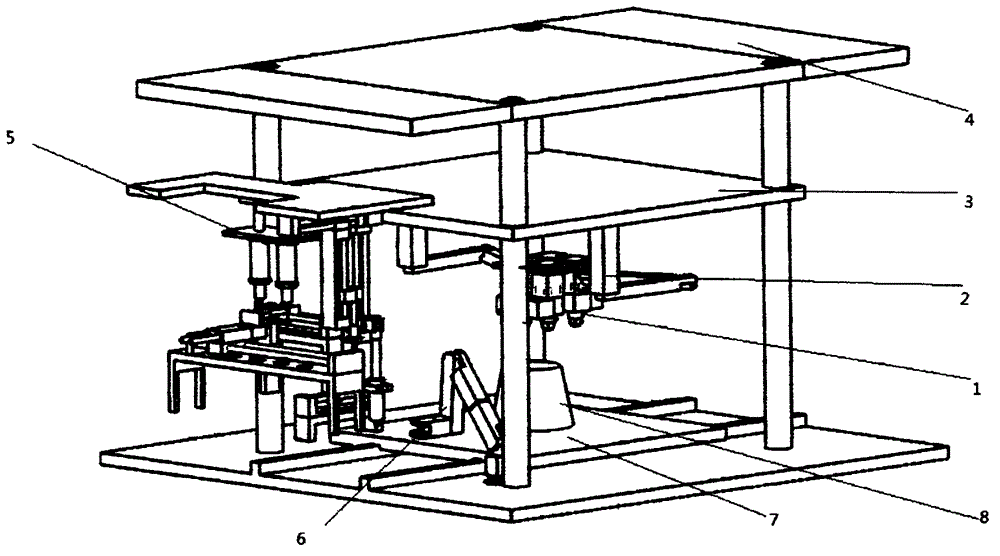

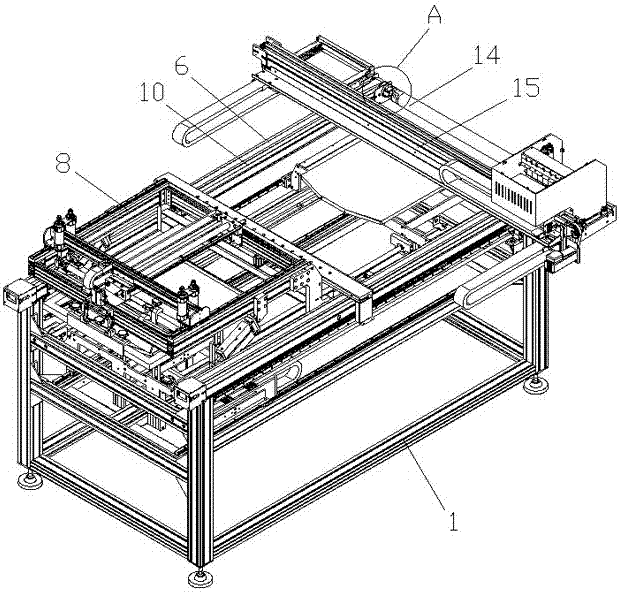

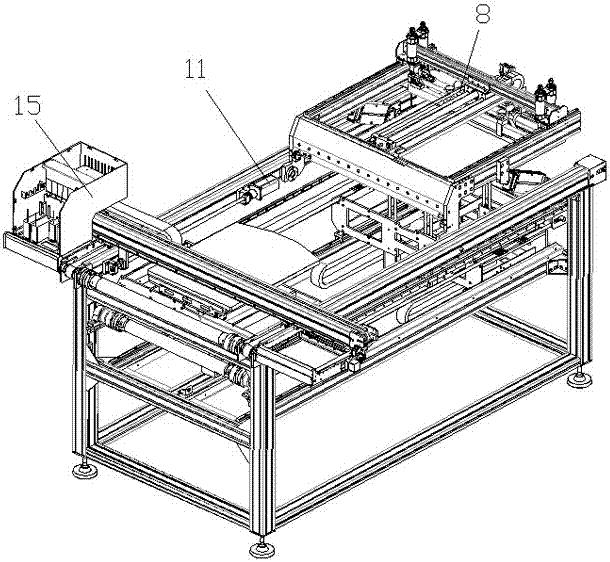

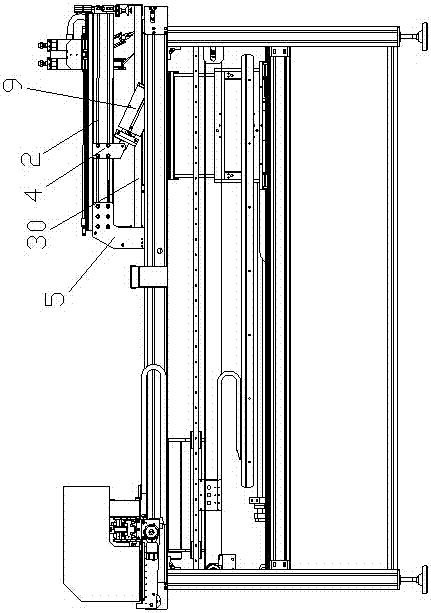

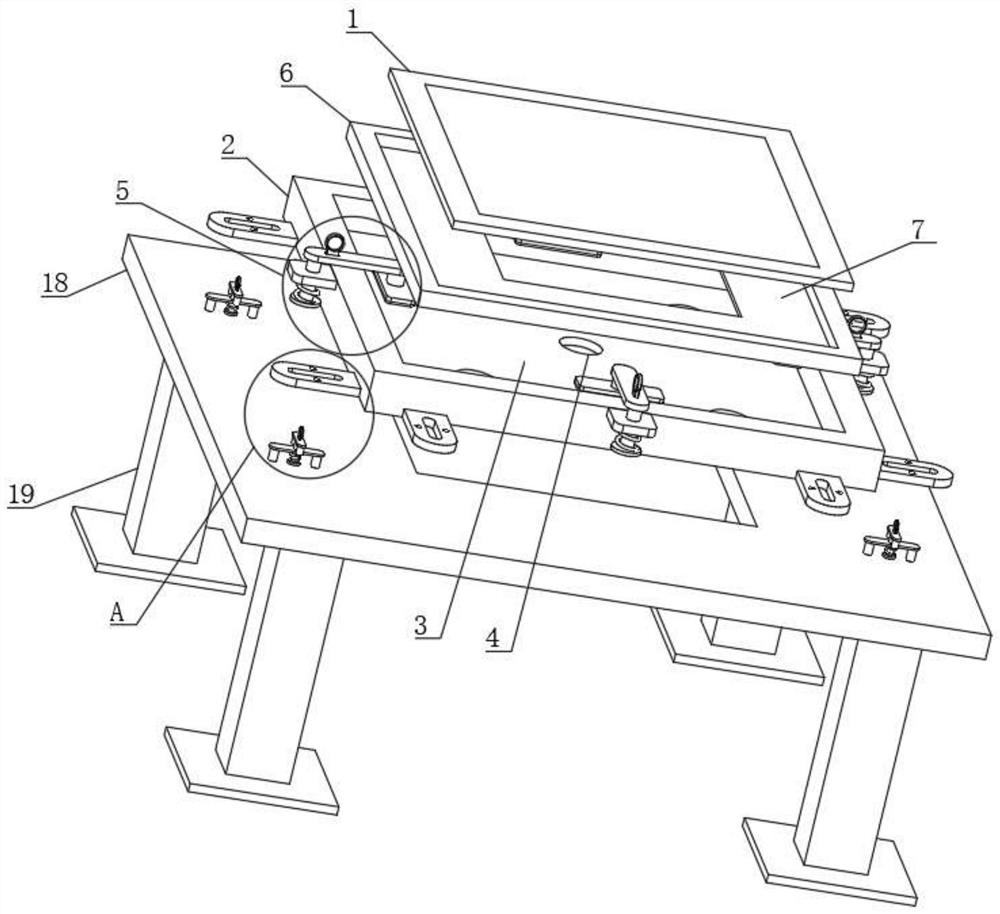

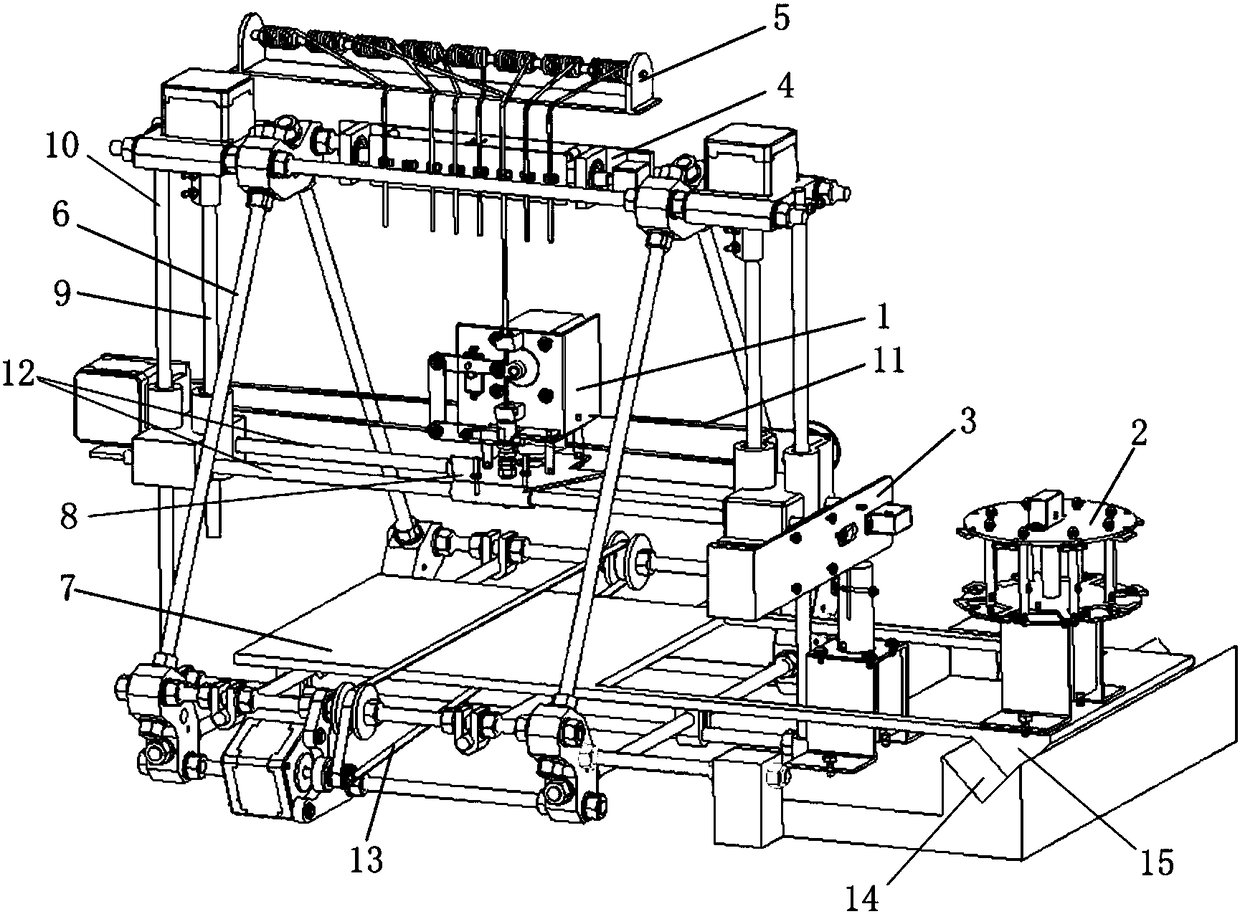

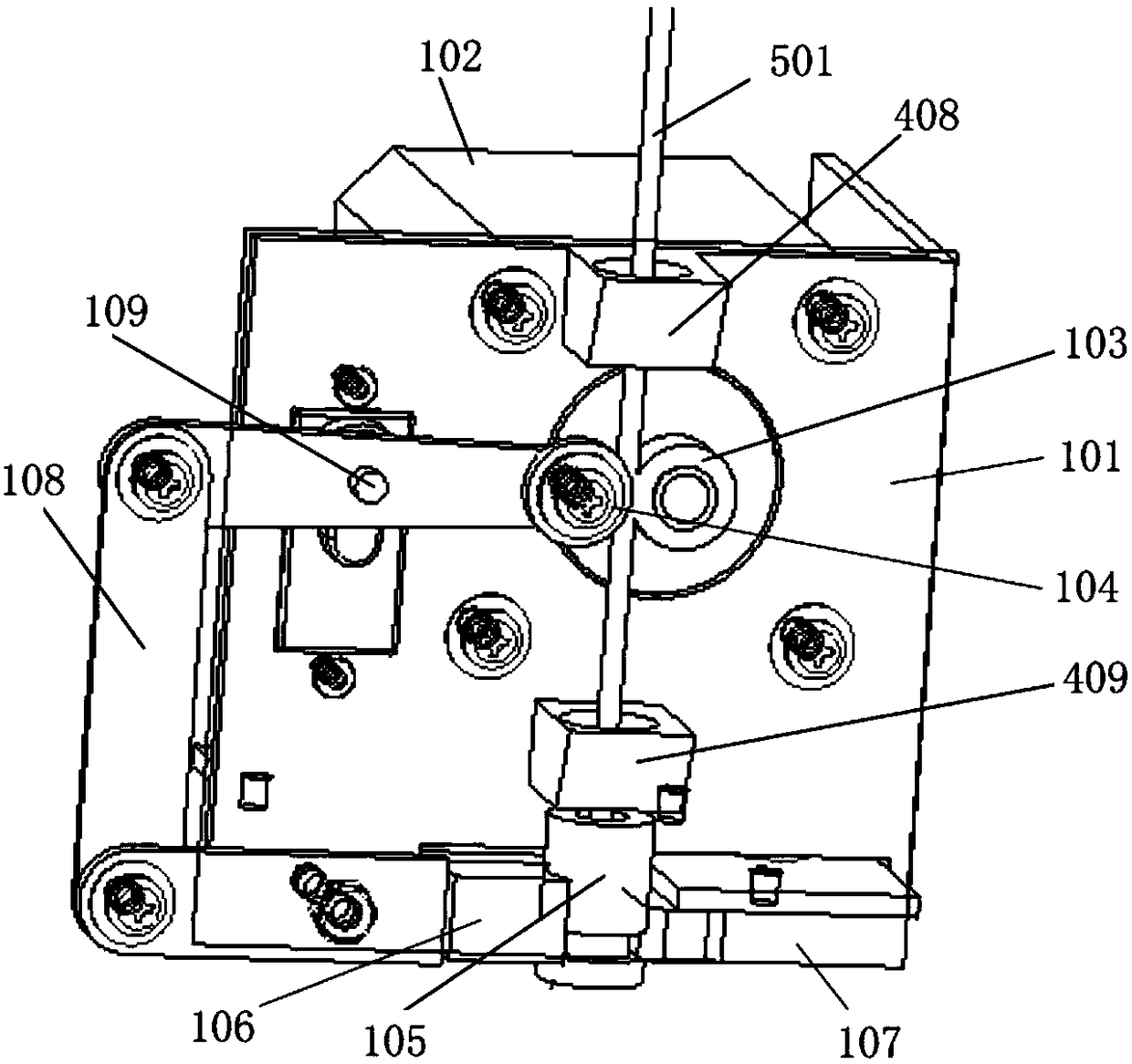

Digital printing machine for ready-made clothes and method for printing ready-made clothes

ActiveCN105235362AImprove printing efficiencyRealize the printing functionDuplicating/marking methodsScreen printersScreen printingDigital printing

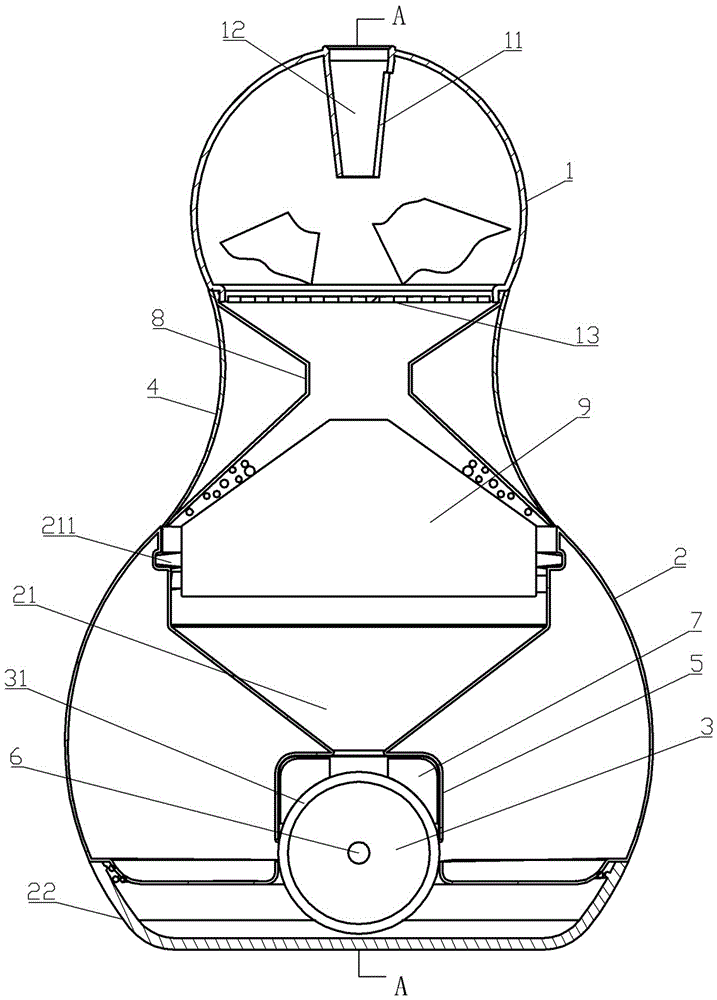

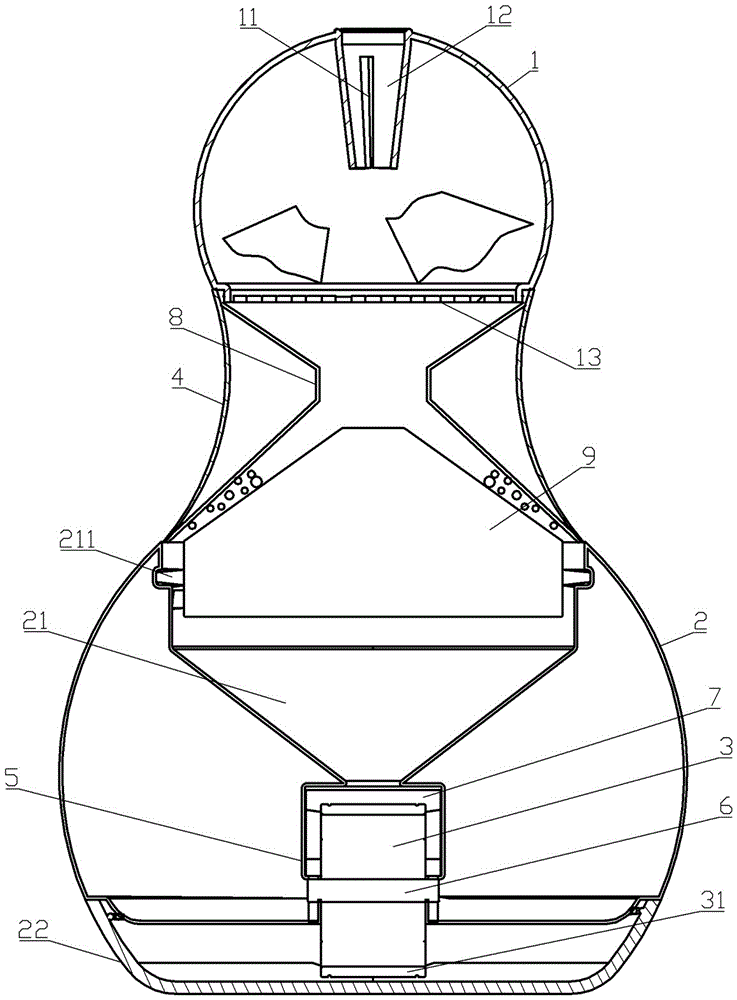

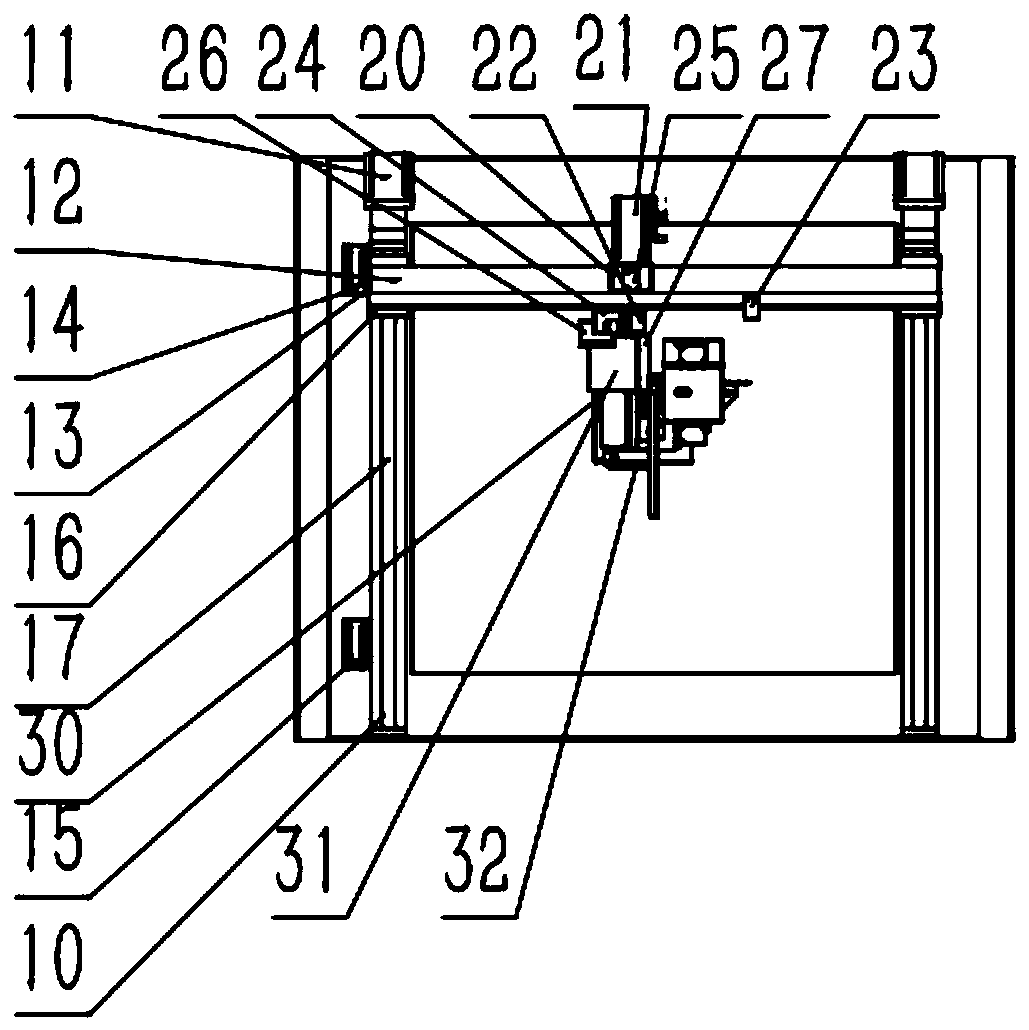

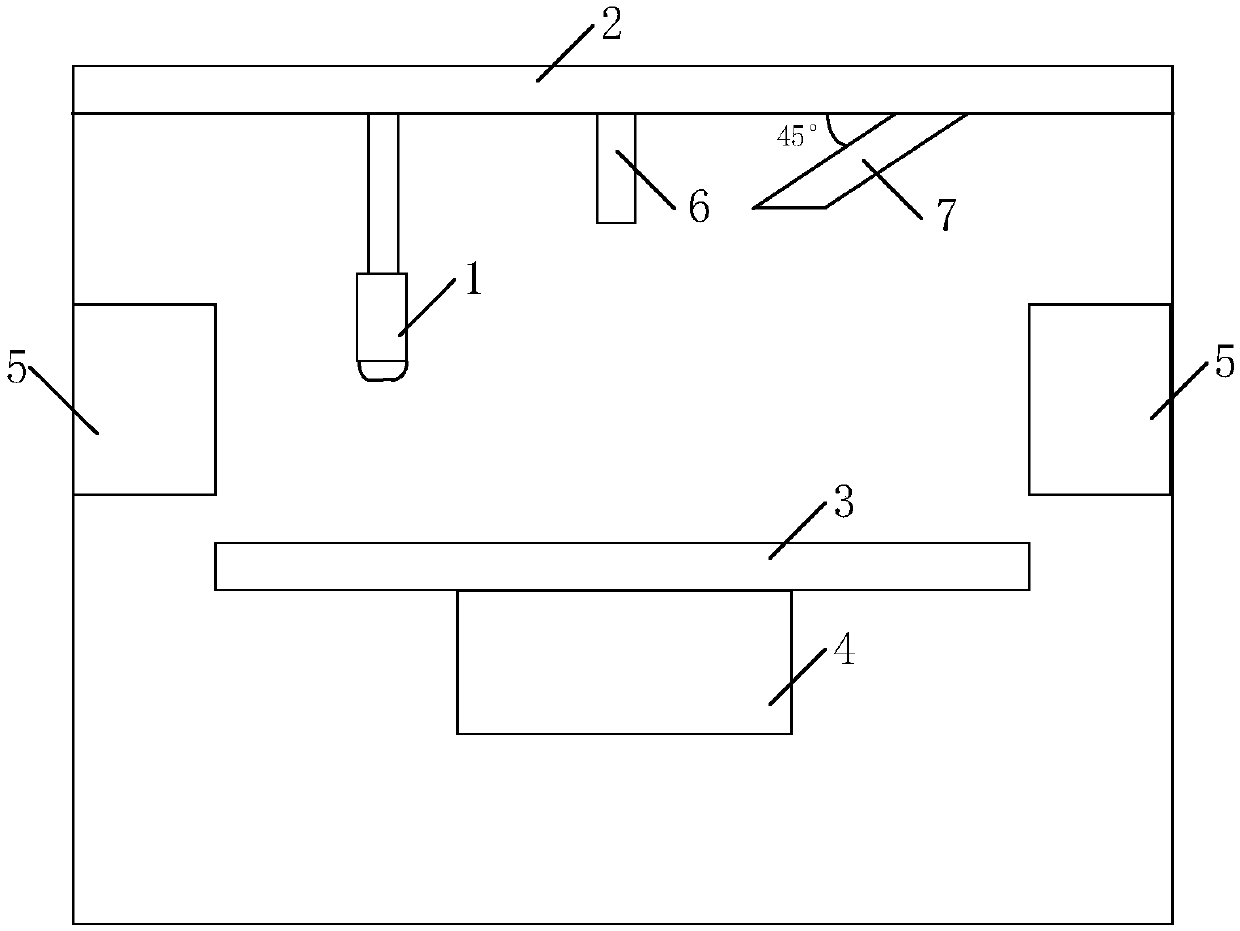

The invention provides a digital printing machine for ready-made clothes and a method for printing the ready-made clothes. According to the digital printing machine for the ready-made clothes and the method for printing the ready-made clothes, a screen printing function and an inkjet printing function are combined. A screen printing machine, an inkjet printing machine and a worktable mechanism are installed on a main rack. The ready-made clothes are printed through the inkjet printing machine in an inkjet printing area. The ready-made clothes are printed through the screen printing machine in a screen printing area. The screen printing machine and the inkjet printing machine are arranged on the main rack in a front-and-back manner in the conveying direction of the ready-made clothes. A movable mechanism is connected with worktables and can drive the worktables to move so that the tabletops of the worktables can move to the inkjet printing area and the screen printing area, and in addition, the tabletops of the worktables can move back and forth between the inkjet printing area and the screen printing area. The number of the worktables is two. When the tabletop of one worktable moves to the inkjet printing area, the tabletop of the other worktable moves to the screen printing area; and when the tabletop of one worktable moves to the screen printing area, the tabletop of the other worktable moves to the inkjet printing area.

Owner:HANGZHOU HONGHUA DIGITAL TECH

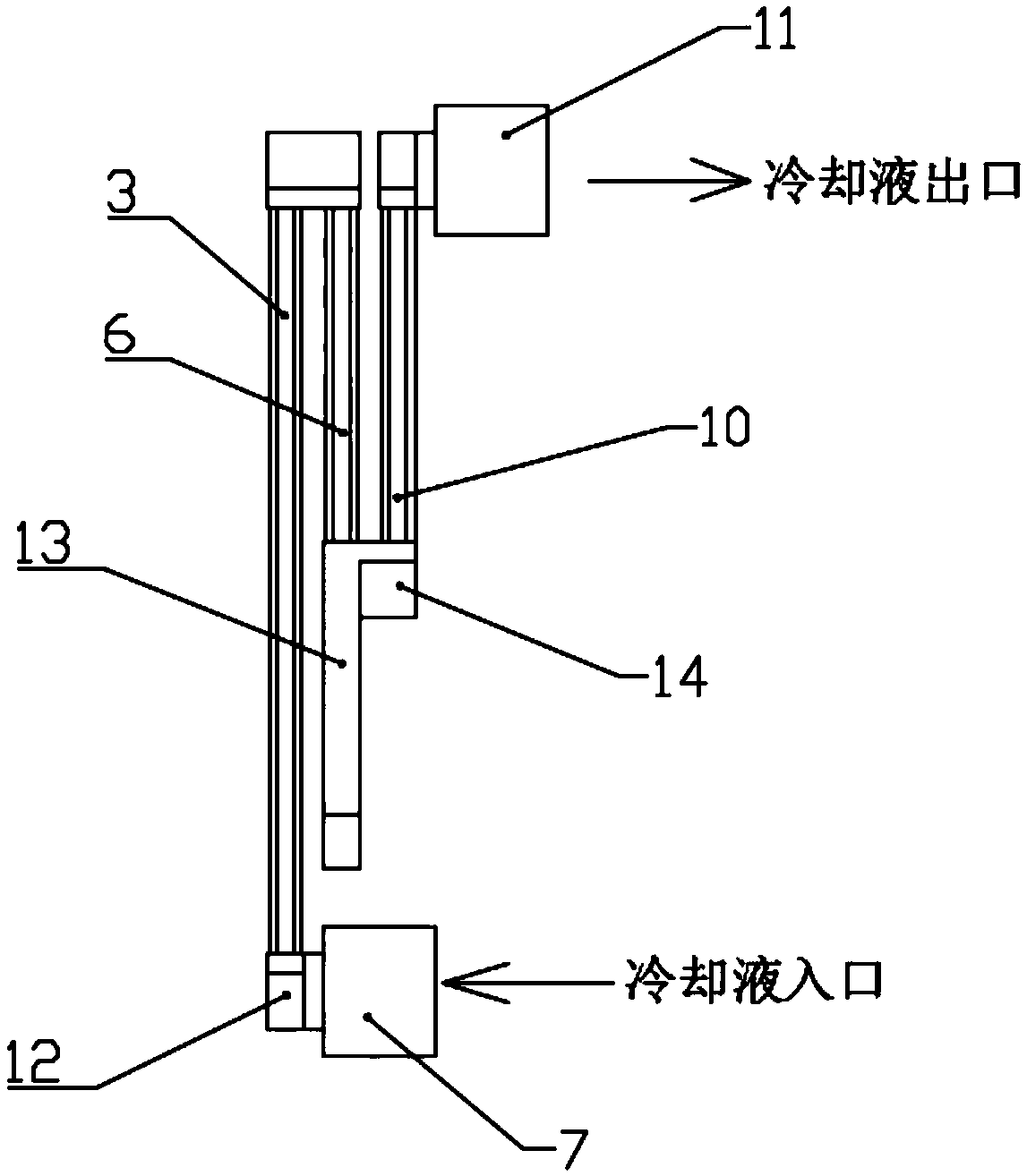

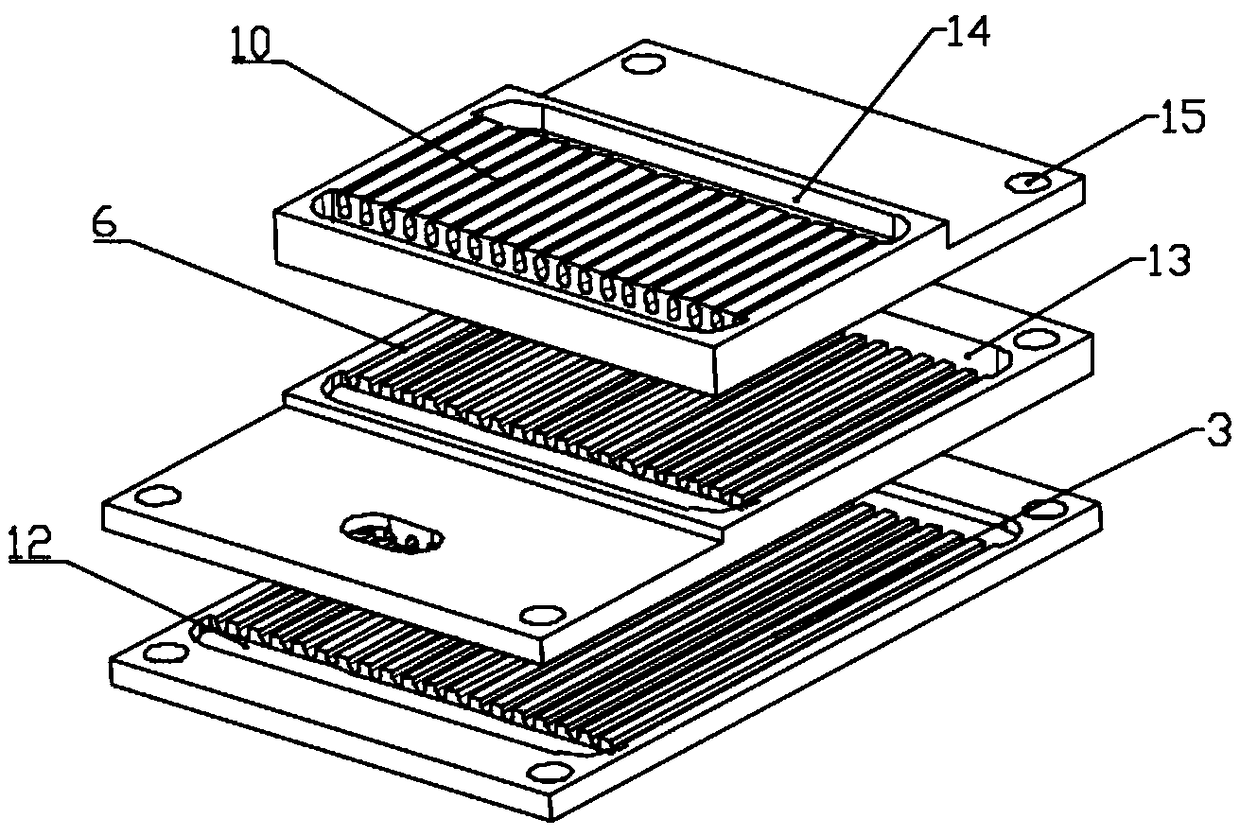

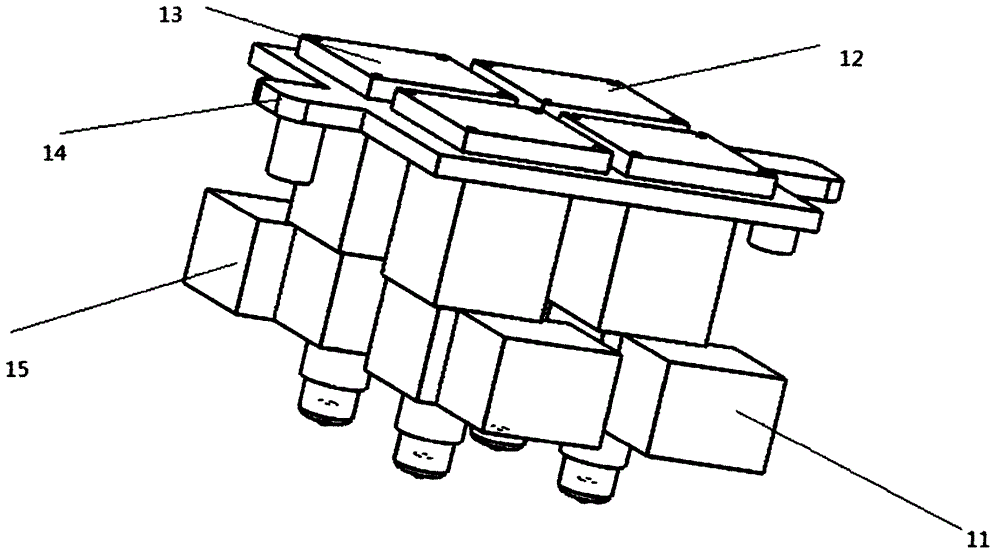

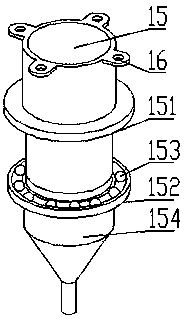

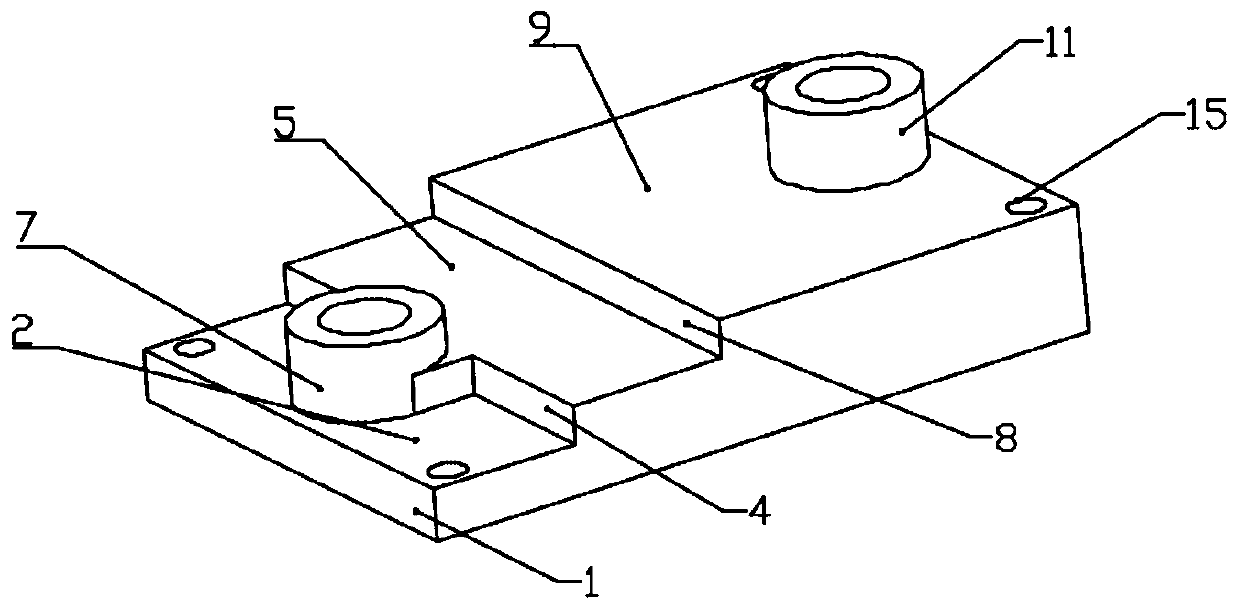

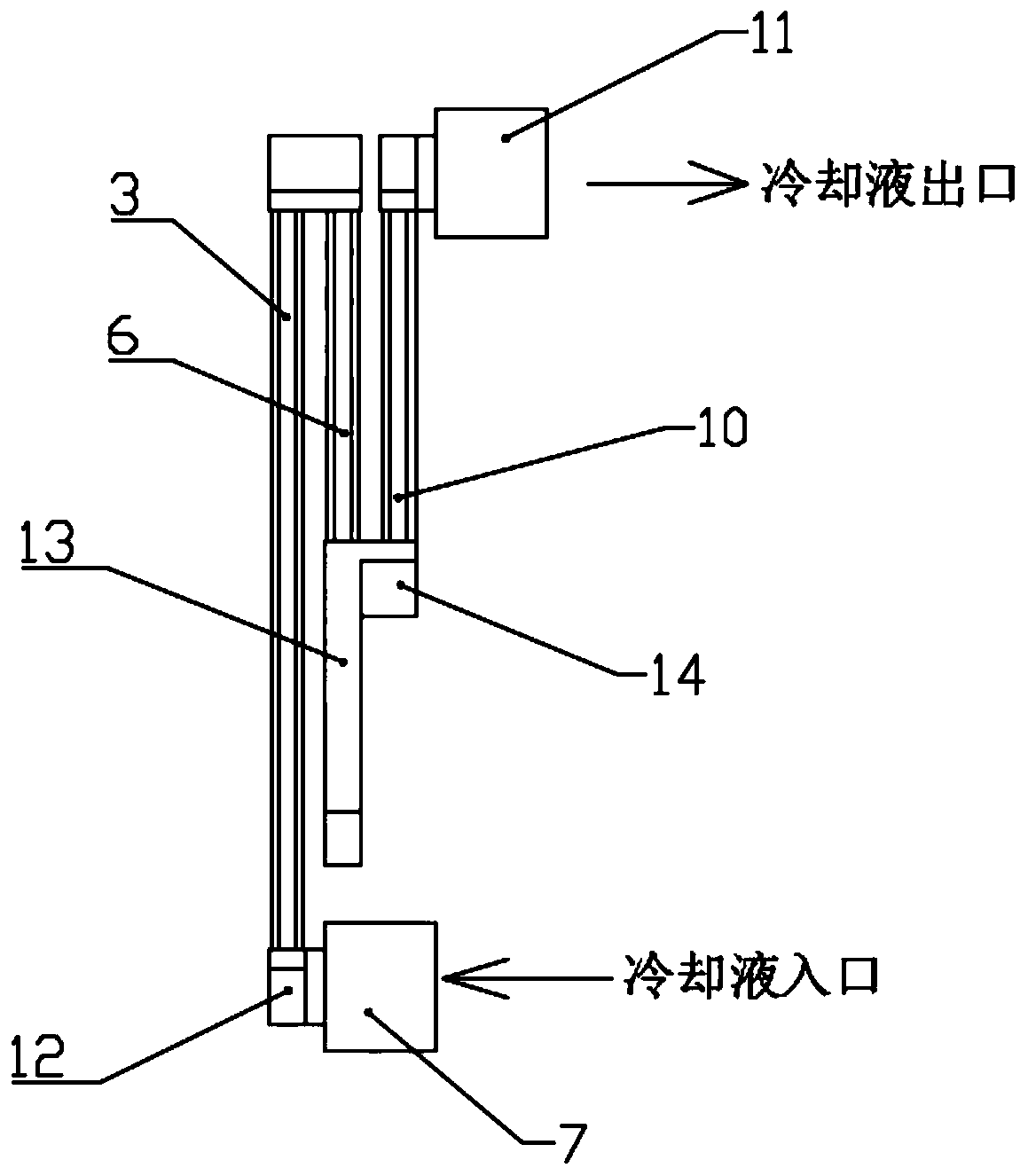

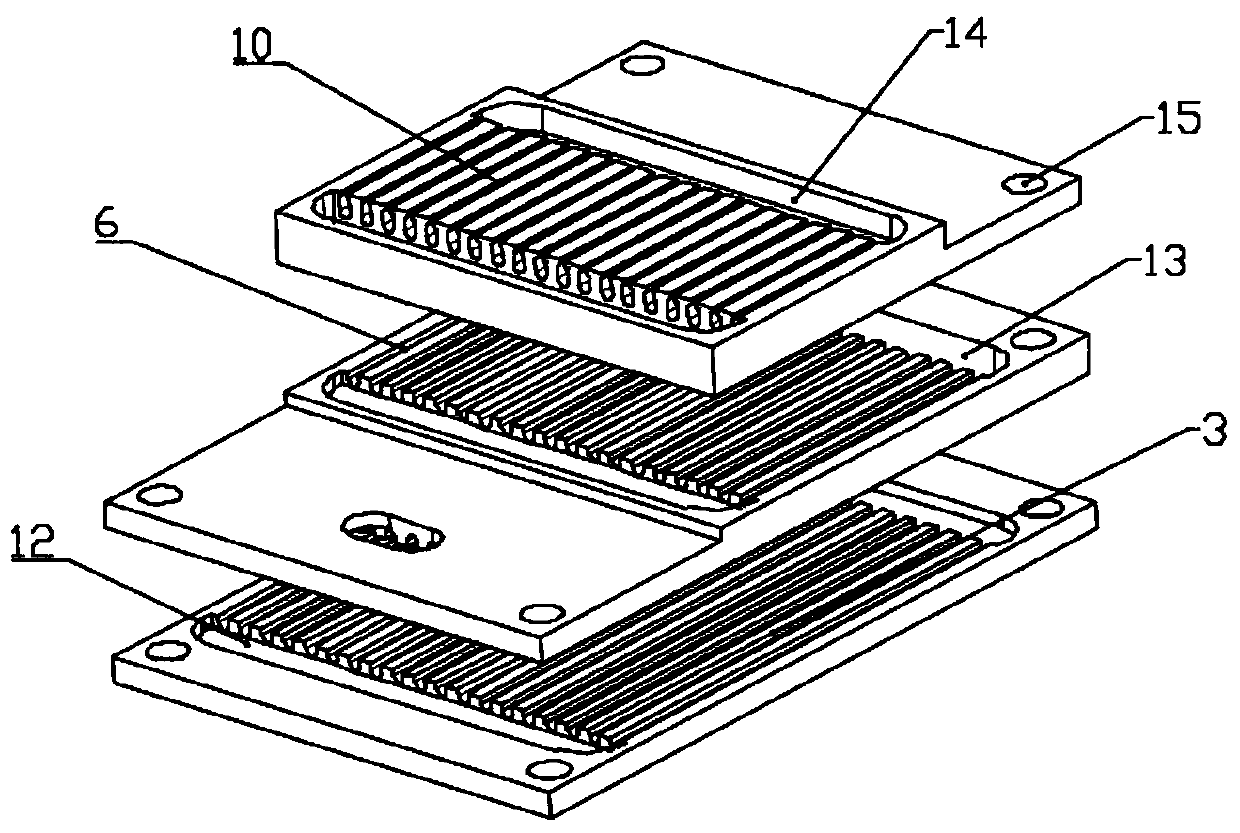

Three-dimensional micro channel and a pulsating flow heat dissipation device

ActiveCN109275311ARealize the printing functionAvoid tightnessModifications using liquid coolingEngineeringMicrochannel heat sink

The invention discloses a three-dimensional microchannel and pulsating flow heat dissipation device, which relates to the technical field of radiators, in particular to a novel three-dimensional microchannel heat dissipation device using pulsating or intermittent fluid and a 3D printing manufacturing method thereof. The heat dissipation device comprises a radiator, a pulse pump, a cooler and a connecting pipe; The heat sink is closely attached to the heat source, Connect the radiator by connecting the pipes, pulsating pump, cooler in series, The heat sink comprises a liquid injection port, a bottom layer heat dissipation structure, an intermediate layer heat dissipation structure, a top layer heat dissipation structure, a liquid outlet, the bottom layer heat dissipation structure, the intermediate layer heat dissipation structure and the top layer heat dissipation structure, which are stacked in turn, and have good heat dissipation effect, and the heat dissipation effect is further improved after the device is made into an organic whole by adopting the 3D printing method.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

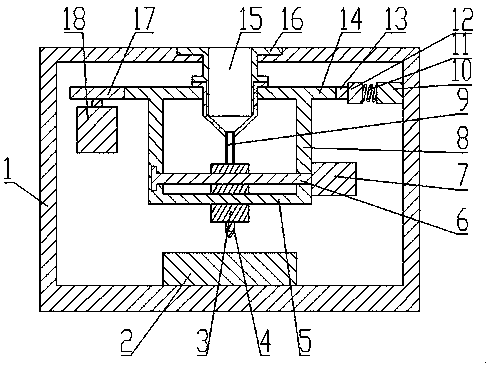

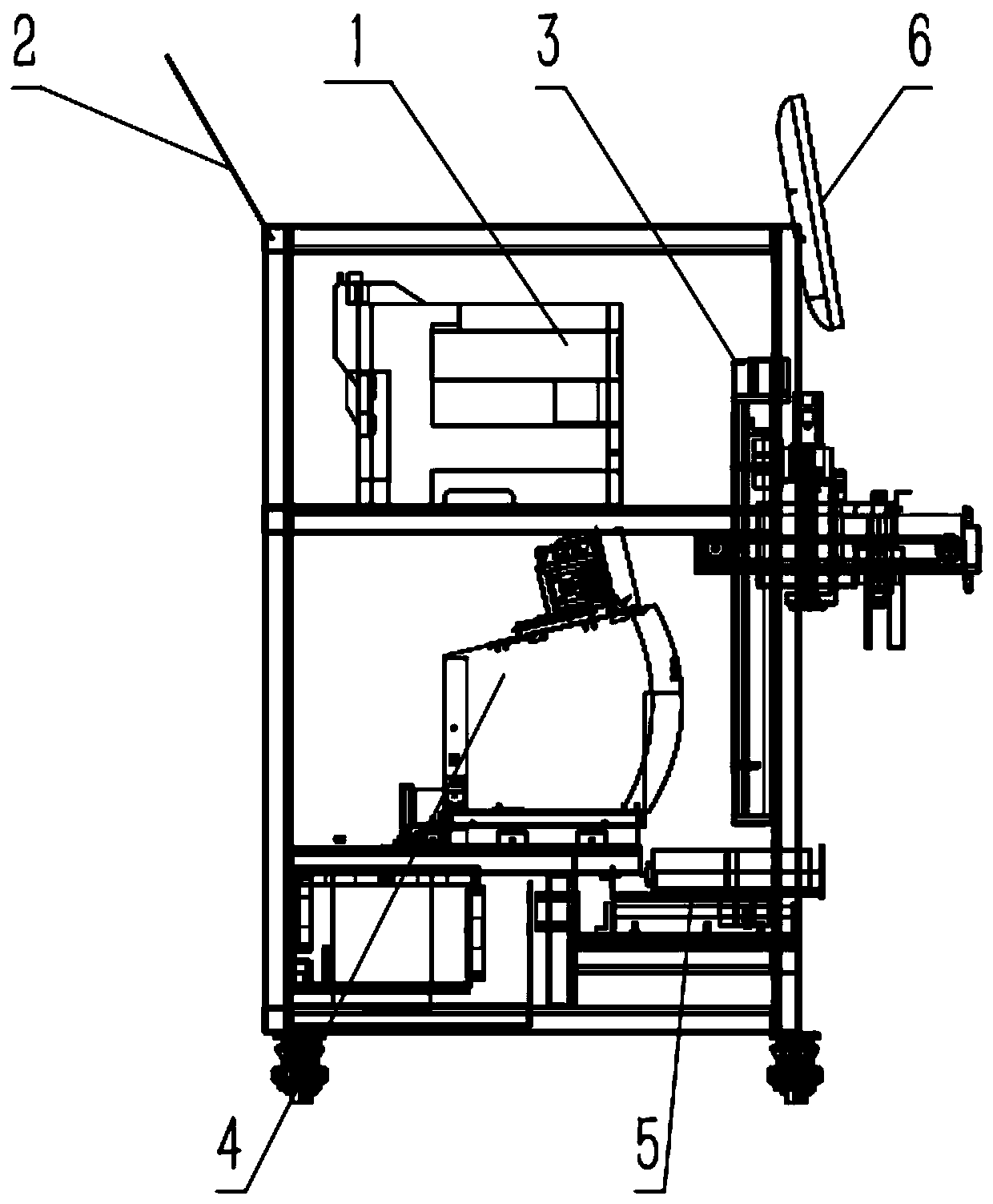

Novel three-dimensional printer

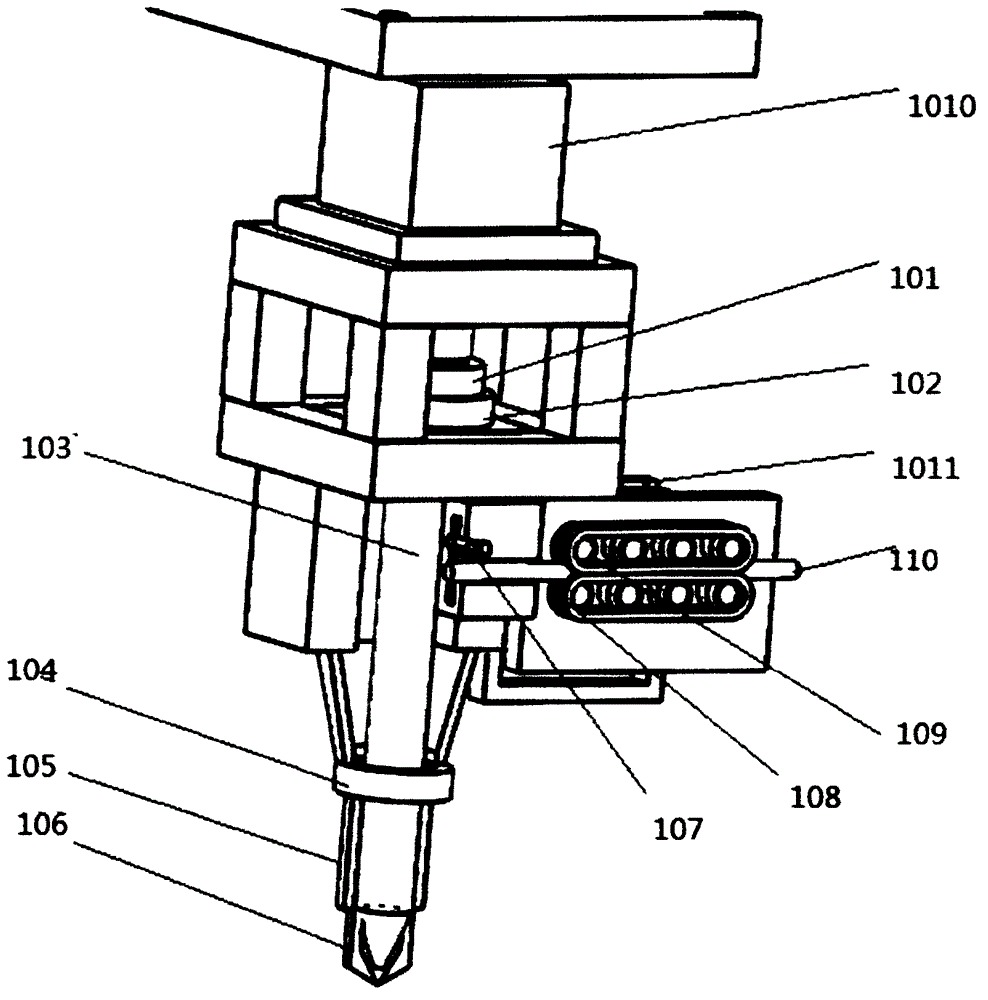

InactiveCN105172147ASolve the slow manufacturing speedSolve the blockageAdditive manufacturing apparatusRobotic controlManipulator

The invention discloses a novel three-dimensional printer which combines a quick forming principle with conventional shooting technique. The printer can be used for printing the spherical shell of an object first and then injecting material into the shell. The specific technical process comprises the following steps: a track is adopted for a nozzle mechanism to convey printing material, and a screw rod is used for pressurizing to extrude melted material. The nozzle is formed by four nozzles with different inner diameters so as to print different composite materials. Double manipulators are used for controlling a nozzle group to move along a printing track. An injection molding device is adopted for carrying out high pressure mixing and vacuum blending on injection molding materials. An injection molding manipulator is adopted to extract injection molding solution from the injection molding device, and then the injection molding solution is injected into the printed shell of the printer so as to obtain the complete entity of a printed piece and achieve efficient forming of the printed piece.

Owner:王黎 +2

Printer combining direct writing type printing and hot melting deposition type printing and printing method

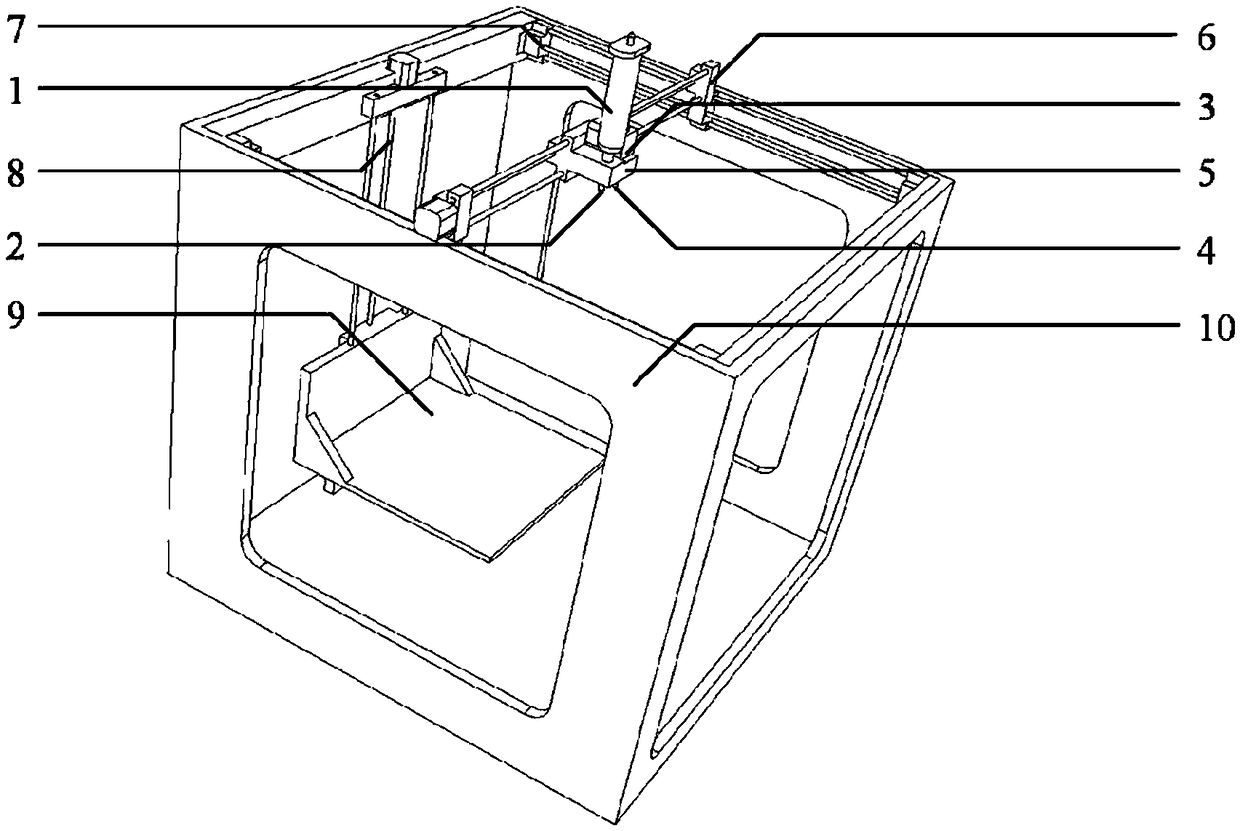

InactiveCN109228306AAny replacementAny replacement positionAdditive manufacturing apparatusAdditive manufacturing with liquidsHot meltDirect writing

The invention discloses a printer combining direct writing type printing and hot melting deposition type printing and a printing method. The printer comprises a hot melting deposition printing head, adirect writing printing head, a printing head fixture, an X-axis displacement table, a Y-axis displacement table, a Z-axis displacement table and a cube printer frame. The printing method comprises the following steps: 1) slicing and layering a 3D model by utilizing slicing software and obtaining position information and material information of each layer, and storing the material information inmodel data corresponding to slicing information in the form of extrusion head codes; commanding the X-axis displacement table, the Y-axis displacement table and the Z-axis displacement table to move by utilizing a motion path containing material information codes, and moving the corresponding printing head based on the material information to a corresponding position; and 3) based on model slicesand the material information, required quantitative printing material is extruded out through the direct writing printing head or the hot melting printing head, so as to achieve direct writing type and hot melting deposition type combined 3D printing. The printer combining direct writing type printing and hot melting deposition type printing and the printing method disclosed by the invention can achieve simultaneous printing of a plurality of materials.

Owner:XI AN JIAOTONG UNIV

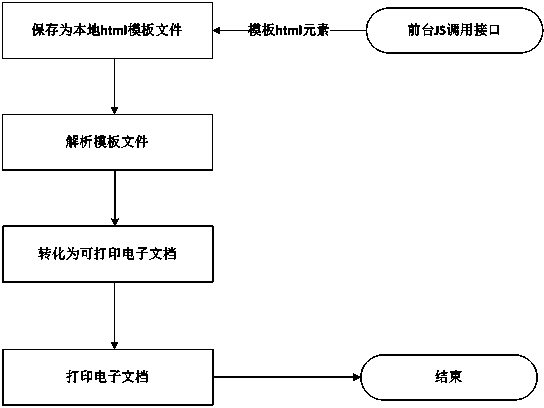

WEB batch-printing method based on fully-domestic CPU and OS and commonly used for multiple browsers

InactiveCN104020967AQuick responseVersatileSpecific program execution arrangementsDigital output to print unitsClient-sideDocumentation

The invention discloses a WEB batch-printing method based on a fully-domestic CPU and an OS and commonly used for multiple browsers and belongs to the field of WEB printing. According to the method, interaction between a foreground and a background of a Web client is achieved through an NPAPI technology; a Web template obtained by the foreground is converted into a printable pdf electronic file through html analysis of Qt and a printing technology; the pdf electronic file is printed with a CUPSAPI technology. Compared with the prior art, the WEB batch-printing method based on the fully-domestic CPU and the OS and commonly used for multiple browsers is mainly used for solving the problem existing in Web batch printing in a fully-domestic software and hardware environment, the printing function of a Web batch printing template is achieved through a browser plug-in, the responding speed of the client can be obviously increased, usage experience of a user is improved, and the method has very good application and popularization value.

Owner:INSPUR SOFTWARE CO LTD

Rotating cantilever type 3D printer with one-key locking function

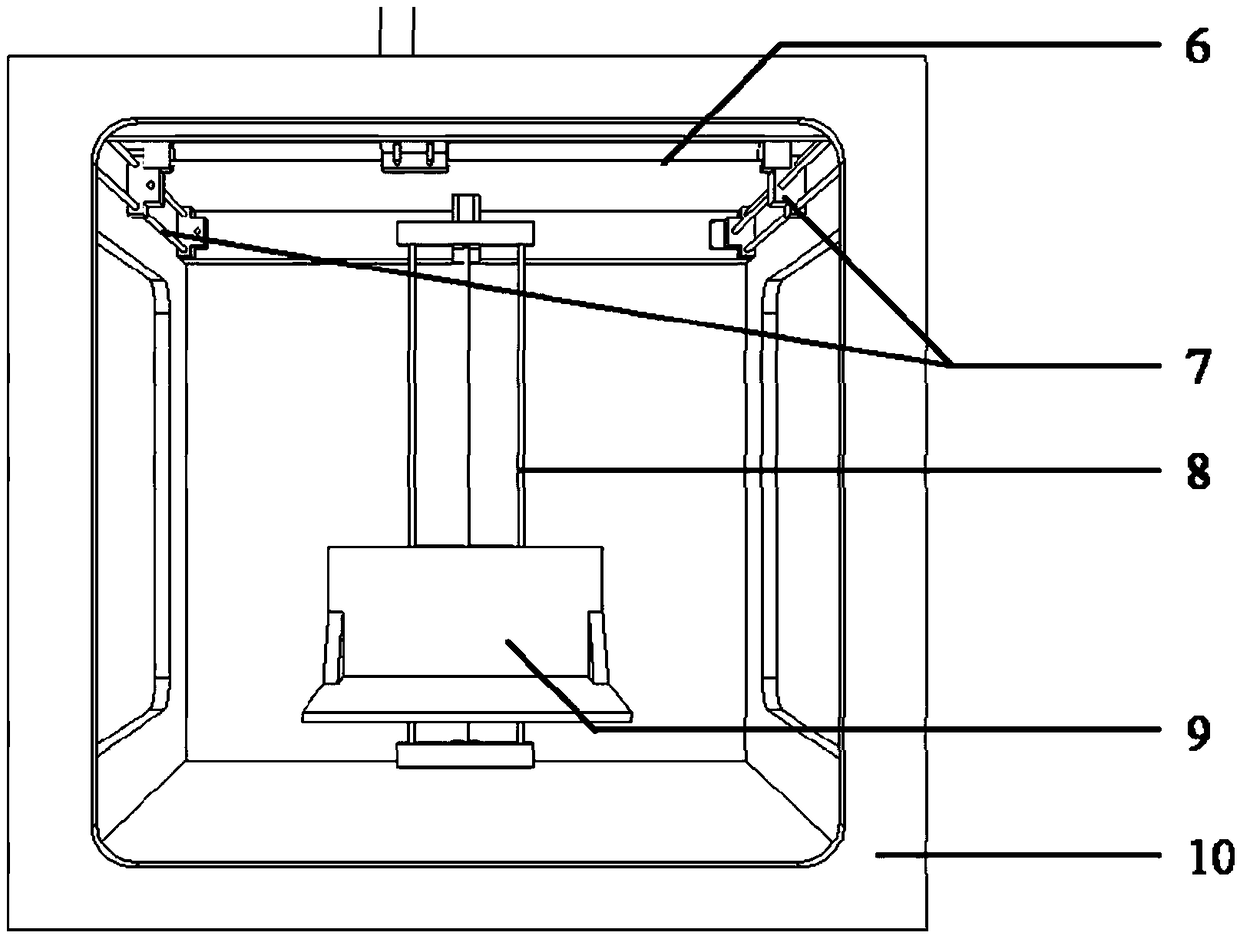

PendingCN108327244ASimple structureSimple designManufacturing driving means3D object support structuresDrive wheelEngineering

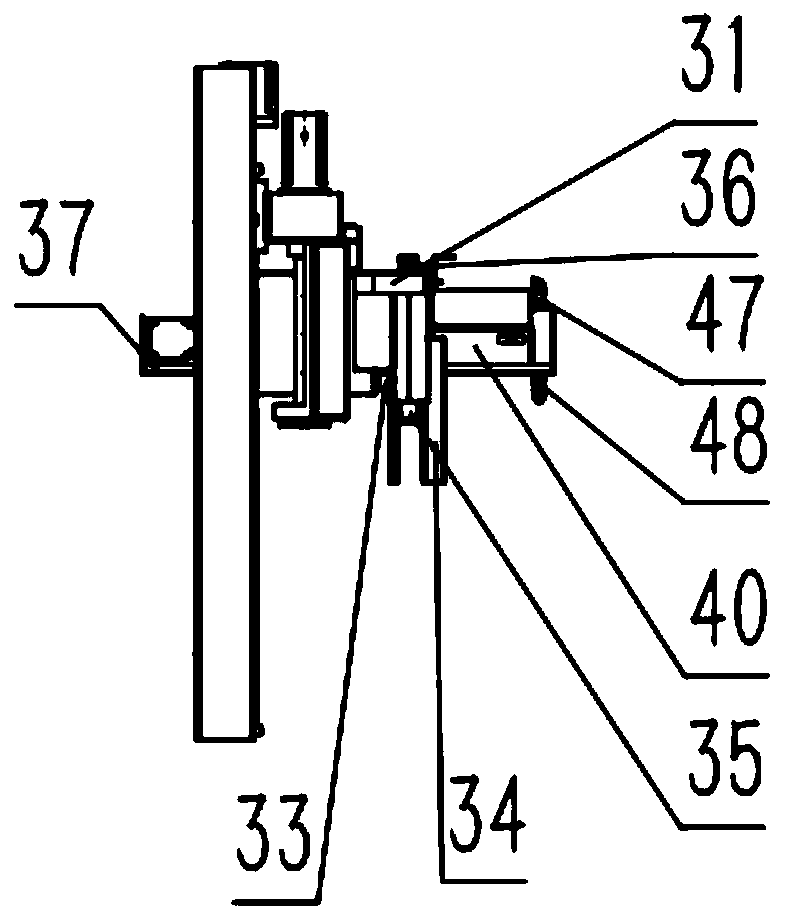

The invention discloses a rotating cantilever type 3D printer with the one-key locking function. The rotating cantilever type 3D printer comprises a case, a worktable, a spraying head, a locking blockand a hopper; the top of the spraying head is inserted in a sliding block, hanging rods are arranged at the left end and the right end of the sliding block, a driven wheel is arranged on the tops ofthe two hanging rods, a driving wheel is arranged on the left side of the driven wheel and is in engaged connection with the driven wheel, a second motor is arranged at the bottom of the driving wheel, the hopper is arranged on the top of the inner side of the case, the locking block is arranged at the right end of the driven wheel, the right end of the locking block is provided with a push blockand is fixedly connected with the push block, an electromagnet is arranged on the right side of the push block and is connected with the push block through a spring, and the worktable is arranged on the bottom of the inner side of the case. Structural design is simple and reasonable, practicability is high, compared with a common cantilever type 3D printer, the printing effect is better and more stable, a clamping block is arranged in the printer, opening and closing of the clamping block are controlled through control over opening or closing of the electromagnet, and use and operation are rapid and convenient.

Owner:TIANJIN ZHIJIE TECH CO LTD

Multifunctional pencil sharpener

The invention discloses a multifunctional pencil sharpener. The multifunctional pencil sharpener comprises a pencil rotating assembly and a printing assembly. The pencil rotating assembly comprises a pencil sharpener shell and a blade. A pencil rotating groove is formed in the surface of the pencil sharpener shell. The blade is arranged in the pencil rotating groove. The printing assembly comprises a seal shell and an idler wheel type seal mounted in the seal shell. A pattern layer is arranged on the surface of the idler wheel type seal. The seal shell is connected to an opening in the lower end of the pencil sharpener shell through an intermediate connecting body. An inner cavity of the seal shell, an inner cavity of the intermediate connecting body and an inner cavity of the pencil sharpener shell are communicated. A filter screen used for separating wood chips from graphite particles is arranged in the inner cavity of the intermediate connecting body or the inner cavity of the pencil sharpener shell. The multifunctional pencil sharpener has the advantages that when a pencil is sharpened, graphite dust enters the inner cavity of the intermediate shell by penetrating through the filter screen, the wood chips are left in the pencil sharpener shell, the wood chips can be poured out independently by unscrewing the pencil sharpener shell from the intermediate shell, and environment pollution caused by raising of the graphite dust is avoided.

Owner:NANHUA UNIV

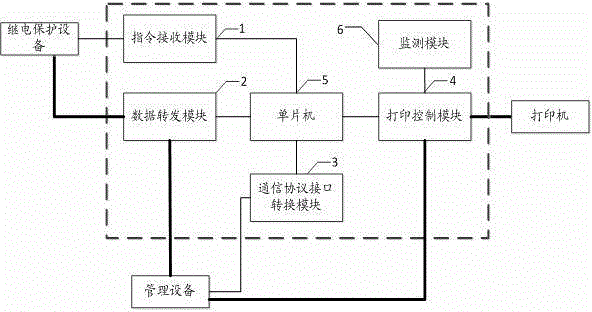

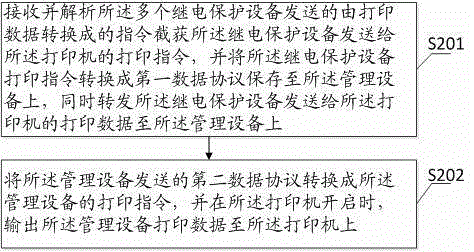

Printing transmission data acquisition device and method for power system relay protection equipment

ActiveCN104932848AFor subsequent proofreadingEasy to editTransmissionDigital output to print unitsMicrocontrollerMicrocomputer

The invention provides a printing transmission data acquisition device for power system relay protection equipment, which is matched with management equipment and is arranged on a data line through which the relay protection equipment is connected with a printer. The printing transmission data acquisition device comprises a command receiving module for intercepting a relay protection equipment printing command, a data forwarding module for forwarding relay protection equipment printing data to the management equipment, a communication protocol interface conversion module for converting between the printing command and a data protocol, a printing control module for outputting management equipment printing data when the printer is started and the management equipment printing command is obtained, and a single-chip microcomputer. Through implementation of the embodiment of the invention, the relay protection equipment printing data can be relayed onto the management equipment, and the storage, calibration and edition of the printing data by the management equipment can be realized.

Owner:SHENZHEN POWER SUPPLY BUREAU

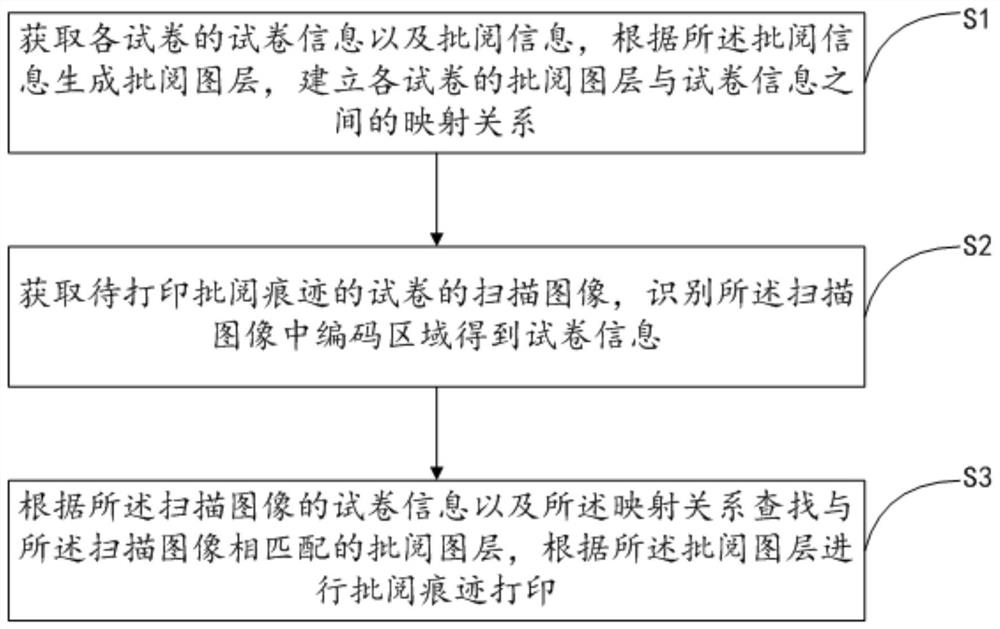

Method and device for printing test paper marking traces

PendingCN112000300ARealize automatic printingAccurate printingCharacter and pattern recognitionDigital output to print unitsAlgorithmIndustrial engineering

The invention relates to the technical field of electronic paper marking, and discloses a method for printing test paper marking traces, which comprises the following steps of: obtaining test paper information and marking information of each piece of test paper, generating a marking layer according to the marking information, and establishing a mapping relationship between the marking layer of each piece of test paper and the test paper information; obtaining a scanning image of test paper with to-be-printed marking traces, and identifying a coding region in the scanning image to obtain test paper information; according to the test paper information of the scanning image and the mapping relationship, searching a review layer matched with the scanning image, and printing a review trace according to the review layer. The method and the device have the technical effect of high marking trace printing efficiency of electronic paper marking.

Owner:武汉诺必答科技有限公司

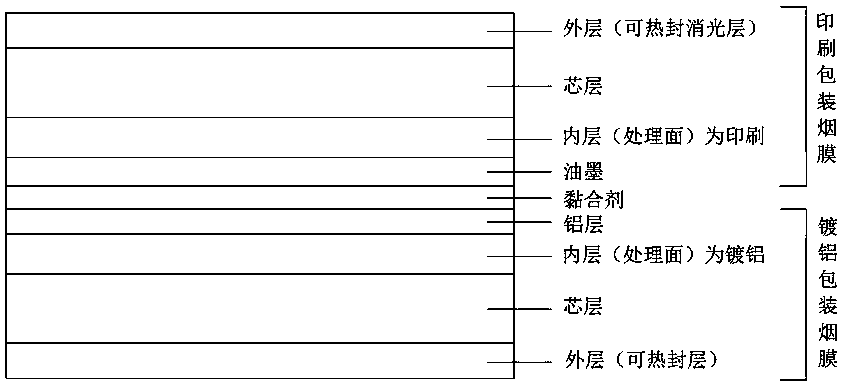

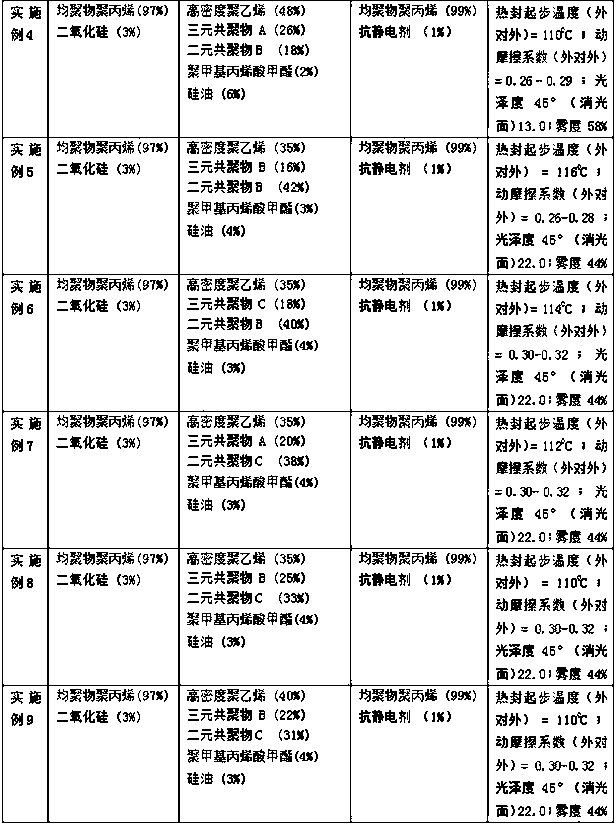

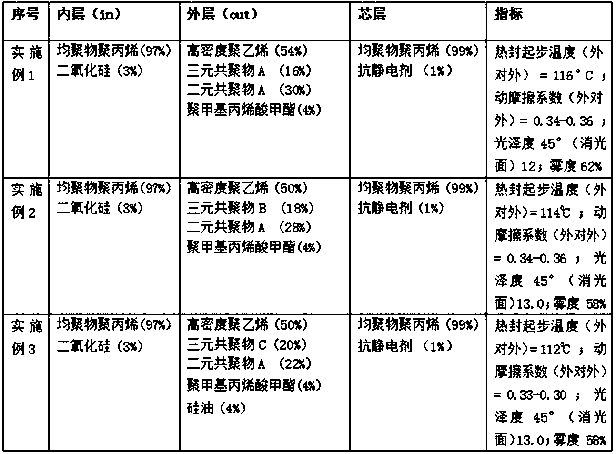

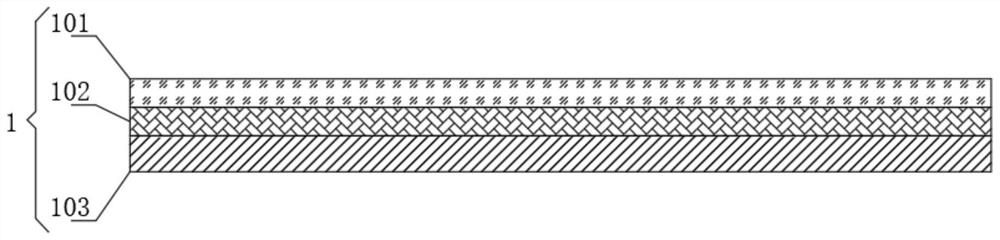

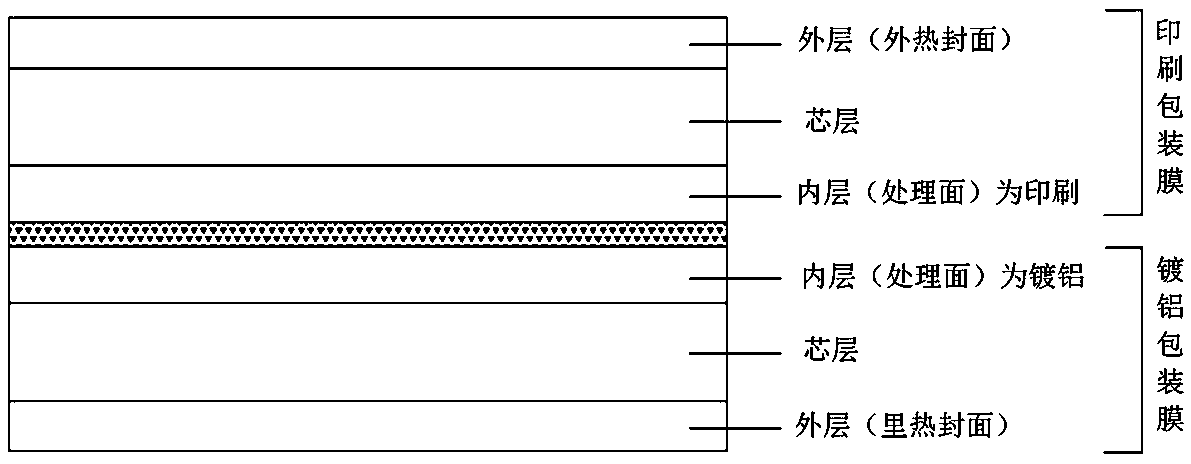

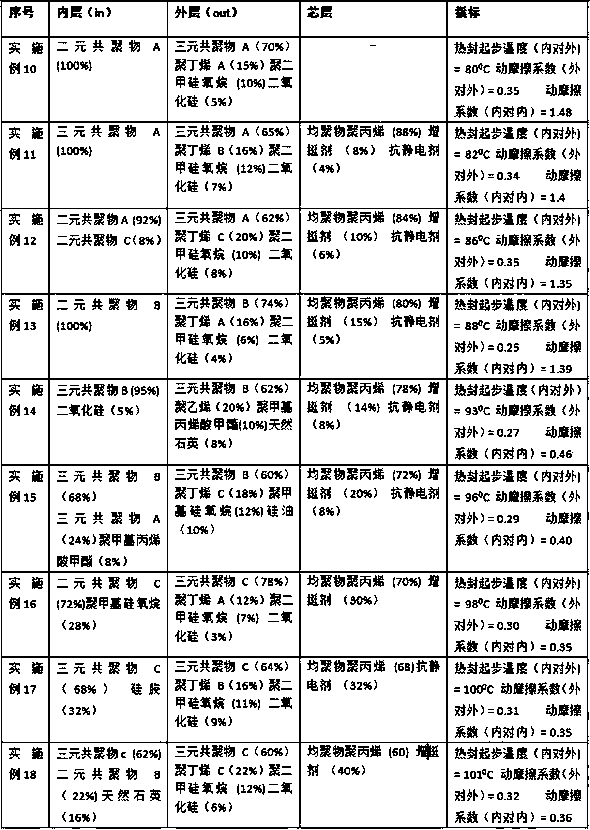

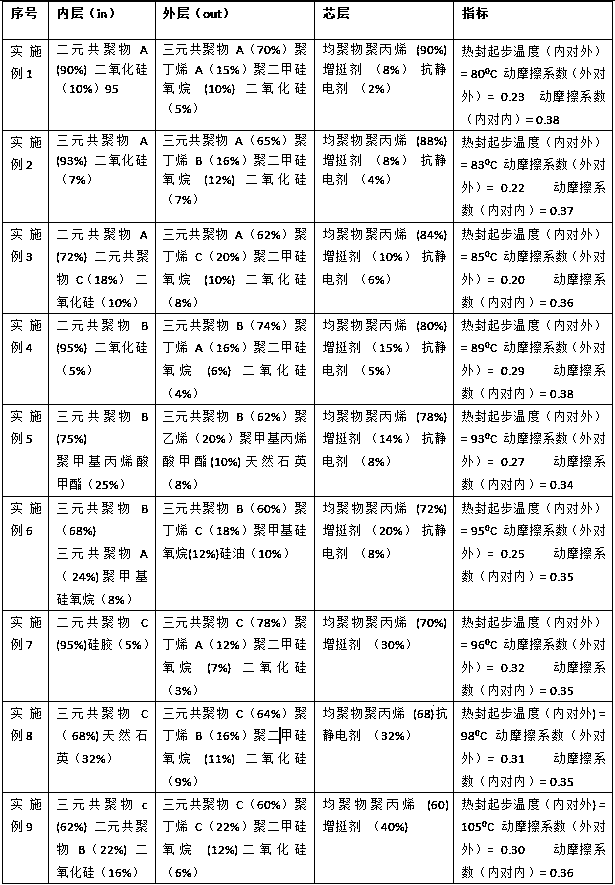

Heat-sealable matte aluminized printed composite packaging film for cigarettes and preparation method thereof

InactiveCN108656687ARealize the printing functionAvoid scratchingFlexible coversWrappersAluminiumHot-melt adhesive

The invention discloses a heat-sealable matte printed aluminized composite packaging film for cigarettes and a preparation method thereof. The composite packaging film comprises a printed matte film and an aluminized film which are laminated and processed by use of a binder or a hot melt adhesive, wherein the printed layer of the matte film can be laminated with the aluminized layer of the aluminized film to obtain the composite packaging film. The composite packaging film provided by the invention has the following advantages: a heat-sealable matte film is creatively proposed to be adopted asa printed packaging film; after inner printing of the inner surface of the matte film, the printed layer of the matte film is laminated with the surface of the aluminized layer of the aluminized film, so the problem of additional coating of a matting coating on the surface of a conventional cigarette packaging film is solved; meanwhile, the matted layer and the aluminized film have medium-and-low-temperature heat sealability, so a film can be packaged and bonded without the need of using a glue when a cigarette is subsequently packaged on a machine; and the composite packaging film provided by the invention realizes medium-and-low-temperature heat sealability and matte effects on the basis of guaranteeing conventional functions, effectively reduces energy consumption, is friendly to the environment, and has a matte metal texture.

Owner:SUZHOU KUNLENE FILM IND CO LTD +1

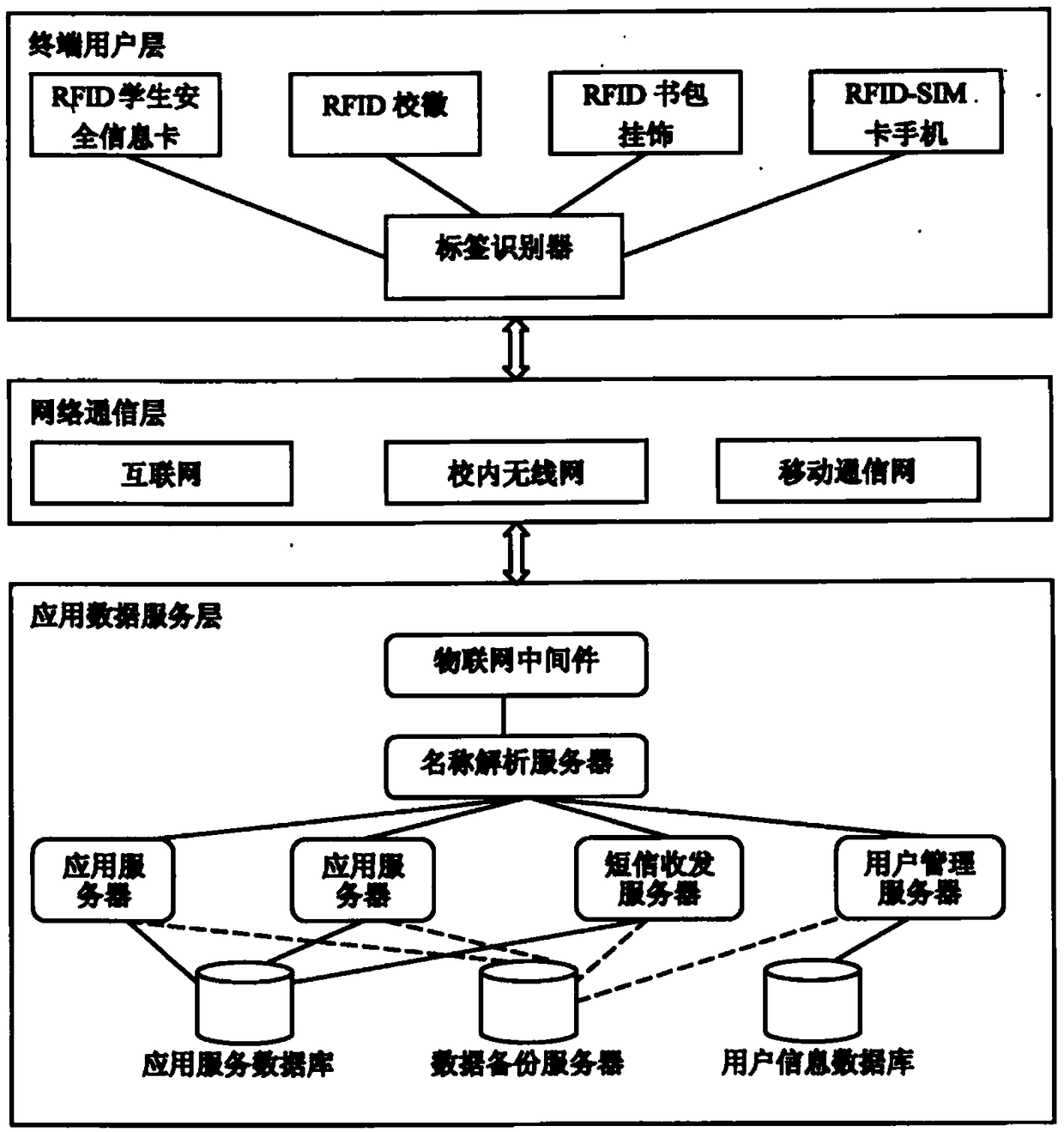

Financial management system based on campus big data

InactiveCN109272427AEasy to discardRealize the printing functionData processing applicationsCoded identity card or credit card actuationDomain nameComputer terminal

The invention discloses a financial management system based on campus big data, including a web-based identity card and a unified user identification mechanism, a unique subscriber identification number is assigned to each security information card, each ID number can read the corresponding information in the background management system, ehe ID number may be an all-digital code newly assigned according to the existing IPV6 or IPV9 digital domain name assignment technology, ehe device terminal is internally provided with a central control processing module, a data storage module and a networking module, wherein the central control processing module is respectively connected with a touch display screen, a printer module, a control keyboard, a camera, a networking module, a data storage module, a bank card swiping module and a card scanning module.

Owner:四川学姿势科技有限公司

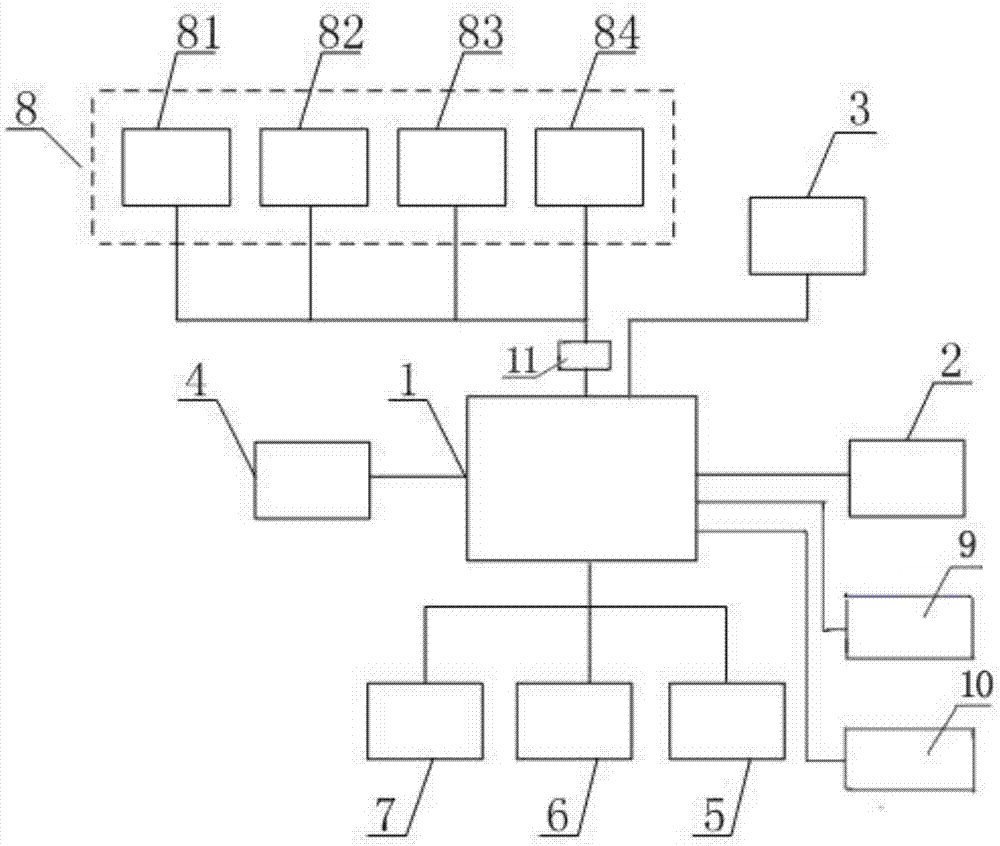

Three-phase energy meter field detection device and detection method

InactiveCN107121659ARealize browsingImplement queryElectrical measurementsMicrocontrollerOvervoltage

The invention discloses a three-phase energy meter field detection device and a detection method. The three-phase energy meter field detection device comprises a core control unit composed of a micro control unit (MCU) or an embedded system (ARM), a data storage unit connected with the control unit, a power management unit, an alternating current sampling unit, a clock generating unit, a Chinese character display unit, a peripheral interface unit, a keyboard input unit, an overvoltage protection circuit and a self-reset circuit, the peripheral interface unit comprises a voltage input interface, a high precision current clamp meter interface, a pulse signal acquisition interface and a data transmission interface, and the input and output interfaces of the peripheral interface unit are connected with an optical isolation circuit. According to the three-phase energy meter field detection device, the meter error can be calculate, under a no load or less load state of users, the device provides virtual loads to conduct single / three-phase mechanical or electronic energy meter field detection without power cut and disconnection, energy meter field detection accuracy and efficiency are improved; and the users' normal use of electricity is not affected, and the energy meter field detection is completed.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Storage tank weld defect automatic detection and recognition device

PendingCN111141765AAuto scanRealize the recognition functionMaterial analysis by transmitting radiationInformation controlControl system

The invention relates to a storage tank weld defect automatic detection and recognition device which comprises a printing mechanism, a paper carrying mechanism and a film automatic recognition mechanism which are arranged in a shell, a control part is arranged at the top of the shell, and a storage mechanism is arranged at a lower part of the shell; the whole detection and recognition device is provided with an inlet, namely the automatic film recognition mechanism, an outlet, namely the paper carrying mechanism and a storage mechanism. The paper carrying mechanism is located over the storagemechanism. The output paper is conveyed to the storage mechanism under the control of a control system; the film automatic recognition mechanism is located obliquely above the storage mechanism, the automatic film recognition mechanism transmits a recognized film to the storage mechanism, film recognition information output by the automatic film recognition mechanism is transmitted into the control system, the control system controls the printing mechanism and the storage mechanism to work according to the received information, and the control part is connected with the control system. According to the invention, the storage, identification and printing of a storage tank weld joint film are realized, and the automation degree of storage tank weld joint detection is improved.

Owner:上海万物智允工业科技有限责任公司

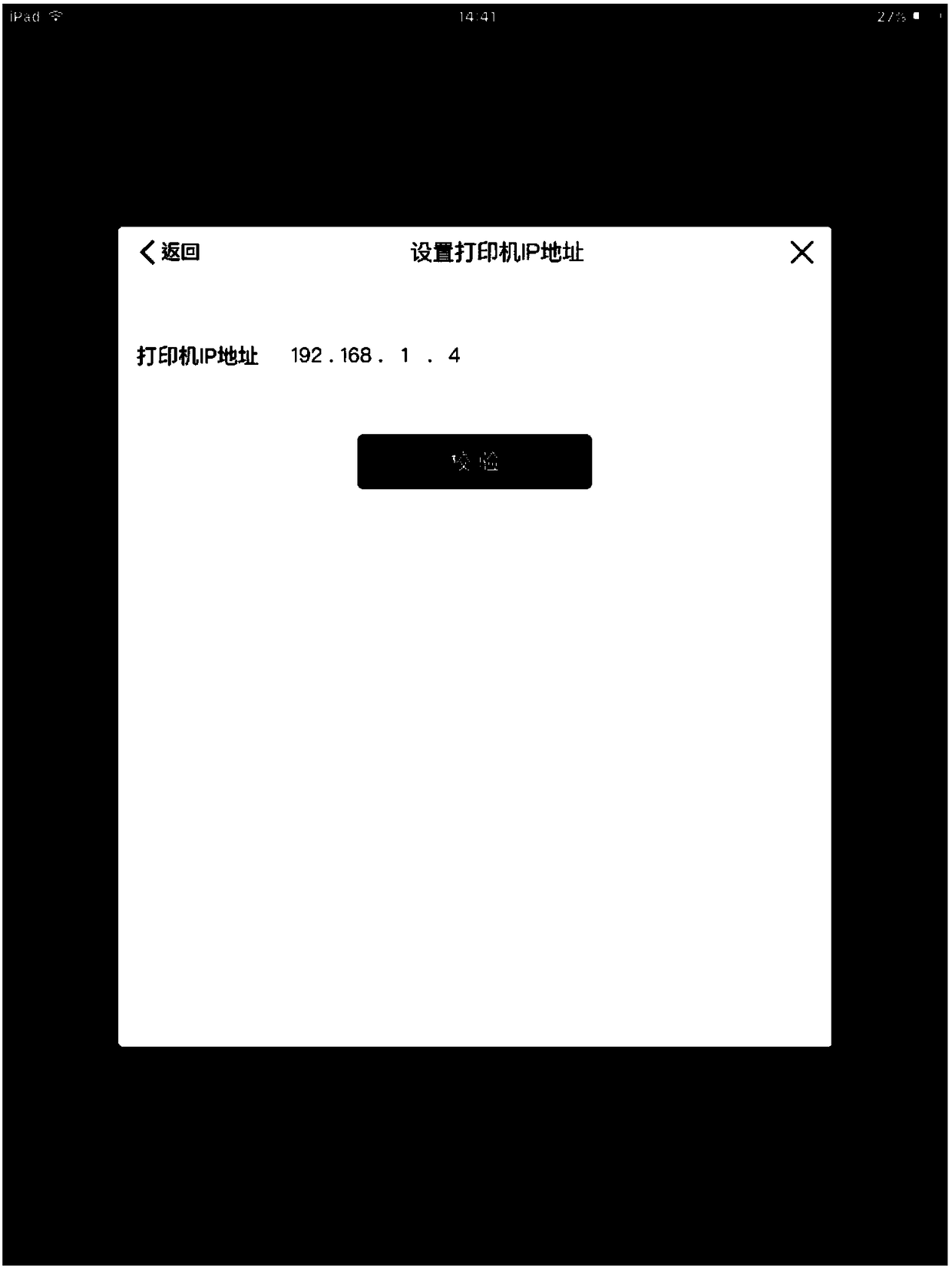

Universal WIFI printing method and system based on iOS mobile equipment

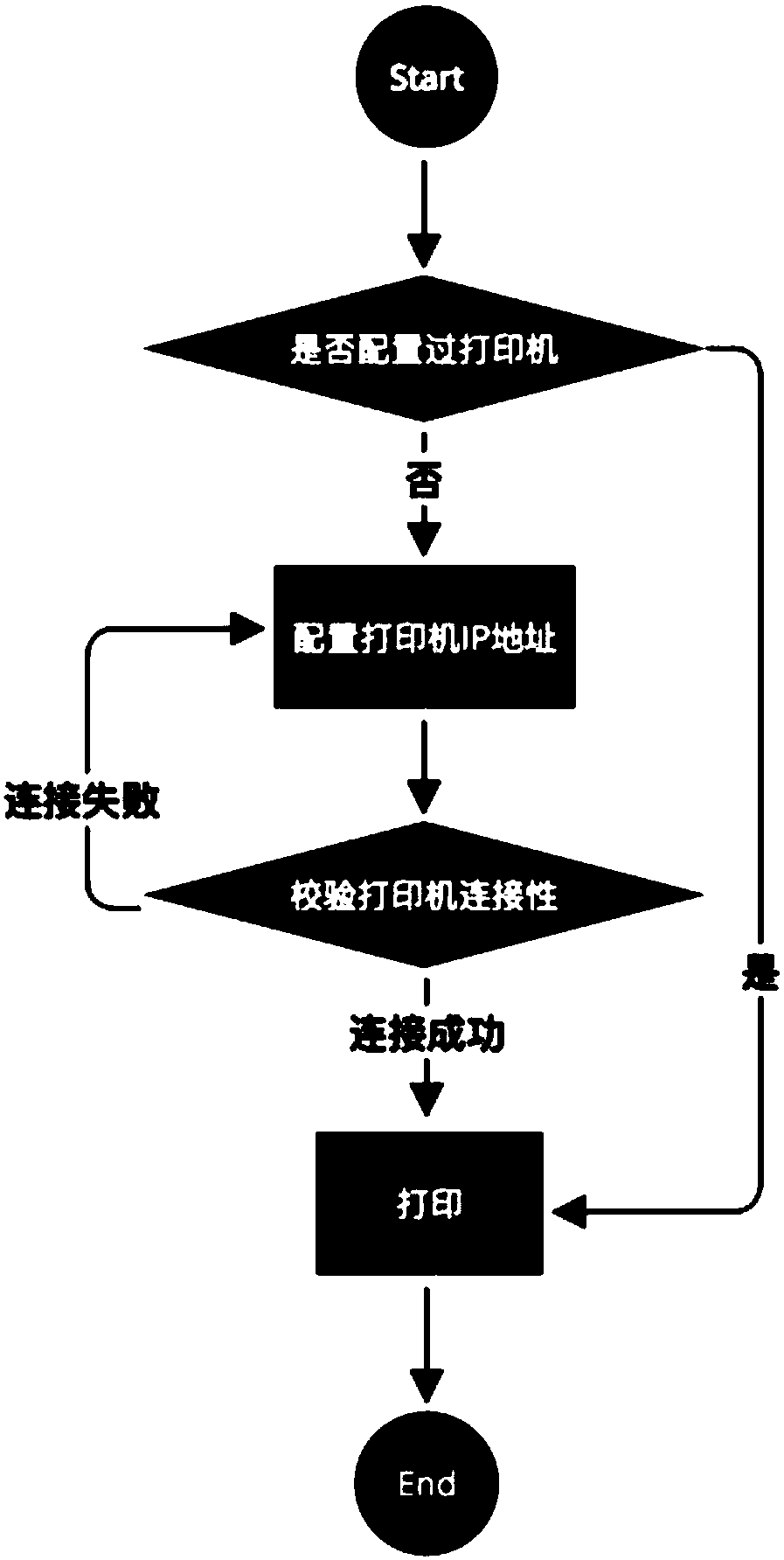

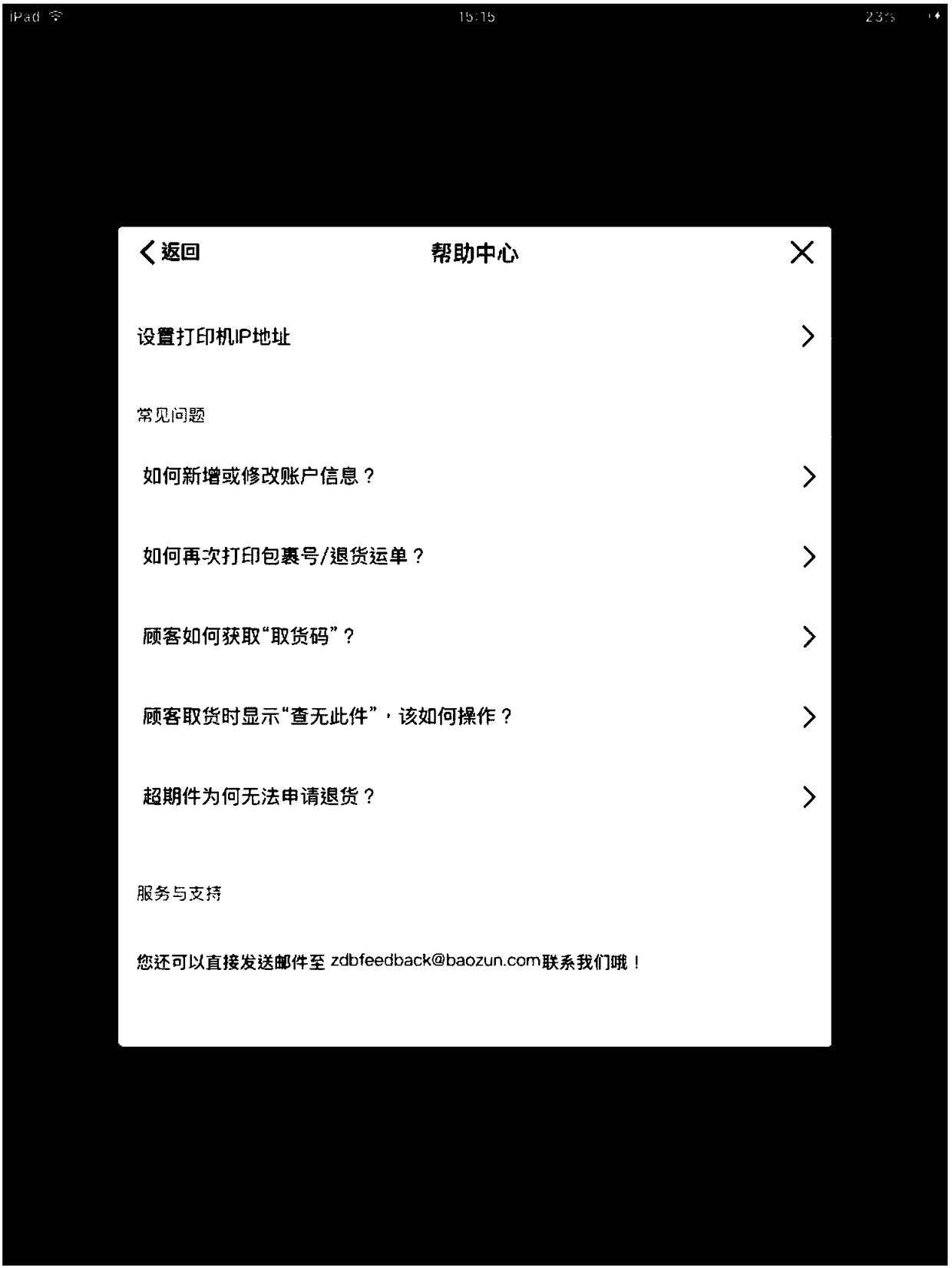

InactiveCN108255444ARealize the printing functionQuick connectionData switching networksDigital output to print unitsIp addressComputer module

The invention relates to a universal WIFI printing method and system based on iOS mobile equipment. The method comprises the following steps: detecting whether the iOS mobile equipment is configured with a printer; if so, directly executing a print order, finishing the printing; if not, to obtain an IP address of the printer configured on the iOS mobile equipment, performing the connectivity verification, and printing after the verification is successful; and detecting the printer configuration after the verification is failure, and re-configuring. The system comprises the iOS mobile equipment, a WIFI router and the printer. The iOS mobile equipment is provided with an order module, a transmitting module used for sending an order in the order module to the printer and a state module for getting a state of the printer. The system is capable of, through connecting the printer and the iOS mobile equipment to the network provided by the WIFI router, realizing a printing function, and suitable for various brands of the printers. The PC transfer is eliminated, the cost of software and hardware is low, the use is convenient and rapid, and the user experience is good.

Owner:上海宝尊电子商务有限公司

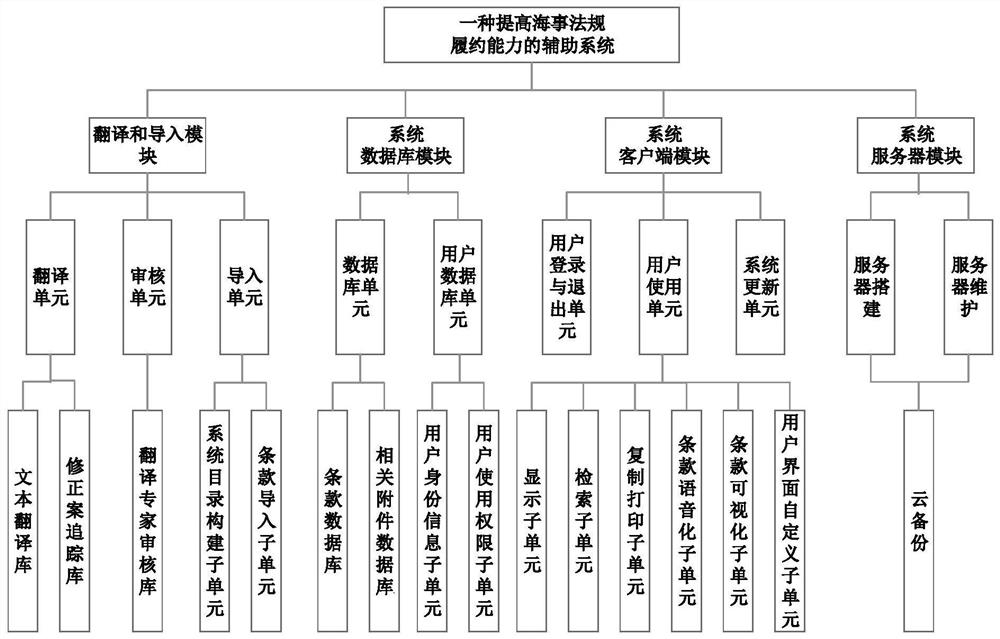

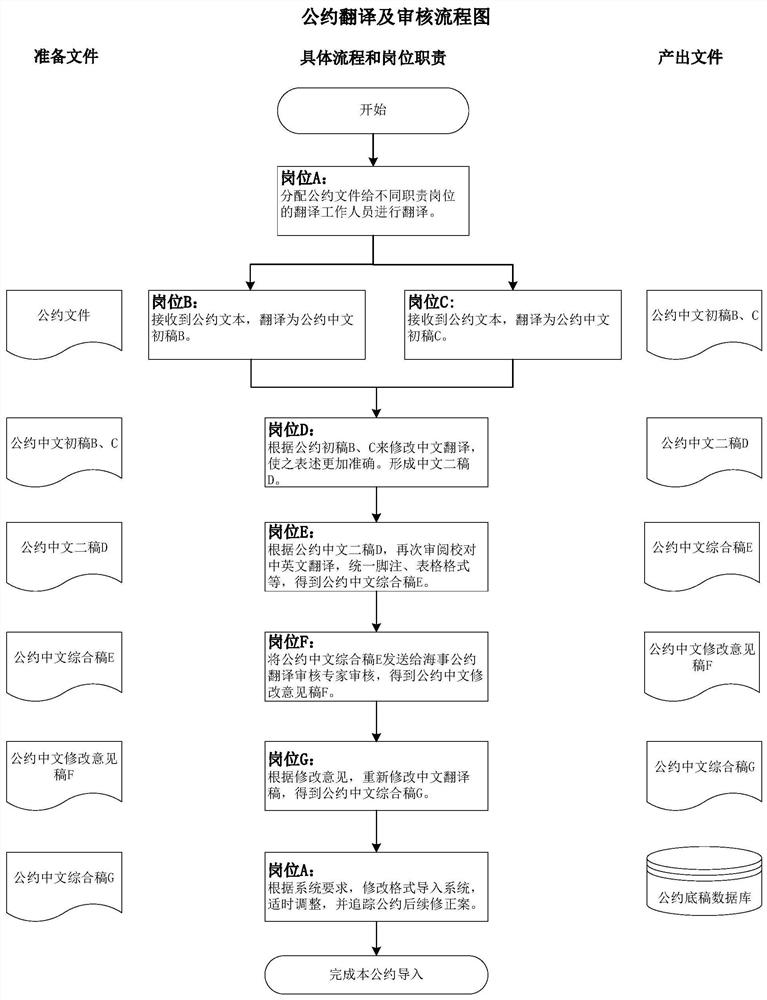

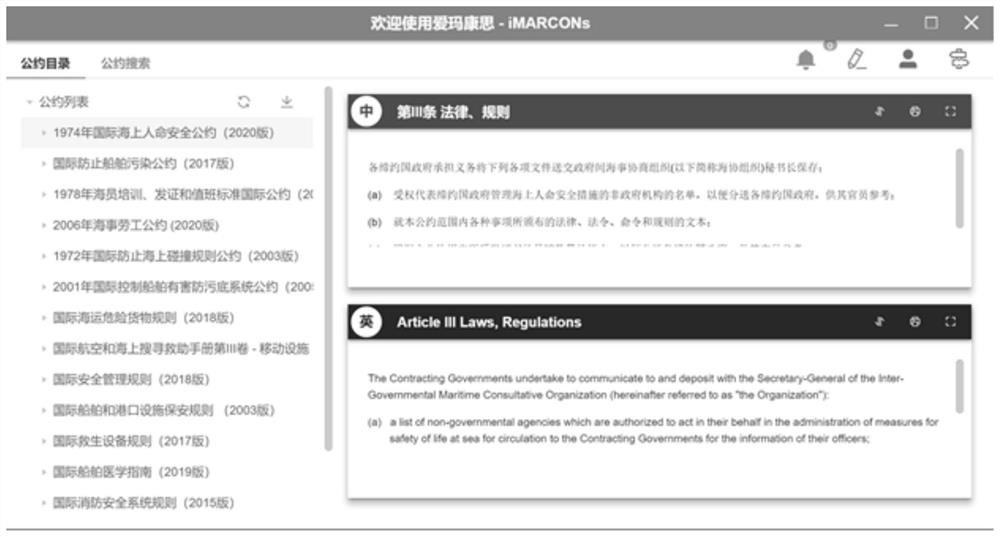

Auxiliary system for improving performance ability of maritime law and regulation

PendingCN113327182AImprove contract performanceEasy to findNatural language translationDatabase updatingSystem serviceSoftware engineering

The invention provides an auxiliary system for improving maritime law and regulation performance capability. The auxiliary system comprises a translation and import module, a system database module, a system client module and a system server module, wherein the translation and import module is provided for background maintenance personnel to use and maintain, and is used for translating and auditing international maritime affair convention, rule and guide rule texts, importing Chinese and English versions of texts into the database according to terms, and importing domestic laws, domestic administrative laws and regulations, domestic department rules and regulations and maritime affair bureau specification files into the database; the system database module is used for storing regulatory terms of Chinese and English versions and user information; the system client module is provided for a user to log in, update, retrieve, download and print, and realizes an interface self-defining function; and the system server module is used for setup and maintenance of a server and performing cloud backup .

Owner:SHANGHAI MARITIME UNIVERSITY

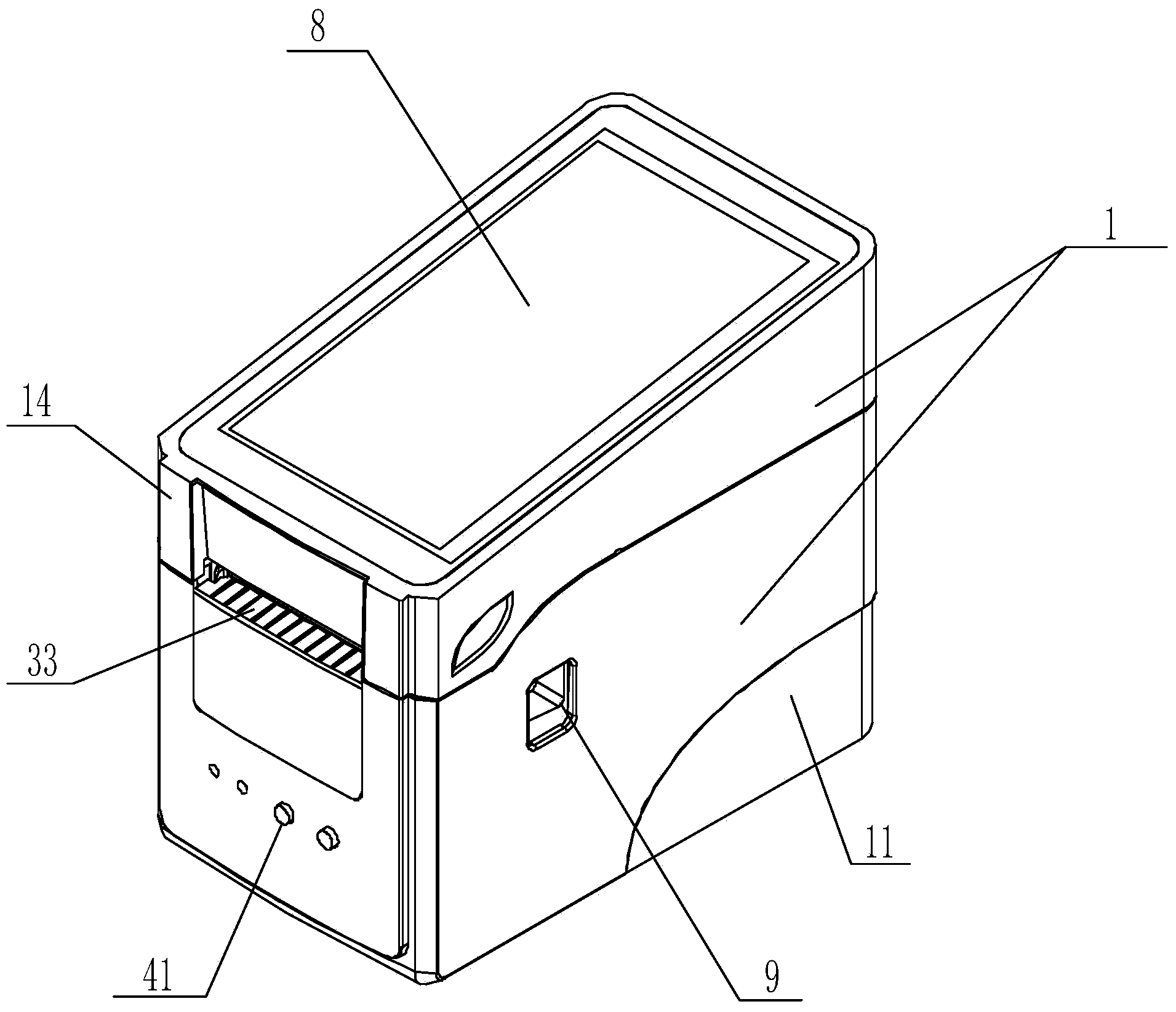

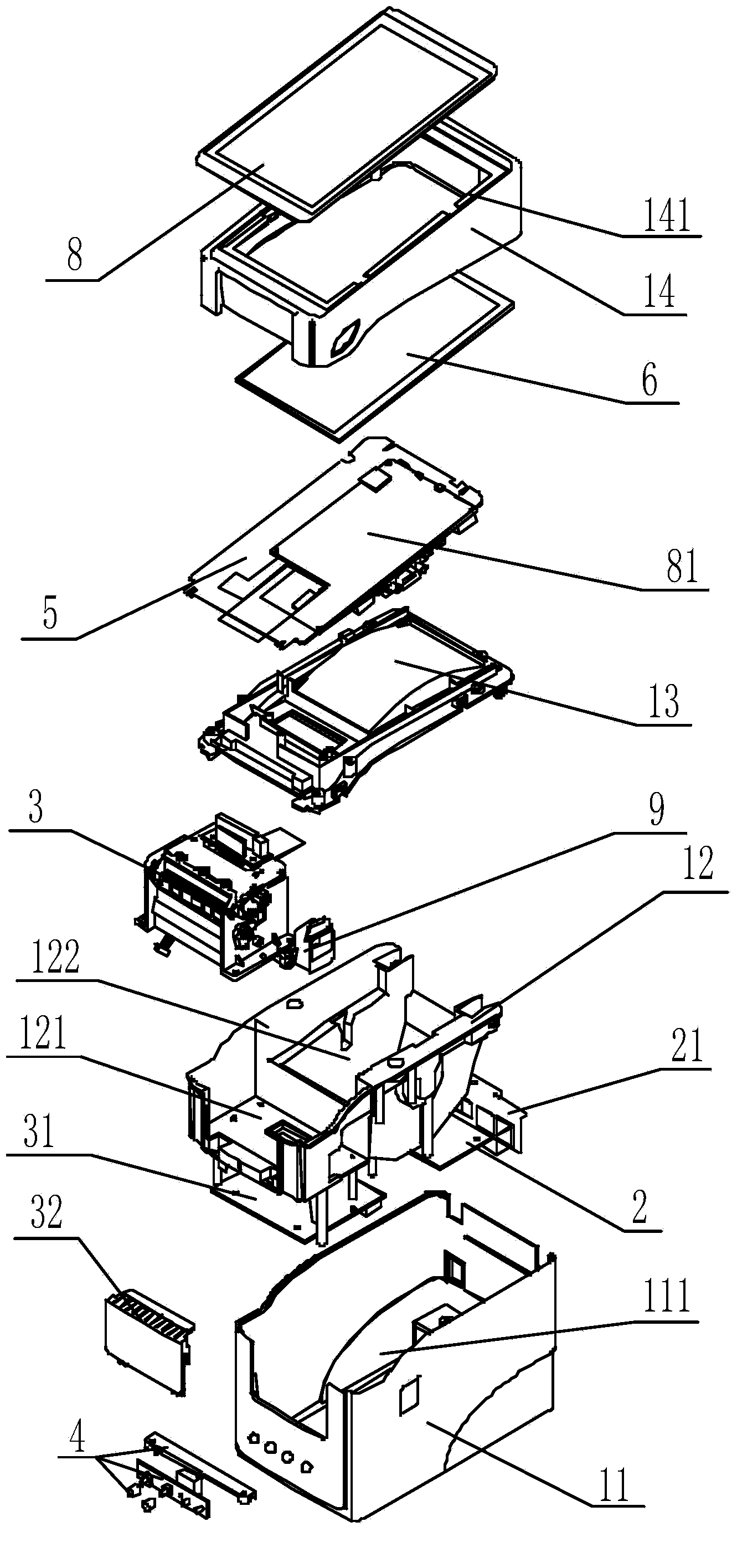

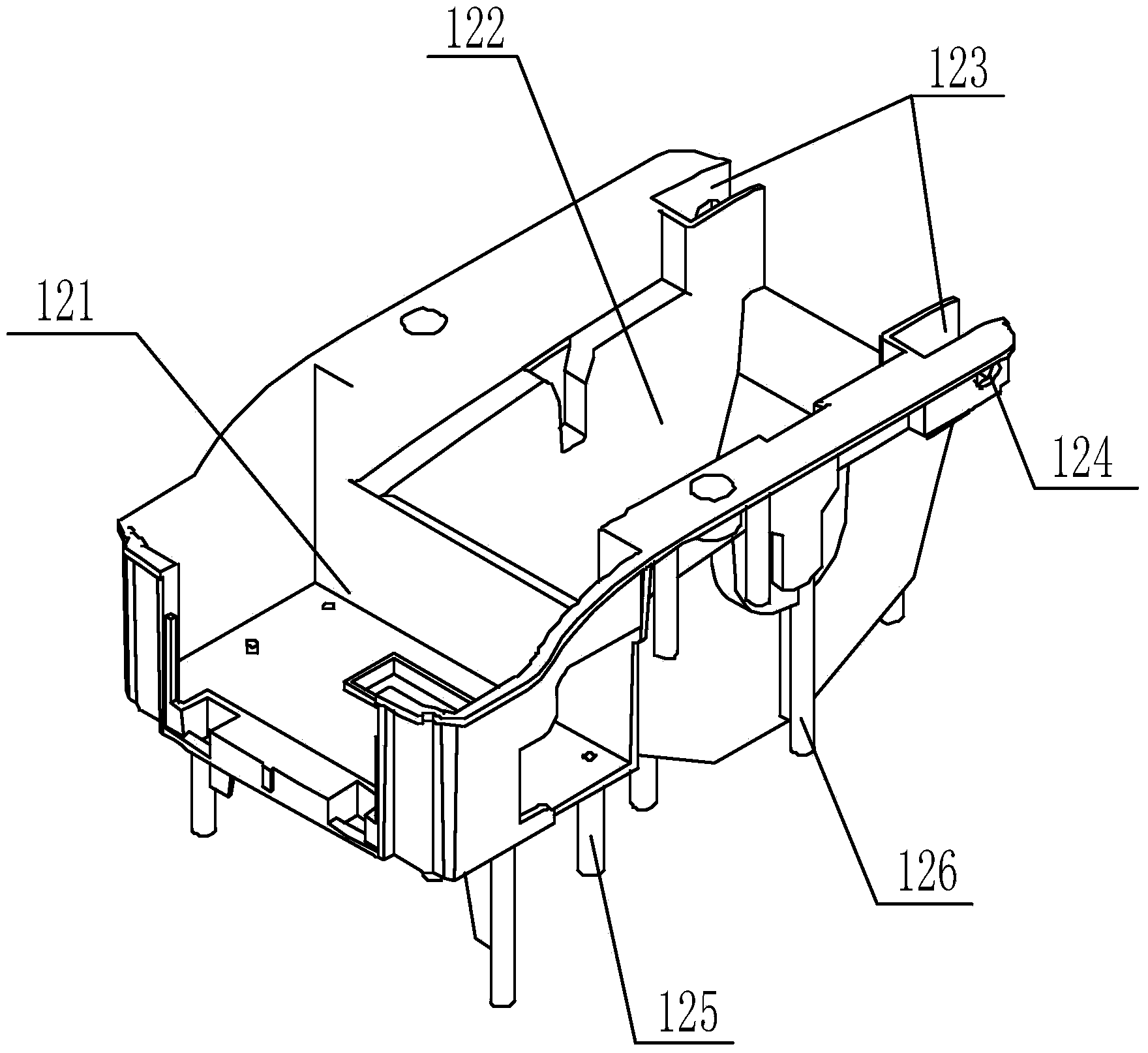

Printing method of intelligent printer and intelligent printer with printing method

InactiveCN104309315AEasy to carryRealize the printing functionTypewritersOther printing apparatusMotherboardComputer engineering

The invention relates to a printing method of an intelligent printer and the intelligent printer with the printing method. The intelligent printer comprises a shell, a printer core, a display screen, a printing head control master board and a master control panel; the shell comprises a base, a printer rack and an upper cover, the base is provided with an installation cavity with an upper opening, the printer rack is arranged in the installation cavity, and the upper cover is connected with the printer rack in an overturned mode; a printer core containing cavity and a paper groove are formed in the printer rack, the printer core is arranged in the printer core containing cavity, the printing head control master board is connected with the printer core to control movement of the printer core, the display screen is arranged on the upper cover, a touch screen is arranged above the display screen, and the master control panel is arranged below the display screen and is in signal connection with the printing head control master board. According to the printing method and the intelligent printer, printing work is completed through an Android operating system; the printing method and the intelligent printer can be applied to various industries; in addition, the touch screen mode is adopted, so that convenience is brought to a user. The intelligent printer is small in size and low in cost.

Owner:广州佳煜信息科技有限公司

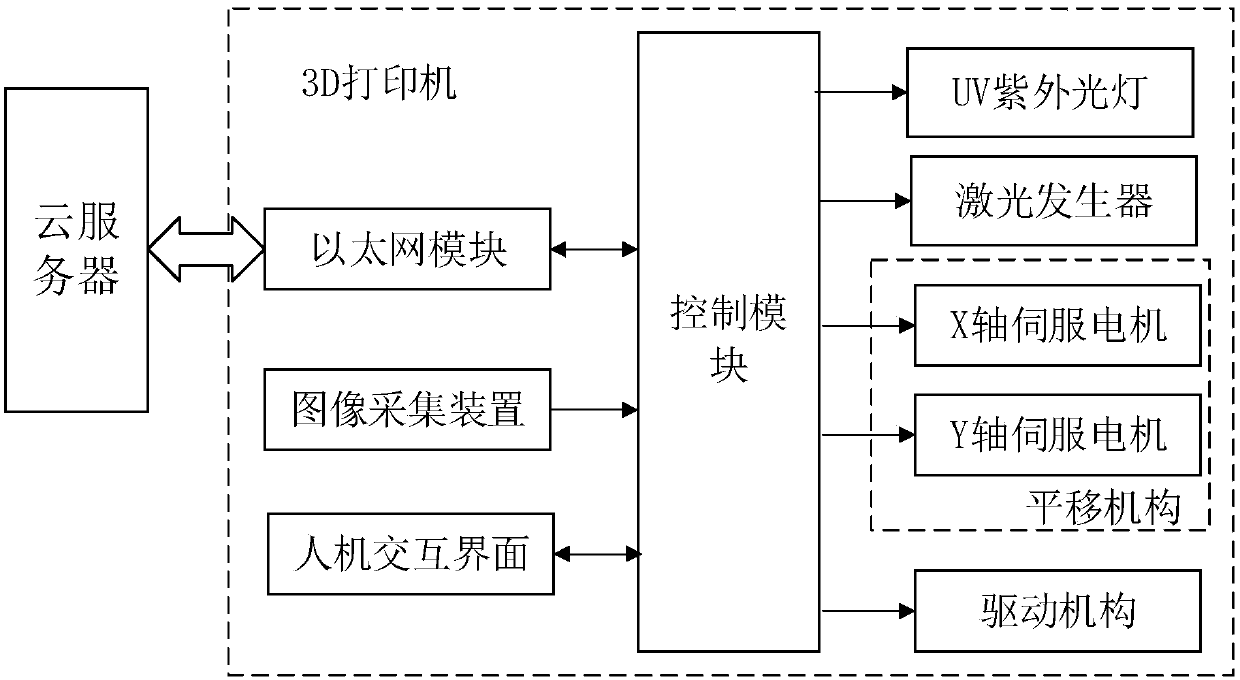

3D printing system based on cloud server function and working method for 3D printing system

InactiveCN109866427AImprove efficiencyRealize the printing functionAdditive manufacturing apparatus3D object support structuresWorking set3d printer

The invention relates to a 3D printing system based on a cloud server function and a working method for the 3D printing system. The 3D printing system comprises a cloud server and a 3D printer, wherein the cloud server is suitable for storing a plurality of printing files, and the 3D printer is suitable for obtaining the printing files from the cloud server. According to the 3D printing system andthe working method for the 3D printing system, the 3D printer also can access to a cloud server end database, obtain the printing files from the cloud server and realize a printing function when being separated from a PC machine, therefore, by means of the 3D printing system and the working method for the 3D printing system, the cooperative work efficiency is improved.

Owner:NANJING ROBOTICS RES INST CO LTD

A three-dimensional microchannel and pulsating flow cooling device

ActiveCN109275311BRealize the printing functionAvoid tightnessModifications using liquid coolingEngineeringPulsatile flow

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Home network control system

InactiveCN101079803ARealization of playback functionRealize remote controlData switching by path configurationInternet networkControl system

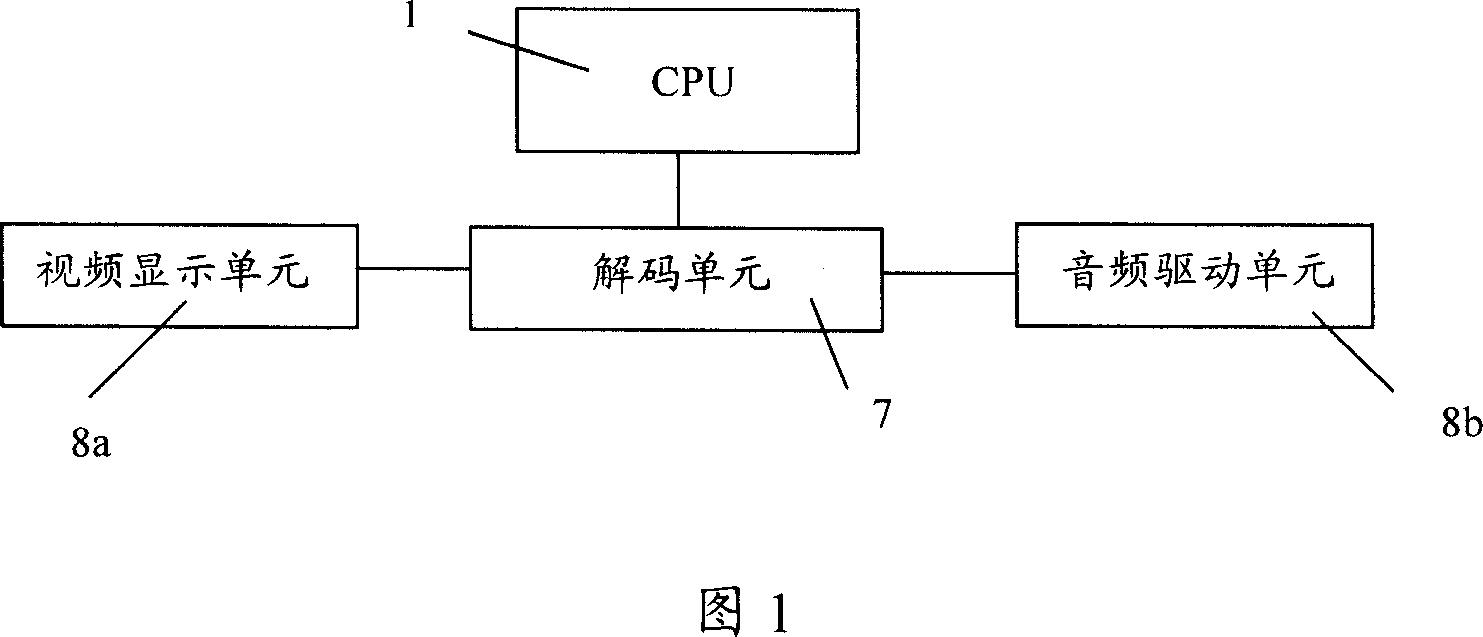

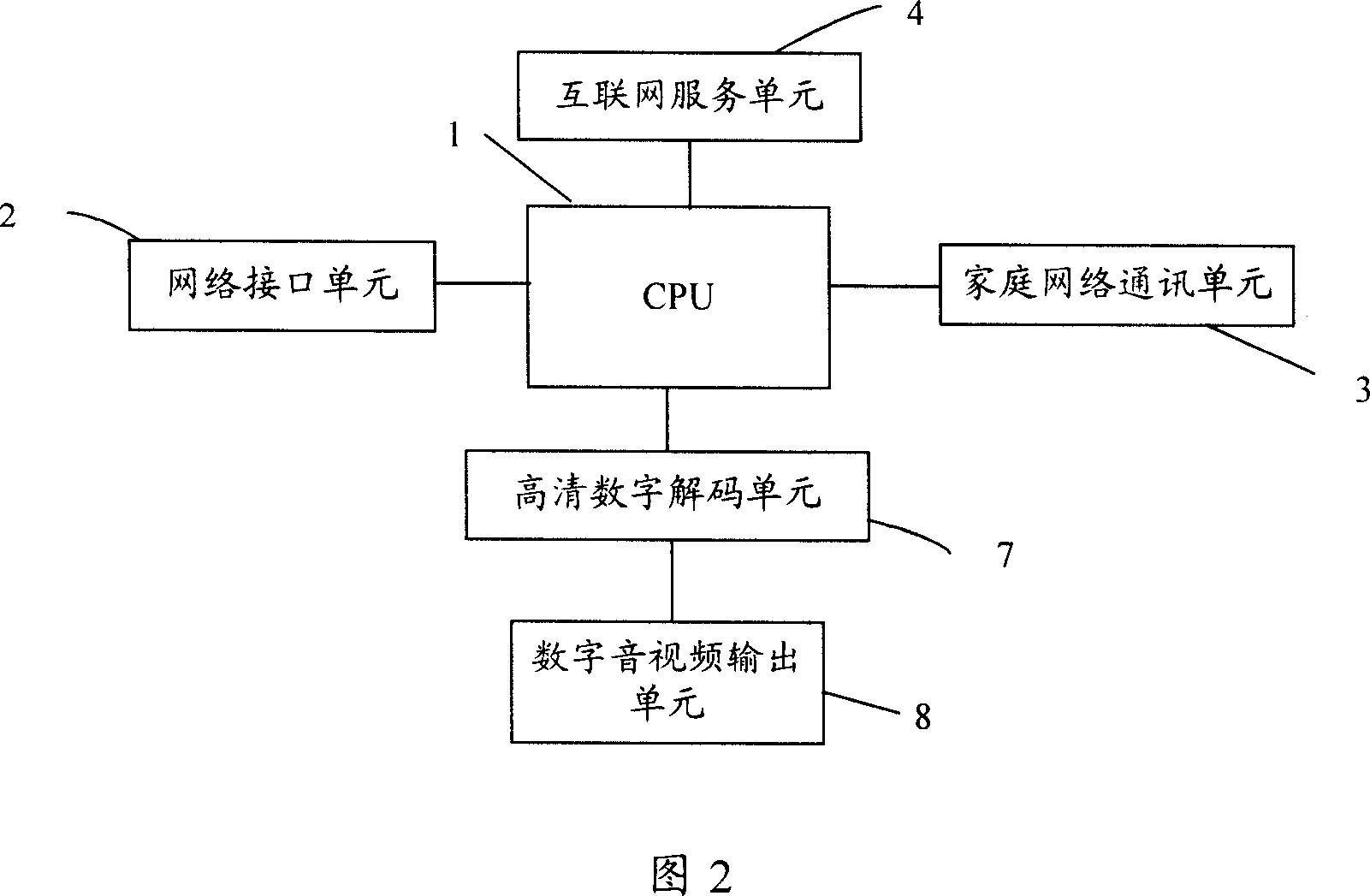

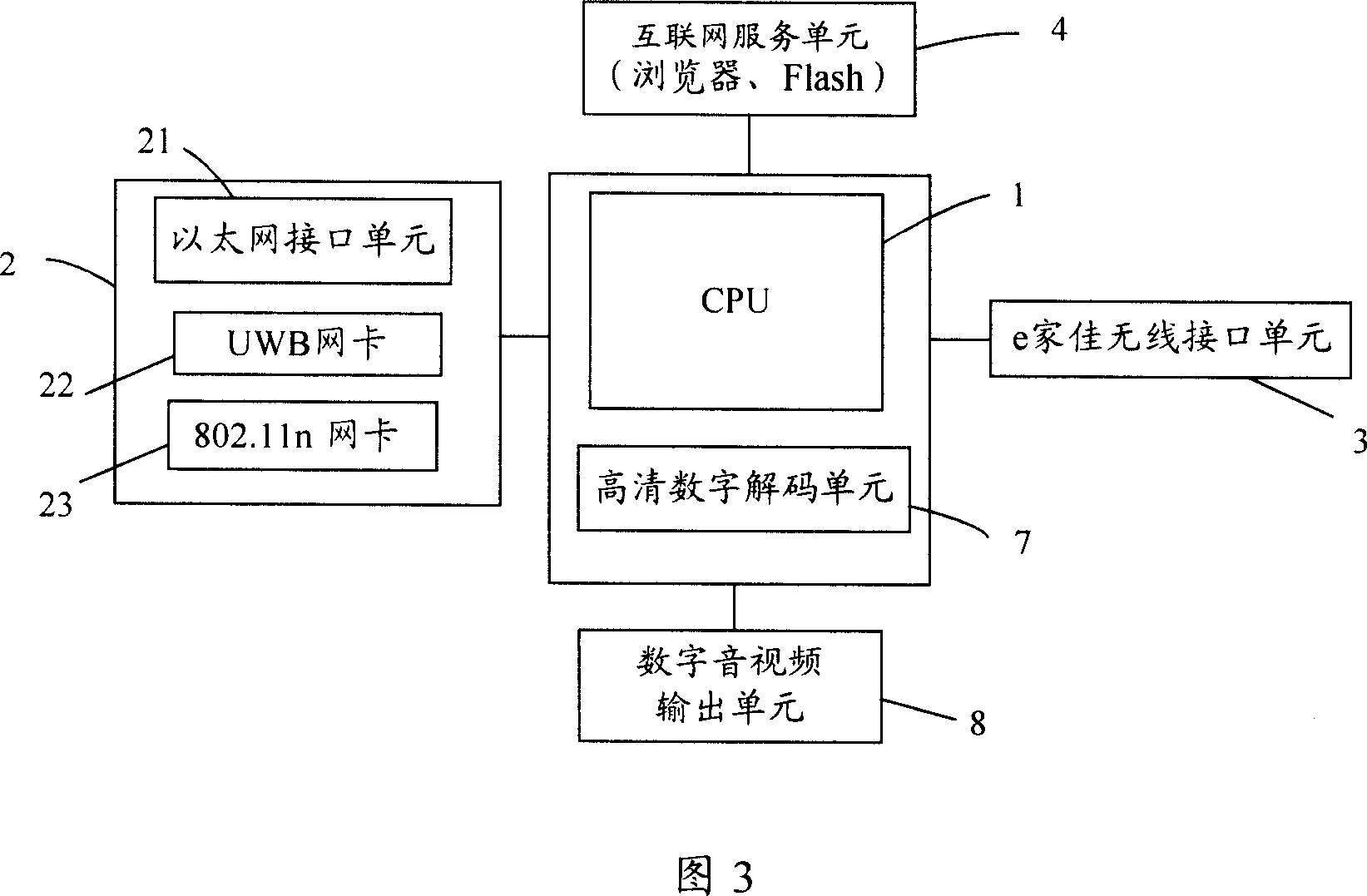

The invention discloses a domestic network control system, which comprises the following parts: main control unit CPU; domestic network communicating unit, which connects the main control unit CPU to receive and send and control the report of household electrical appliance in the domestic network controlled by main control unit CPU; network interface unit, which connects the main control unit CPU to connect network controlled by main control unit CPU; internet network service unit, which connects the main control unit CPU to provide protocol and connect the internet; high-definition digital decoding unit, which connects the main control unit CPU; back-flow media file, which connects the high-definition digital decoding unit to output the decoded medial file. The invention can realize surging on-line, domestic electric appliance control and network flow media play.

Owner:HAIER GRP CORP +1

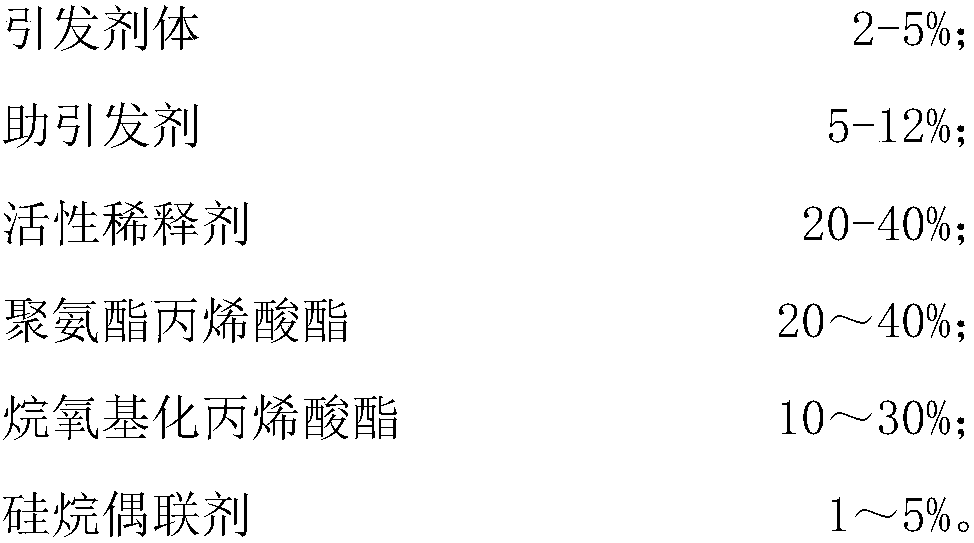

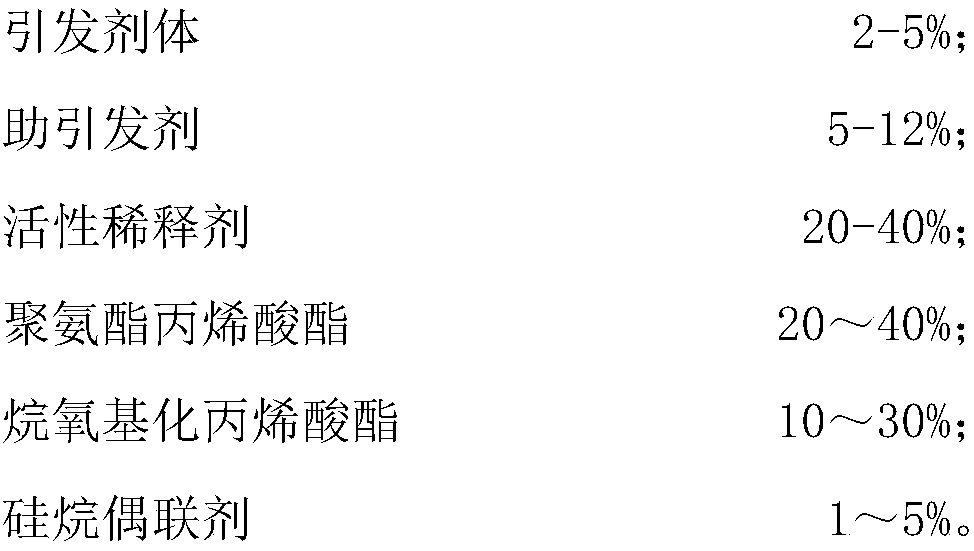

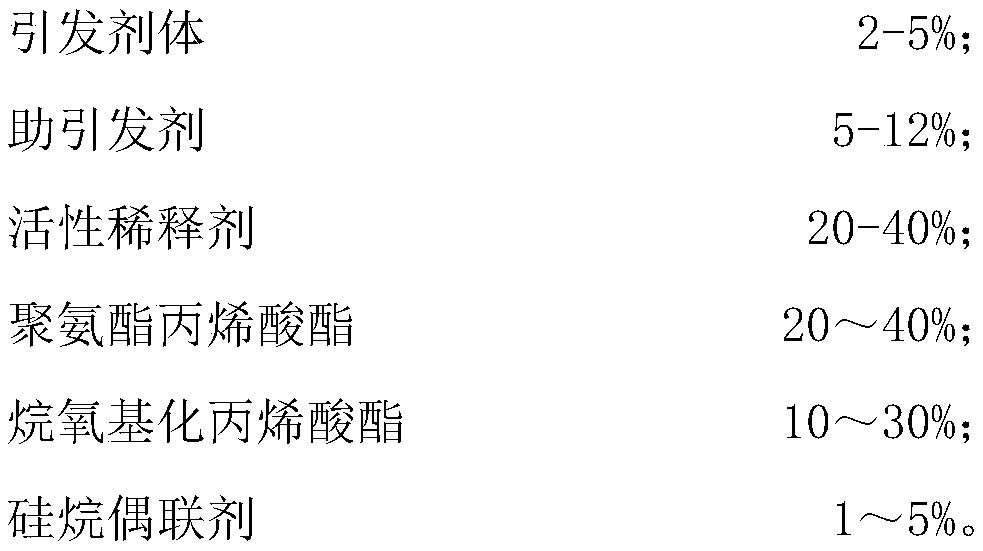

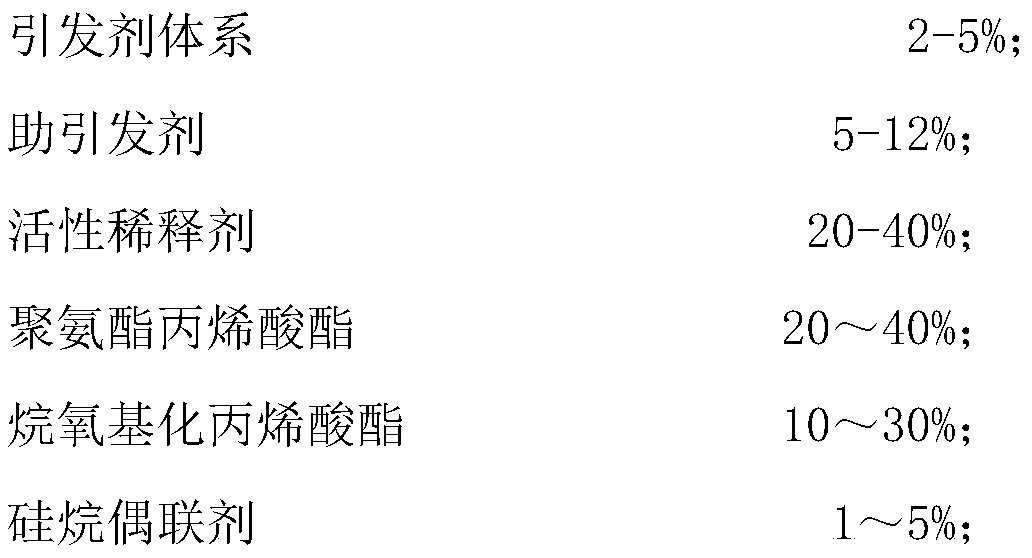

Highly wear-resistant UV release agent coating applied to slipper transfer and preparation method thereof

ActiveCN108250940ARealize the printing functionGood flexibilityPolyurea/polyurethane coatingsSolubilityOrganic solvent

The invention provides a highly wear-resistant UV release agent coating applied to slipper transfer and a preparation method thereof. The coating comprises the following components in percentage by weight: 2-5% of an initiator body, 5-12% of a promoter, 20-40% of a reactive diluent, 20-40% of urethane acrylate, 10-30%of alkoxylated acrylate and 1-5% of a silane coupling agent. The UV release agentcoating prepared in the invention is high in curing degree and excellent in solubility, the absorption wavelength reaches 390nm, any organic solvent is not released in the curing process and in the prepred product, the needed amount of the cured ultraviolet energy is 50mj / cm<2> only, the curing time only needs 1-3 seconds, and the prepared coating is a high-efficiency, energy-saving and environmental-friendly photocuring release coating and can be widely applied to slipper transfer.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

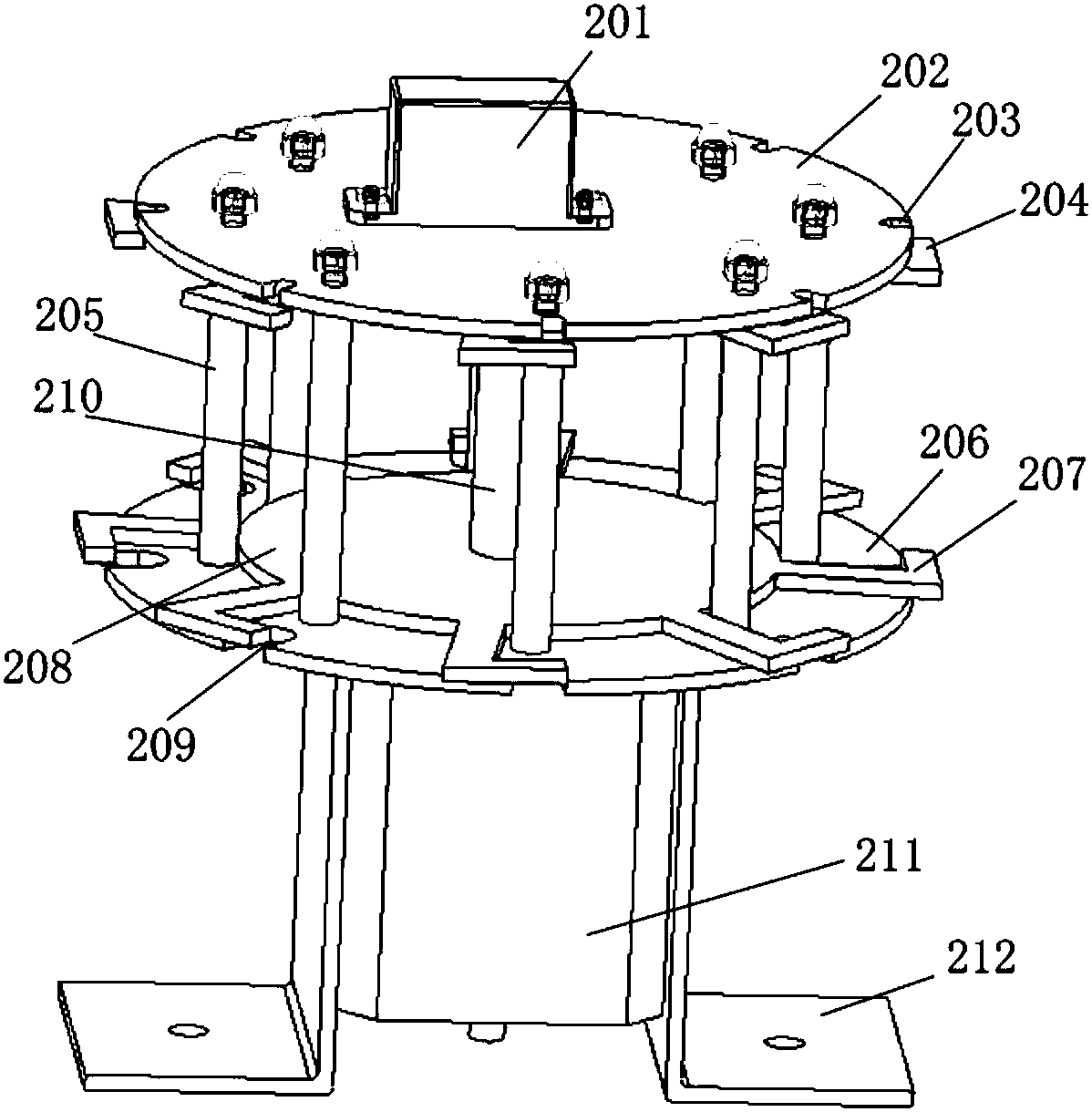

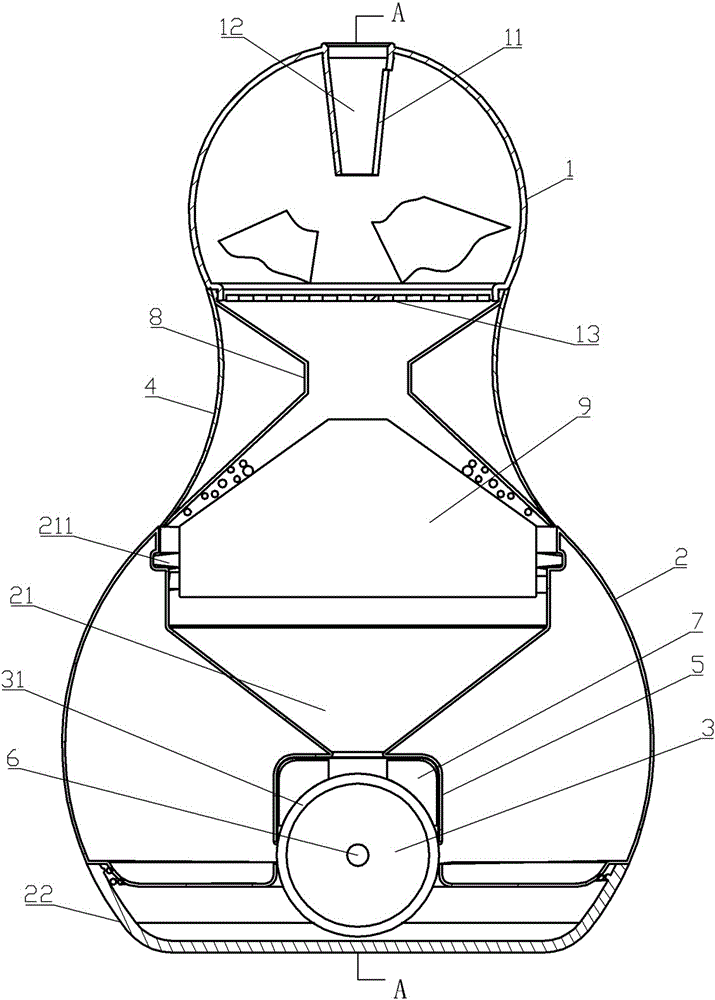

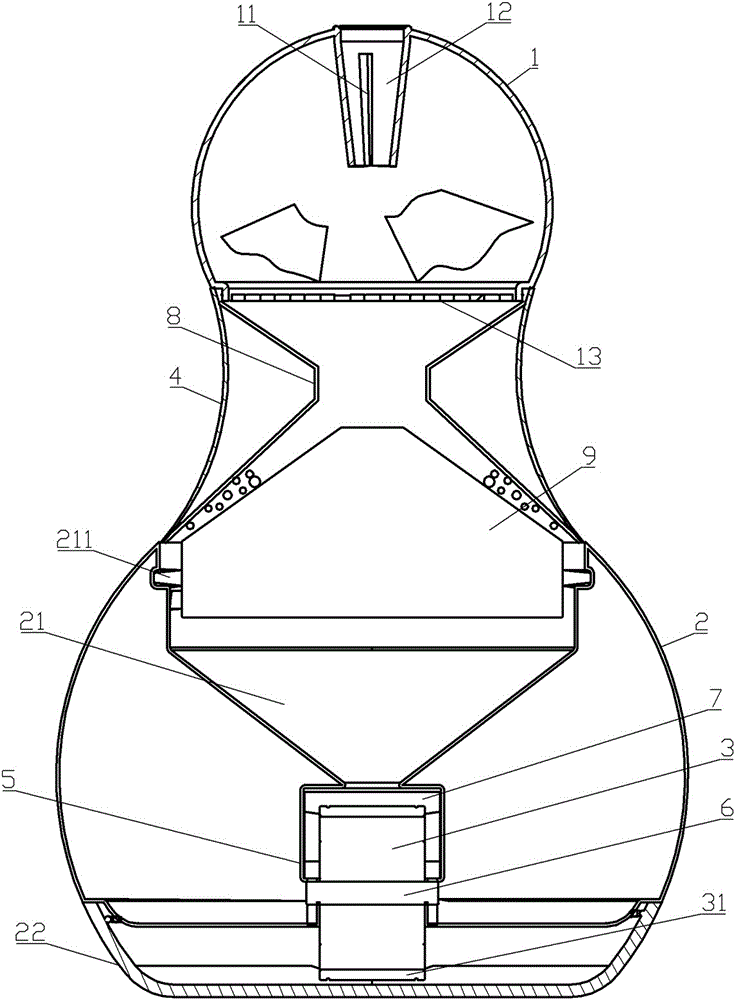

A digital garment printing machine and a method for printing garments

ActiveCN105235362BImprove printing efficiencyRealize the printing functionScreen printersDuplicating/marking methodsScreen printingDigital printing

The invention provides a garment digital printing machine and a method for printing garments, which combine the functions of screen printing and inkjet printing. The screen printing machine, the inkjet printing machine and the workbench mechanism are installed on the main frame; the ready-made garments are printed by the inkjet printing machine in the inkjet printing area; the ready-made garments are printed by the screen printing machine in the screen printing area; screen printing The machine and the inkjet printing machine are arranged front and back on the main frame along the conveying direction of the garments; the moving mechanism is connected to the workbench and can drive the workbench to move, so that the tabletop of the workbench moves to the inkjet printing area and the screen printing area, and the The tabletop of the worktable can move back and forth between the inkjet printing area and the screen printing area; there are two worktables. When the tabletop of one worktable moves to the inkjet printing area, the tabletop of the other worktable moves. to the screen printing area, and when the tabletop of one workstation moves to the screen printing area, the tabletop of the other workstation moves to the inkjet printing area.

Owner:HANGZHOU HONGHUA DIGITAL TECH

High wear-resistant UV release agent coating applied to slipper transfer printing and preparation method thereof

ActiveCN108250940BHigh degree of curingHigh absorption wavelengthPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The invention provides a highly wear-resistant UV release agent coating applied to slipper transfer and a preparation method thereof. The coating comprises the following components in percentage by weight: 2-5% of an initiator body, 5-12% of a promoter, 20-40% of a reactive diluent, 20-40% of urethane acrylate, 10-30%of alkoxylated acrylate and 1-5% of a silane coupling agent. The UV release agentcoating prepared in the invention is high in curing degree and excellent in solubility, the absorption wavelength reaches 390nm, any organic solvent is not released in the curing process and in the prepred product, the needed amount of the cured ultraviolet energy is 50mj / cm<2> only, the curing time only needs 1-3 seconds, and the prepared coating is a high-efficiency, energy-saving and environmental-friendly photocuring release coating and can be widely applied to slipper transfer.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

Device and method for realizing one-time screen printing function through screen attaching and secondary coating

ActiveCN113853065AGuaranteed stabilityMeet needsFinal product manufactureConductive pattern formationScreen printingEngineering

The invention belongs to the technical field of FPC solder resist printing, and particularly relates to a device for realizing a one-time screen printing function through screen attaching and secondary coating. The device is provided with a screen body and a screen tray, and the top surface of the screen tray is provided with a containing groove. The method comprises the steps that the screen body is placed in the containing groove and fixed through a fixing assembly; a layer of photosensitive water film is attached to the surface of the screen body, and then primary local exposure is carried out; and the photosensitive water film subjected to primary local exposure is coated with a layer of photosensitive resist, and then secondary local exposure is carried out. According to the processing method, a layer of photosensitive water film is attached to an existing screen, local exposure is carried out, then photosensitive glue is coated, secondary coating is carried out, and local exposure is carried out, so the one-time screen printing function is achieved, the customer requirement is met, the product efficiency is improved, the one-machine multifunctional printing effect is achieved, meanwhile, the labor cost is reduced by 50%, the material cost is reduced by 50%, and the product productivity is synchronously improved by 50%.

Owner:吉安新宇腾跃电子有限公司

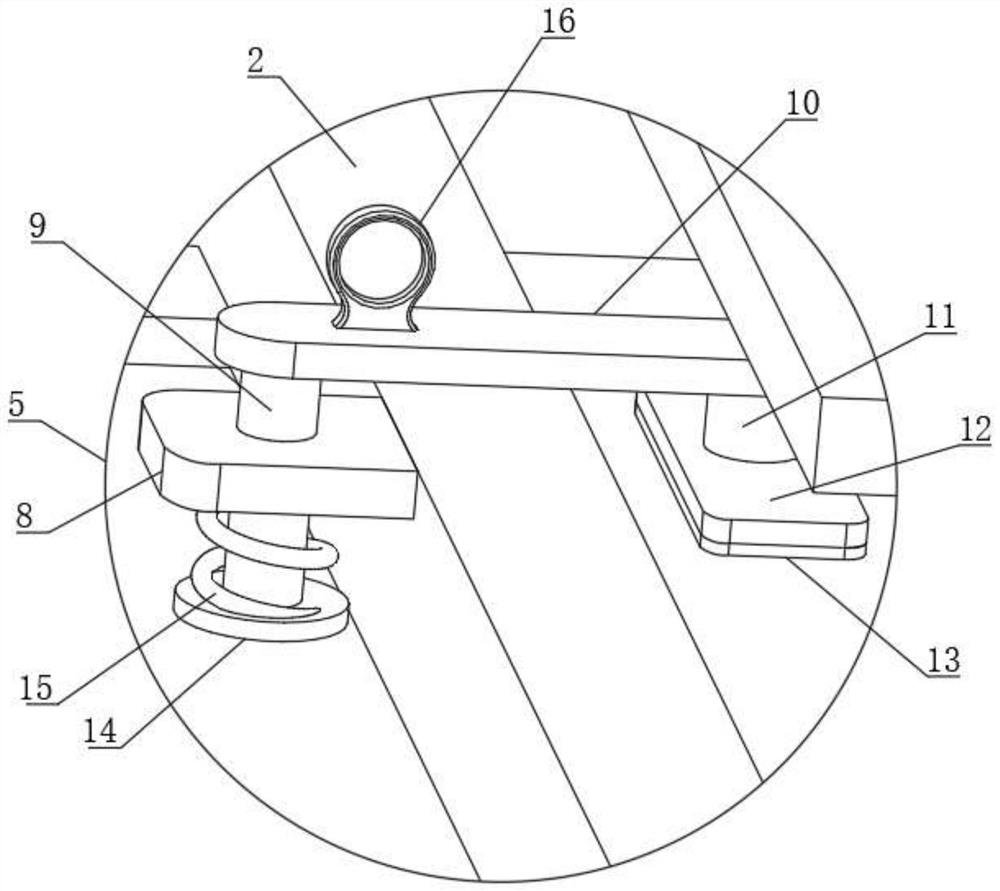

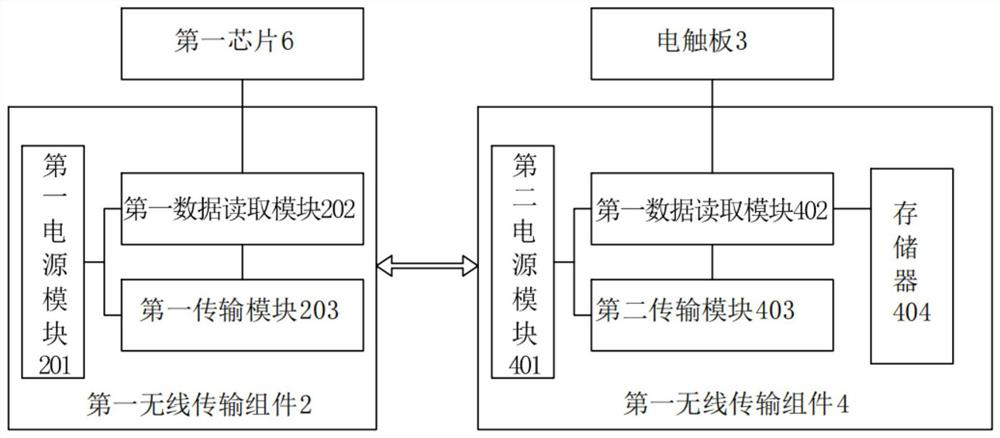

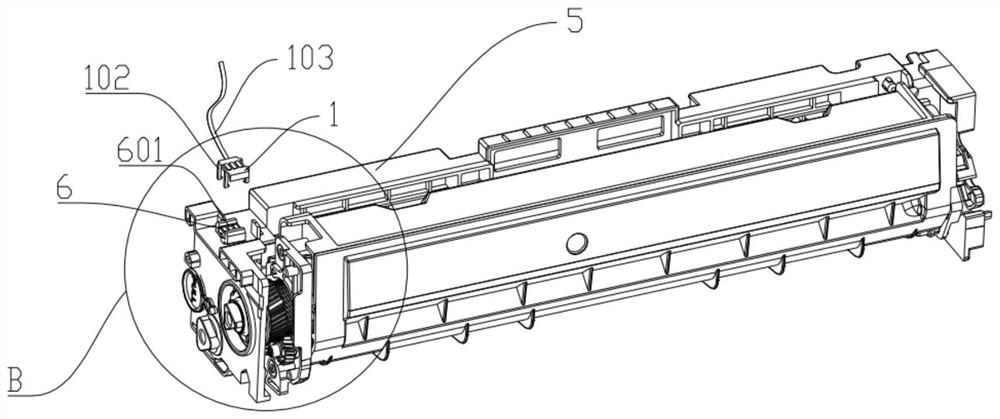

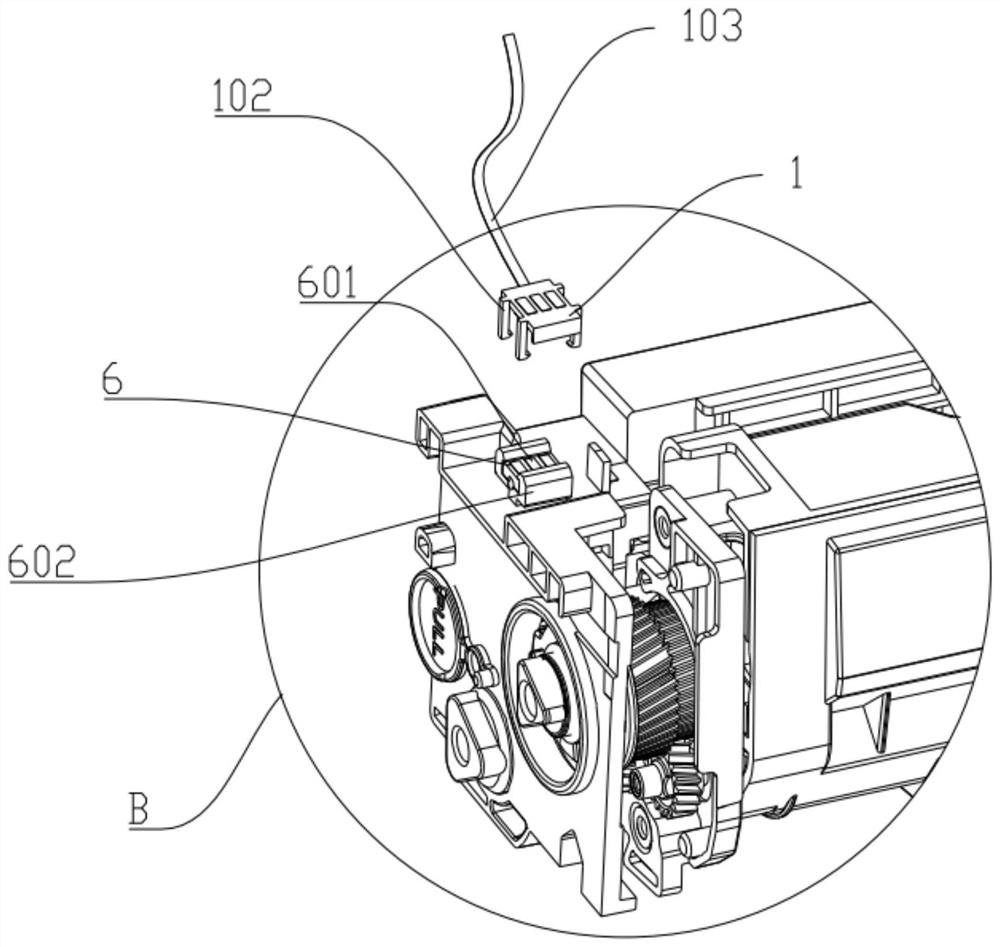

Printing consumable chip multiplexing device, multiplexing method, printing consumable and printing system

PendingCN114750516AAchieve reuseReduce use costPrintingEnergy efficient computingMultiplexingWireless transmission

The invention provides a printing consumable chip multiplexing device and method, a printing consumable and a printing system.The printing consumable chip multiplexing device comprises a chip connector, a first wireless transmission assembly, an electric touch panel and a second wireless transmission assembly. The chip connector comprises an electric connecting piece, and the electric connecting piece is electrically connected with the first wireless transmission assembly; a second electric contact is arranged on the electric contact plate, and the second electric contact is electrically connected with the second wireless transmission assembly; and the first wireless transmission assembly and the second wireless transmission assembly perform data interaction. According to the printing consumable chip multiplexing device provided by the invention, the printing consumable chip is simply and quickly reused in a manner of not disassembling the printing consumable chip, so that the resource waste is reduced, and the use cost is saved; and a wireless transmission mode is adopted, so that the limitation of a data line is eliminated, and the use experience is better.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

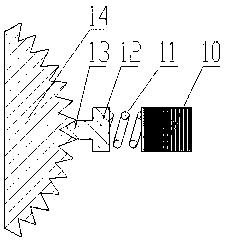

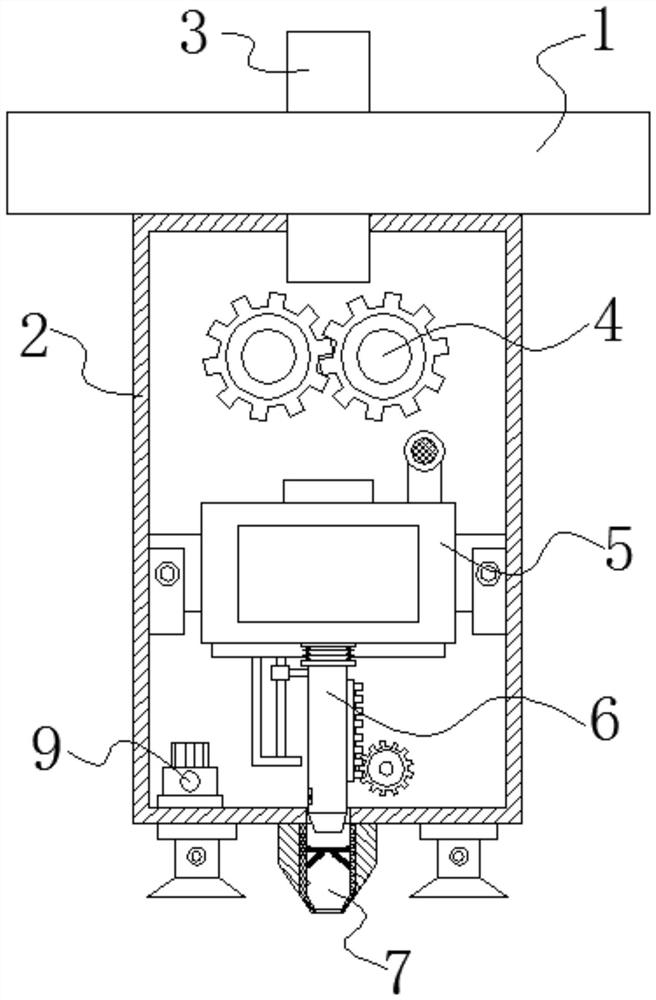

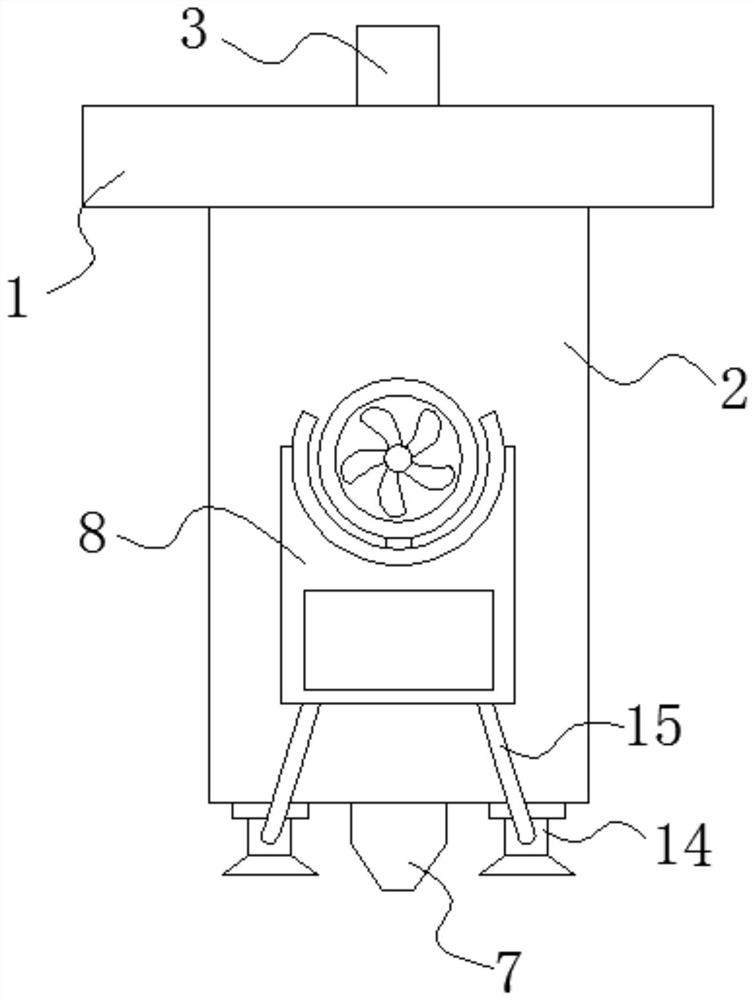

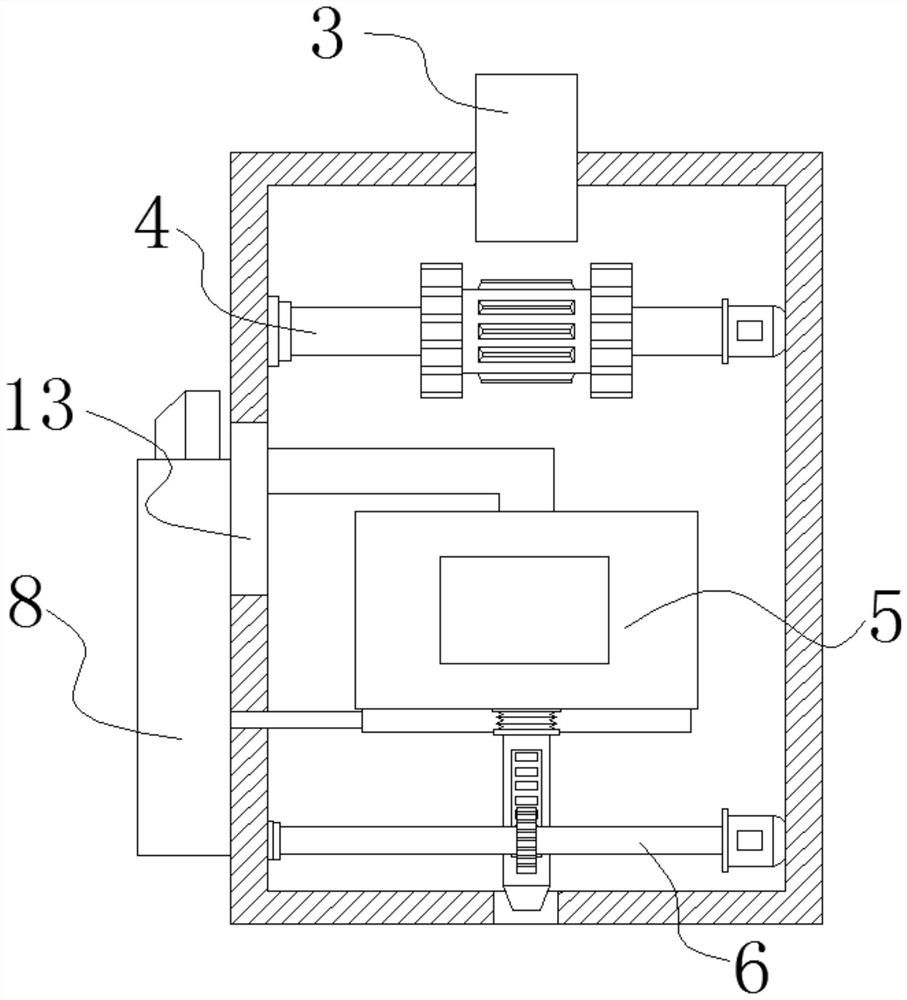

Hot melting nozzle device for alloy type 3D printer

InactiveCN112706404AAvoid cloggingAffect flatness3D object support structuresManufacturing auxillary operationsComputer printingGear wheel

The invention belongs to the technical field of 3D printer application, and particularly relates to a hot melting nozzle device for an alloy type 3D printer. The hot melting nozzle device comprises a first shell, a rod feeding pipe, a pushing assembly, a hot melting assembly, a pressing assembly and a nozzle assembly; the rod feeding pipe is fixedly mounted at the top of the first shell, and one end of the rod feeding pipe penetrates into the first shell; the pushing assembly comprises a first motor, a first rotating rod, a second rotating rod, two sets of transmission gears, two sets of driven gears and a plurality of sets of pushing teeth; and the first motor is fixedly installed on the inner wall of one end of the first shell, one end of the first rotating rod is in transmission connection with the output end of the first motor through a coupler, the second rotating rod is arranged on one side of the first rotating rod in parallel, and the two sets of transmission gears are both fixedly installed on the first rotating rod. According to the hot melting nozzle device, the 3D printing quality can be improved, the pushing smoothness of raw material rods is improved, and the heat dissipation effect is enhanced.

Owner:WUHU AISANDI ELECTRONICS TECH CO LTD

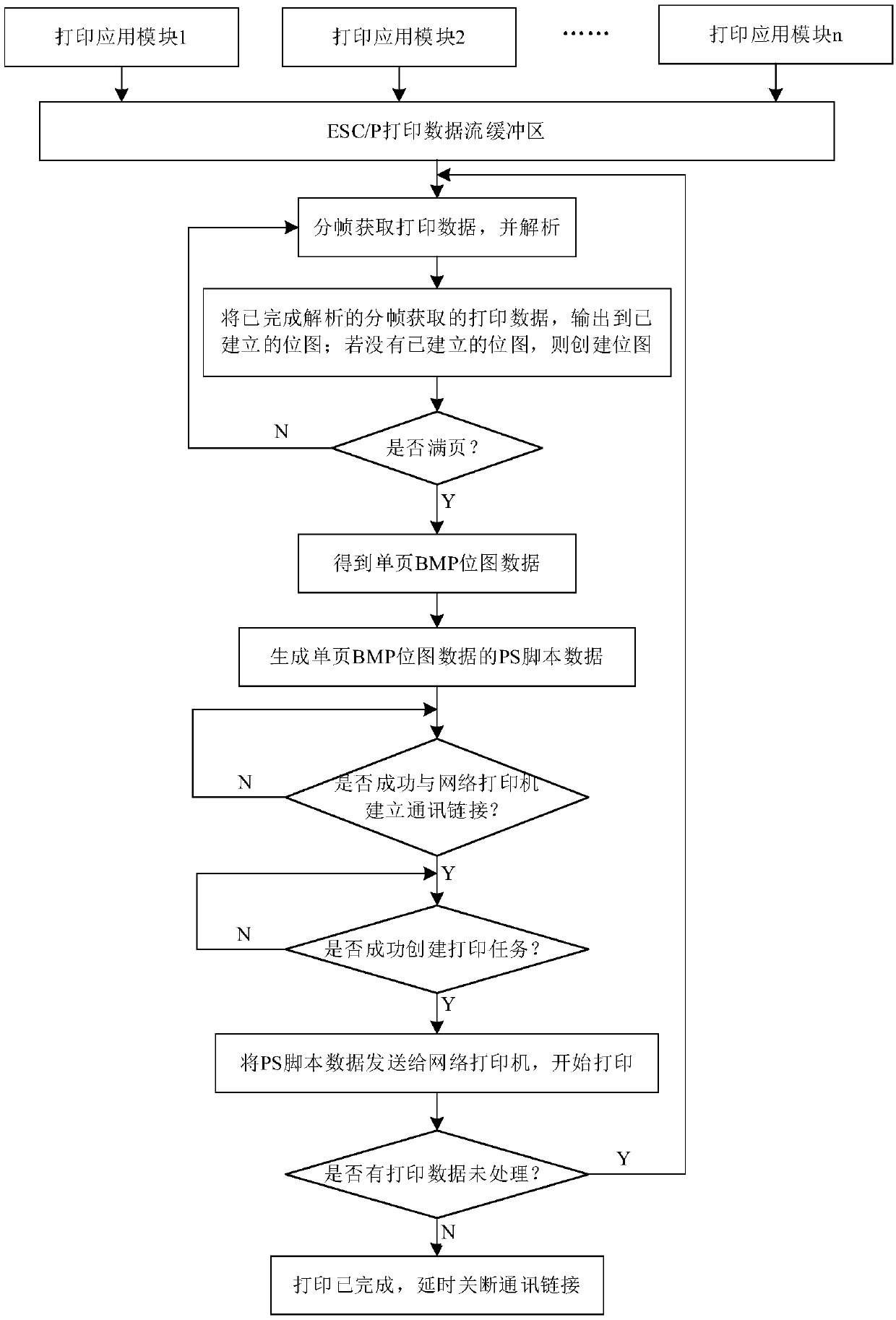

Embedded relay protection device and a network printing method thereof

InactiveCN109656489ARealize the printing functionEasy to operateDigital output to print unitsData streamBitmap

The invention provides an embedded relay protection device and a network printing method thereof, and belongs to the technical field of electric power data digital processing. The network printing method provided by the invention comprises the following steps: (1) analyzing printing data in an ESC / P printing data stream buffer area according to an ESC / P printing data coding format; Generating a BMP bitmap corresponding to the printing data by utilizing a BMP bitmap generation engine according to the typesetting format of the printing data; (2) generating script data corresponding to the BMP bitmap by utilizing a script conversion engine; And (3) sending the script data to a network printer for printing. The embedded relay protection device solves the problem that the existing embedded relay protection device cannot realize a network printing function due to the fact that a related driver of a network printer cannot be installed inside the existing embedded relay protection device.

Owner:XUJI GRP +2

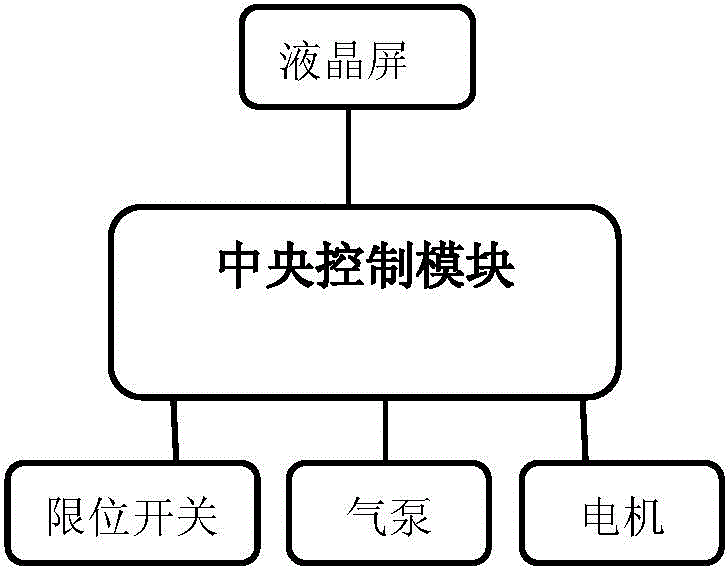

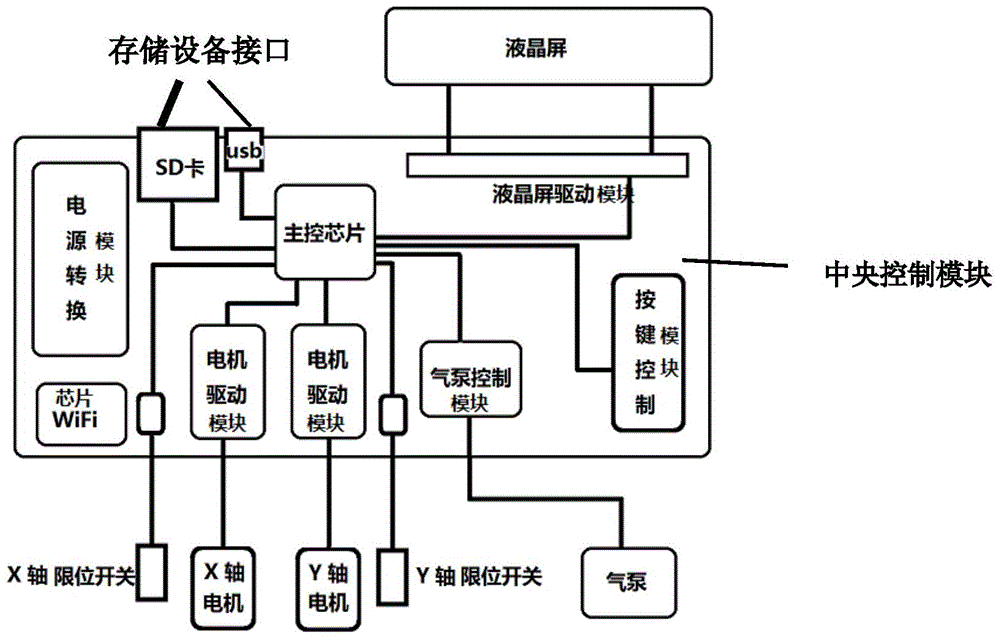

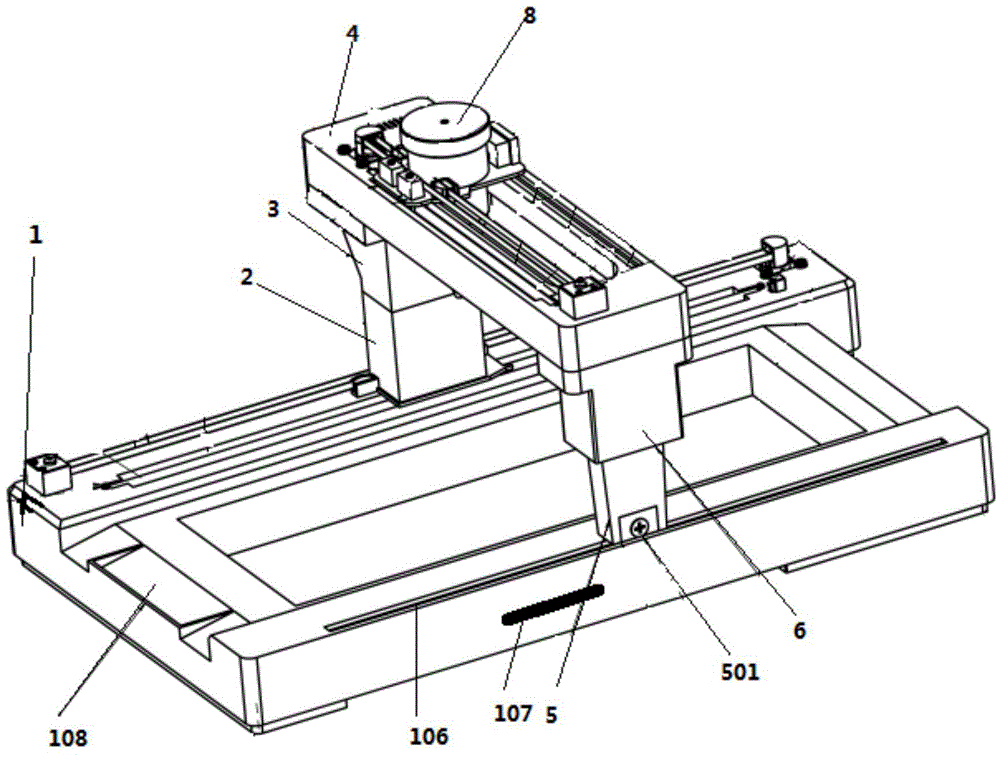

Control device for controlling automatic printing food baking device

ActiveCN104921282ARealize the printing functionControllable outflowFood shapingProgramme control in sequence/logic controllersKey pressingMotor drive

The invention discloses a control device for controlling an automatic printing food baking device. The control device comprises a liquid crystal display, a central control module, a limit switch, an air pump and a motor. A power conversion module, a WIFI chip, a main control chip, a storage device interface, a liquid crystal display driver module, a motor drive module, an air pump control module and a key control module are arranged on the central control module. The control device can be used for controlling the automatic printing food baking device, food is printed and heated at the same time, food making time is saved, and food making efficiency is improved. The air pump control module is used for controlling the air pump in the baking device to pressurize a funnel, the food can be printed through viscid materials such as diluted flour, and meanwhile outflow and the flow of the viscid materials are controlled.

Owner:WANGYUN WUHAN 3D TECH CO LTD

A composite packaging film for aluminized and printed cigarettes and its preparation method

ActiveCN107804039BSolve the problem of reduced heat sealing performanceImprove barrier propertiesSynthetic resin layered productsCoatingsAdhesiveCeramic materials

The invention discloses an aluminized and printed composite packaging film for tobaccos and a preparation method of the aluminized and printed composite packaging film. The composite packaging film comprises a printed packaging film and an aluminized packaging film which are compounded by using an adhesive, and the composite packaging film can be obtained by compounding a printed layer of the printed packaging film with an aluminized layer of the aluminized packaging film. The invention creatively puts forwards the combination of a printed surface of the printed packaging film and an aluminized surface of the aluminized packaging film, so that not only is the problem that the heat sealing performance of the fully-printed surface of an existing printed packaging film is reduced solved, butalso the aluminized and printed composite packaging film has extremely high barrier performance; due to the combination of the printed surface of the printed packaging film and the aluminized surfaceof the aluminized packaging film, not only can double surfaces be subjected to heat sealing, but also a printing function is realized, and the aluminized layer is prevented from being scratched; and the aluminized and printed composite packaging film for tobaccos realizes low-temperature heat sealing on the basis of existing functions, effectively reduces the energy consumption and is environment-friendly.

Owner:YUNNAN KUNLENE FILM IND

A 3D printer with a multi-nozzle automatic switching system

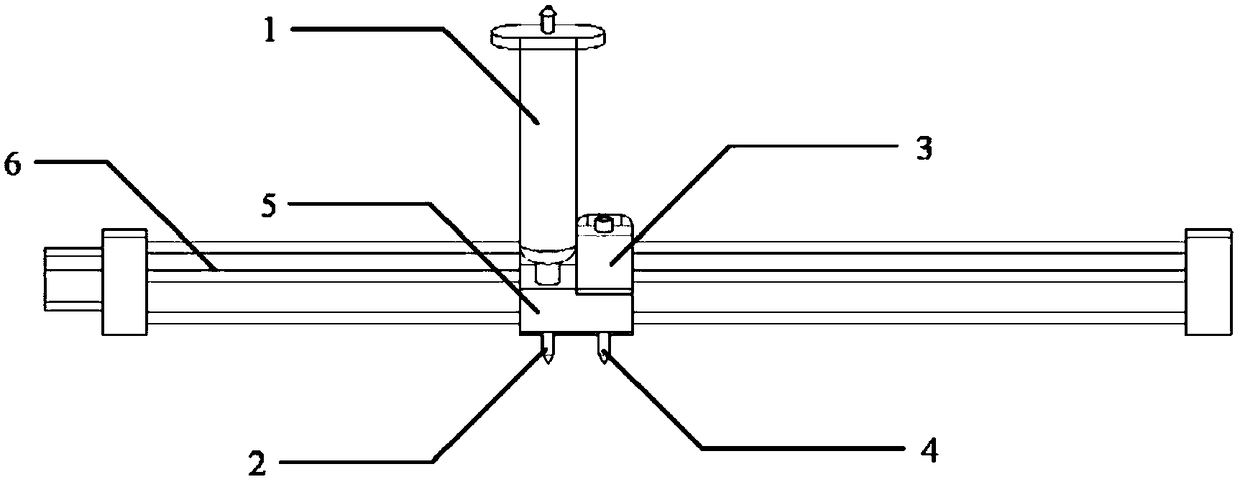

ActiveCN106493944BReduce volumeSimple structureManufacturing platforms/substratesManufacturing driving meansMulti materialSpray nozzle

The invention discloses a 3D printer with a multi-nozzle automatic switching system, which includes a frame, and the multi-nozzle automatic switching system is arranged on the frame. The mobile sprinkler device moving in the Z direction, the manipulator mechanism is arranged between the sprinkler library mechanism and the mobile sprinkler device; the sprinkler library mechanism includes a rotating bracket and several standby sprinklers arranged along the circumference of the rotating bracket, and the mobile sprinkler device includes a moving bracket , the printing nozzle and the clamping mechanism that is arranged on the mobile bracket and clamps and positions the printing nozzle. The manipulator mechanism includes a manipulator for clamping and releasing the printing nozzle and the standby nozzle, and drives the manipulator in the nozzle library mechanism and the mobile nozzle device. Rotary drive unit for position switching. The invention has simple structure and small volume, and can realize multi-nozzle, multi-material and multi-color 3D printing.

Owner:SHANDONG UNIV OF SCI & TECH

multifunctional pencil sharpener

The invention discloses a multifunctional pencil sharpener. The multifunctional pencil sharpener comprises a pencil rotating assembly and a printing assembly. The pencil rotating assembly comprises a pencil sharpener shell and a blade. A pencil rotating groove is formed in the surface of the pencil sharpener shell. The blade is arranged in the pencil rotating groove. The printing assembly comprises a seal shell and an idler wheel type seal mounted in the seal shell. A pattern layer is arranged on the surface of the idler wheel type seal. The seal shell is connected to an opening in the lower end of the pencil sharpener shell through an intermediate connecting body. An inner cavity of the seal shell, an inner cavity of the intermediate connecting body and an inner cavity of the pencil sharpener shell are communicated. A filter screen used for separating wood chips from graphite particles is arranged in the inner cavity of the intermediate connecting body or the inner cavity of the pencil sharpener shell. The multifunctional pencil sharpener has the advantages that when a pencil is sharpened, graphite dust enters the inner cavity of the intermediate shell by penetrating through the filter screen, the wood chips are left in the pencil sharpener shell, the wood chips can be poured out independently by unscrewing the pencil sharpener shell from the intermediate shell, and environment pollution caused by raising of the graphite dust is avoided.

Owner:NANHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com