Highly wear-resistant UV release agent coating applied to slipper transfer and preparation method thereof

A technology of high wear resistance and release agent, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of slow curing, and achieve the effect of high curing degree, high absorption wavelength and fast light curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

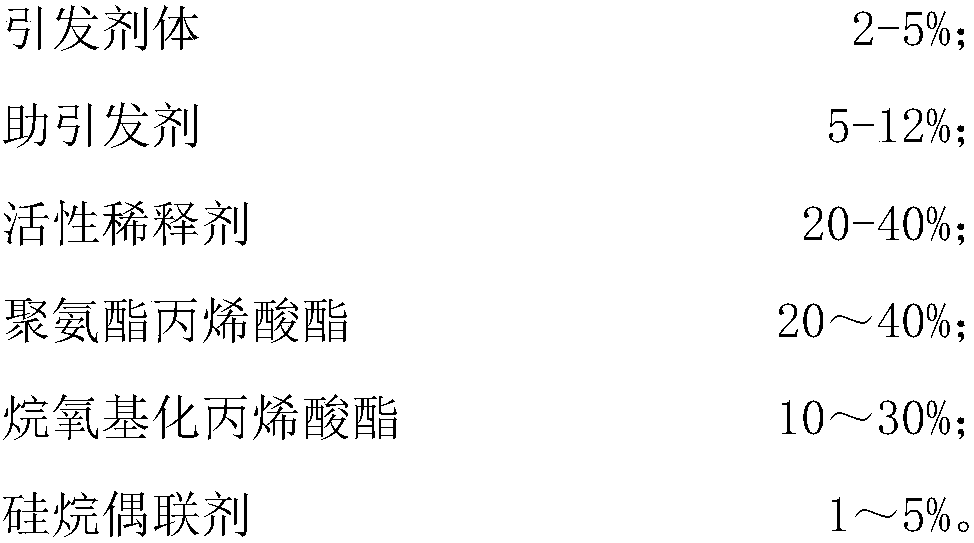

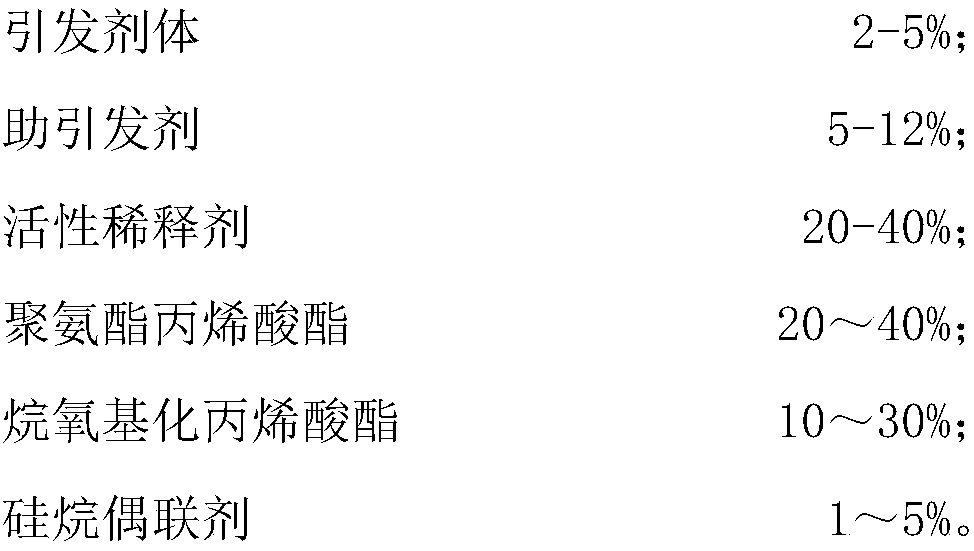

[0028] This embodiment provides a kind of high wear-resistant UV release agent coating applied to slipper transfer printing and its preparation method. The components and weights of the high wear-resistant UV release agent coating applied to slipper transfer printing are shown in the table 1.

[0029] The preparation method is specifically:

[0030] (1) Add urethane acrylate and alkoxylated acrylate into the reactive diluent, stir evenly until completely dissolved;

[0031] (2) Add initiator body, co-initiator and silane coupling agent to the mixture prepared in step A1, and stir evenly at high speed;

[0032] (3) cooling, measuring viscosity and solid content, filtering and packaging to obtain UV release agent coating.

[0033] (4) Apply the coating on the OPP / CPP film, the coating amount is 1.5g / m 2 , at UV energy 200mj / cm 2 Under the condition of aerobic curing for 1-3s, after curing, use an infrared tester to confirm that the curing effect is very good (the curing degr...

Embodiment 2

[0037] This embodiment provides a kind of high wear-resistant UV release agent coating applied to slipper transfer printing and its preparation method. The components and weights of the high wear-resistant UV release agent coating applied to slipper transfer printing are shown in the table 2.

[0038] The preparation method is the same as in Example 1. The paint is coated on the OPP / CPP film, the coating amount is 1.5g / m 2 , at UV energy 200mj / cm 2 Under the condition of aerobic curing for 1-3s, after curing, use an infrared tester to confirm that the curing effect is very good (the curing degree reaches 93%), the flexibility test uses TMI to test the release force of 0.047, the pencil hardness reaches 2H, and the gravure ink is printed yellow The fastness of , red, and orange is very good, and it is transferred to slippers to test the flexibility (almost no cracks after bending 360°) and wear resistance (almost no scratches after artificial wear for more than 40 days).

[...

Embodiment 3

[0042] This embodiment provides a kind of high wear-resistant UV release agent coating applied to slipper transfer printing and its preparation method. The components and weights of the high wear-resistant UV release agent coating applied to slipper transfer printing are shown in the table 3.

[0043] The preparation method is the same as in Example 1. The paint is coated on the OPP / CPP film, the coating amount is 1.5g / m 2 , at UV energy 200mj / cm 2Under the condition of aerobic curing for 1-3s, after curing, use an infrared tester to confirm that the curing effect is very good (curing degree reaches 88%), the flexibility test uses TMI to test the release force of 0.036, the pencil hardness reaches 2H, and the gravure ink is printed yellow , red, and orange have very good fastness, and they are transferred to slippers to test their flexibility (almost no cracks when bent 360°) and wear resistance (almost no scratches after artificial wear for more than 40 days).

[0044] tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com