Control device for controlling automatic printing food baking device

A control device, automatic printing technology, applied in sequence/logic controller program control, food forming, electrical program control and other directions, can solve the problem of long time, high graphics and color limitations, and inability to print patterns on coffee. Problems such as milk foam or beer foam can save time and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

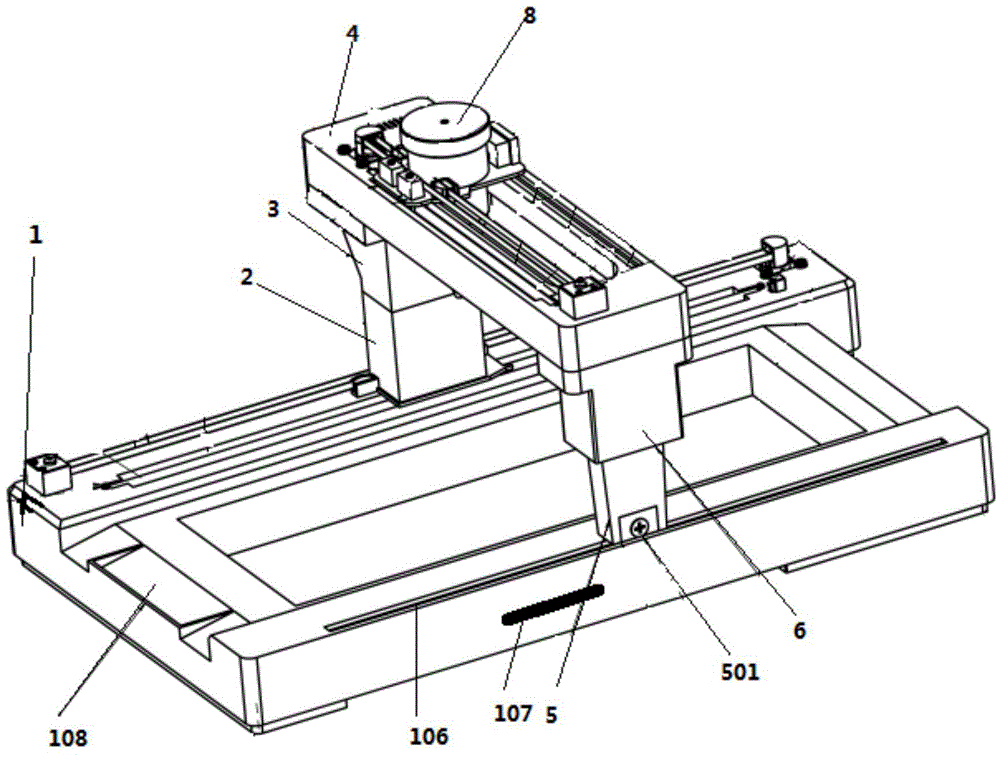

[0033] The embodiments of the present invention are described in detail below. The embodiments described below with reference to the drawings are exemplary, and are only used to explain the present invention, but should not be understood as limiting the present invention.

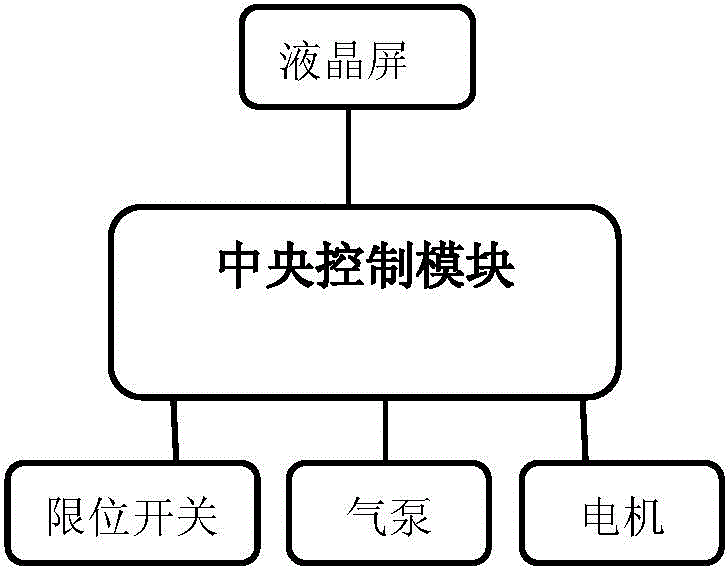

[0034] The invention provides a control device for controlling an automatic printing food frying and roasting device, such as figure 1 Shown:

[0035] Including LCD screen, central control module, limit switch, air pump and motor,

[0036] The LCD screen, limit switch, air pump and motor are independently connected to the central control device through signal lines;

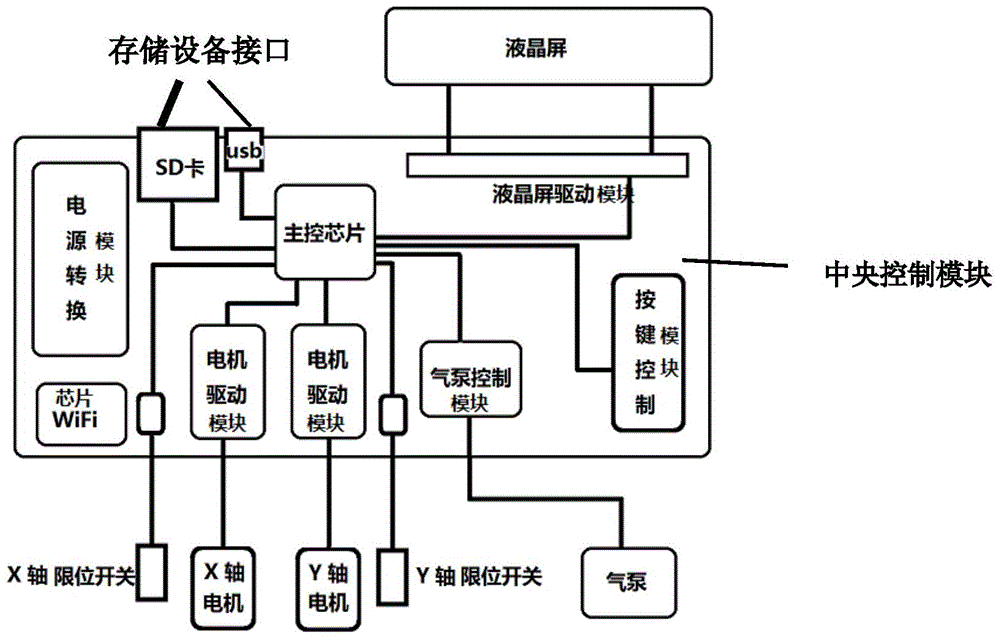

[0037] The central control device is provided with a power conversion module, a WIFI chip and a main control chip, a storage device interface, an LCD screen drive module, a motor drive module, an air pump control module and a button control module;

[0038] The main control chip is respectively connected with a storage device interface, a liquid crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com