Patents

Literature

93results about How to "Outflow control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

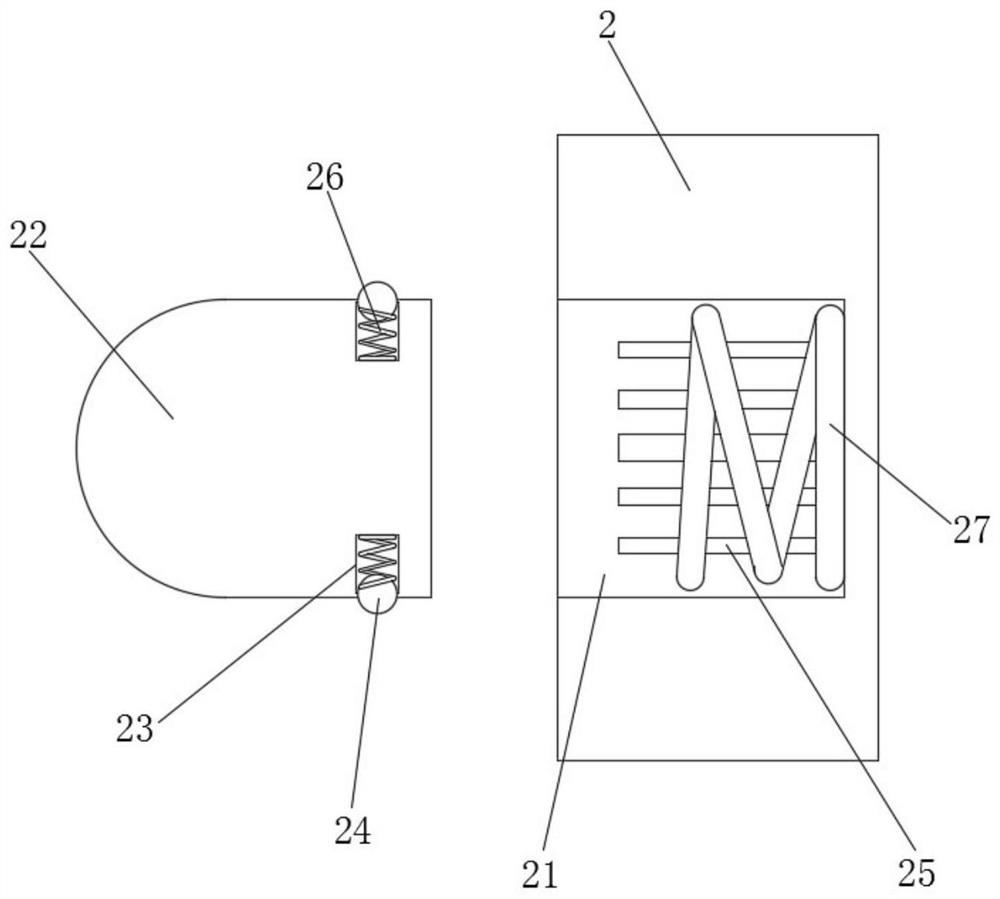

Urine drainage device, drainage control device, drainage control system and urination method

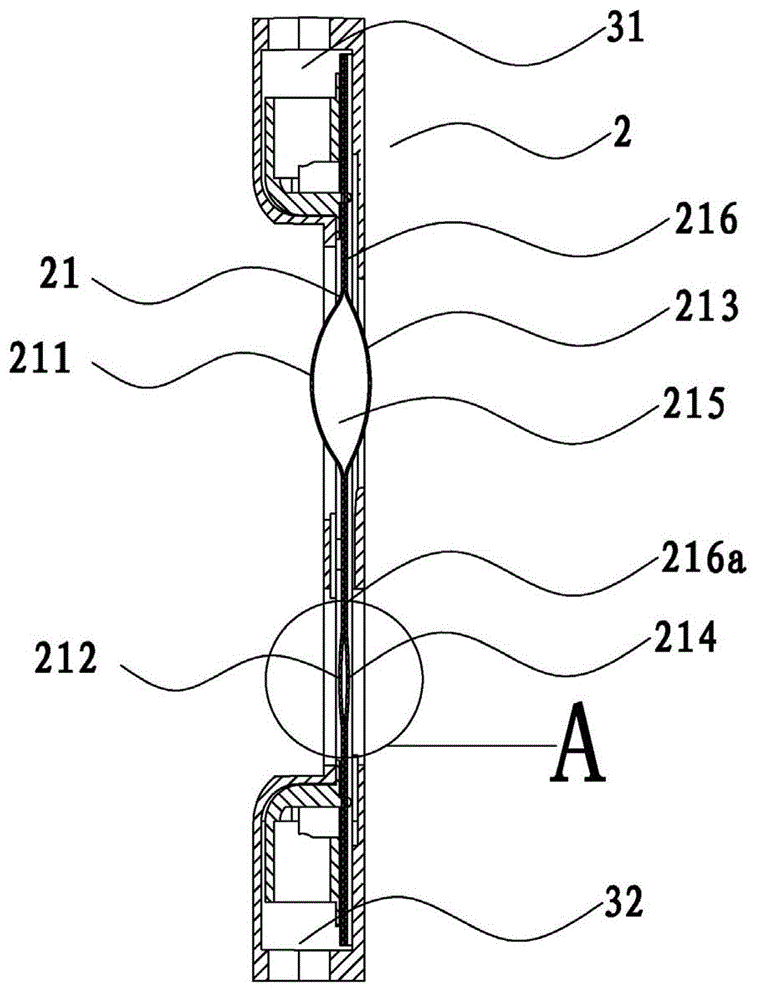

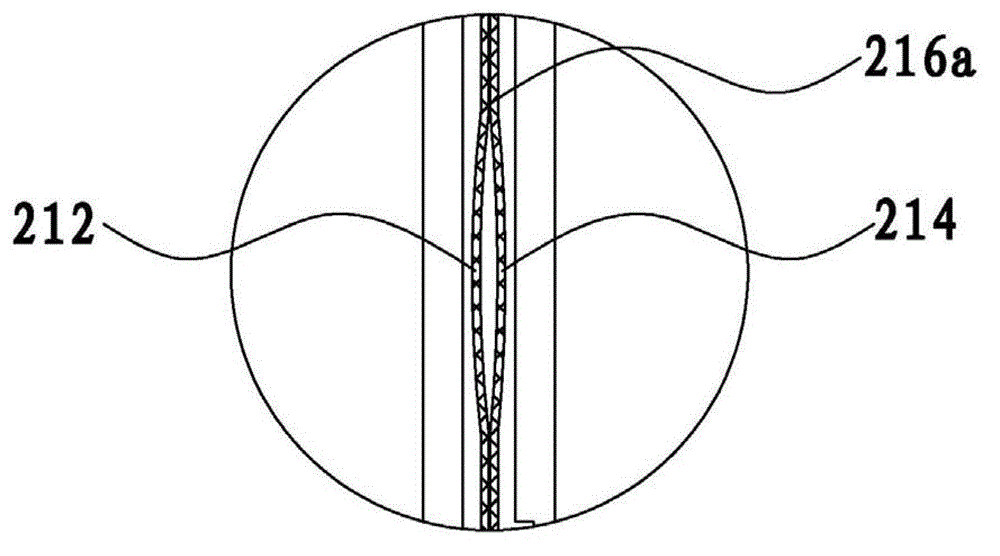

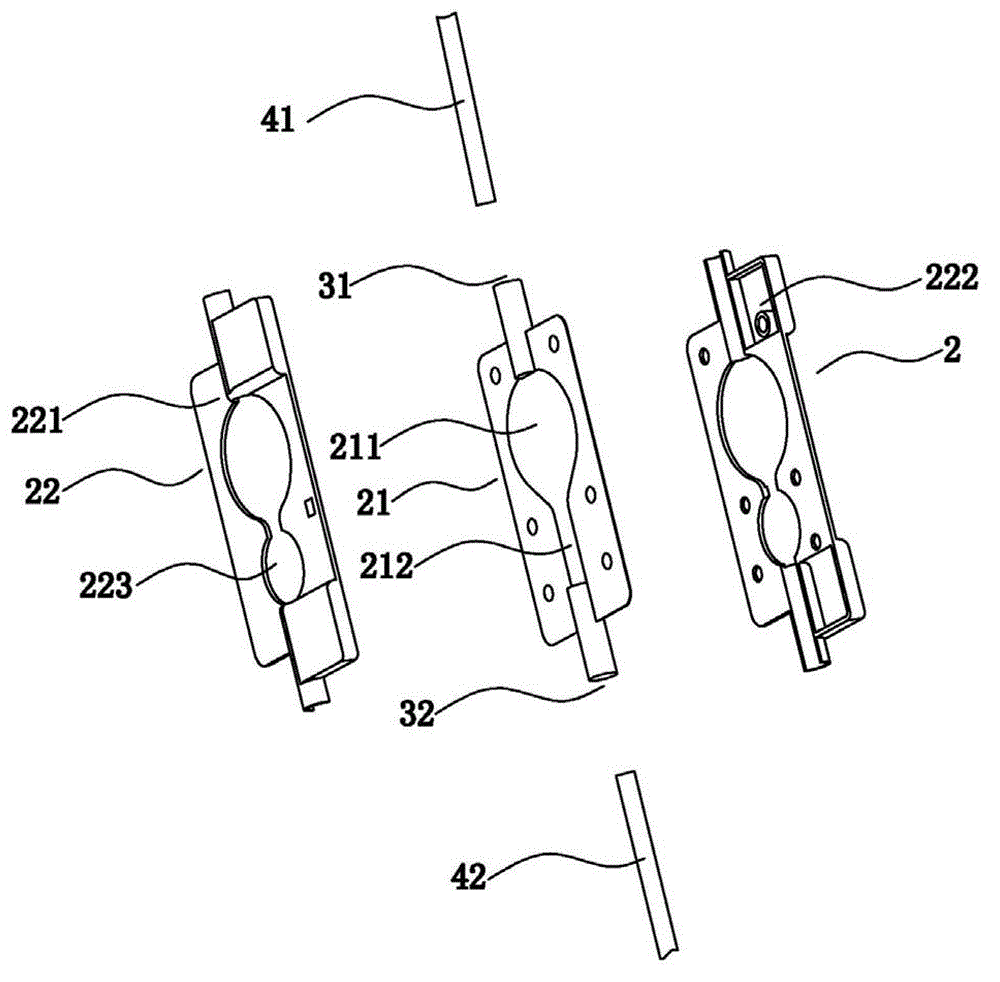

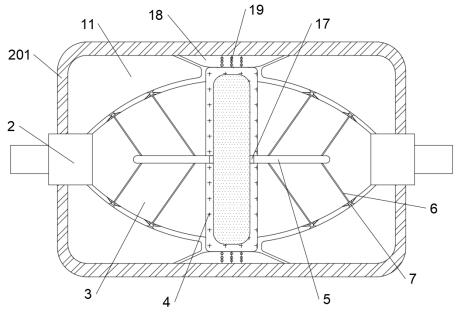

The invention discloses a urine drainage device, a drainage control device, a drainage control system and a urination method. The urine drainage device comprises a urine inlet, a urine outlet and a bladder bionics unit, wherein the bladder bionic unit comprises a main part forming a liquid storage cavity, a first pressure transmission surface and a second pressure transmission surface, wherein the liquid storage cavity is communicated with the urine inlet and the urine outlet via a connecting pipeline, and the first pressure transmission surface and the second pressure transmission surface deform along with the change of the pressure of urine in the liquid storage cavity; a connecting lower pipeline is provided with a first action region and a second action region which are affected by external forces; when the first action region and the second action region are synchronously affected by the external forces, the liquid storage cavity and the urine outlet are blocked; and the liquid storage cavity is communicated with the urine outlet when any one external force on the action regions is eliminated. The change of the pressure of the urine in the liquid storage cavity of the urine drainage device can be represented through the deformation of the pressure transmission surfaces, and further whether the urine is drained or not is determined according to the deformation capacity of the pressure transmission surfaces, so that the function assisting a patient to drain the urine is achieved, and the structure is simple and scale production is applicable.

Owner:BEIJING WANSHENG RENHE TECH

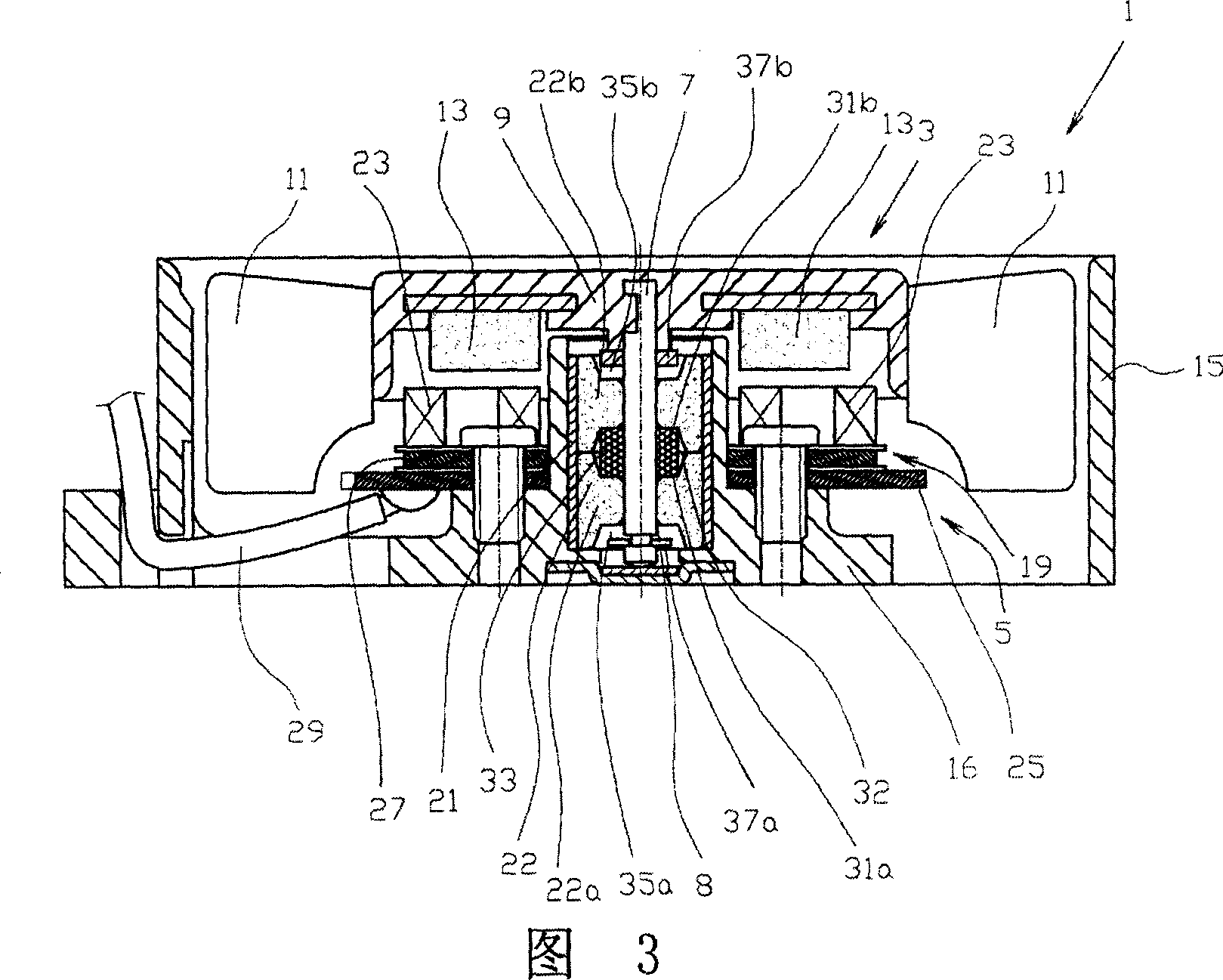

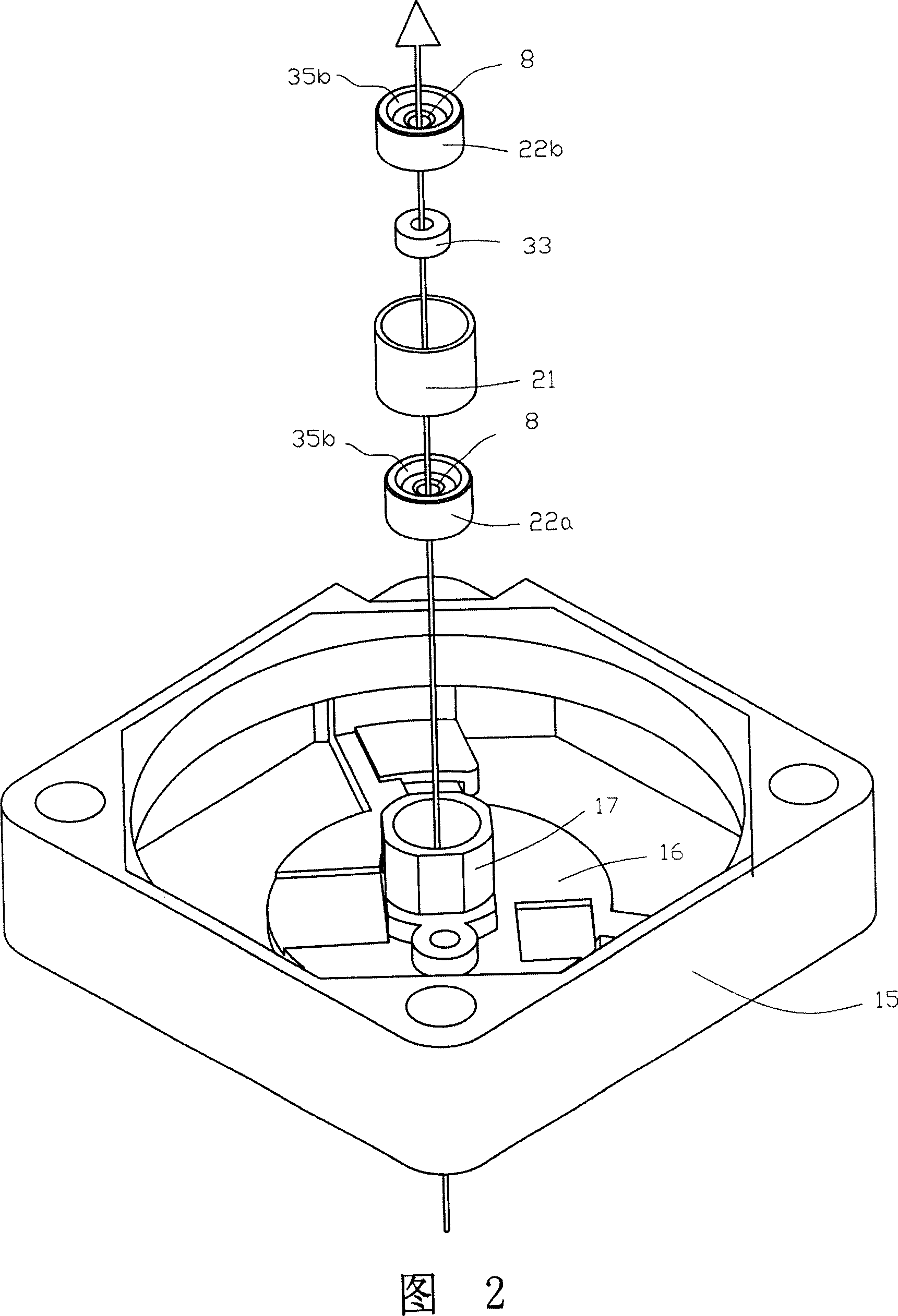

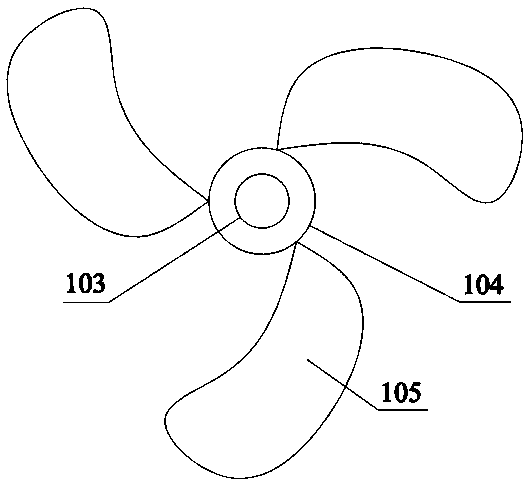

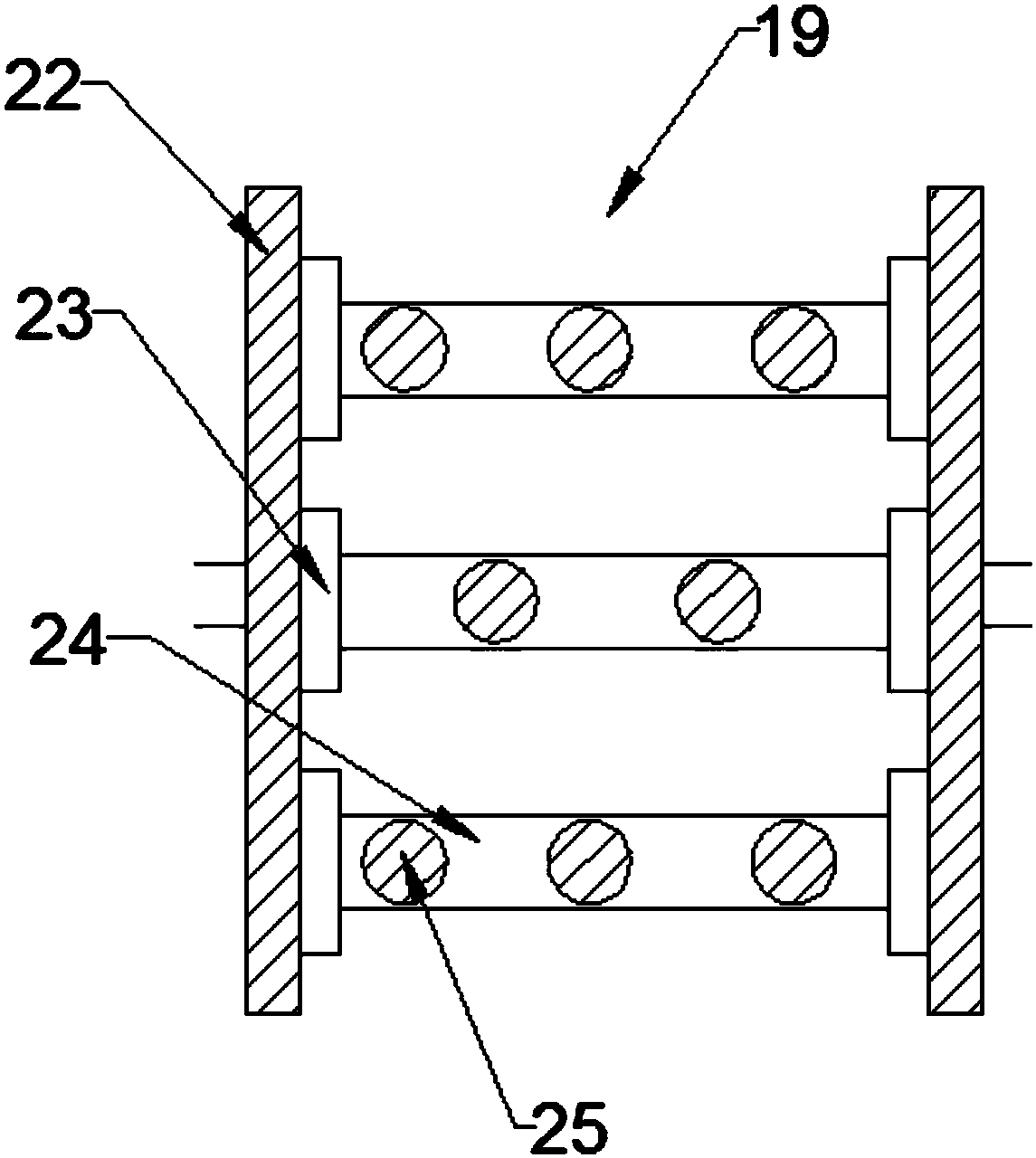

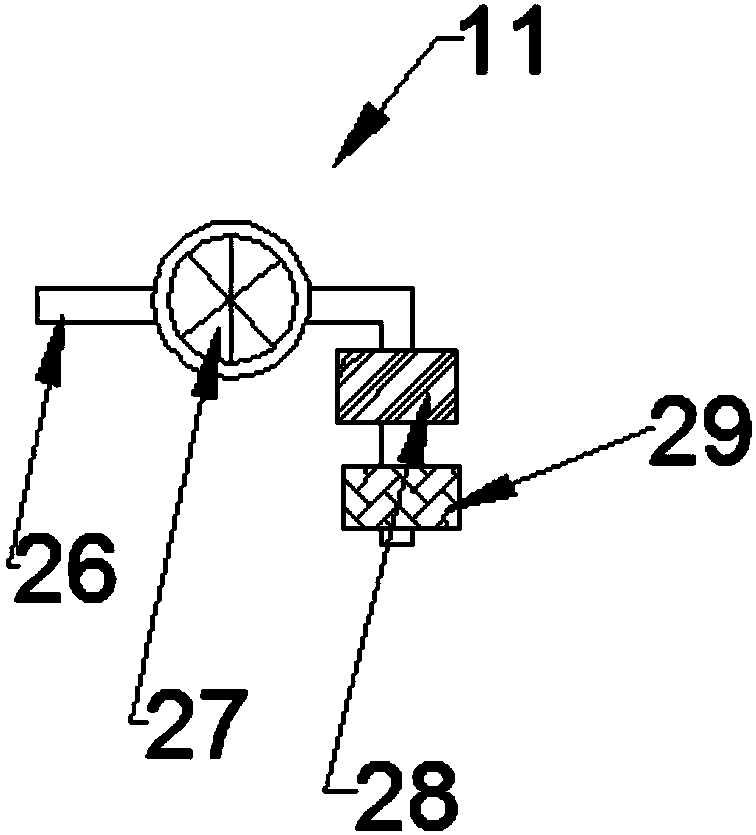

Oil container for bearing component of motor

InactiveCN1940321AEasy to processEasy to manufacturePump componentsBearing componentsElectricityEngineering

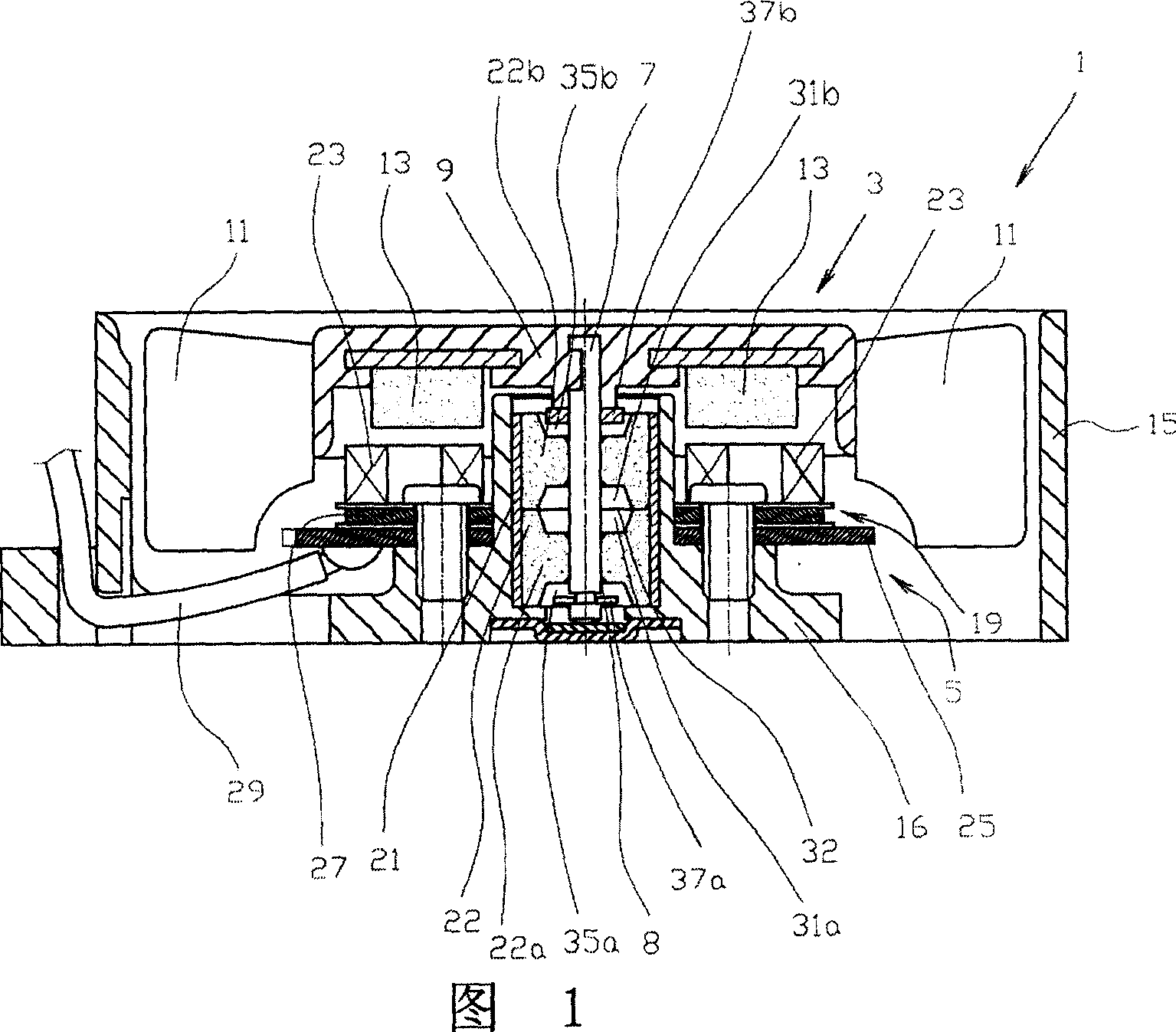

The invention comprises a rotor and a stator for making up a motor. The rotor includes a rotary axle sleeve of a holding axle, several blades disposed on the periphery of the rotary axle sleeve and a magnet on the back of the axle sleeve. The stator includes a housing, a round bearing-holding part in the housing, a small electric machine and a base station for holding the small electric machine. An oil-impregnated bearing set in the round bearing-holding part is divided into upper and lower bearing parts. In the upper and lower bearing parts are disposed plugholes of a rotating axle and on the sandwich surface of the upper and lower bearing parts form dents separately. The dents of the upper and lower bearing parts are closed to form an oil-storage part.

Owner:SHANGHAI SHICOH ELECTRONICS CO LTD

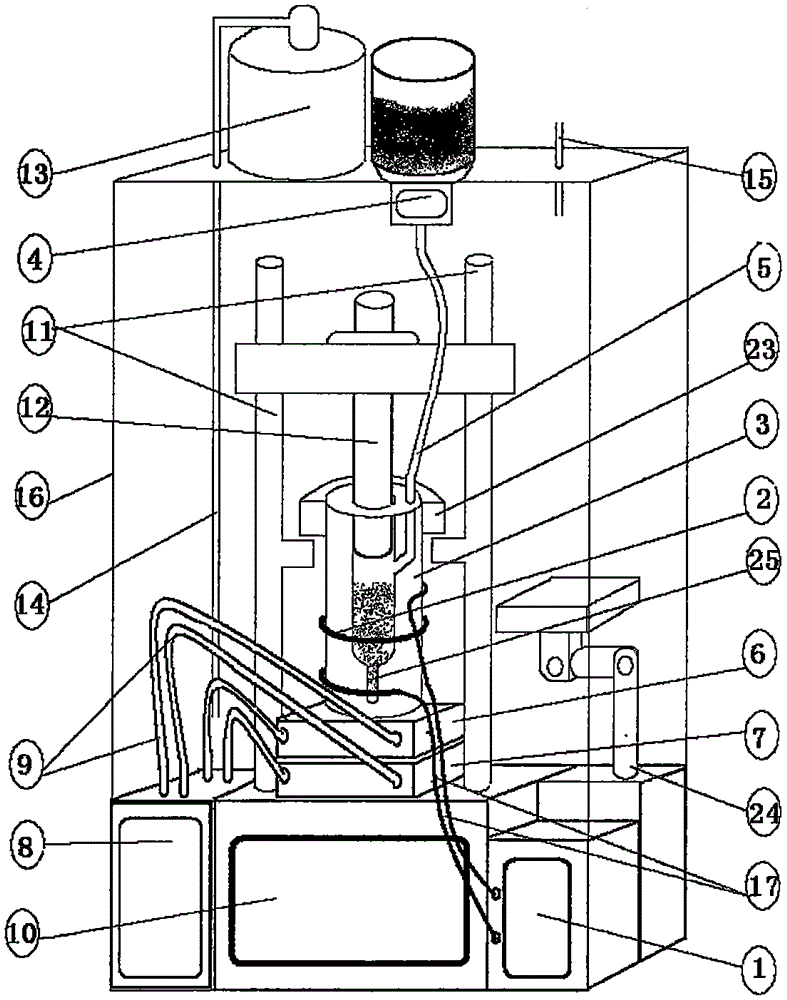

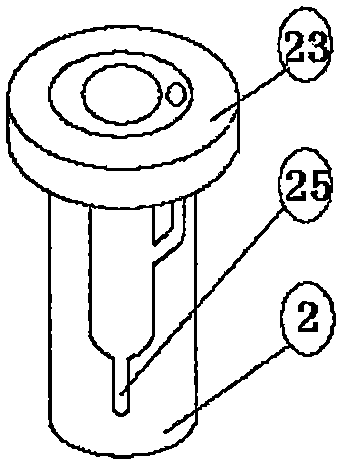

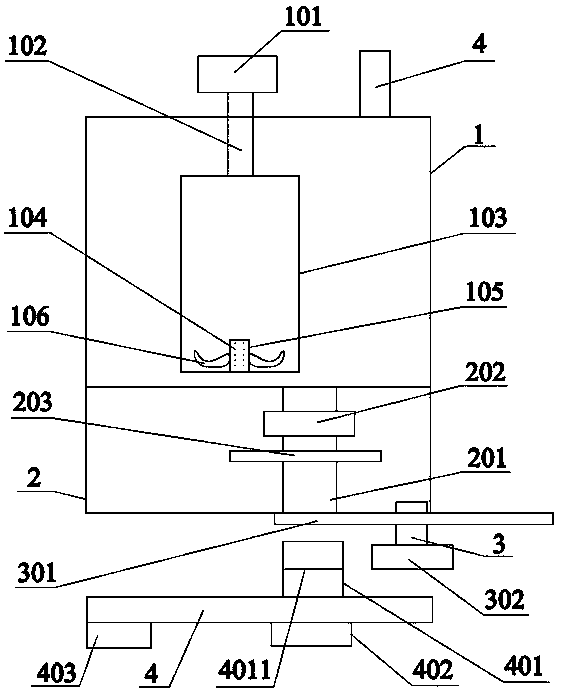

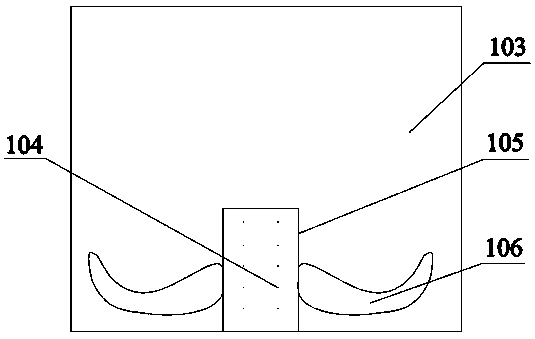

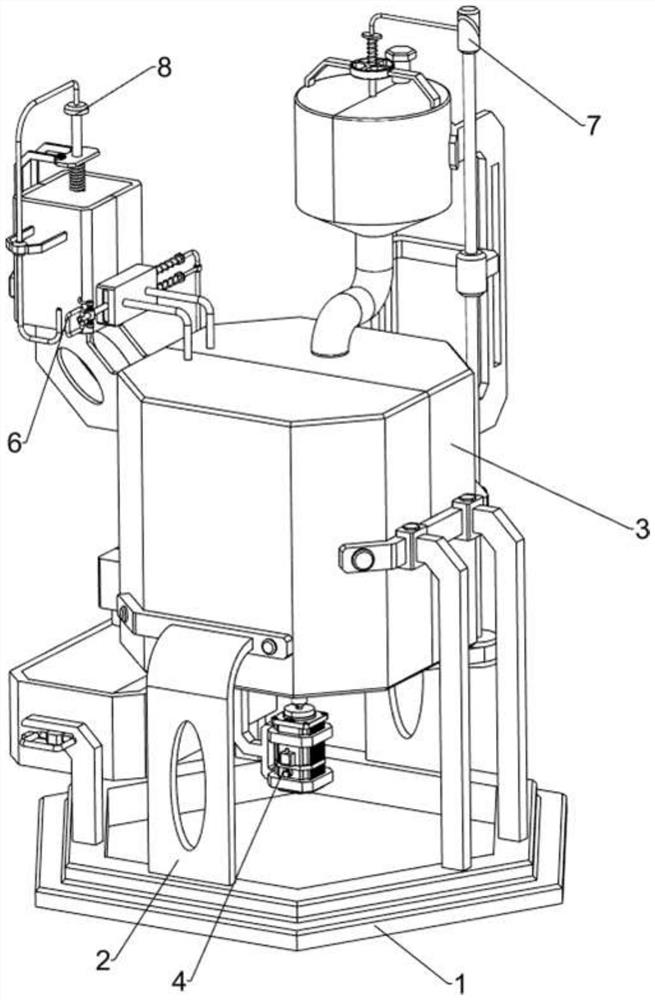

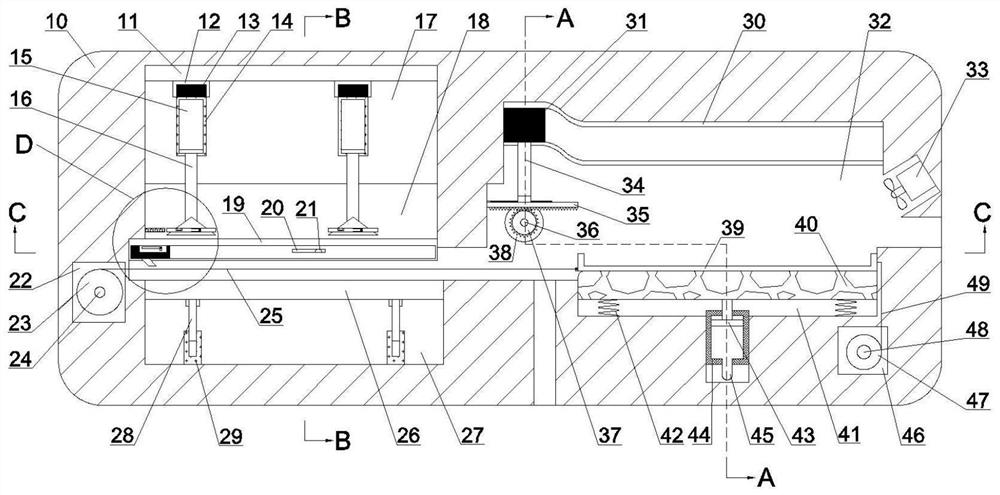

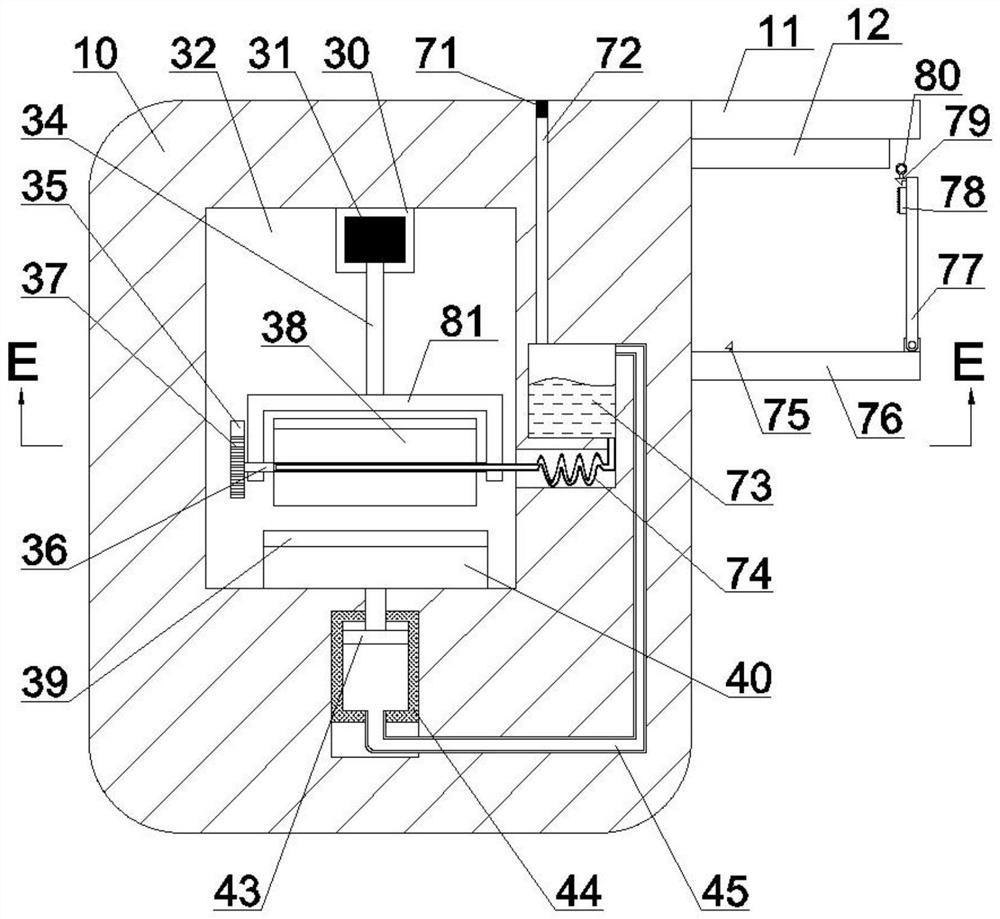

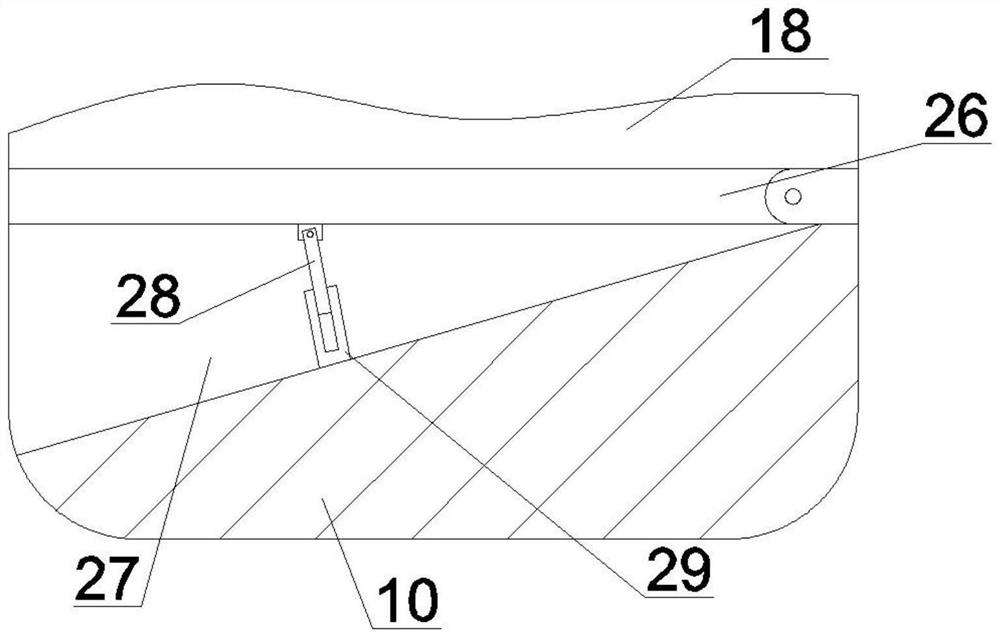

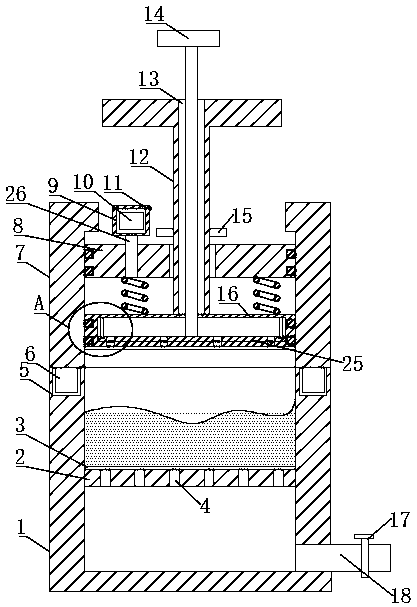

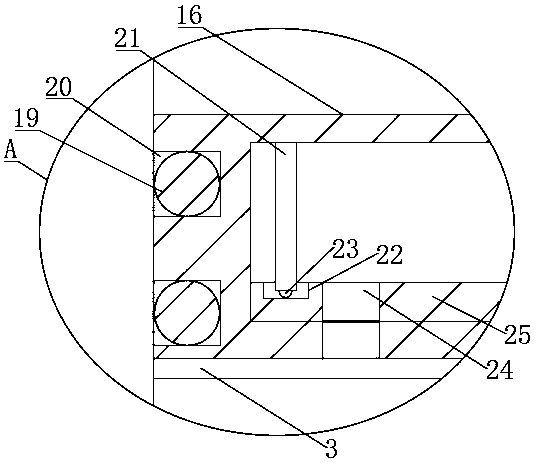

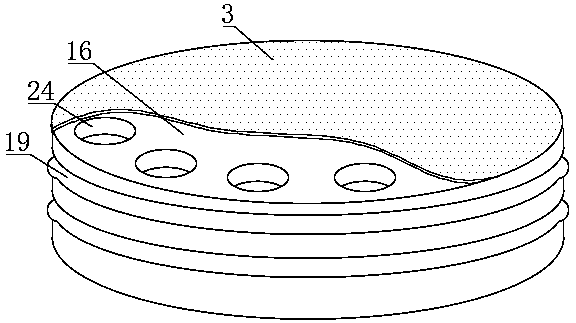

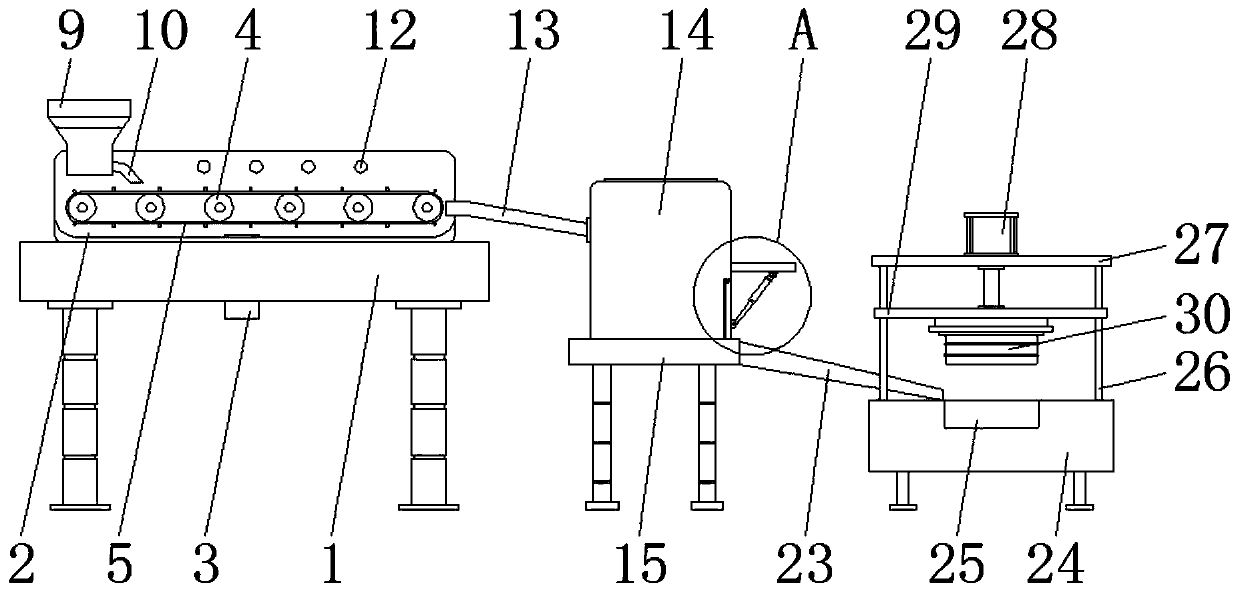

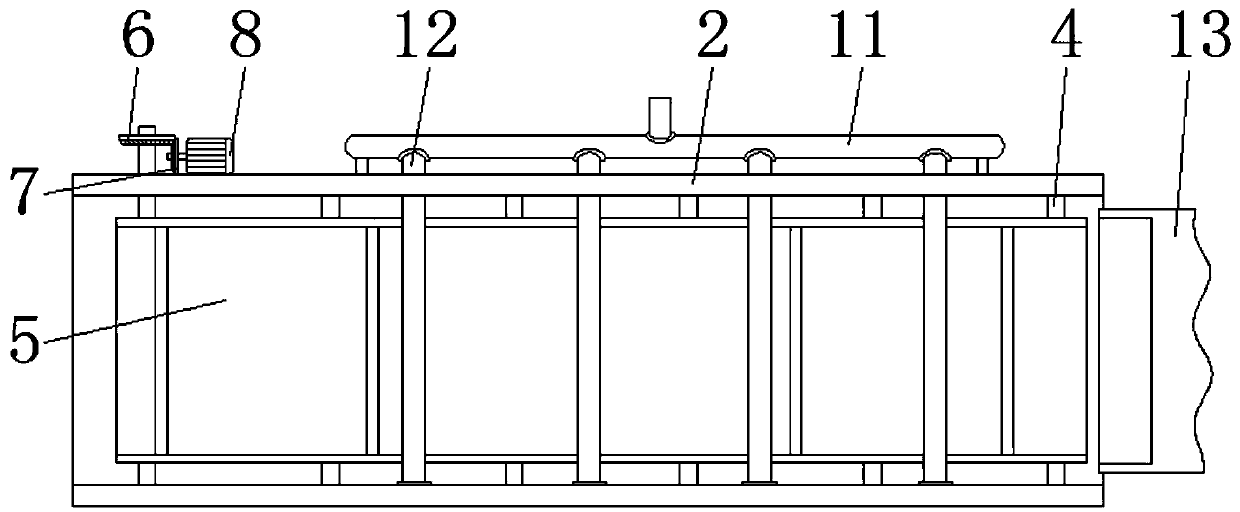

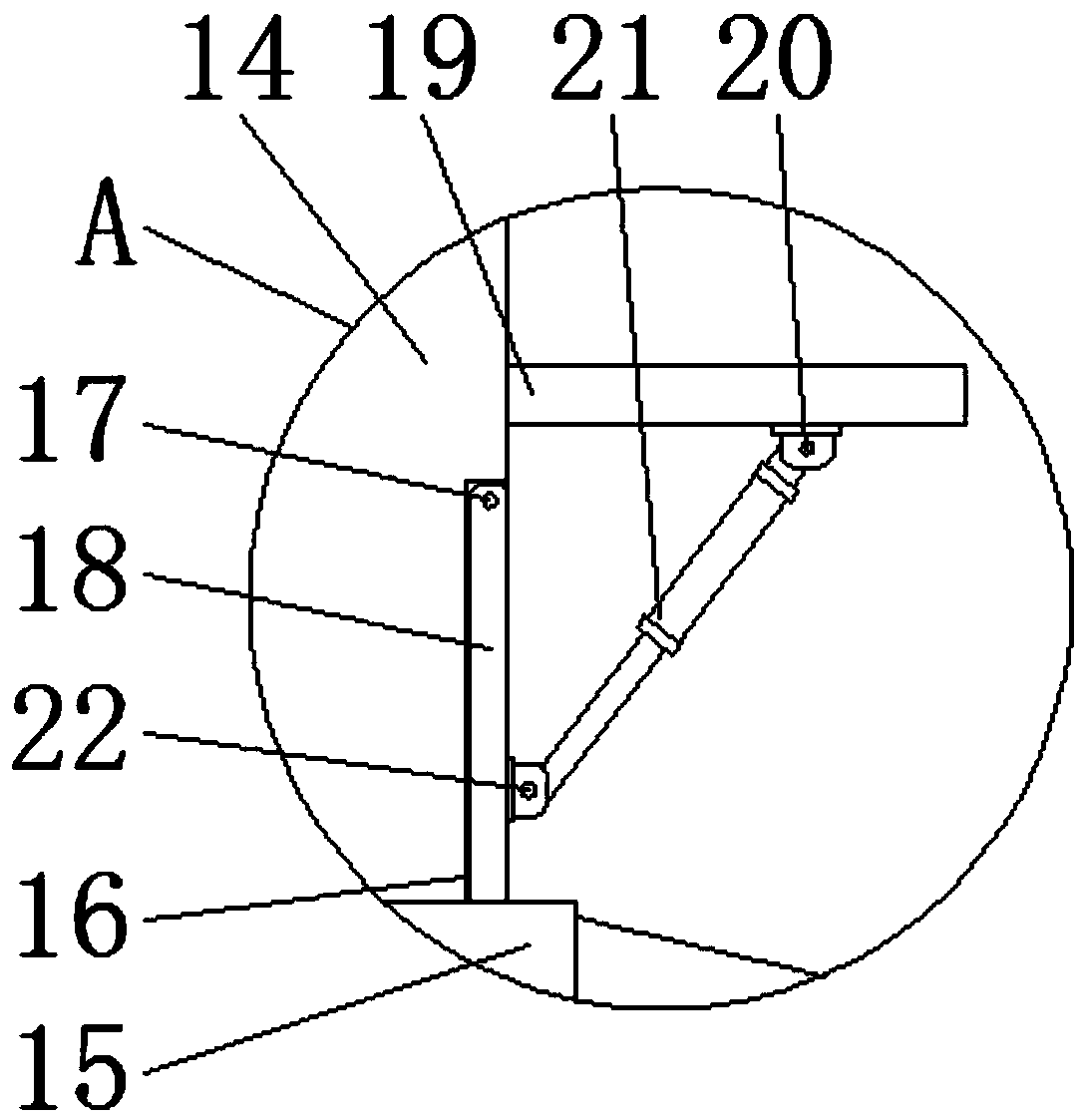

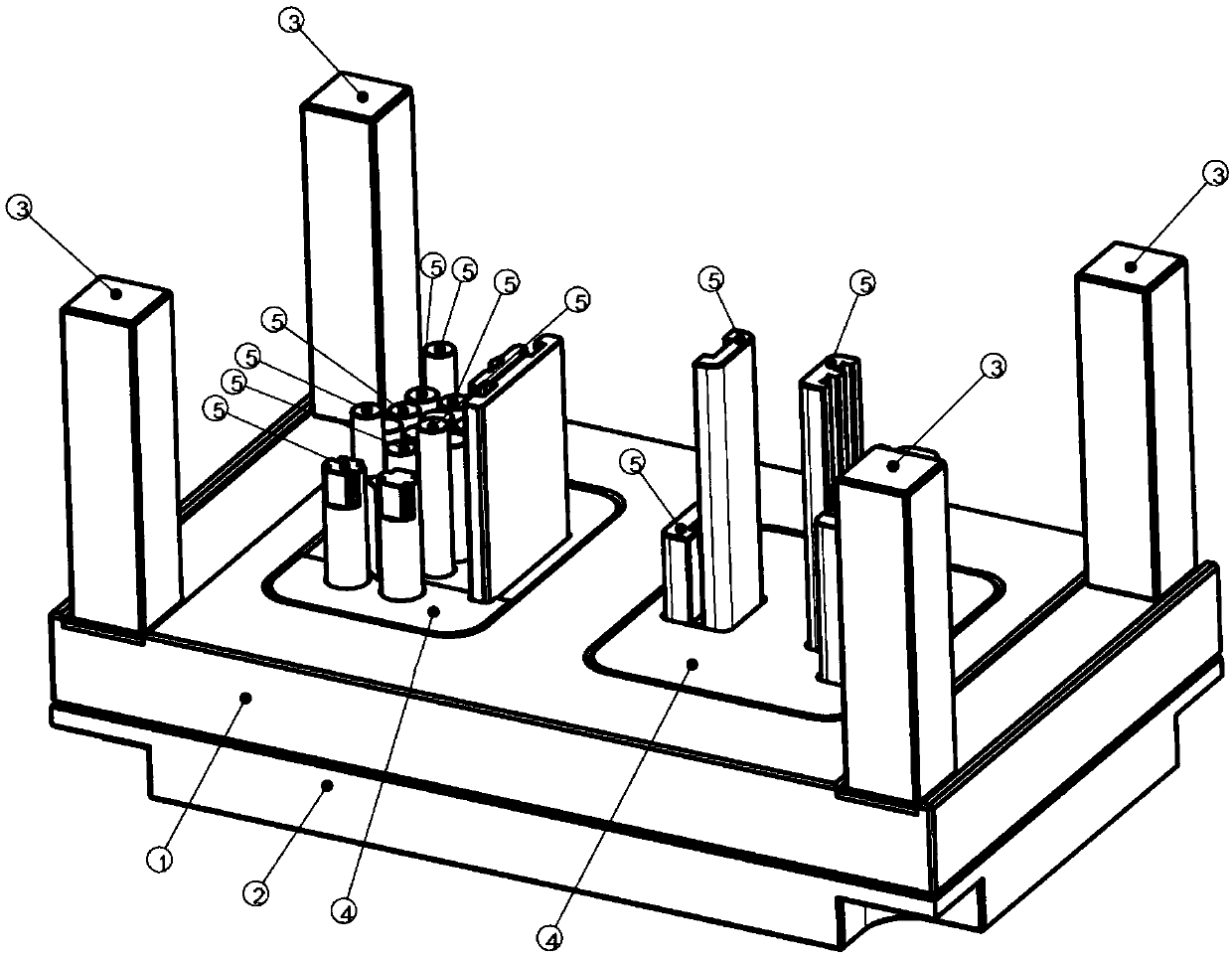

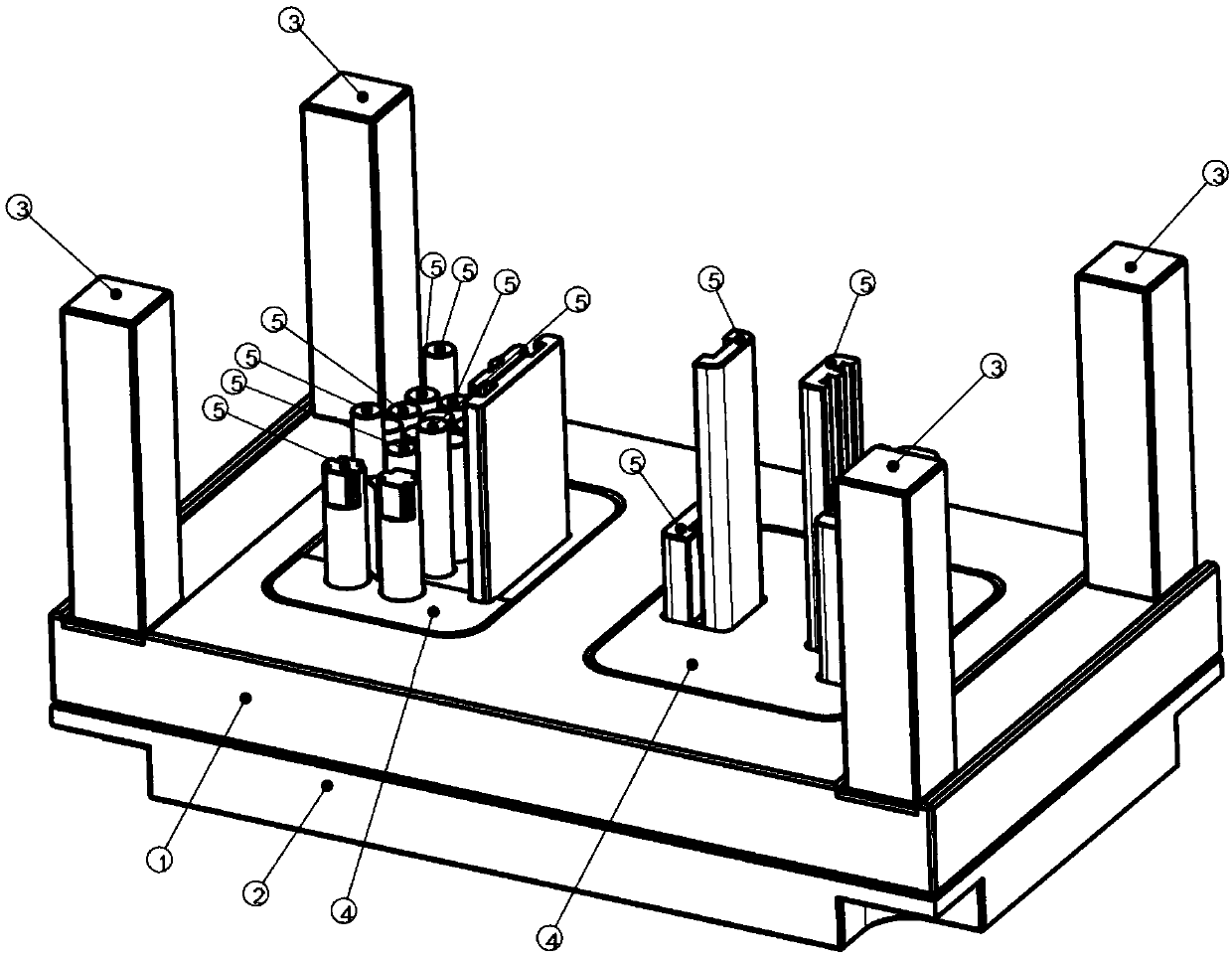

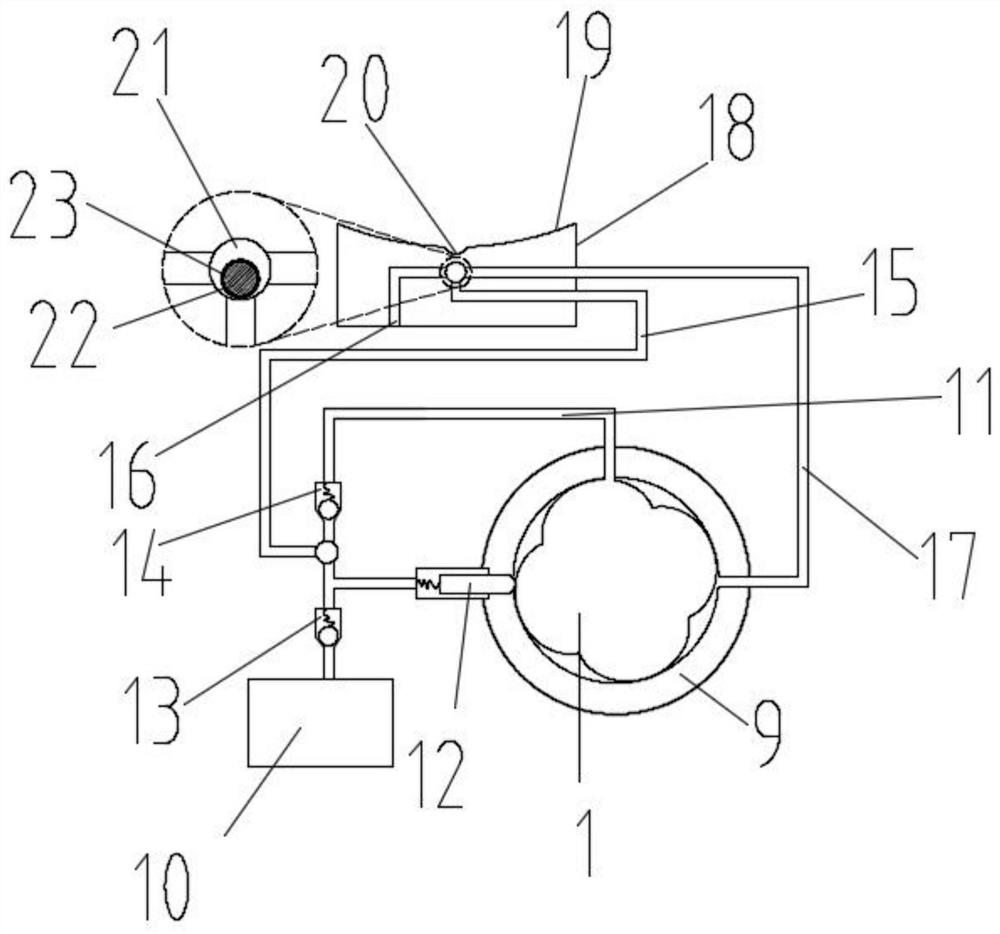

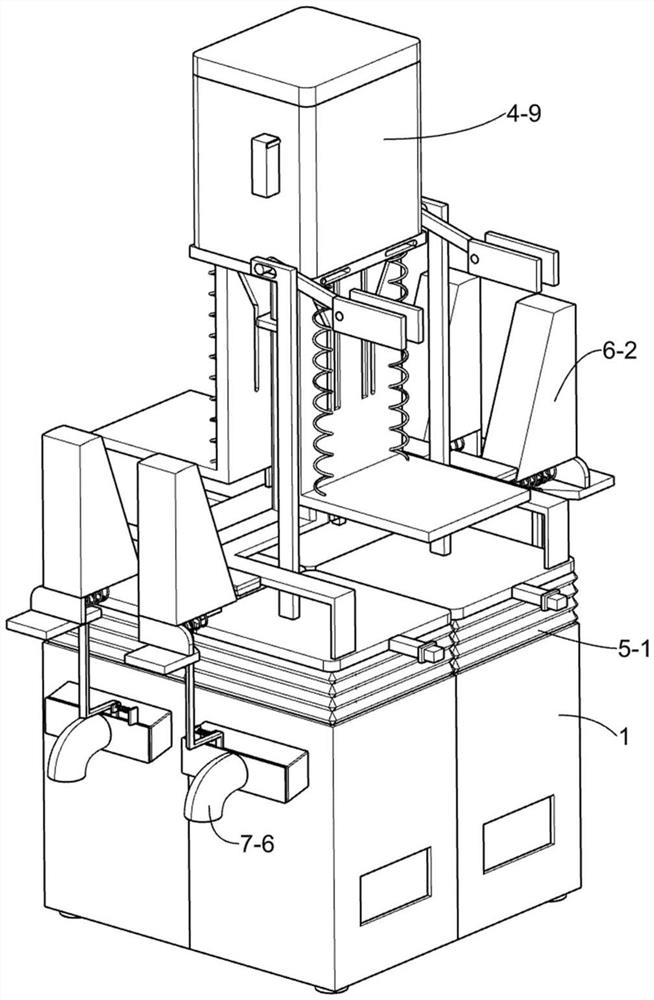

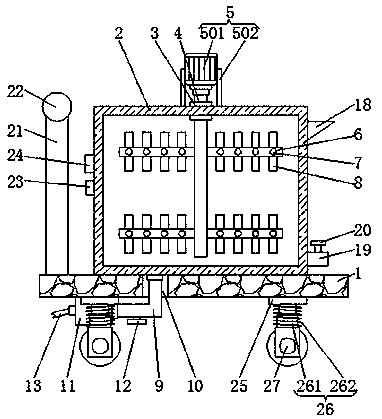

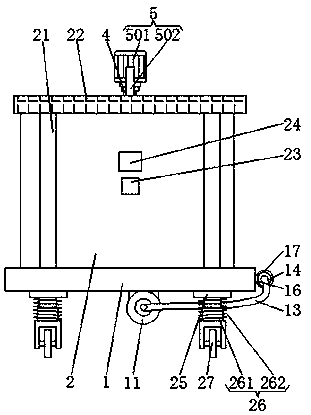

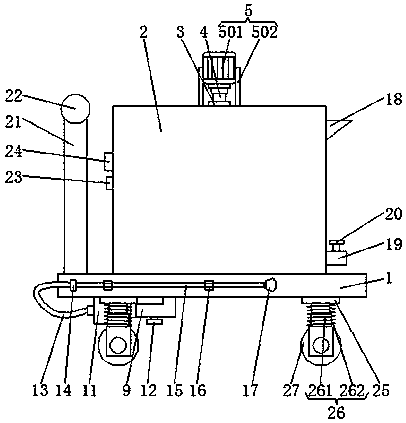

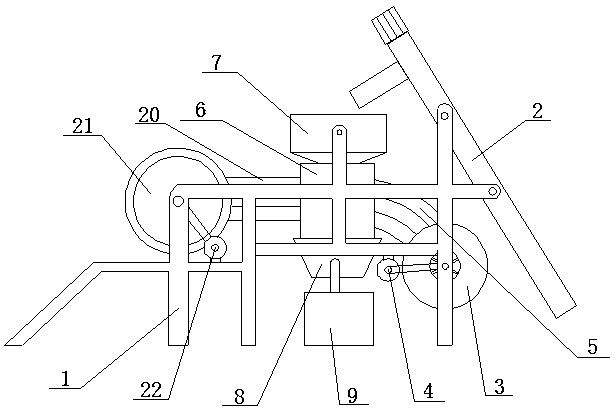

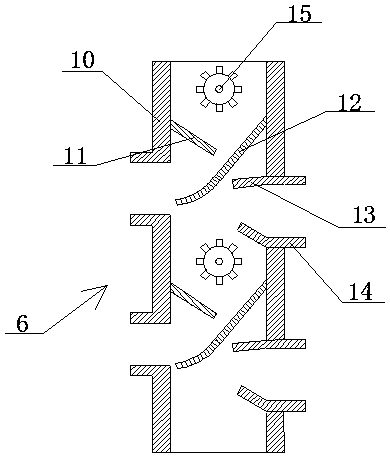

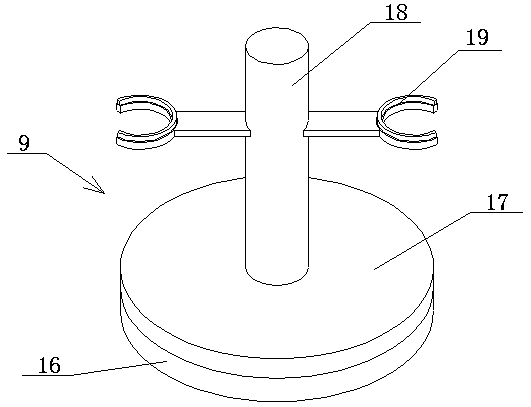

Manufacturing technology and device for shell of amorphous alloy watch

InactiveCN105344964ASolve the problem of rapid liquefactionSolve the problem of rapid solidification and one-shot moldingPressure die castingSlipcasting

The invention discloses a manufacturing technology and device for a shell of an amorphous alloy watch and belongs to the technical field of metal casting. The manufacturing device is composed of a raw material melting system, a mold system, a pressure casting system and a non-vacuum system. The non-vacuum amorphous alloy material machining device is designed through a vertical pressure casting technology. The raw material melting system is used for achieving the purpose of fast liquefying of amorphous alloy. The mold system is used for systematically achieving the purpose of fast solidification and one-time molding of the shell of the watch. The vertical pressure casting system is used for achieving the purpose that amorphous alloy liquid is rapidly and perpendicularly pressed into a mold cavity of the shell of the watch, and the problem that quality is affected due to bubbles generated in a casting is solved. The non-vacuum system is used for achieving the purpose of insulating air in the melting and pressure casting processes. The manufacturing device for the shell of the amorphous alloy watch is made of granular amorphous alloy raw materials containing zirconium, aluminum, copper, nickel and zinc, and the manufactured shell of the watch has the gloss of precious metal, namely platinum and is high in hardness and invariant in color. The device is suitable for being used as a universal device for manufacturing amorphous alloy products through one-time molding.

Owner:刘南林

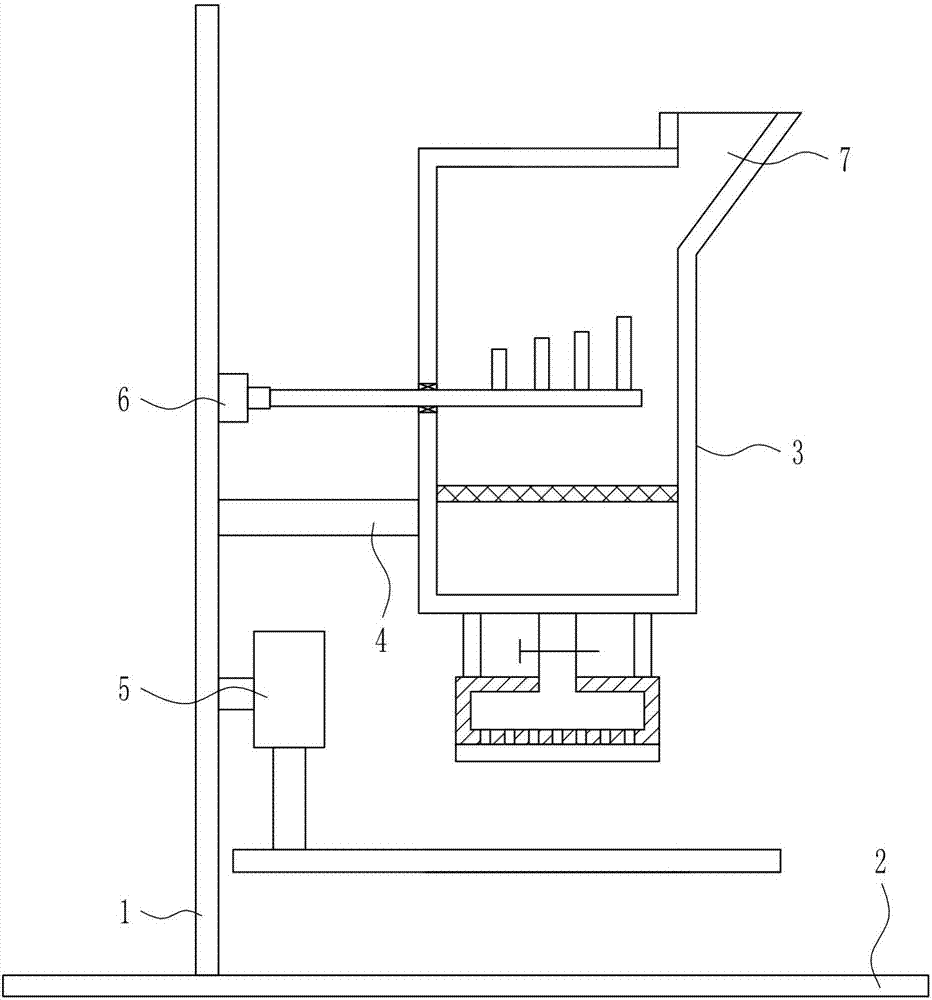

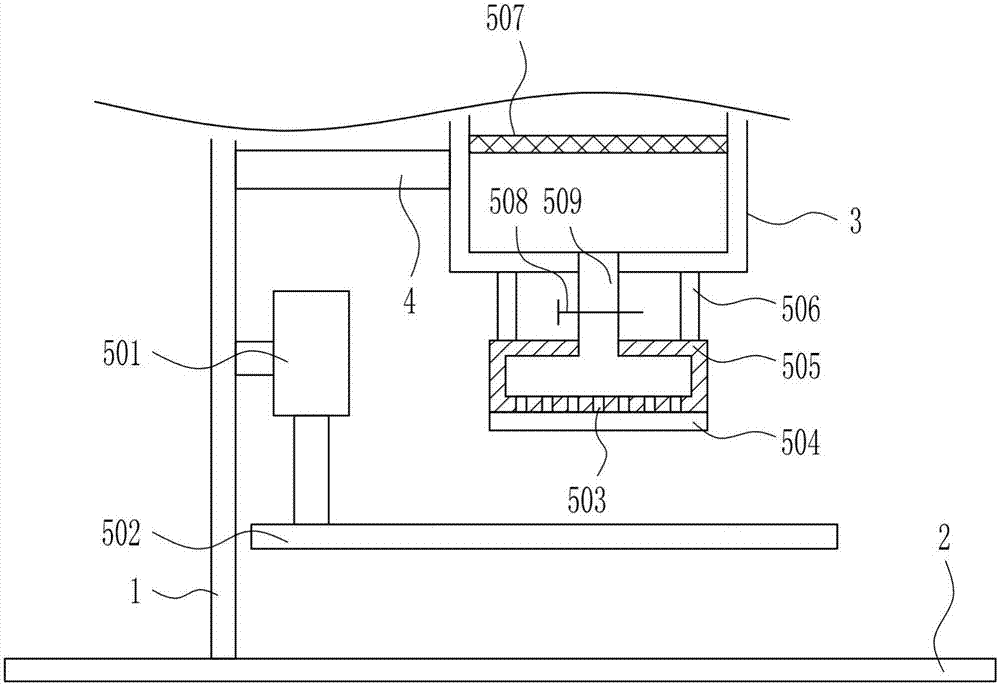

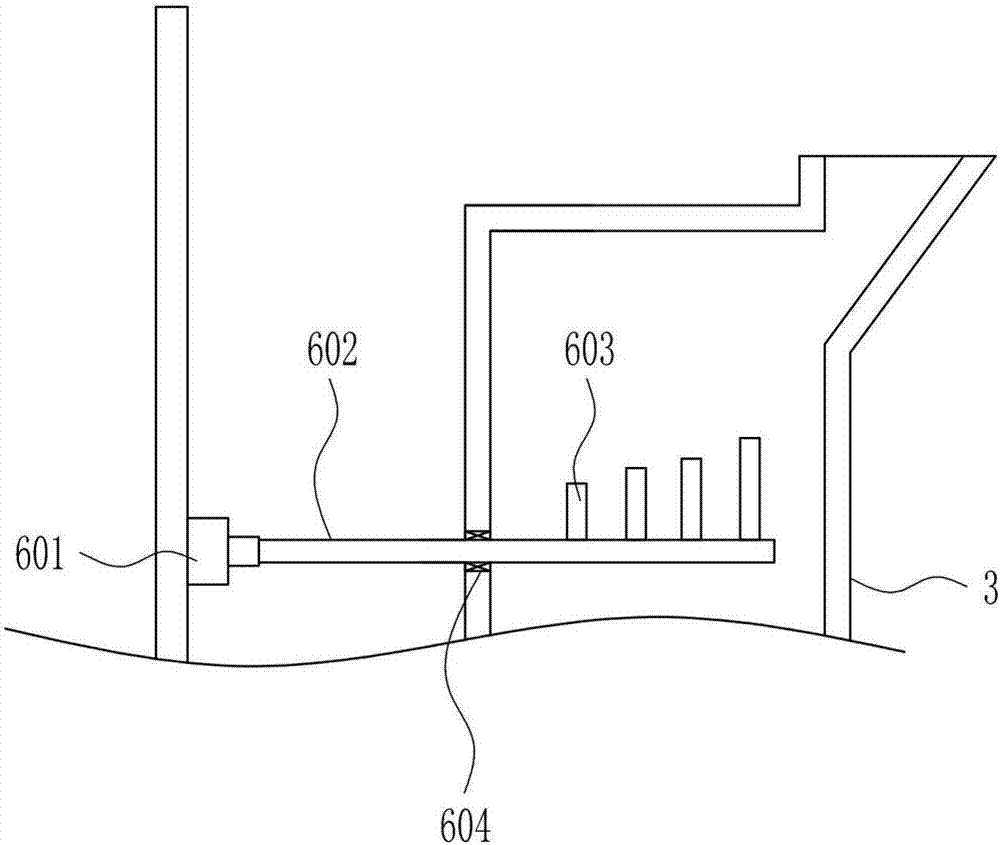

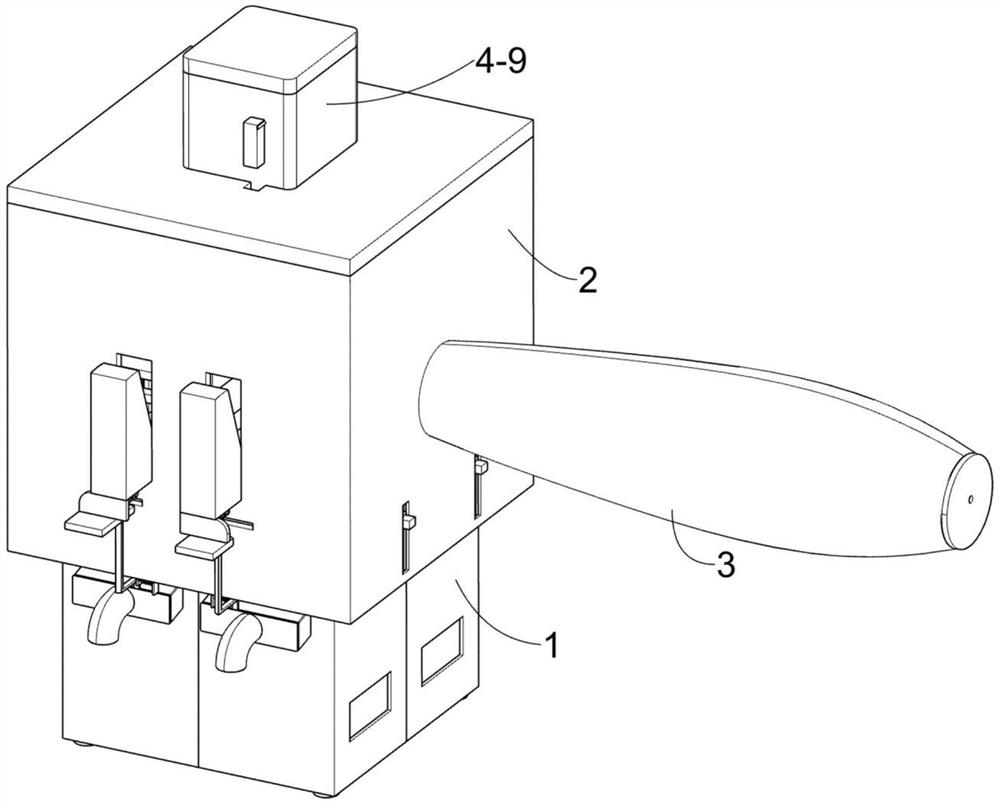

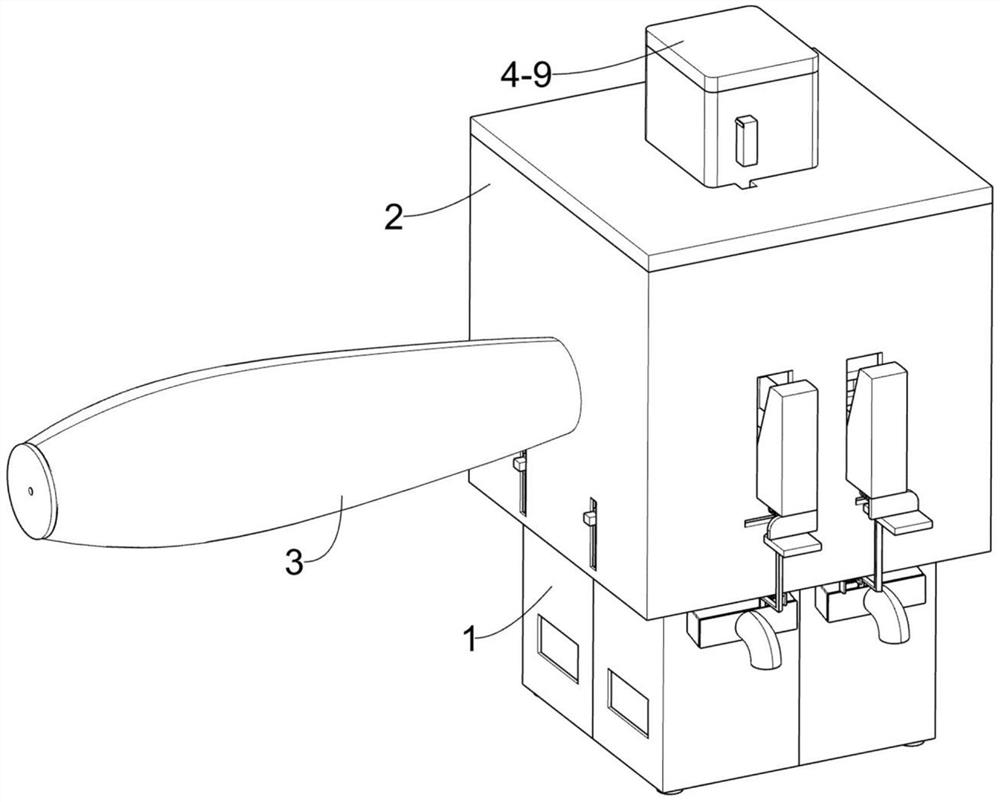

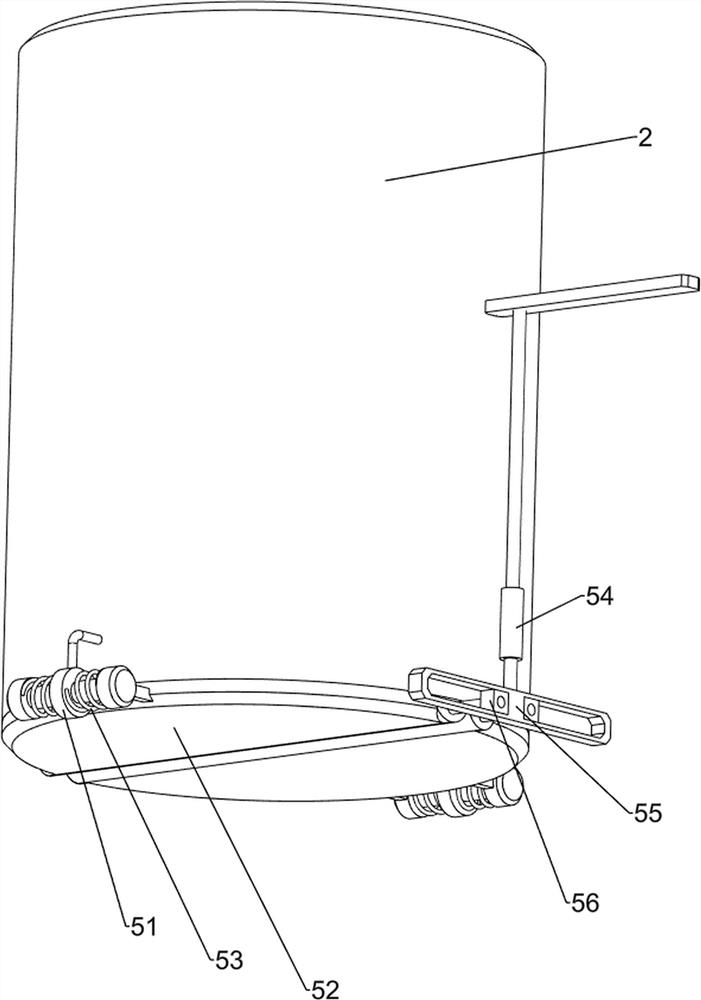

Processing device for preparing ice cream

The invention provides a processing device for preparing ice cream. The processing device is arranged under a discharge opening of an ice cream freezing machine, and the processing device includes a stirring mechanism, a quantitative mechanism, a molding mechanism, and a receiving mechanism. The processing device can save the trouble that a shop assistant needs to manually rotate an ice cream cupor a cone to take the ice cream into a certain shape every time, and the shop assistant does not need to manually rotate the ice cream cup or the cone, and according to the choice, the ice cream can be rotated in a variety of different fixed shapes, which is more beautiful. The processing device has the characteristics of strong applicability, reliable work, and the like, and is suitable for use in various places where ice cream is sold by the ice cream freezing machine, and is suitable for batch development. The processing device also has the characteristics of simple structure, and convenient operation and the like.

Owner:HENAN UNIV OF SCI & TECH

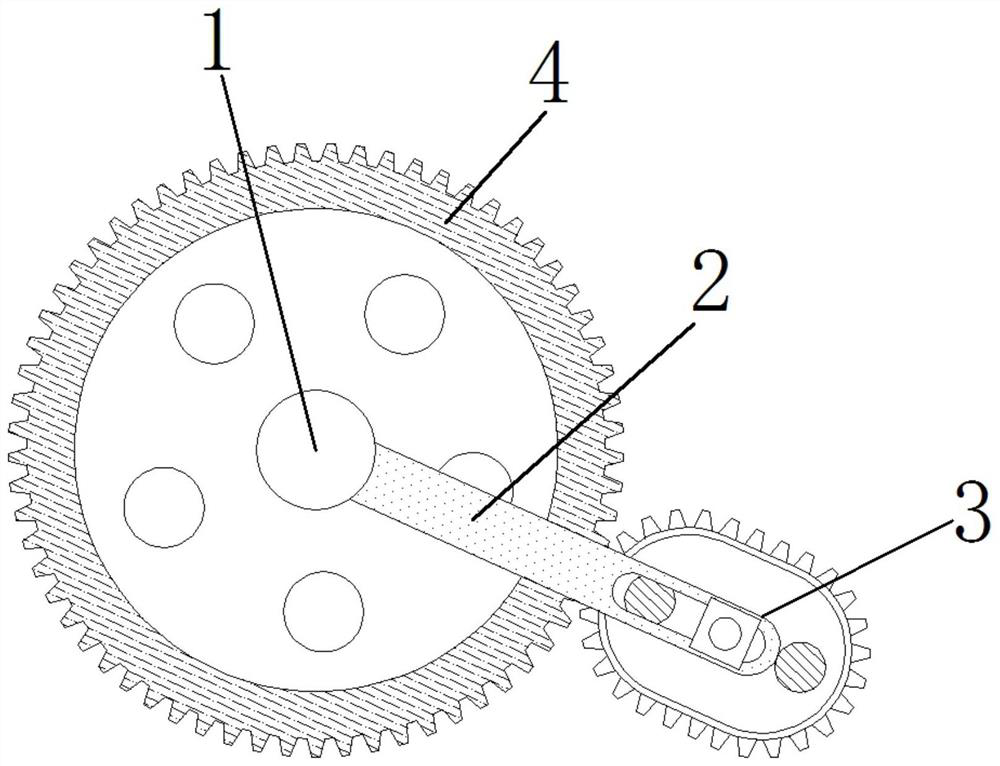

Mixing device and mixing method

PendingCN106582386APrevent oxidationEvenly mixedRotating receptacle mixersTransportation and packagingCarbon Dioxide / HeliumShielding gas

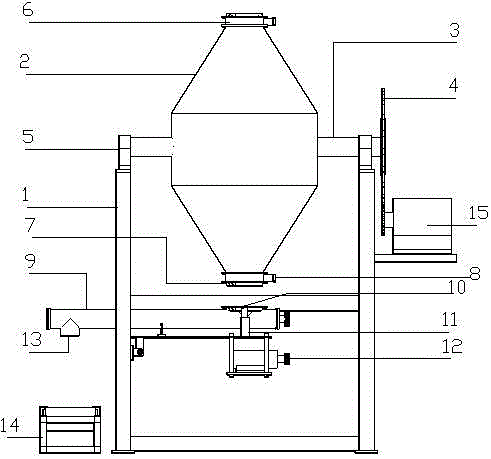

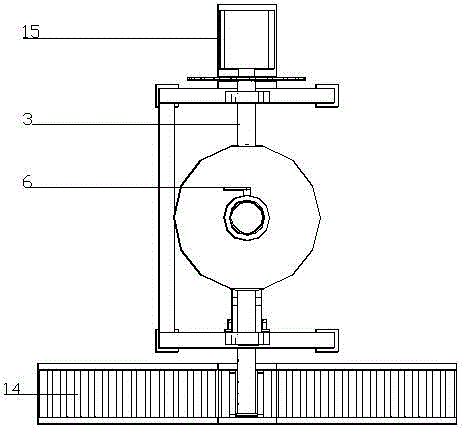

The invention relates to a mixing device and a mixing method and aims to overcome defect that the conventional mixing device is non-uniform in mixing and low in mixing efficiency. The mixing device comprises a vertical two-sided bracket, a mixing barrel and a driving device, wherein a rotating shaft penetrates the center of the mixing barrel, bearing blocks for supporting the rotating shaft are arranged at two ends of the bracket, the driving device is mounted on a platform on one side of the bracket and connected with the rotating shaft through a pair of mutually meshed gears, a through hole is formed in the center of one end of the rotating shaft and serves as a shield gas inlet, a handle type butt clamp butterfly valve is arranged at a top feeding port of the mixing barrel, materials are fed through an opening of the butterfly valve, and a fixed flange is arranged at a bottom outlet of the mixing barrel and is controlled by a valve on one side to open and close. During mixing, the mixing barrel can turn over in the range of 0-360 degrees, the materials at the bottom of the barrel can be conveyed to the upper part of the barrel for mixing, a mixing dead angle is avoided, the materials are mixed more sufficiently and uniformly, and the mixing efficiency is high and can reach 2 ton / h.

Owner:江西江钨稀有金属新材料股份有限公司

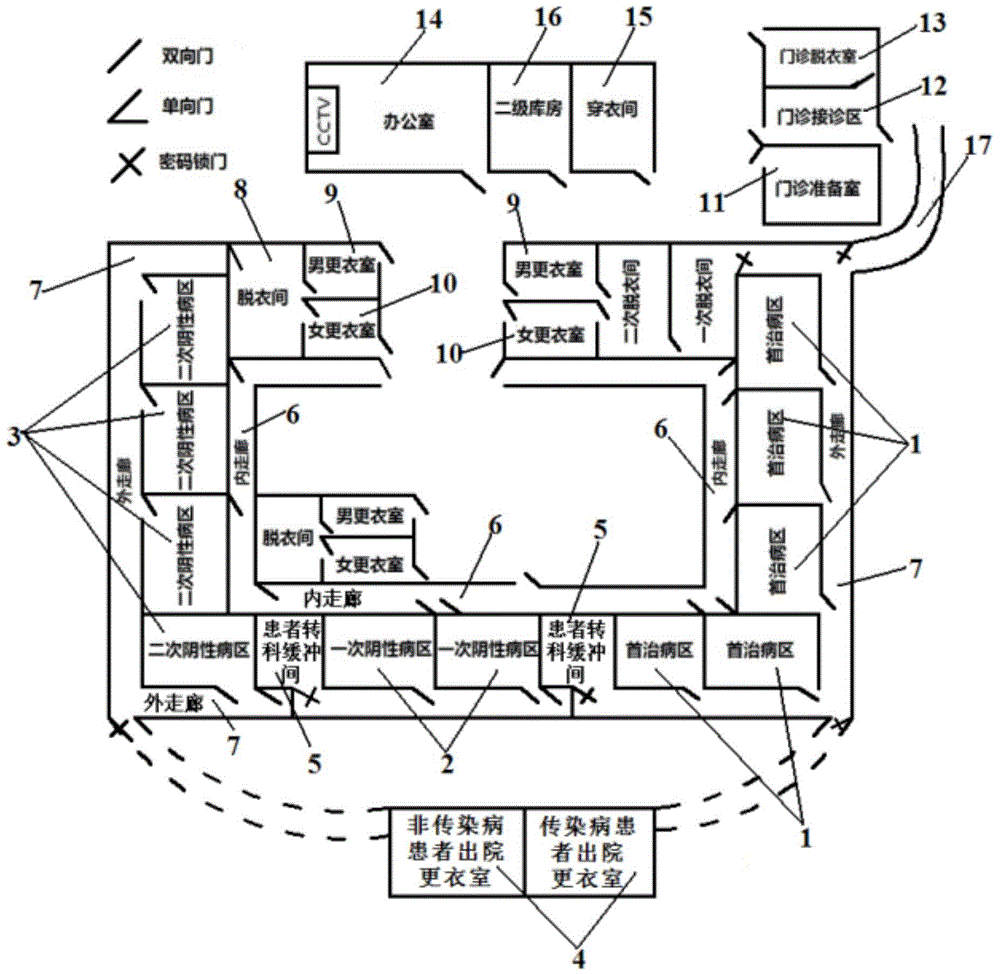

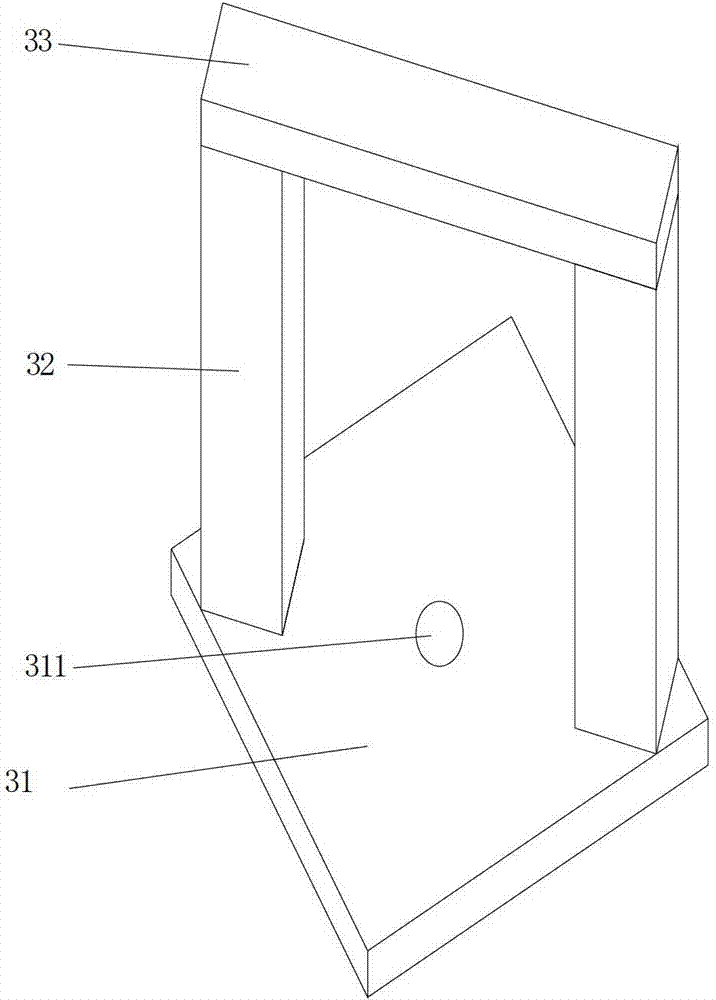

Temporary infectious disease sick house layout structure

InactiveCN104912351AOutflow controlControl cross infectionHospitalsSchoolsPatient roomIntensive care medicine

The invention discloses a temporary infectious disease sick house layout structure, which comprises three sequentially connected irreversible three sick wards, wherein the three sick wards comprise a first treating sick ward, a primary negative sick ward and a secondary negative sick ward; the first treating sick ward is used for treating suspected infectious disease infected patients and judging whether the suspected infectious disease infected patients are infected by infectious diseases or not; the primary negative sick ward is used for receiving and treating patients primarily judged not to be infected by the infectious diseases and secondarily judging whether the patients are infected by the infectious diseases or not; the secondary negative sick ward is used for receiving and treating patients secondarily judged not to be infected by the infectious diseases; and each of the first treating sick ward and the secondary negative sick ward is independently connected with a special hospital leaving changing room. The temporary infectious disease sick house layout structure solves the problem that cross infection can be easily caused between patients and medical personnel and among the patients in the prior art.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

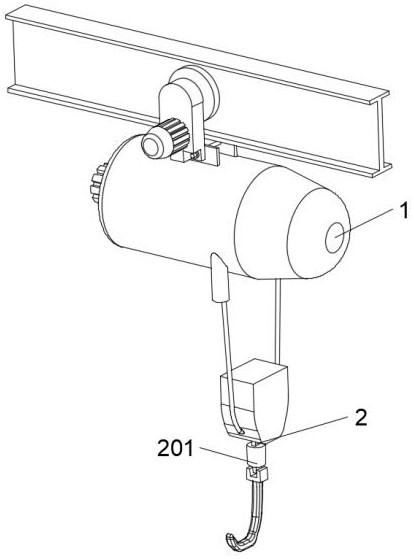

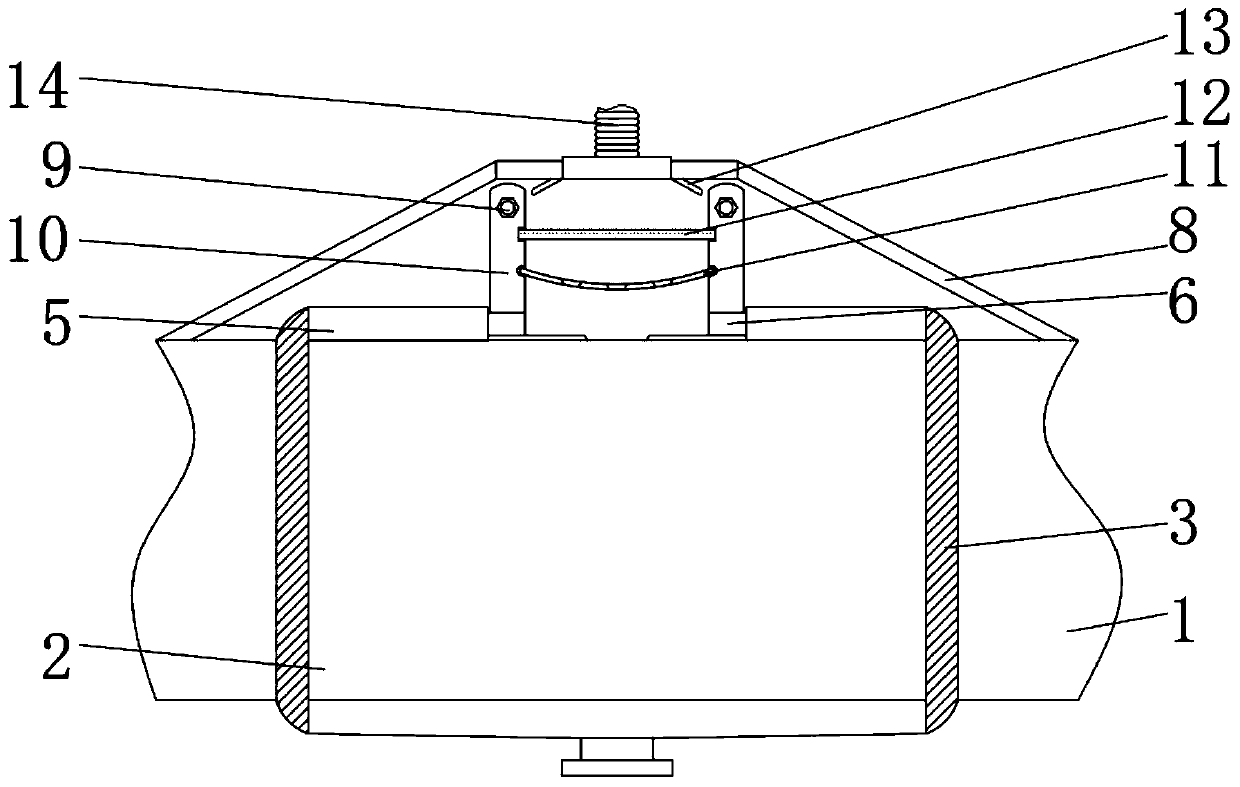

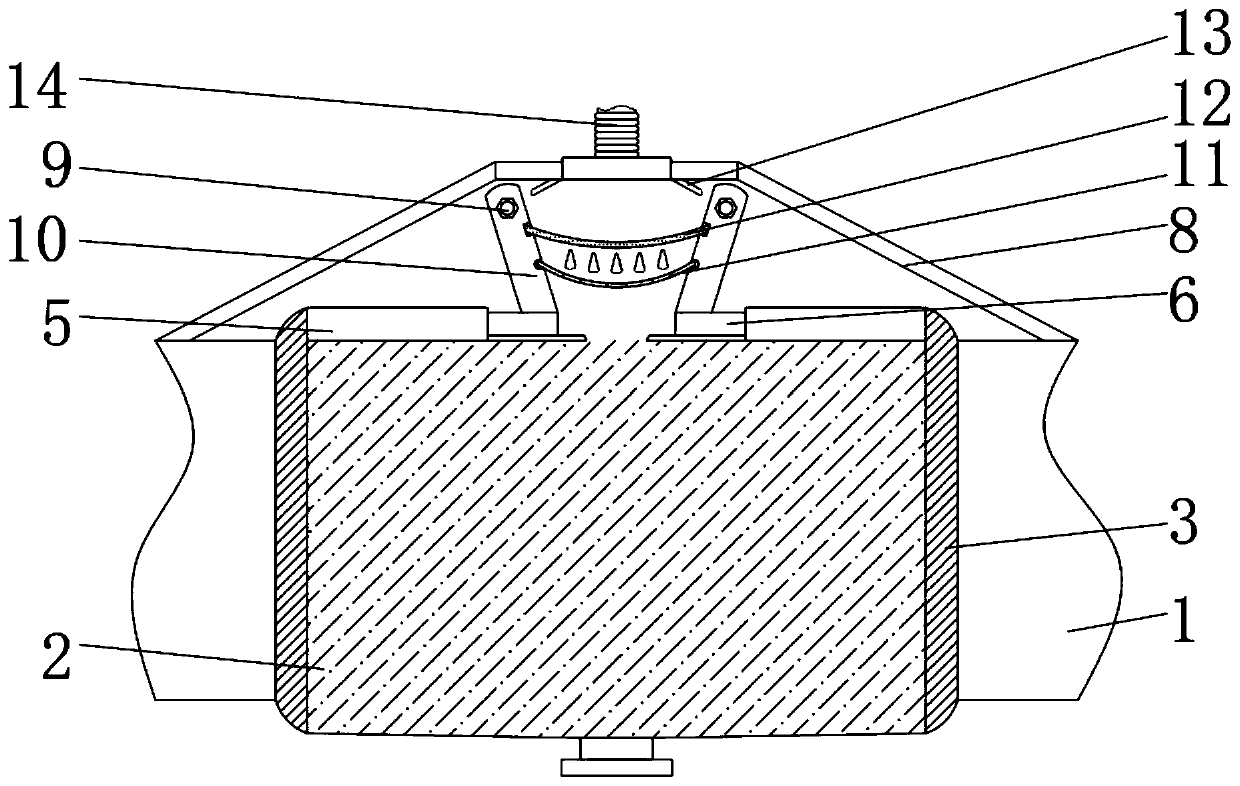

Electric hoist with low-friction spherical hinge

InactiveCN114394527AImprove securityReduce wearNon-rotating vibration suppressionWinding mechanismsClassical mechanicsStructural engineering

The invention discloses an electric hoist with a low-friction type spherical hinge, and belongs to the field of electric equipment.The electric hoist with the low-friction type spherical hinge comprises an electric hoist body, the lower end of the electric hoist body is connected with a spherical hinge connecting shaft, and the outer end of the spherical hinge connecting shaft is wrapped with a hard protective shell barrel; the flexible buffer hemispheres are symmetrically and fixedly mounted in the spherical hinge connecting shaft, and through cooperative use of the flexible buffer hemispheres and the flexible anti-friction blocks, instantaneous traction force generated when the electric hoist is started is decomposed and offset, and damage caused by instantaneous impact force to the spherical hinge connecting shaft and the flexible buffer hemispheres is reduced; when the flexible buffer hemisphere deforms due to traction, the surface of the flexible anti-friction block is lubricated, abrasion of the surface of the flexible buffer hemisphere and aging of rubber are reduced, the service life of the device is effectively prolonged, the damping effect of the spherical hinge connecting shaft during instantaneous traction is improved, and then the use safety of the electric hoist body is effectively improved.

Owner:南通鼎城船舶技术有限公司

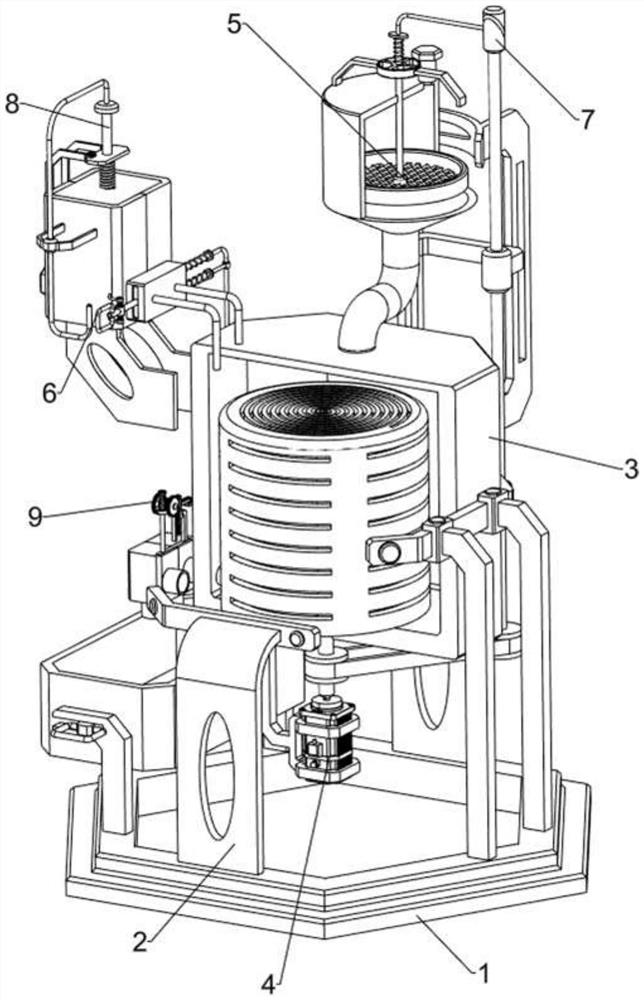

Cylinder cooling device of piston air compressor

ActiveCN110332095ARealize intelligent coolingStable jobPositive displacement pump componentsPositive-displacement liquid enginesWater storageEngineering

The invention relates to the technical field of air compressors, and discloses a cylinder cooling device of a piston air compressor. The device comprises a cylinder block; a sleeve is mounted on the outer wall of the cylinder block; a positioning cylinder is mounted at the top end of the sleeve; an extension pipe is mounted in the positioning cylinder; the extension pipe is filled with an expansion object; and the positioning cylinder, the extension pipe and the extension object are heated to form a transmission device. The surface temperature of the cylinder block is transmitted into the extension pipe for self-adaption expansion of the expansion object in the extension pipe along with the surface temperature of the cylinder block; when the temperature of the cylinder block is gradually increased, the expansion object drives the extension pipe to axially move, so that a rubber rod can be opened and closed by different angles; liquid in a water storage plate is extruded by using expansion strength to flow into the sleeve; and the cooling device can be adjusted in a self-adaption mode along with the temperature of the cylinder block, so that the intelligent cooling of the cylinder block can be realized without arranging such other parts as a temperature sensor.

Owner:武义广利机电有限公司

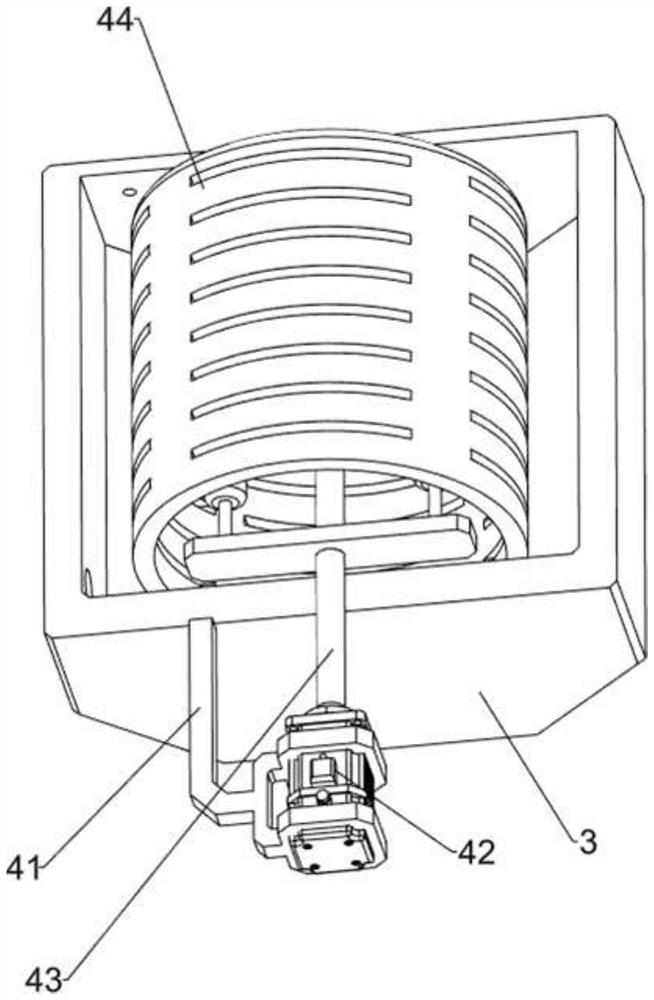

Waste lithium battery electrolyte wastewater recovery treatment device

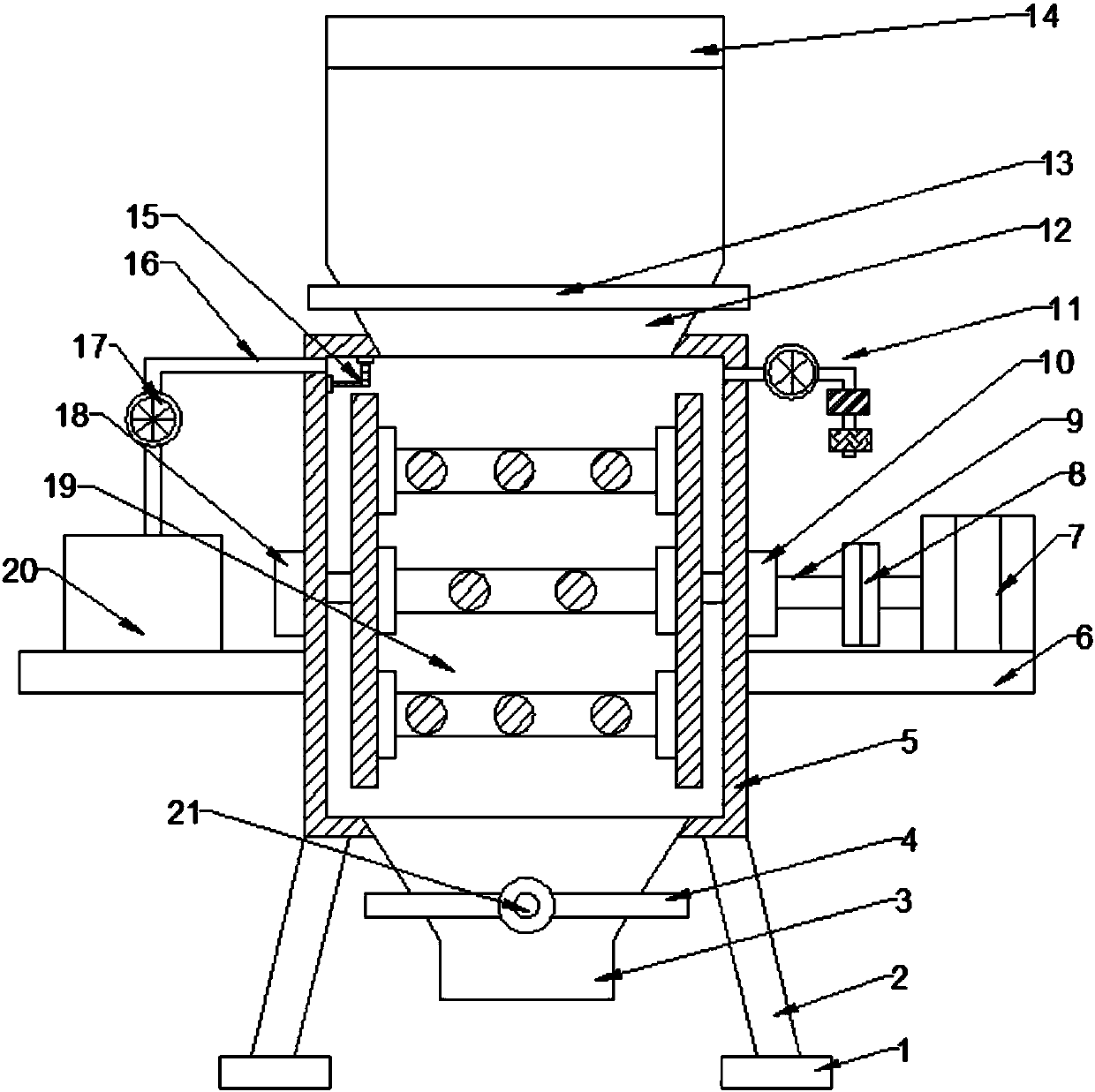

ActiveCN113023799ARealize screeningRealize the effect of acid supplementation at intervalsTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsElectrolytic agentProcess engineering

The invention relates to a treatment device, in particular to a waste lithium battery electrolyte wastewater recovery treatment device. The technical problem is to provide a waste lithium battery electrolyte wastewater recovery treatment device which can automatically recover and treat electrolyte wastewater and is simple and safe to operate. According to the technical scheme, the waste lithium battery electrolyte wastewater recycling device comprises a base and first supporting columns arranged on the two sides of the base; a box body connected between the first supporting columns; a rotating mechanism arranged on the box body; and a shaking mechanism arranged on one side of the box body. Through cooperation of an acid supplementing mechanism, the rotating mechanism and the shaking mechanism, wastewater can be screened, and meanwhile, the effect of interval acid supplementing is achieved.

Owner:YICHUN JINHUI NEW ENERGY MATERIALS

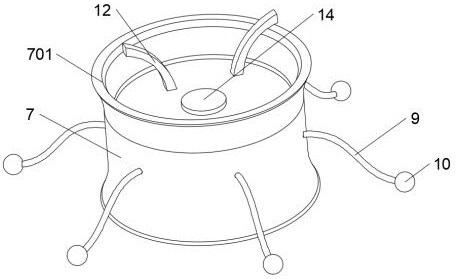

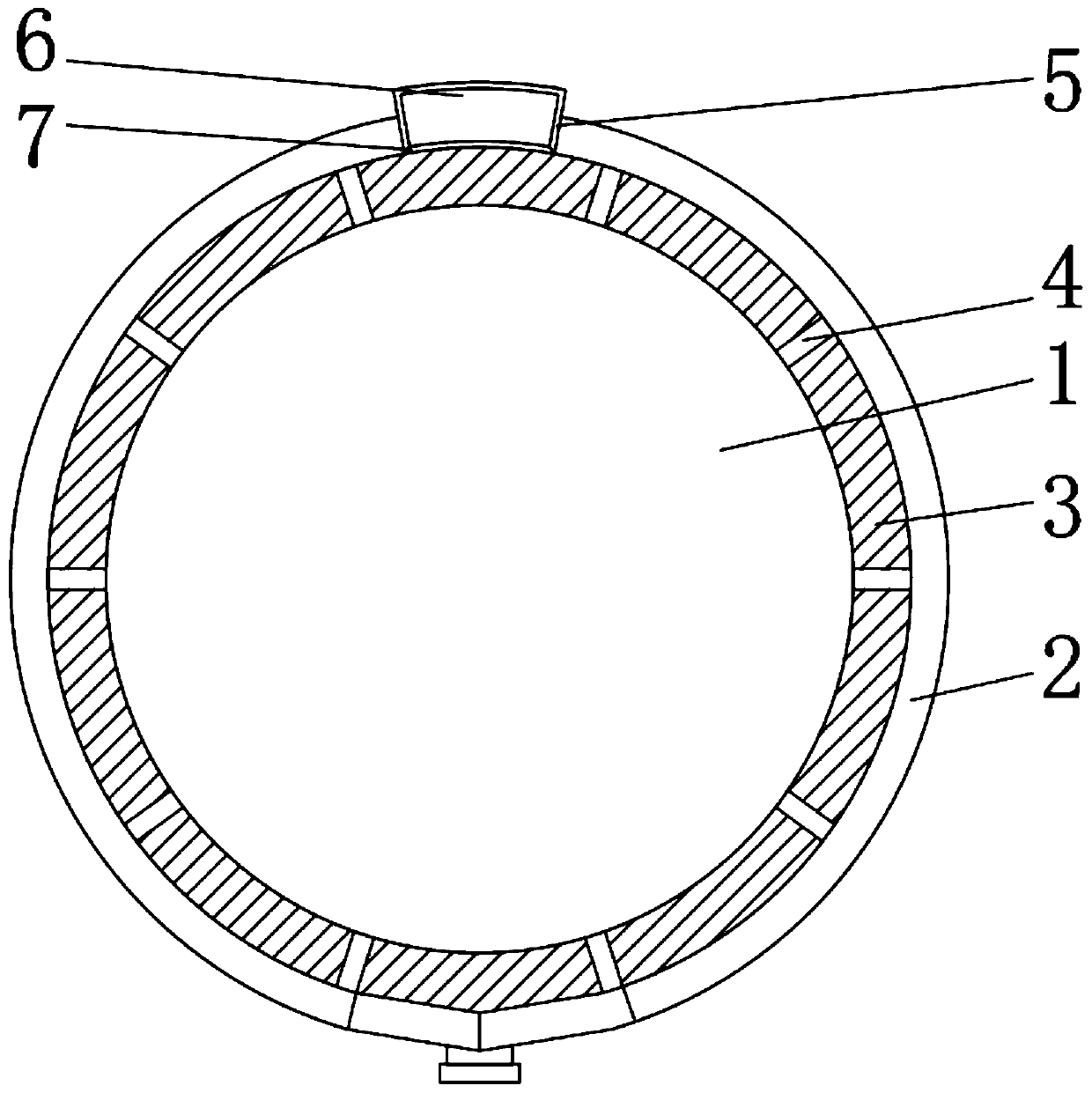

Running-in device of hydraulic operating mechanism used for high-pressure SF6 breaker

ActiveCN104733255ALow costFast implementationHigh-tension/heavy-dress switchesProtective switch operating/release mechanismsTime dynamicsPiston

The embodiment of the invention discloses a running-in device of a hydraulic operating mechanism used for a high-pressure SF6 breaker. The running-in device of the hydraulic operating mechanism used for the high-pressure SF6 breaker comprises a totally enclosed columnar box body, a piston, medium containing device, a driving connecting rod and damping mediums. The piston is embedded inside the box body, the outer surface of the piston is abutted against the inner wall of the box body, and the box body is divided into an upper cavity and a lower cavity by the piston, wherein the upper cavity and the lower cavity are not communicated with each other. The medium containing device is arranged outside the box body, the medium containing device is connected with the upper cavity and the lower cavity through two guide pipes, and the communication is achieved. One end of the driving connecting rod is placed inside the lower cavity and fixed on the piston, and the other end of the driving connecting rod is placed outside the box body and is matched with the hydraulic operating mechanism. The upper cavity and the lower cavity are filled with the damping mediums. When the driving connecting rod moves, the piston is driven to slide along the inner wall of the box body in the direction of facing or deviating from the lower cavity. According to the running-in device of the hydraulic operating mechanism used for the high-pressure SF6 breaker, the adaptability is high, aiming at the damping changing condition of various high-pressure SF6 breakers in the divide-shut braking process, the real-time dynamic closed-loop adjustment on the damping is achieved, the installing and fitting testing time of the hydraulic operating mechanism and the high-pressure SF6 breaker is shortened, and the delivering efficiency and the quality of the mechanism are improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

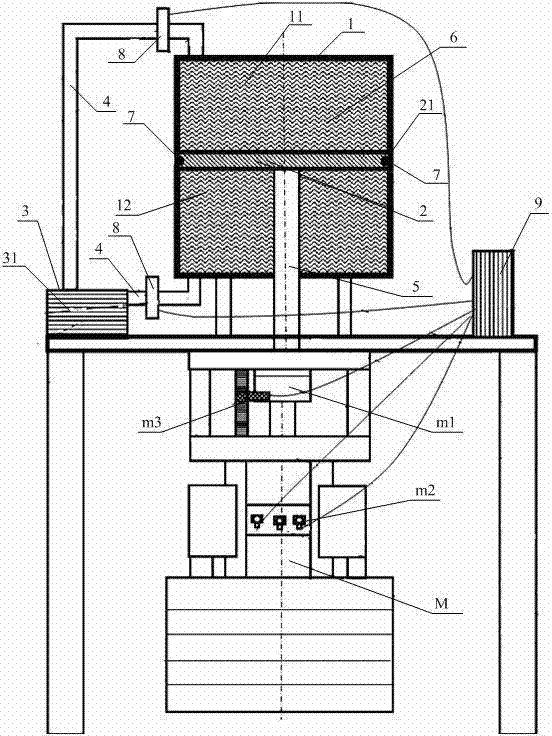

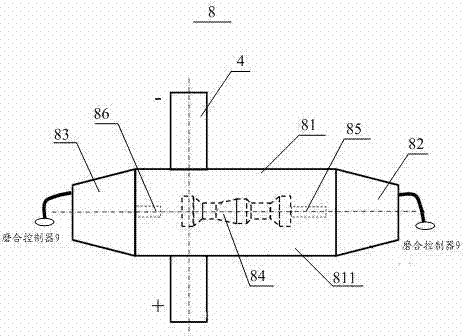

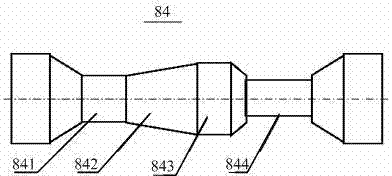

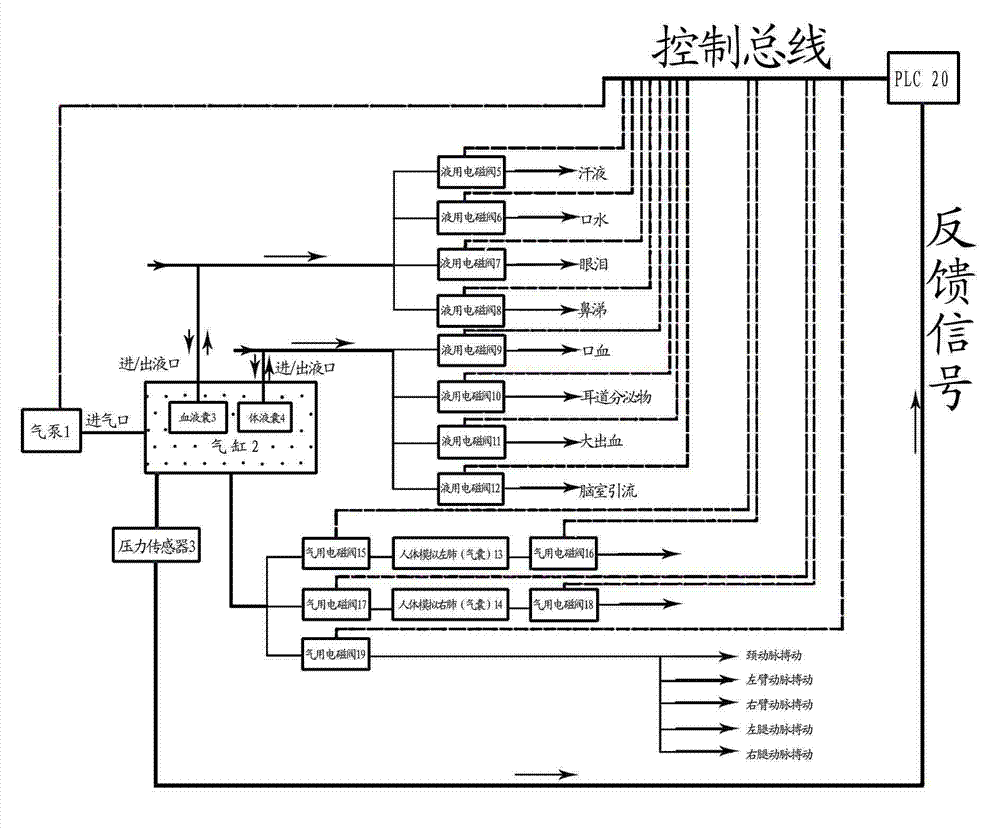

Biochemical device and method for simulating humoral secretion

The invention relates to biochemical device and method for simulating humoral secretion and mainly relates to the field of medical teaching. The biochemical device is characterized by mainly comprising a cylinder, an air pump, a pressure sensor, liquid sacs, an air sac, electromagnetic valves and a guide tube. The air cylinder is provided with an air inlet and an air outlet. The air inlet is connected with the air pump. The air cylinder is connected with the pressure sensor. The humoral sac and a blood sac are disposed inside the air cylinder. The biochemical method includes: allowing the air pump to pump air into the air cylinder to squeeze the liquid sacs, allowing the pressure sensor to detect inner pressure of the air cylinder, converting the pressure valve into transmittable signals transmitted to an PLC (programmable logic controller), allowing the PLC to receive the signals before converting and judging, controlling the air pump to pump the air cylinder or not according to the judged valve; and allowing the PLC to judge according to data input by a user and control on or off of certain electromagnetic valve according to the judged valve.

Owner:TIANJIN TELLYES SCI INC

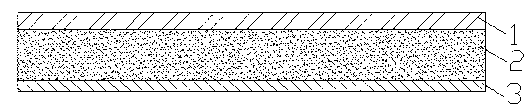

Self-heating thermal fabric

InactiveCN102991041AGood weather resistanceOutflow controlSynthetic resin layered productsPolyesterSurface layer

The invention discloses a self-heating thermal fabric. The self-heating thermal fabric comprises an upper windproof layer, a heating layer and a close-fitting comfortable layer, wherein the heating layer is arranged below the windproof layer; the close-fitting comfortable layer is arranged below the heating layer; the windproof layer is formed by blending and weaving 120 spandex fibers and 160 flax fibers; the heating layer is formed by weaving polyamide fabrics which are covered by high-purity iron powders and a catalyst; and the close-fitting comfortable layer is formed by weaving polyester blend fibers; the surface layer is formed by blending and weaving high-court fiber fabrics, can resist the invasion of cold wind to achieve a thermal insulation function, can automatically generate heat or carry out chemical reaction to generate heat energy, and is packaged by polyamide fabrics which are coated by high-purity iron powders and the catalyst without a side effect; the polyamide fabrics have good weather fastness, can control the heat outflow to avoid burning the body; and the close-fitting comfortable layer is formed by weaving blended polyester with heat resistance, is comfortable to wear and can not be oxidized or damaged by overheat.

Owner:SUZHOU YIYUN NEEDLE TEXTILE

Dyeing fat liquoring equipment for leather dyeing machining

ActiveCN106957931AEfficient and convenient dippingFatliquoring is efficient and convenientLeather impregnationEngineeringHigh fat

The invention relates to dyeing fat liquoring equipment, in particular to dyeing fat liquoring equipment for leather dyeing machining and aims at achieving the technical purpose of providing the dyeing fat liquoring equipment for leather dyeing machining, wherein the dyeing fat liquoring equipment for leather dyeing machining is high in fat liquoring efficiency. To achieve the above technical purpose, the dyeing fat liquoring equipment for leather dyeing machining is provided and comprises a left support and the like. The left support is arranged on the left side of the top of a bottom plate. The right side of the left support is sequentially provided with a stirring device, a support rod and a fat dipping device from top to bottom. A treatment box is arranged at the right end of the support rod, an inlet is formed in the right side of the top of the treatment box, and the treatment box is connected with the stirring device. The dyeing fat liquoring equipment achieves the effect of high fat liquoring efficiency, the dyeing fat liquoring equipment is utilized for leather fat liquoring, the stirring device is mainly utilized for stirring fat liquoring mixing liquid, and then the fat liquoring device is utilized for fat dipping.

Owner:江西泽晞新材料有限公司

Automatic film sticking machine for mobile phones

InactiveCN111745947AOutflow controlAvoid wastingCleaning using toolsDomestic articlesEngineeringMechanical engineering

The invention discloses an automatic film sticking machine for mobile phones. The automatic film sticking machine comprises a machine body, a cleaning space arranged in the machine body, a cleaning device arranged in the cleaning space, a film pressing device arranged on the left side of the cleaning device, a film placing device arranged on the rear side of the film pressing device, a sliding device arranged on the lower side of the film pressing device and pulling devices arranged on the left side and the right side of the sliding device. A screen of a mobile phone is cleaned before a film is sticked to the mobile phone, and meanwhile the cleaning device carries out self-cleaning, so that the cleaning effect is guaranteed to be still good when the device is repeatedly used; alcohol is controlled from flowing out, so that the alcohol is prevented from being volatilized and wasted when the device does not work; and when the mobile phone film is pressed, the film sequentially drops fromleft to right and is pressed at the same time, so that air bubbles are prevented from being produced.

Owner:张苏芬

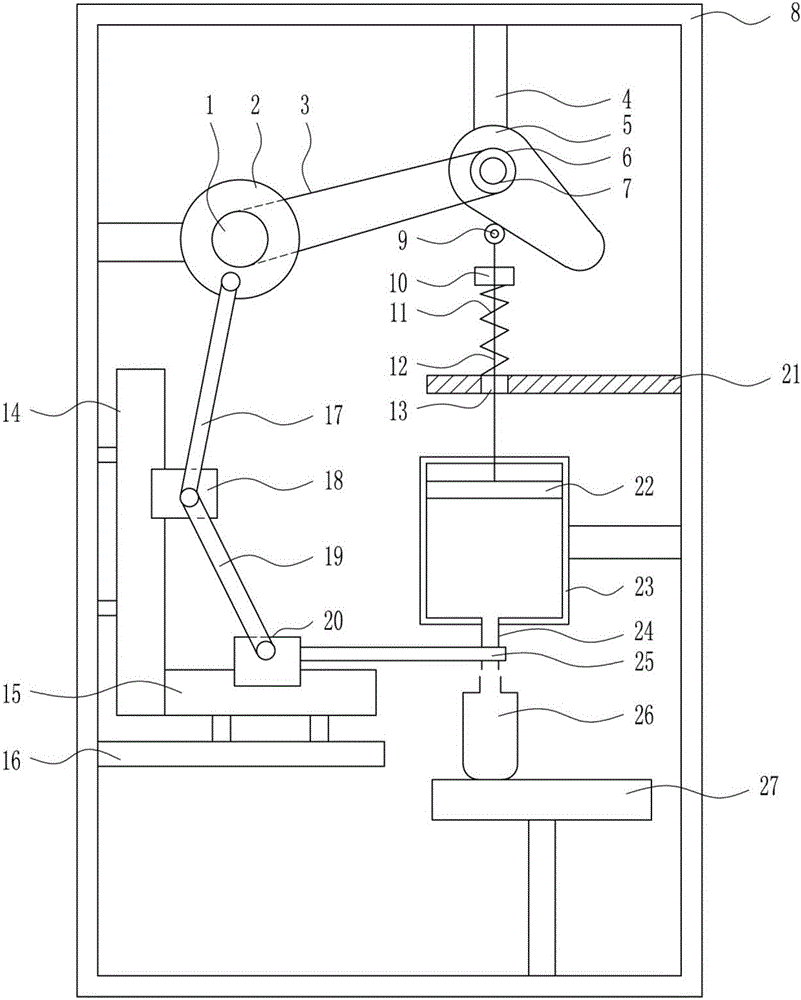

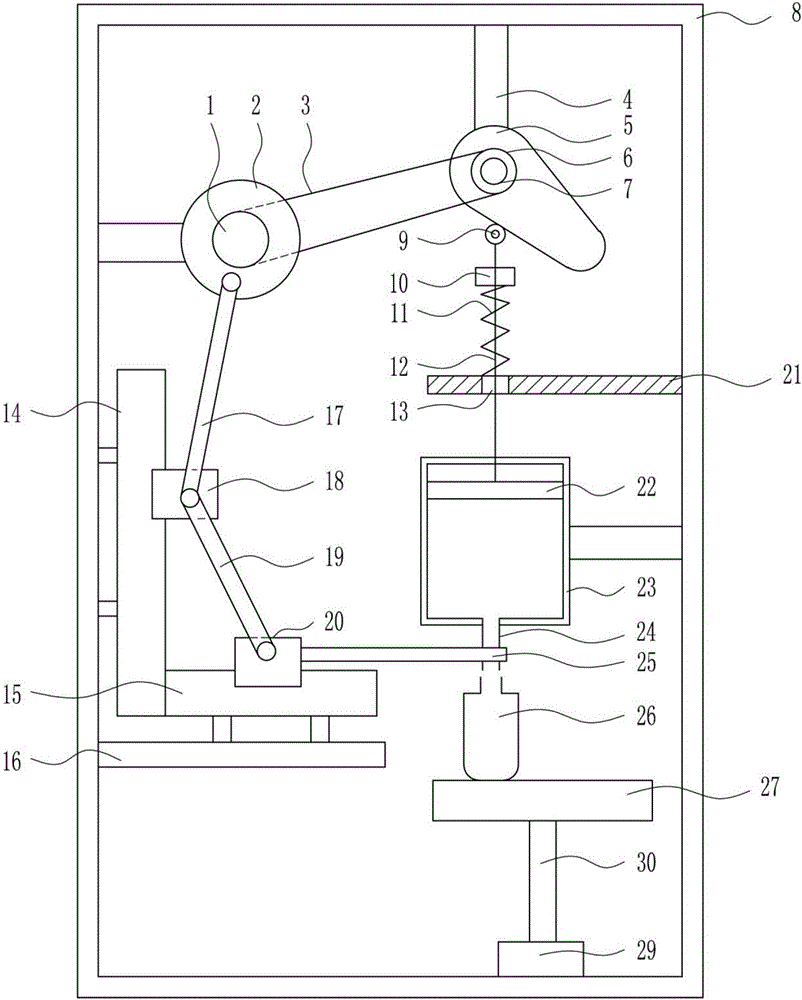

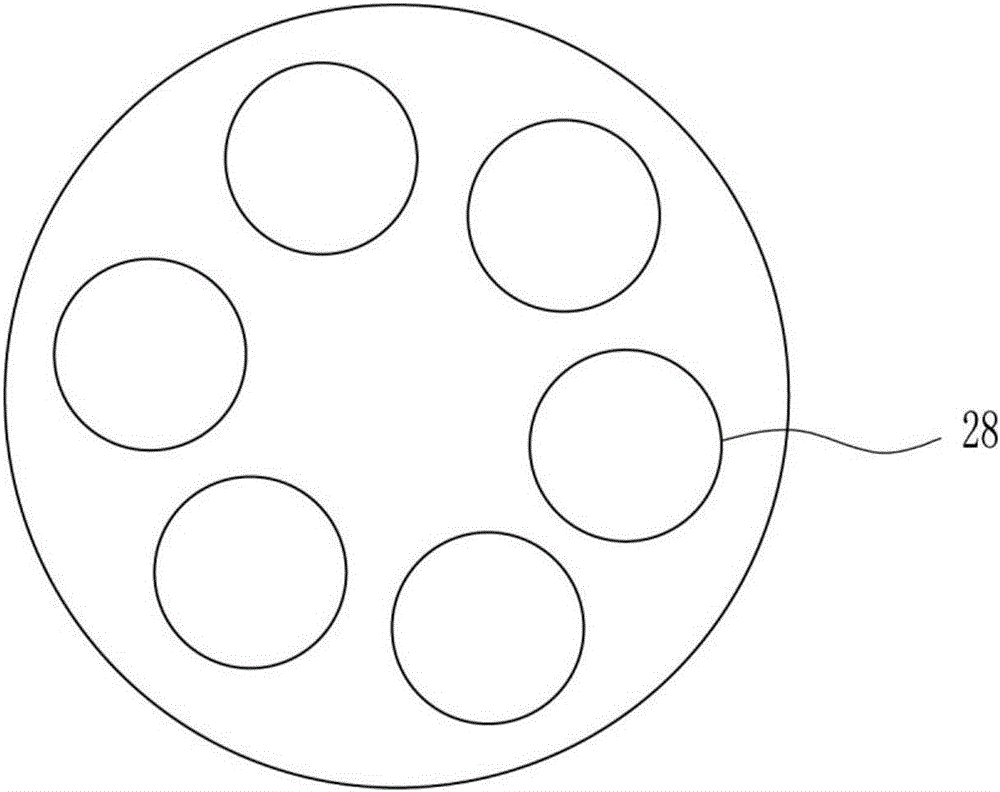

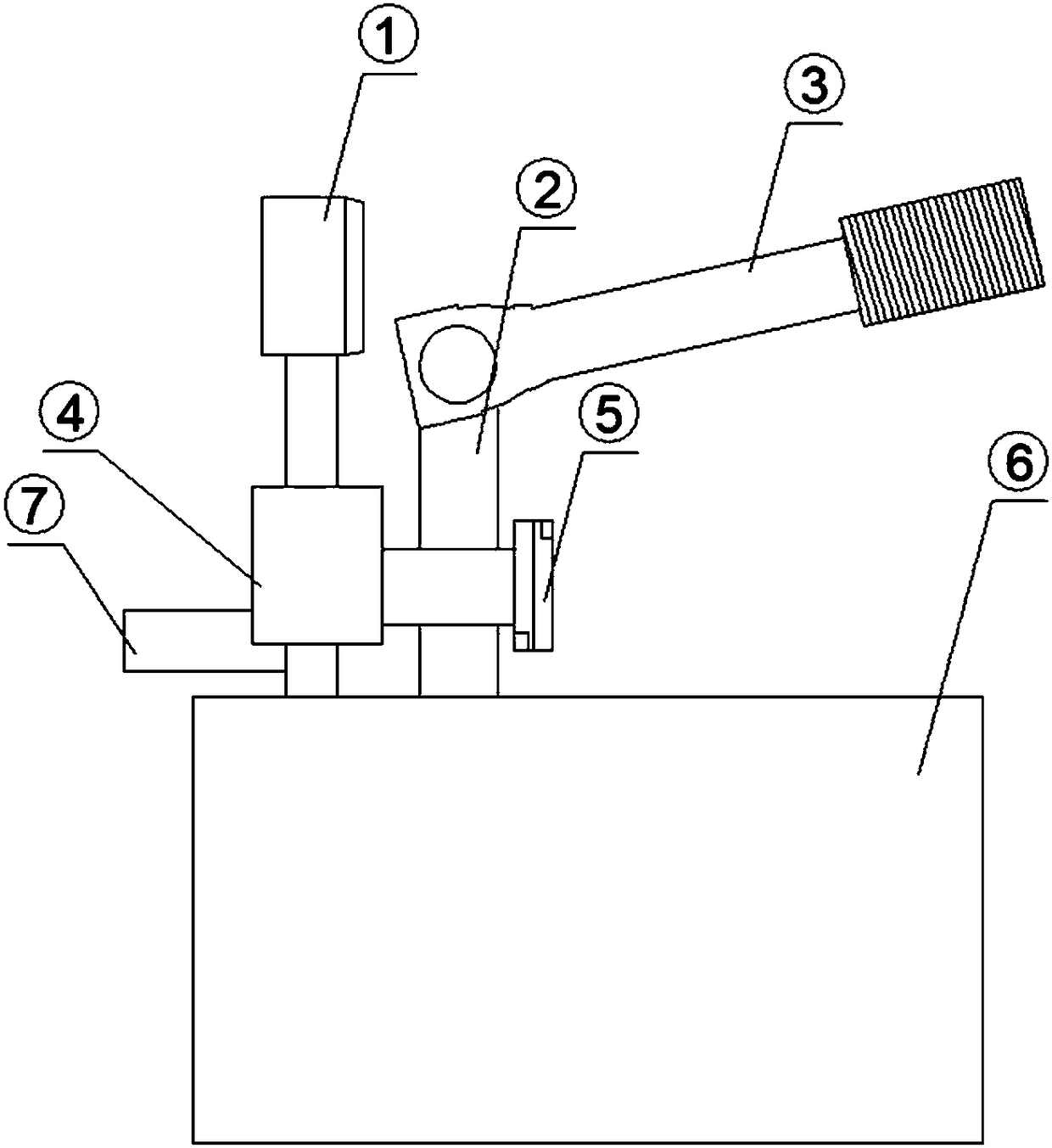

Cosmetic rapid tinning device

The invention relates to a tinning device, in particular to a cosmetic rapid tinning device. The technical problem to be solved by the invention is to provide a cosmetic rapid tinning device which is high in tinning efficiency, simple in tinning operation and high in practicability. In order to solve the technical problem, the invention provides the cosmetic rapid tinning device. The cosmetic rapid tinning device comprises a large belt wheel, a disc, a flat belt, a connecting rod, a cam, a small belt wheel, a first motor, a container, a contact rolling wheel, a fixing plate, a spring, a lifting rod, a first sliding rail, a second sliding rail, a support plate, a first connecting rod, a first sliding block, a second connecting rod, a second sliding block, a guide plate, a pushing block, a box body, a discharging pipe, a plug pin and a placing platform. The connecting rod is arranged at the top of the interior of the container. The first motor is connected to the bottom end of the connecting rod. The cosmetic rapid tinning device achieves the effects of being high in tinning efficiency, simple in tinning operation and high in practicability.

Owner:张大伟

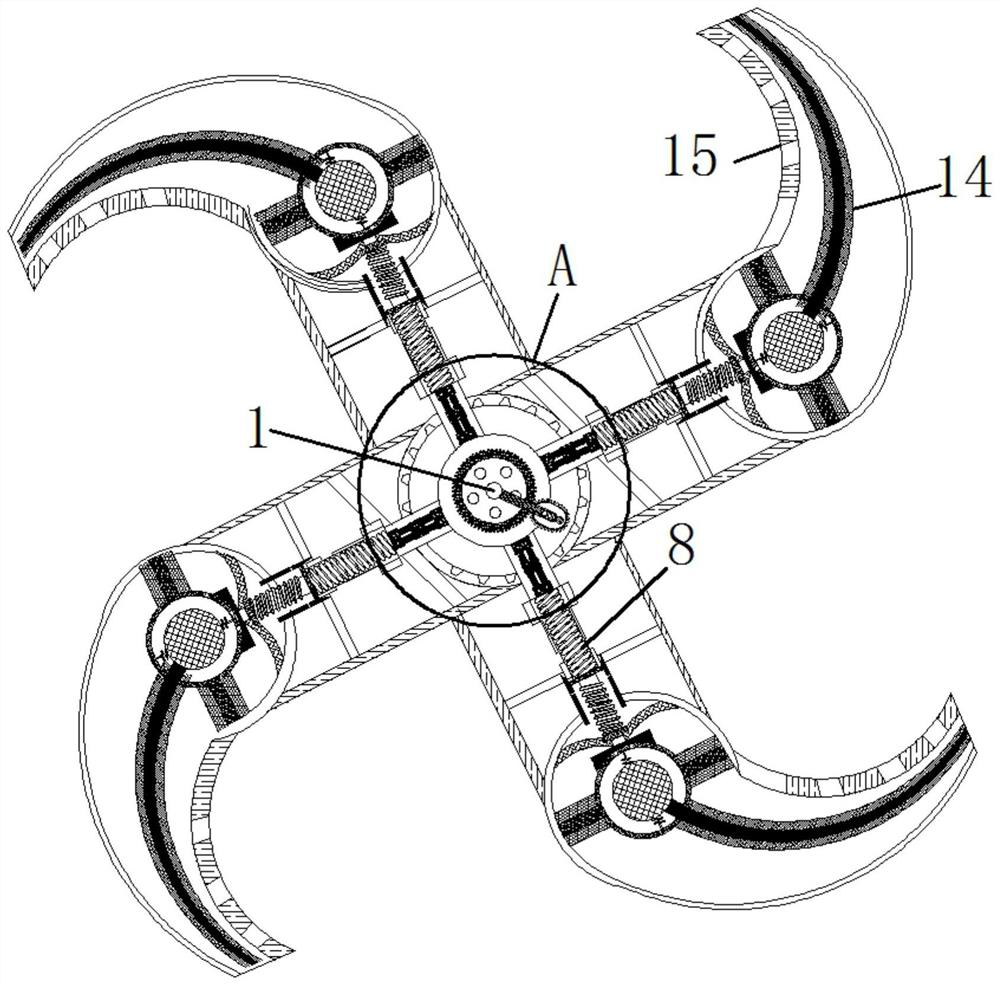

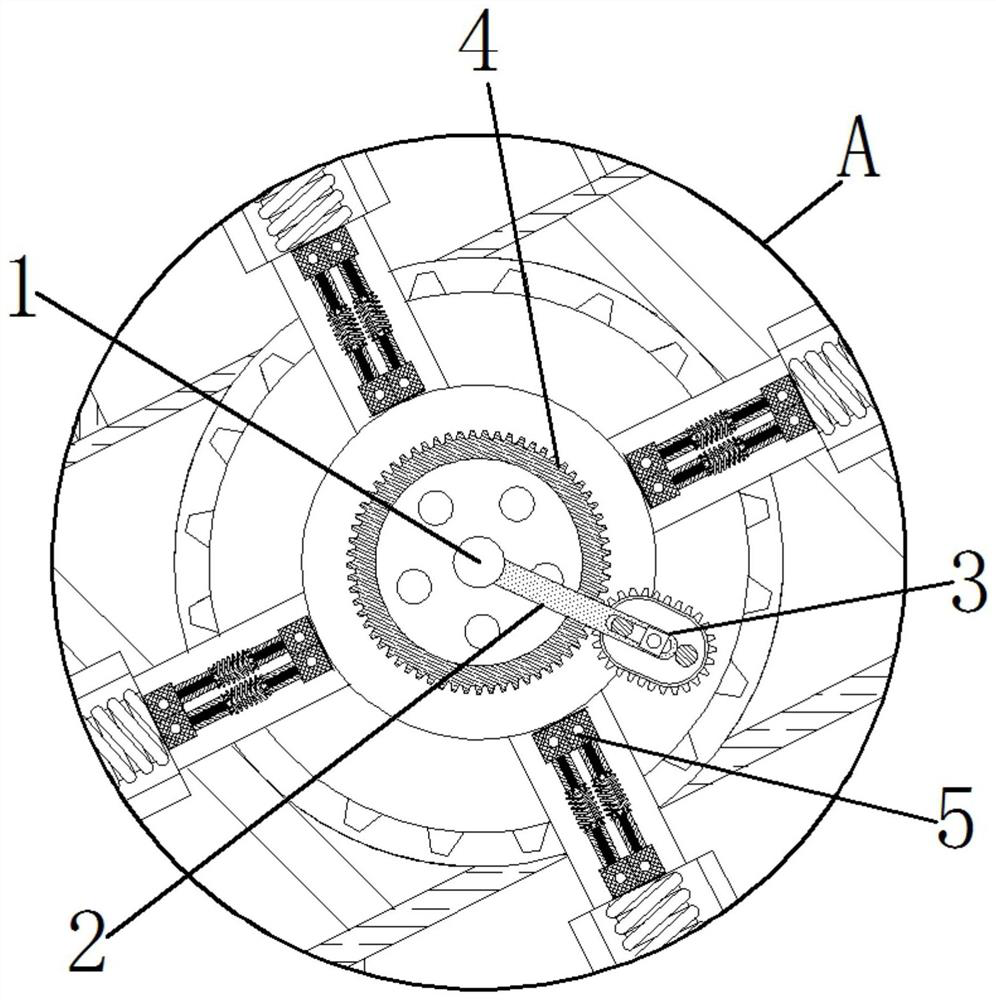

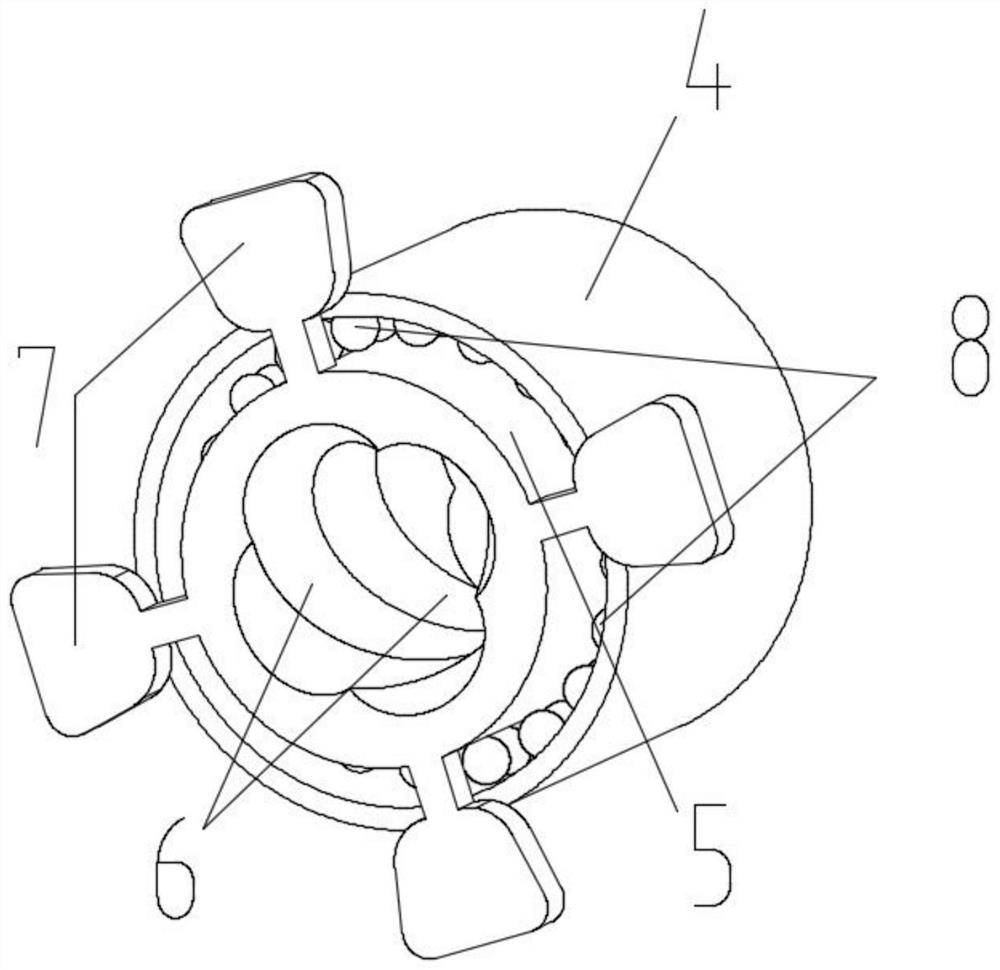

Fiber cutting knife heat dissipation equipment based on ethanol volatilization heat absorption principle

The invention relates to the technical field of fiber cutting, and discloses fiber cutting knife heat dissipation equipment based on the ethanol volatilization heat absorption principle. The fiber cutting knife heat dissipation equipment based on the ethanol volatilization heat absorption principle comprises a rotating shaft center, wherein a shaft rod is movably connected to the outer side of therotating shaft center; an abutting block is movably connected to one end, away from the rotating shaft center, of the shaft rod; an outer ring gear is engaged with the inner side of the abutting block; pushing blocks abut against the outer side of the abutting block; pushing rods are movably connected to the outer sides of the pushing blocks; reset springs are movably connected to the ends, awayfrom the pushing blocks, of the pushing rods; pushing springs are movably connected to the ends, away from the pushing rods, of the pushing blocks; pushing screws are movably connected to the outer sides of the pushing springs; and the ends, away from the pushing springs, of the pushing screws are movably connected with pressing blocks. According to the fiber cutting knife heat dissipation equipment based on the ethanol volatilization heat absorption principle, the rotating shaft center serves as a rotating base point, so that the whole equipment is driven to rotate, cutting blades continuously rotate to work, and textile fibers are cut.

Owner:南储芬

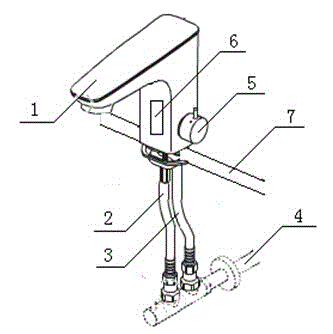

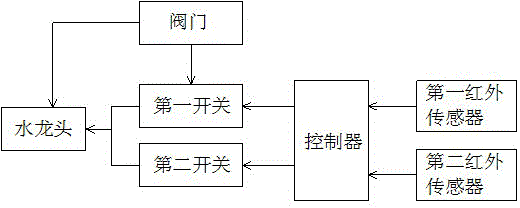

Inductive control type dual-purpose energy-saving faucet

InactiveCN104315193AOutflow controlSave waterOperating means/releasing devices for valvesMultiple way valvesTime delaysWater resources

The invention discloses an inductive control type dual-purpose energy-saving faucet. A water inlet pipe of a faucet is provided with two water inlet pipes, wherein one water inlet pipe is controlled by a manual valve and an automatic valve respectively, and the other water inlet pipe is controlled by an automatic valve; meanwhile, two sensors are arranged, one sensor is used for detecting user hand information, and the other sensor is used for detecting the information about the existence of a user; when the user is detected, the automatic valve on the water inlet pipe with the manual valve is opened, so that the user can open the faucet by virtue of the manual valve as well as the automatic valve; when the user is not detected, the automatic valve on the manual valve is closed after a time delay, so that the outflow of water in the faucet can be timely controlled to save water resources when the user forgets to close the manual valve.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

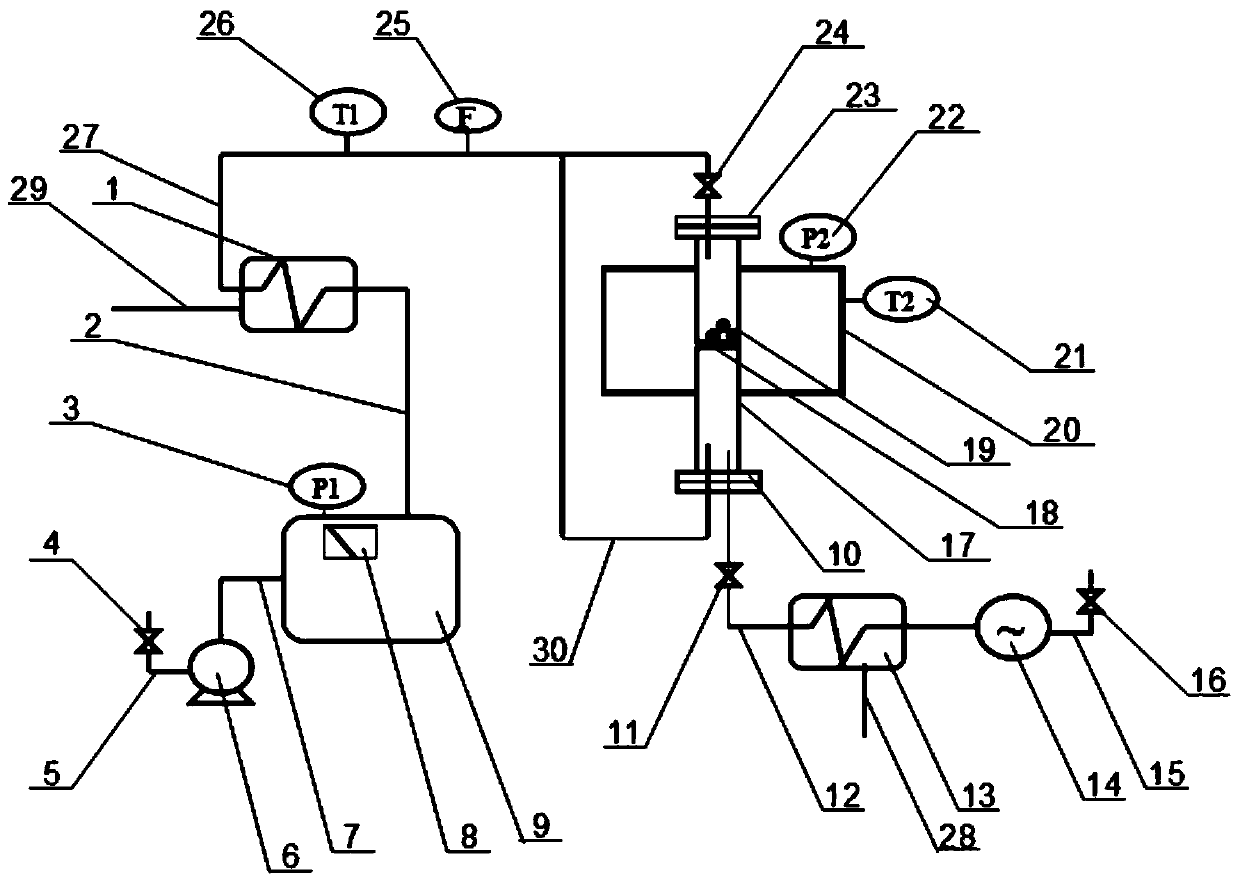

Experimental device for hydrogen production by multi-atmosphere up-and-down gas inlet gasification

InactiveCN110791323AEven contactReduce lossesHydrogen productionCombustible gas productionThermodynamicsWater vapor

The invention discloses an experimental device for hydrogen production by multi-atmosphere up-and-down gas inlet gasification, and belongs to the technical field of biomass gasification hydrogen production. The experimental device is provided with a steam generator, a steam superheater, a gasification tube, a high-temperature atmosphere furnace and a condenser which are connected to realize the purpose of producing hydrogen by gasification of biomass in various atmospheres including water vapor. According to the experimental device, multi-atmosphere superheated steam is obtained by arranging the steam superheater and a gas-distributing pipe, the multi-atmosphere superheated steam is simultaneously fed into the gasification pipe through a steam connection II and a lower gas inlet pipe, conditions for the biomass gasification reaction are provided, water vapor in products is converted into liquid water through a condenser, and hydrogen is collected. The device for hydrogen production byusing biomass gasification in a water vapor atmosphere is provided, each reaction link in the device is reasonably designed, the reaction links are compactly connected, unnecessary energy loss is reduced, and the experimental device has high application value in the technical field of biomass gasification hydrogen production.

Owner:张俊霞

Cow dung compression, dehydration and deodorization device

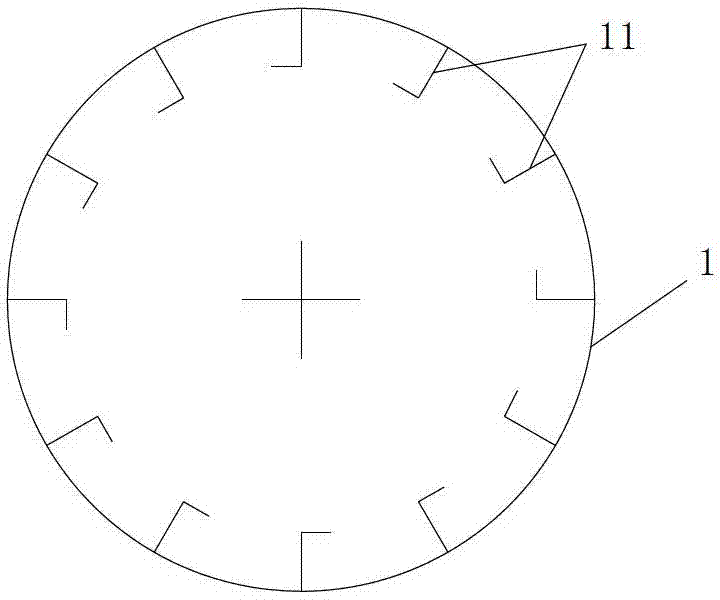

PendingCN109320042APrevent spillageOutflow controlGas treatmentSludge treatmentCircular discEngineering

The invention discloses a cow dung compression, dehydration and deodorization device. The cow dung compression, dehydration and deodorization device comprises a lower cylindrical barrel, an upper cylindrical barrel, a movable plate, a stopping block and a hollow circular disc, wherein the upper cylindrical barrel is arranged at the top of the lower cylindrical barrel; an annular clamping block isarranged at the bottom of the upper cylindrical barrel and is mutually clamped with an annular clamping groove formed in the top of the lower cylindrical barrel; a fixed circular plate is fixedly arranged in the lower cylindrical barrel; a liquid outlet pipe is arranged at a position, close to the bottom end, of a right side face of the lower cylindrical barrel; a flow limiting valve is arranged on the liquid outlet pipe. In an actual application process, the upper cylindrical barrel located on the upper layer can be screwed off and then the lower cylindrical barrel is filled with cow dung tobe located above the fixed circular plate; then the lower cylindrical barrel is fixed at the bottom of the upper cylindrical barrel; meanwhile, a T-shaped rod is pushed to downward push the hollow circular disc, so that the cow dung is compressed between the hollow circular disc and the fixed circular plate and water in the cow dung is squeezed out and leaks out from a liquid leakage hole on the fixed circular plate, and furthermore, the cow dung is dehydrated.

Owner:贵州苗家尚品生态农业发展有限公司

Air leakage detection device used for automobile connector

PendingCN108225678AOutflow controlPrevent outflowDetection of fluid at leakage pointAtmospheric pressureElectrical and Electronics engineering

The invention relates to an air leakage detection device used for an automobile connector. The device includes a connector holding mechanism, a water storage box, an air pressure cavity and an air pressure valve. The air pressure valve is mounted on an air pressure cavity. The air pressure cavity communicates with the water storage box. After the connector holding mechanism clamps the to-be-testedautomobile connector, the automobile connector is placed in water of the water storage box and the air pressure valve is opened at the same time. If the water in the water storage box bubbles, abnormity of the automobile connector is proved. Compared with the prior art, the device provided by the invention has advantages of high detection precision, operation convenient and good practicability and the like.

Owner:SHANGHAI CHIEF LAND ELECTRONICS CO LTD

Chemical plant waste residue treatment device and operation method thereof

InactiveCN109530385ATo achieve the effect of cleaning waste residueOutflow controlSolid waste disposalCleaning using liquidsChemical plantMotor drive

The invention relates to the technical field of chemical environmental protection equipment, and discloses a chemical plant waste residue treatment device. The chemical plant waste residue treatment device comprises a base, a transport frame is fixedly installed at the top of the base, a drain pipe fixedly communicates with the bottom of the transport frame, six rollers are movably connected in the transport frame in a sleeving mode, and a transport net is movably connected to the outer surfaces of the six rollers in a sleeving mode. According to the chemical plant waste residue treatment device and an operation method thereof, a motor drives a transmission gear and a fixed gear to rotate, and the fixed gear rotates to drive the rollers to rotate, so that the transport net on the rollers moves; waste residue slowly flows out of a feeding box by using a discharging pipe, so that the waste residue is tiled on the transport net, and in cooperation with spray heads on water outlet pipes, the waste residue on the transport net is cleaned; and the drain pipe discharges water flow in the transport frame, and finally the waste residue on the transport net is enabled to enter a dischargingbox by using an inclined pipe so as to achieve the role of cleaning the waste residue.

Owner:FOSHAN SITECH CHEM TECH

Device for detecting blockage of automobile connector pin hole

PendingCN111123392AEasy to put inEasy to detectGeological measurementsEngineeringStructural engineering

The invention relates to a device for detecting the blockage of an automobile connector pin hole. The device includes a fixed plate, a clamping groove is formed on the fixed plate, a pin fixing insertis embedded in the clamping groove, a pin for detection is arranged on the pin fixing insert, when the device is used, the pin for detection is inserted into a to-be-detected automobile connector pinhole, if the pin for detection can be inserted into the to-be-detected automobile connector, the to-be-detected automobile connector pin hole is not blocked, and if the pin for detection cannot be inserted into the to-be-detected automobile connector , the to-be-detected automobile connector pin hole is blocked. Compared with the prior art, the device is simple in structure, convenient to use andhigh in detection efficiency, outflow of defective products is effectively controlled, and the phenomenon of detecting whether a broken pin blocks the hole in a product only through visual inspectionis avoided. The device is convenient to operate, if a product cannot be inserted smoothly, a hole blockage phenomenon of the product can be found immediately, a defective product can be found, and outflow of the defective product is effectively avoided.

Owner:SHANGHAI CHIEF LAND ELECTRONICS CO LTD

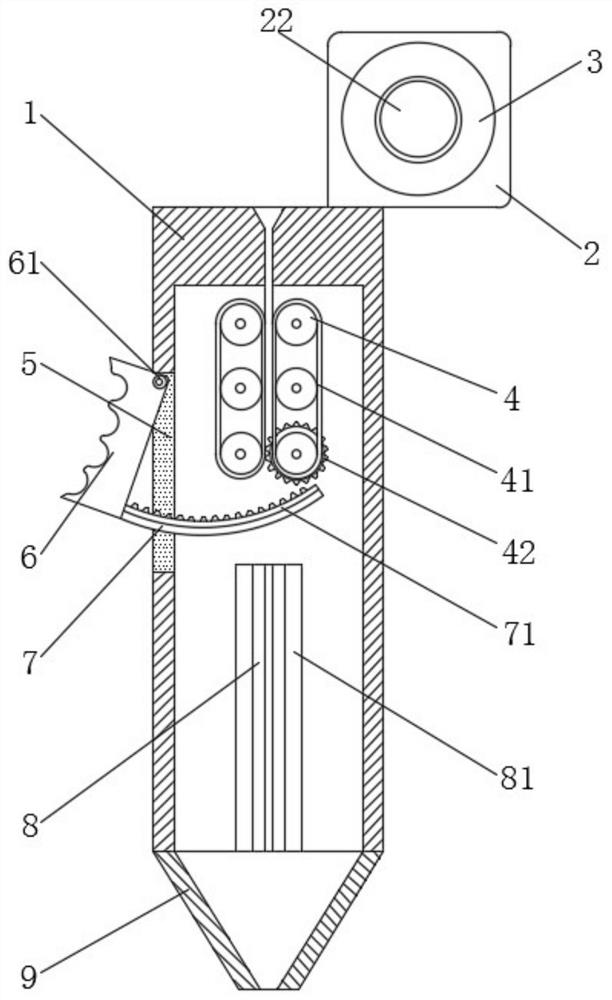

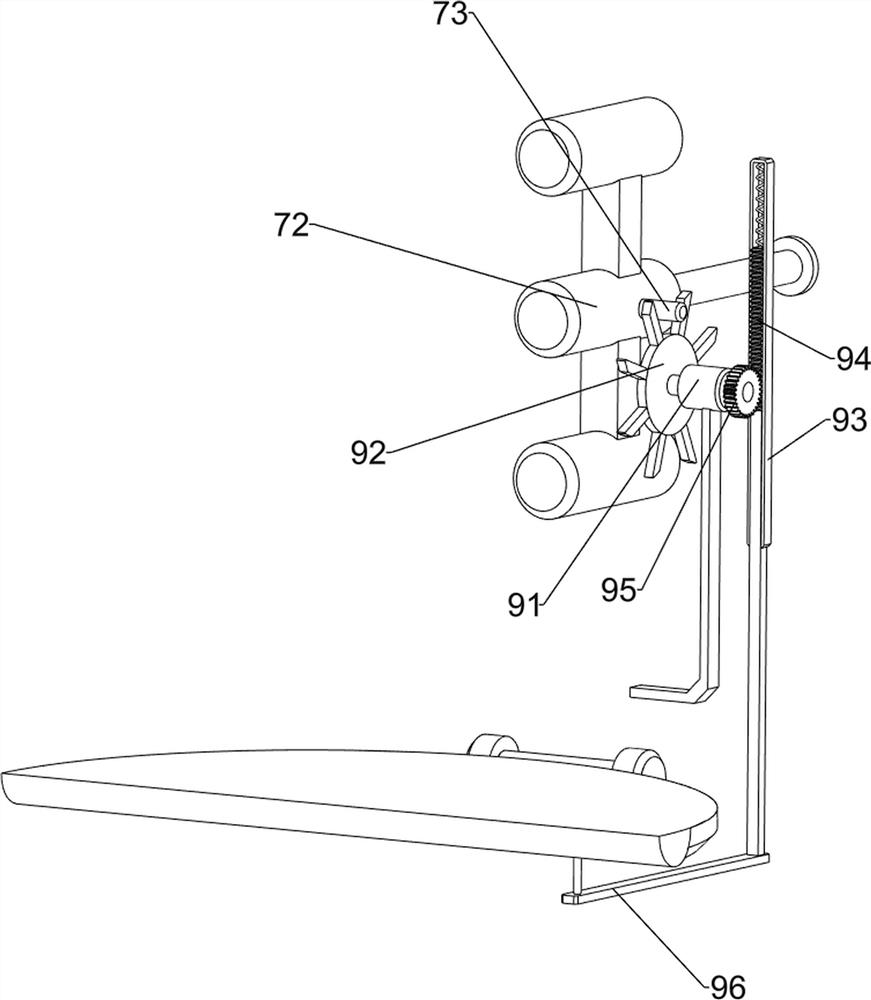

Tin soldering device and method for circuit board of intelligent home appliance

InactiveCN111805043AOutflow controlAvoid oversolderingWelding/soldering/cutting articlesMetal working apparatusGear driveGear wheel

The invention discloses a tin soldering device and method for a circuit board of an intelligent home appliance. The tin soldering device comprises a handheld barrel; a fixing frame is arranged at thetop end of the handheld barrel, and a tin bar barrel is installed in the fixing frame; a plurality of rotating rollers are arranged at the position, close to the top end, in the handheld barrel; a movable groove is formed in the outer wall of the handheld barrel, a press plate is hinged in the movable groove, and a transmission frame is fixed to the bottom end of one side of the press plate; a heating barrel is installed in the handheld barrel; a discharge port is fixed to the bottom end of the handheld barrel; a movable hole is formed in the center, right facing the side inner wall, of the fixing frame, a compression spring is installed between the inner wall, away from the opening, of the movable hole and a rotating rod, and channels are formed in the inner wall of the movable hole; theouter walls of the two sets of rotating rollers are in sleeved connection with conveyor belts, a gear is fixed to the outer wall of the rotating roller at the bottommost end in the set on the right side, and a rack is fixed to the top side of the transmission frame; and the outer wall of a shaft rod through which the press plate is hinged to the movable groove is in sleeved connection with a torsional spring. Through the cooperative use of the devices, the difficulty of getting started on spot welding can be reduced, and the situation of over-welding or false welding can be avoided.

Owner:NANJING BAIYA INTELLIGENT TECH CO LTD

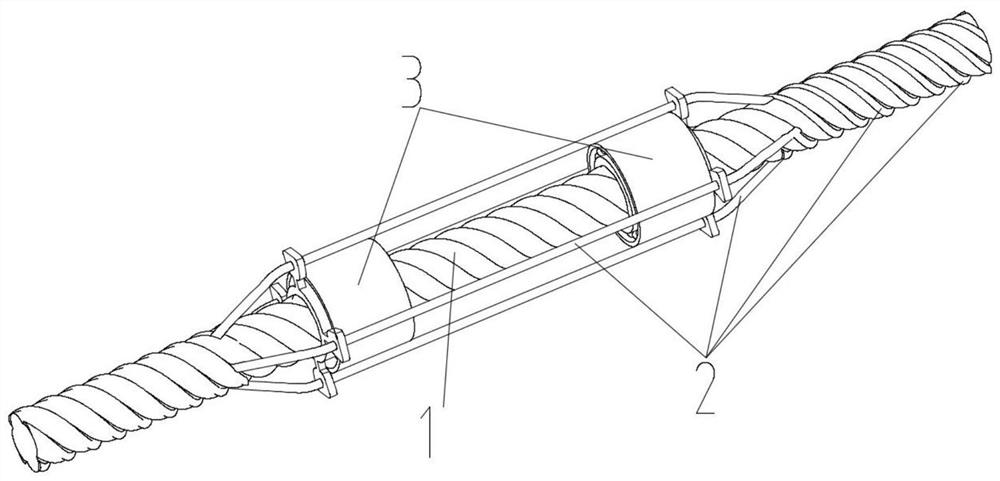

Cableway vehicle safety device

ActiveCN112319513AHigh strengthSolution to short lifeRope railwaysMarine engineeringStructural engineering

The invention discloses a cableway vehicle safety device which comprises a main steel cable, two sets of circulating winding mechanisms are arranged on the surface of the main steel cable, a maintenance sleeve is arranged between the two sets of circulating winding mechanisms, a maintenance oil mechanism and a water storage mechanism are arranged in the maintenance sleeve, and the maintenance oilmechanism is connected with the water storage mechanism through a pipeline. The main steel cable is in a twisted shape formed by twisting multiple strands of steel cables, a rotating sleeve is arranged in the circulating winding mechanism, a spiral curved surface is arranged on the inner surface of the rotating sleeve, the spiral curved surface and the main steel cable are of a matched structure,an auxiliary steel cable is wound on the surface of the main steel cable, and four sets of winding plates are evenly arranged on one side of the rotating sleeve. And the four sets of winding plates and the auxiliary steel cables are all of a matched structure, a shell is arranged outside the rotating sleeve, and balls are arranged between the rotating sleeve and the shell. The cableway vehicle safety cable maintenance device has the beneficial effects of being high in practicability and capable of maintaining the steel cables in the cableway vehicle running process.

Owner:ZHUZHOU CSR SPECIAL EQUIP TECH

Cell collection device capable of obtaining multiple samples in hematology department

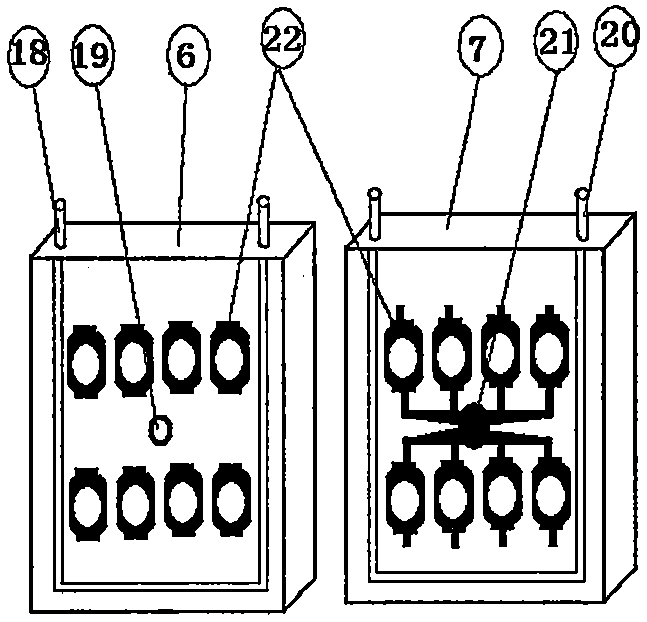

ActiveCN112980662ARealize the collectionSuction upBioreactor/fermenter combinationsBiological substance pretreatmentsMedicineTissue fluid

The invention relates to the field of medical apparatus and instruments, in particular to a cell collection device capable of obtaining multiple samples in hematology department. The cell collection device comprises four rectangular perforated groove racks, a rectangular perforated mounting frame, a grip, an inlet control assembly and the like; adjacent rectangular perforated groove racks are fixedly connected; the rectangular perforated mounting frame is fixedly connected to the rectangular perforated groove racks; the grip is fixedly connected to one side of the rectangular perforated mounting frame; and the inlet control assembly is mounted on the rectangular perforated mounting frame in a sliding mode. According to the cell collecting device, through cooperation of the rectangular hole perforated groove racks, a groove opening rectangular frame, a transmission frame, an L-shaped clamping block and devices on the L-shaped clamping block, a closed space is formed in a container when cell tissue fluid is collected; and through cooperation of a Z-shaped compression suction box of a suction assembly, the rectangular perforated groove racks, the groove opening rectangular frame and devices on the groove opening rectangular frame, pressure difference is formed in the rectangular perforated groove racks, and the cell tissue fluid on the samples is fully sucked, so that researchers can quickly collect the cell tissue fluid.

Owner:青岛市黄岛区中心医院

Park spraying device convenient to use

InactiveCN108739739AEasy to useStir wellTransportation and packagingRotary stirring mixersEngineeringOrchard

The invention discloses a park spraying device convenient to use. The device comprises a base plate. A shell is fixedly connected to the upper surface of the base plate. A bearing is clamped to the upper surface of the shell, a rotating shaft is sleeved with the bearing, the top end of the rotating shaft is fixedly connected to the upper surface of the shell through a driving device, and four stirring rods are fixedly connected to the surface of the rotating shaft. According to the park spraying device convenient to use, by arranging a motor, an output shaft of the motor rotates to drive the rotating shaft to rotate, the rotating shaft drives the stirring rods and stirring pieces to rotate, liquid medicine inside the shell can be sufficiently stirred, then, by pulling a handrail, the handrail moves to drive the shell through the base plate, a connecting block, an elastic device and a roller to move, an orchard worker does not need to carry a pesticide box on the back to spray pesticideto trees, and therefore labor intensity of the orchard worker is lowered, and the orchard worker can more conveniently spray pesticide to trees.

Owner:芜湖盛创新材料科技有限公司

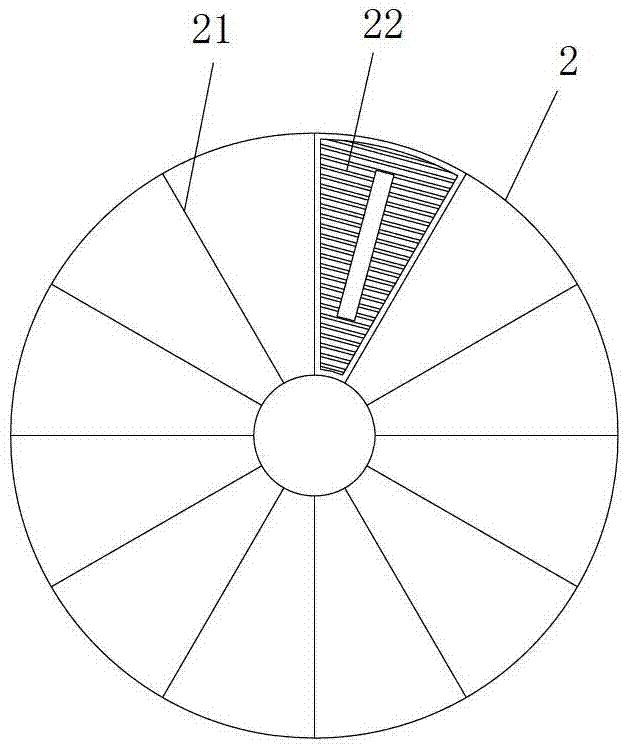

Preparation method of superfine slag powder admixture

The invention discloses a preparation method of a superfine slag powder admixture and relates to superfine slag powder. The preparation method of the superfine slag powder admixture can overcome disadvantages of the existing independent powder milling process. A dryer is adopted to dry slag; water content of the dried slag is controlled within 0.5-1.0%; a flap valve is arranged at a feed port of the dryer; the front part and the rear part of the dryer are sealed by labyrinth seal rings; a barrel of the dryer is provided with a thermal insulation layer; raising plates of the dryer are L-shaped and are centripetally and uniformly distributed; the number of the raising plates is 10-16 generally; a de-ironing separator is adopted to remove iron impurities from the dried slag; the slag is then fed into a ball mill for powder milling; and the superfine slag powder admixture is obtained.

Owner:厦门市易亨利工贸有限公司

Multi-functional iron removal device for chemical industry material

InactiveCN108043580AHas the function of dehumidification and dryingEasy to remove ironGranular material dryingDrying gas arrangementsChemical industryCoupling

The invention provides a multifunctional iron removal device for chemical industry material, and belongs to the field of chemical industry. The multifunctional iron removal device for the chemical industry material comprises an iron removal device and a dust removal drying device. The control valve is arranged on a material hopper. The right end of the upper portion of a supporting plate is fixedly provided with a driving motor. The left end of the driving motor is connected with a right bearing through a coupling. The left end of the right bearing is provided with a rotating shaft. The iron removal device is arranged on the left side of the rotating shaft. The drying device is arranged on the upper end of the right side of a processing box. The upper end of a dust collecting box is connected with a suction fan by a dust suction pipe. Magnetic rods are arranged on connecting rods through fixing blocks, the magnetic rods on the connecting rods of each group are arranged in a staggered mode, so that the function of removing the iron from the material conveniently is achieved; the right end of a blower is connected with a heater by an air inlet pipe, the right end of the heater is provided with a filter, so that the function of removing fresh and hot air into the processing box to the dehumidification and drying of the material is achieved; and the multifunctional iron removal device for the chemical industry material has the characteristics of simple structure, strong practicability and good iron removal effect.

Owner:长沙德科投资管理咨询有限公司

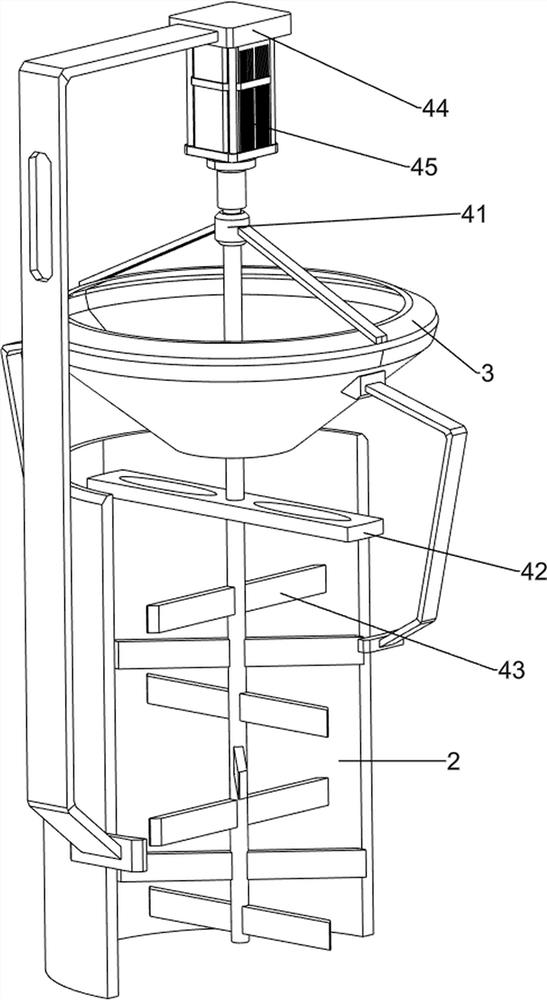

Rare earth purification equipment for rare earth collection

ActiveCN113481392AImprove the distillation effectPrevent Rare Earth WasteProcess efficiency improvementElectric machineryProcess engineering

The invention relates to rare earth purification equipment, in particular to rare earth purification equipment for rare earth collection. The invention provides rare earth purification equipment for rare earth collection. The equipment is large in distillation contact area and capable of comprehensively taking out rare earth. The rare earth purification equipment for rare earth collection comprises a bottom frame, a heating barrel and a hopper, wherein the heating barrel is arranged on the bottom frame, the hopper is arranged on the heating barrel, a stirring mechanism is arranged on the heating barrel, and a discharging mechanism is arranged on the lower portion of the heating barrel. By arranging the stirring mechanism and the discharging mechanism, the discharging mechanism can control distilled rare earth to flow out, the stirring mechanism can uniformly stir the rare earth, and the effect of improving the rare earth distillation effect is achieved; by arranging the feeding mechanism and the vibration mechanism, as the hopper is located below the first motor, rare earth can be poured into the feeding mechanism more conveniently, the vibration mechanism can knock off the rare earth left on the inner wall of the heating barrel in a vibration mode, so that the purpose of preventing rare earth waste is achieved.

Owner:王鲜

Automatic grain thrower for farm

ActiveCN109550691AExtension of timeOutflow controlSievingGas current separationAgricultural engineeringImpurity

The invention discloses an automatic grain thrower for a farm. The automatic grain thrower for the farm comprises a machine frame, the right end of the machine frame is movably connected with a spiralconveying device, and a blower device is rotatably connected to the lower right side of the machine frame; a first motor is arranged on the left side of the blower device, and the left side of the blower device is fixedly connected with a first blast pipe; a screening device is fixedly connected to the left end of the first blast pipe, a funnel is arranged at the top of the screening device, a distributing device is arranged under the screening device, and packing devices are arranged on the front side and the rear side of the distributing device; the screening device comprises a screening device body, and the left side and the right side of the inner part of the screening device body are correspondingly and fixedly connected with flow limiting plates and filtering sieves; rectangle openings are formed in the positions under the filtering sieves, rollers are arranged on the upper parts of the positions between the flow limiting plates and the filtering sieves, and the front ends and the rear ends of the rollers are rotatably connected with the inner part of the screening device body. When the automatic grain thrower is used, impurities can be separated from grains fully, and meanwhile the separated grains can be packed and the separated impurities can be subjected to automatic extrusion and collection.

Owner:张家界数字乡村有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com