Running-in device of hydraulic operating mechanism used for high-pressure SF6 breaker

A technology of hydraulic operation and circuit breaker, applied in the direction of protection switch operation/release mechanism, high voltage/high current switch, circuit, etc., can solve the problem of inaccurate simulation of opening and closing load changes, and insufficient influence ability of exhaust hole damping changes , Inability to quickly adjust the opening and closing load, etc., to achieve the effect of fast implementation, shortening the installation and testing time, and improving the efficiency and quality of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

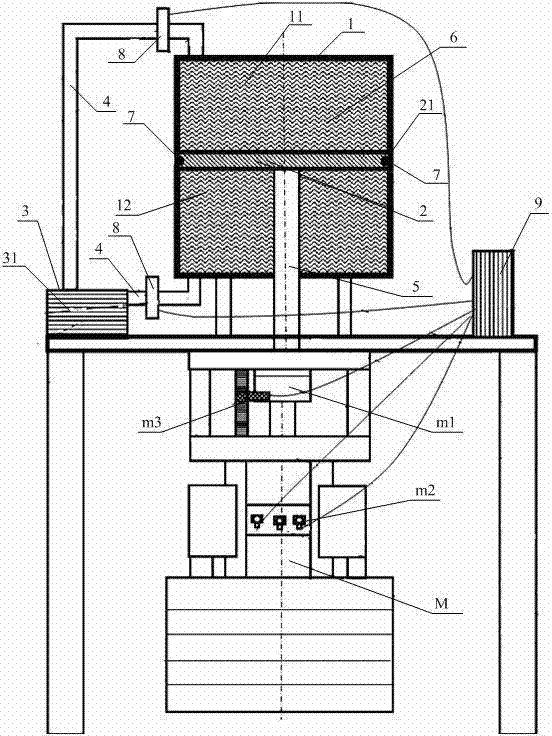

[0042] like figure 1 As shown, in the embodiment of the present invention, a kind of running-in device for the hydraulic operating mechanism on the high-voltage SF6 circuit breaker proposed, which cooperates with the hydraulic operating mechanism M on the high-voltage SF6 circuit breaker, including:

[0043] Fully enclosed cylindrical box 1;

[0044] The piston 2 embedded in the box body 1, the outer surface 21 of the piston 2 abuts against the inner wall of the box body 1, and separates the box body 1 into an upper cavity 11 and a lower cavity 12 that are not connected to each other;

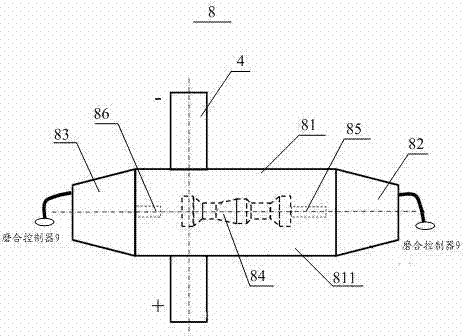

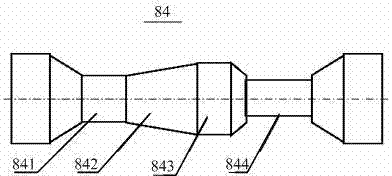

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com