Dyeing fat liquoring equipment for leather dyeing machining

A leather and equipment technology, applied in the field of leather dyeing and fatliquoring equipment, can solve the problems of low fatliquoring efficiency and achieve efficient and convenient fatliquoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

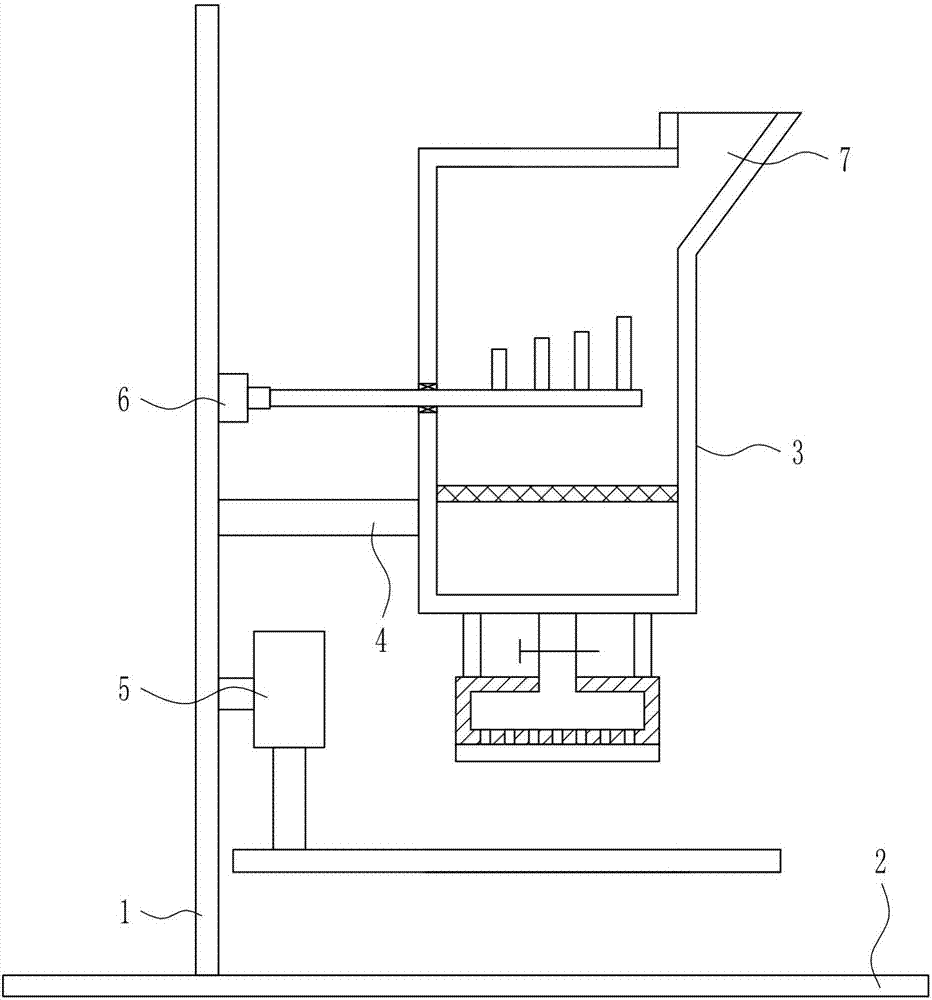

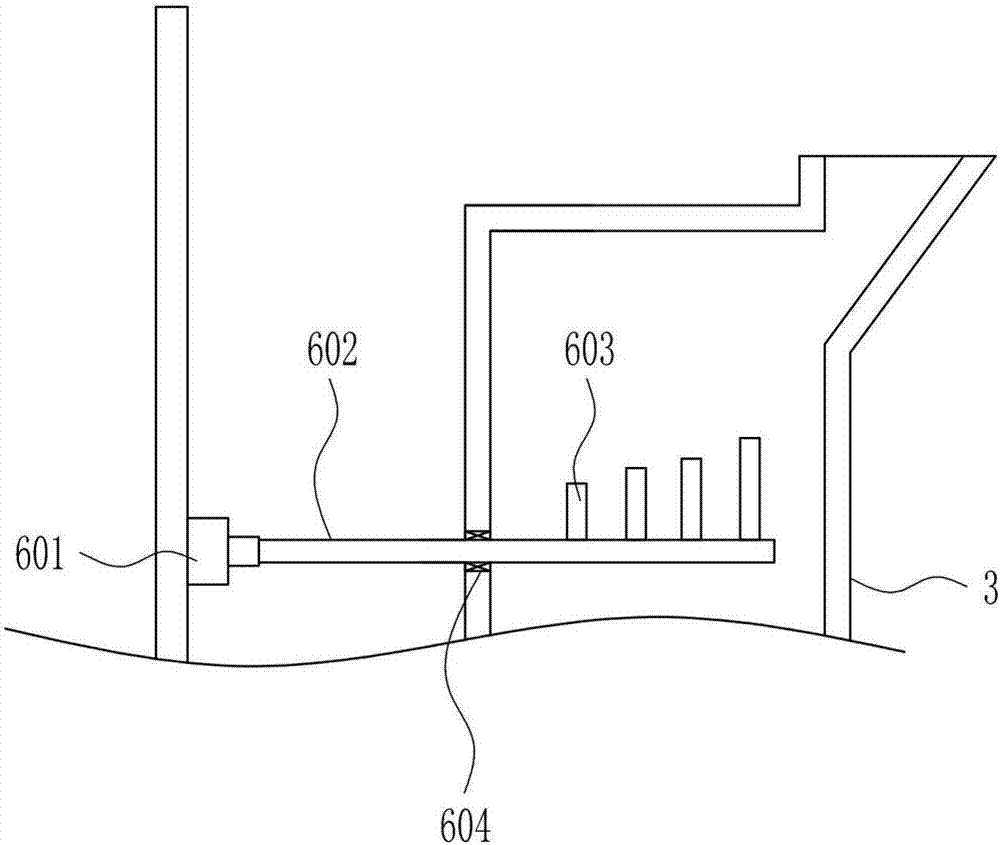

[0039] A kind of dyeing and fatliquoring equipment for leather dyeing and processing, such as Figure 1-8 As shown, it includes a left support 1, a bottom plate 2, a processing box 3, a support rod 4, a fat dipping device 5 and a stirring device 6. The left support 1 is arranged on the left side of the top of the bottom plate 2, and the right side of the left support 1 is from top to bottom. A stirring device 6, a pole 4 and a fat dipping device 5 are arranged in sequence, a processing box 3 is arranged at the right end of the pole 4, an inlet 7 is opened on the right side of the top of the processing box 3, and the processing box 3 is connected with the stirring device 6.

Embodiment 2

[0041] A kind of dyeing and fatliquoring equipment for leather dyeing and processing, such as Figure 1-8 As shown, it includes a left support 1, a bottom plate 2, a processing box 3, a support rod 4, a fat dipping device 5 and a stirring device 6. The left support 1 is arranged on the left side of the top of the bottom plate 2, and the right side of the left support 1 is from top to bottom. A stirring device 6, a pole 4 and a fat dipping device 5 are arranged in sequence, a processing box 3 is arranged at the right end of the pole 4, an inlet 7 is opened on the right side of the top of the processing box 3, and the processing box 3 is connected with the stirring device 6.

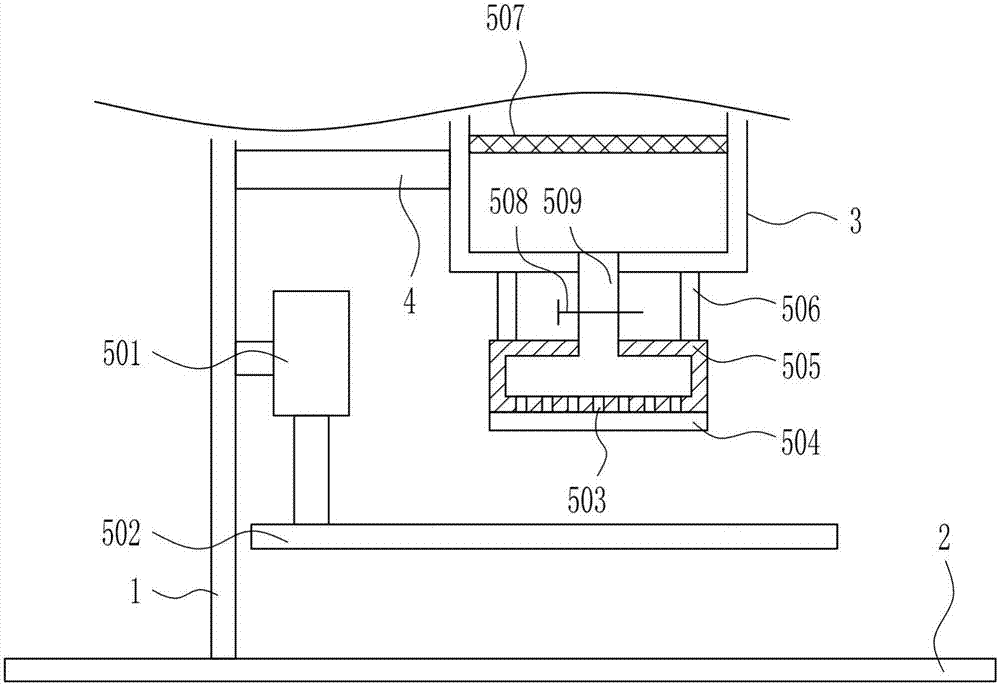

[0042] The fat dipping device 5 includes an electric push rod 501, a placement plate 502, a sponge 504, a buffer box 505, a fixed rod 506, a second filter screen 507, an electric control valve 508 and a discharge pipe 509, and an electric push rod 509 is arranged on the right side of the left support 1. Th...

Embodiment 3

[0044] A kind of dyeing and fatliquoring equipment for leather dyeing and processing, such as Figure 1-8 As shown, it includes a left support 1, a bottom plate 2, a processing box 3, a support rod 4, a fat dipping device 5 and a stirring device 6. The left support 1 is arranged on the left side of the top of the bottom plate 2, and the right side of the left support 1 is from top to bottom. A stirring device 6, a pole 4 and a fat dipping device 5 are arranged in sequence, a processing box 3 is arranged at the right end of the pole 4, an inlet 7 is opened on the right side of the top of the processing box 3, and the processing box 3 is connected with the stirring device 6.

[0045] The fat dipping device 5 includes an electric push rod 501, a placement plate 502, a sponge 504, a buffer box 505, a fixed rod 506, a second filter screen 507, an electric control valve 508 and a discharge pipe 509, and an electric push rod 509 is arranged on the right side of the left support 1. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com