Tin soldering device and method for circuit board of intelligent home appliance

A circuit board and soldering technology, which is applied in the field of circuit board soldering devices for smart home appliances, can solve the problems that the amount of solder cannot be well controlled, it is difficult to get started, and circuit boards are prone to false soldering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

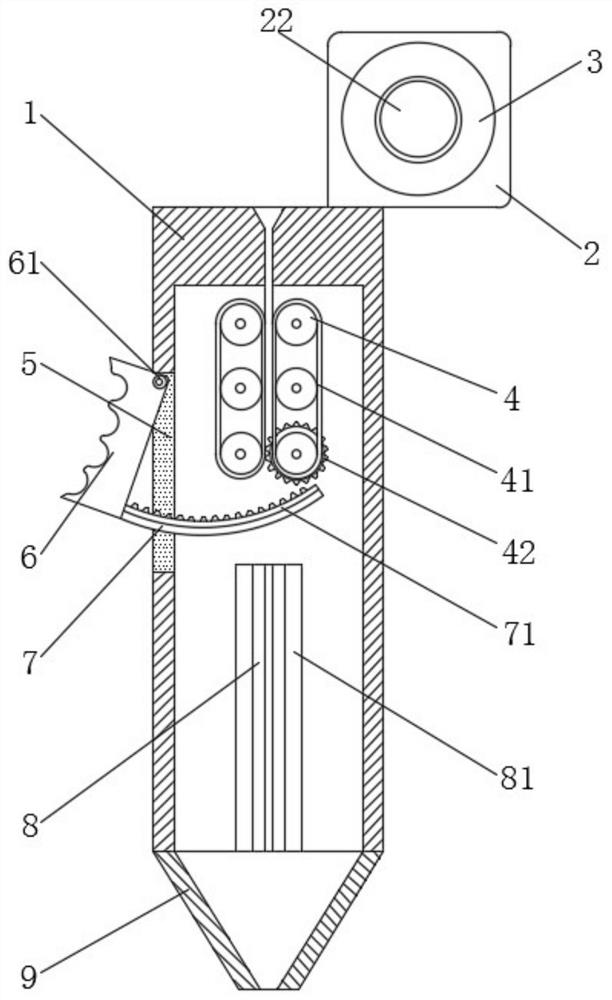

[0021] see Figure 1-2 , the present embodiment provides a circuit board soldering device for smart home appliances, including a hand-held tube 1, a fixing frame 2 with a U-shaped structure is arranged on the top of the holding tube 1, a tin bar tube 3 is installed inside the fixing frame 2, and the holding tube 1. A plurality of rotating rollers 4 are arranged near the top. The outer wall of the hand-held tube 1 is provided with a movable groove 5. The inside of the movable groove 5 is hinged with a pressing plate 6. The bottom end of the pressing plate 6 close to the inner side of the handheld tube 1 is fixed. There is a transmission frame 7, a heating cylinder 8 is installed near the bottom end of the hand-held tube 1, and a discharge port 9 is fixed at the bottom of the hand-held tube 1, and the top of the discharge port 9 extends into the inside of the hand-held tube 1 and is connected with the heating tube 1. The bottom end of cylinder 8 is fixed.

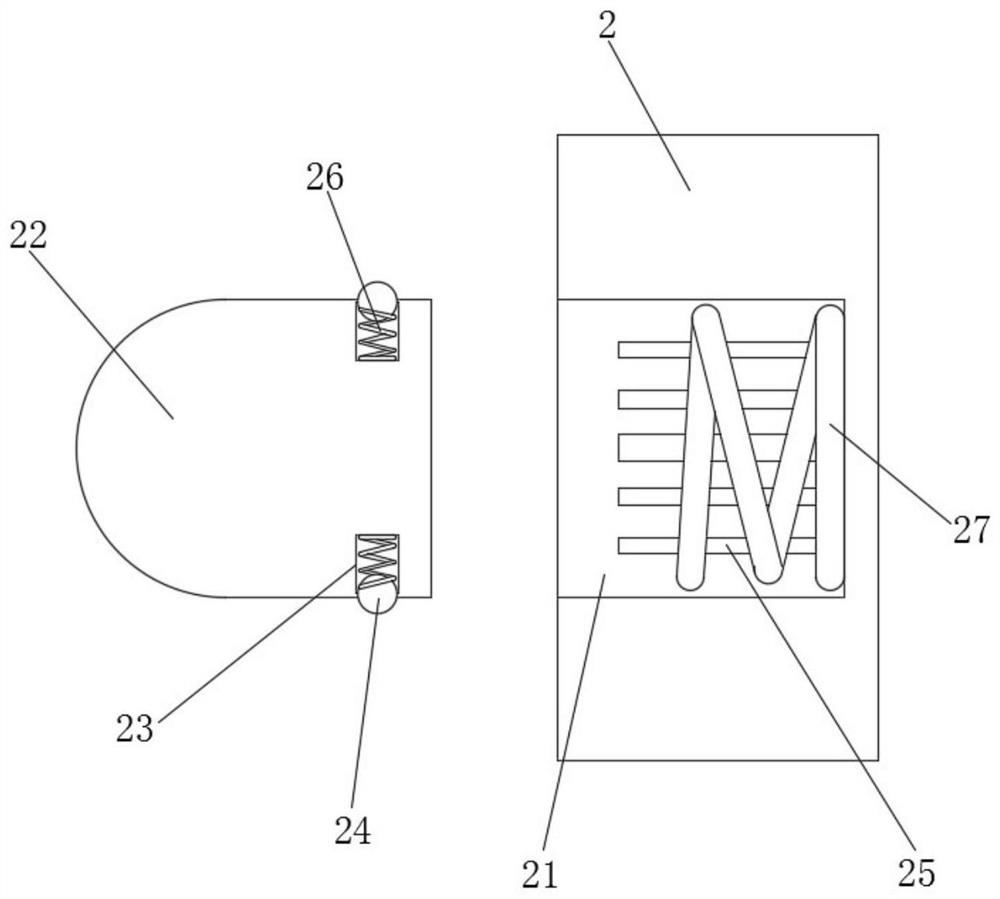

[0022] Fixed frame 2...

Embodiment 2

[0031] see figure 1 , made further improvement on the basis of Embodiment 1: the rotating roller 4 is a waist drum structure, the top view of the transmission frame 7 is a U-shaped structure, the top side of the transmission frame 7 is fixed with a rack 71, and the rack 71 and the gear 42 Mesh, through the U-shaped transmission frame 7 can make the force of the roller 4 more balanced, can make the roller 4 rotate more smoothly, and the drum-shaped roller 4 can increase the contact area with the outer wall of the tin bar, so that the tin bar The transfer inside the handheld tube 1 is smoother.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com