Preparation method of superfine slag powder admixture

A technology of slag micropowder and admixture, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. Drying thermal efficiency, improving spreading uniformity, preventing cold air from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preparation method of the slag micropowder admixture described in the embodiment of the present invention comprises the following steps:

[0027] 1) Selection of raw materials, the raw materials are selected from the slag of Jiangxi Xinyu Steel Plant.

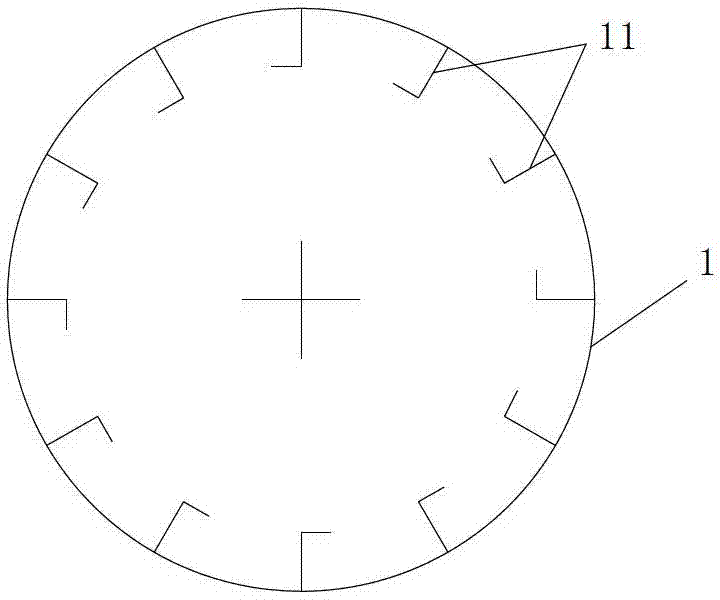

[0028] 2) Drying of raw materials, using a dryer to dry the slag, the moisture content of the slag after drying is controlled at 0.5% to 1.0%; the feed port of the dryer is equipped with a flap valve, and the front and rear of the dryer are sealed Both use labyrinth seal rings, and the cylinder of the dryer is equipped with an insulation layer. The inner wall of the dryer barrel 1 is provided with 12 "L" shaped lifting plates 11, and each lifting plate 11 is evenly distributed centripetally. The bending angle of the lower end of the "L"-shaped lifting plate 11 can be optimized in depth according to the actual situation, and the effect can be better (see figure 1 ).

[0029] 3) Iron removal, using an iron remover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com