Mixing device and mixing method

A mixing device and mixing technology, which are applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of low mixing efficiency and uneven mixing, and achieve high mixing efficiency, sufficient mixing, and high mixing efficiency. To achieve the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

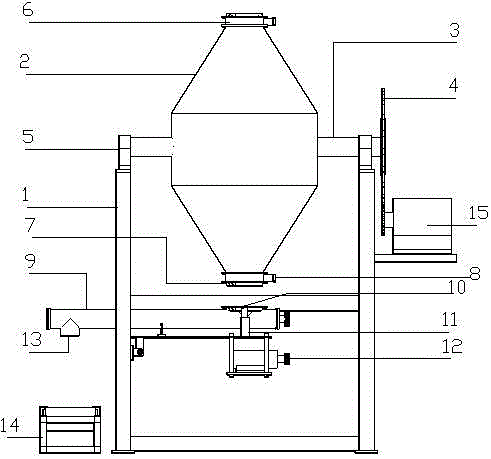

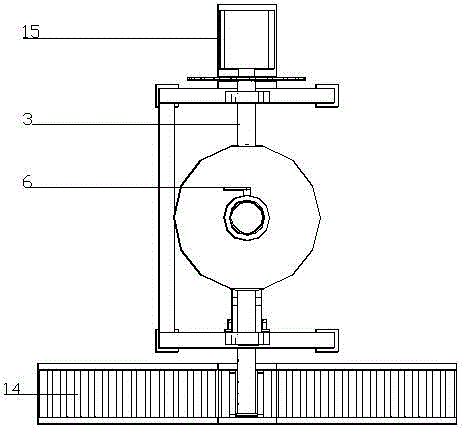

[0022] As shown in the figure: a mixing device, including vertical brackets 1 on both sides, a mixing tube 2 and a driving device, a rotating shaft 3 runs through the center of the mixing tube, and two ends of the bracket 1 are provided with supports for supporting the rotating shaft bearing housing. A driving device is installed on the platform at one side of the support 1, and is connected with the rotating shaft through a pair of gears 4 meshing with each other. A through hole is provided at the center of one end of the rotating shaft 3 as a protective gas inlet 5 . A handle-type wafer butterfly valve 6 is provided at the feed inlet on the top of the mixing barrel 2, and the material is added by controlling the opening of the butterfly valve. A fixed flange 7 is provided at the bottom outlet of the mixing barrel 2, and the opening and closing of the fixed flange 7 is controlled by a valve 8 on one side. A discharge pipe 9 is arranged below the fixed flange 7, a movable fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com