A composite packaging film for aluminized and printed cigarettes and its preparation method

A composite packaging film, printing and packaging technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of reduced heat-sealing performance of the printing surface, no heat-sealing performance, and weak functionality , to achieve the effect of reducing the initial temperature of heat sealing, avoiding scratches and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

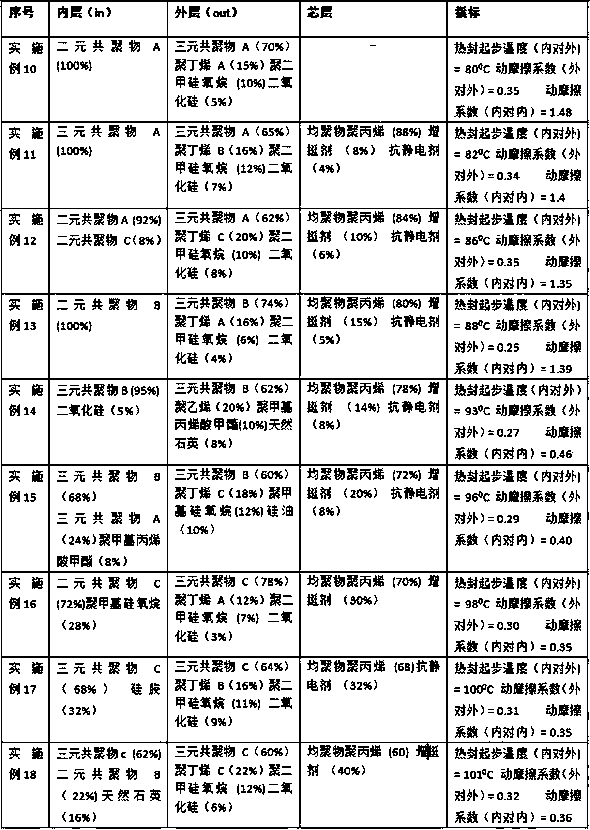

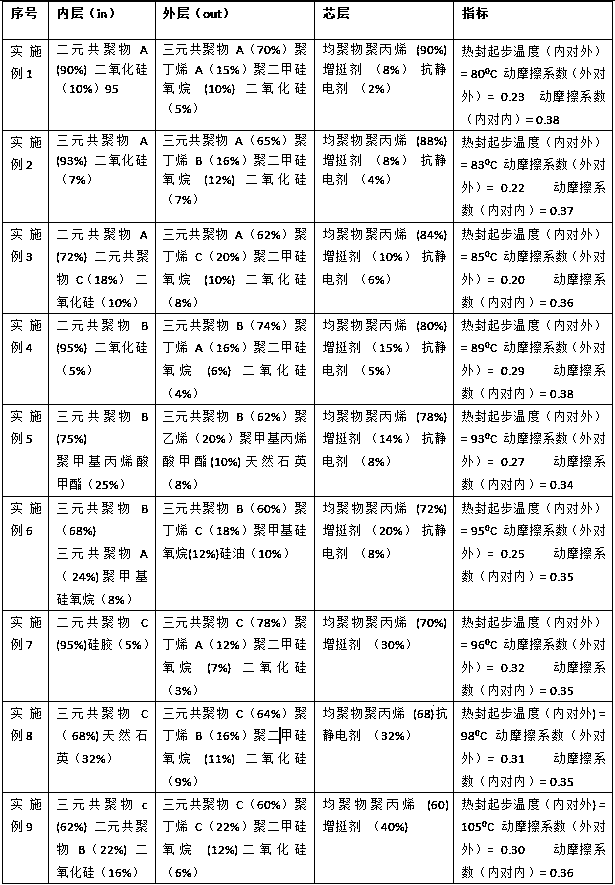

Examples

preparation example Construction

[0027] The preparation method of the composite packaging film for aluminized and printed cigarettes of the present invention comprises the following steps:

[0028] A. Preparation of printed packaging film: adopt multi-layer co-extrusion polypropylene biaxial stretching preparation process and polypropylene film gravure printing processing technology, and use inner printing to prepare, wherein the longitudinal stretching temperature is 60-130 °C, and the transverse stretching temperature The temperature is 100-175°C, the extruder temperature is 200-250°C, and the draw ratio is 4-10;

[0029] B. Preparation of aluminum-coated packaging film: It is prepared by multi-layer co-extrusion polypropylene biaxial stretching preparation process and polypropylene film vacuum aluminum plating process, wherein the longitudinal stretching temperature is 60-130 ° C, and the transverse stretching temperature is 100 ~175℃, extruder temperature 200~250℃, draw ratio 4~10; vacuum degree 1.3×10 -...

Embodiment 19

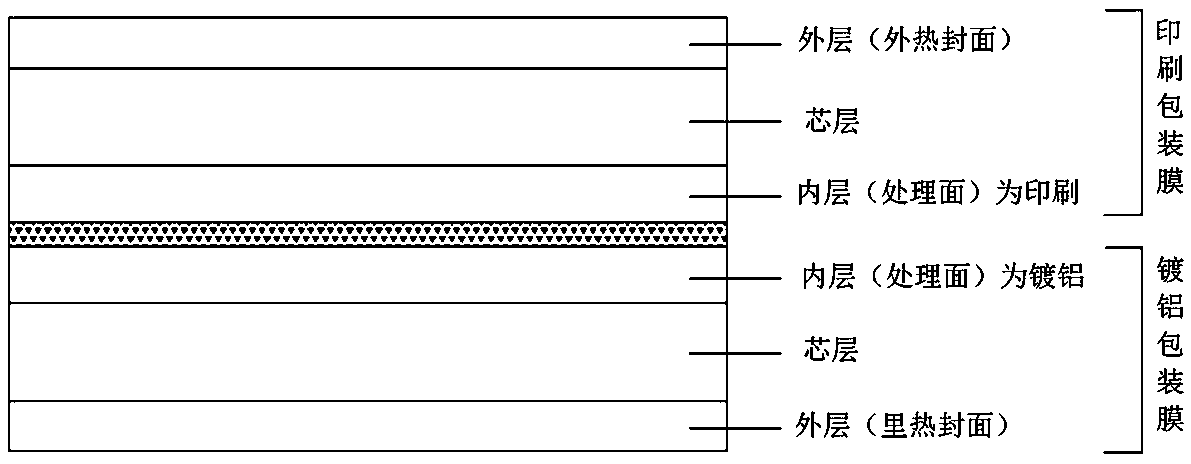

[0038] The printed packaging film includes an inner layer, an outer layer and a core layer arranged between the inner and outer layers, the core layer includes homopolymer polypropylene, hydrocarbon resin and masterbatch; the outer layer is heat-sealed Layer, the heat-sealing layer contains main material and additives, the main material is polypropylene copolymer, the additive is polybutene, silicon dioxide; the inner layer is the printing layer, the The printing layer contains main material and additives, the main material is polypropylene copolymer, and the additive is silicon dioxide.

[0039] The aluminized packaging film includes an inner layer, an outer layer and a core layer arranged between the inner and outer layers, the core layer comprises polypropylene homopolymer, hydrocarbon resin and masterbatch; the outer layer is heat-sealed Layer, the heat-sealing layer contains main material and additives, the main material is polypropylene copolymer, the additive is polyeth...

Embodiment 20

[0041] The printed packaging film includes an inner layer, an outer layer and a core layer arranged between the inner and outer layers, the core layer includes homopolymer polypropylene, hydrocarbon resin and masterbatch; the outer layer is heat-sealed Layer, the heat-sealing layer contains main material and additives, the main material is binary copolymer A, the additive is polyethylene, natural quartz; the inner layer is the printing layer, the printing The layer includes main material and additives, the main material is terpolymer B, and the additive is silica gel.

[0042] The aluminized packaging film includes an inner layer, an outer layer and a core layer arranged between the inner and outer layers, the core layer comprises polypropylene homopolymer, hydrocarbon resin and masterbatch; the outer layer is heat-sealed Layer, the heat-sealing layer contains main material and additives, the main material is terpolymer B, the additive is polyethylene, natural quartz; the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com