Patents

Literature

44results about How to "Printable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screen inner rupture-proof film, and preparation method thereof

ActiveCN106244037AProtect electronic componentsPrintableNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryImpressionability

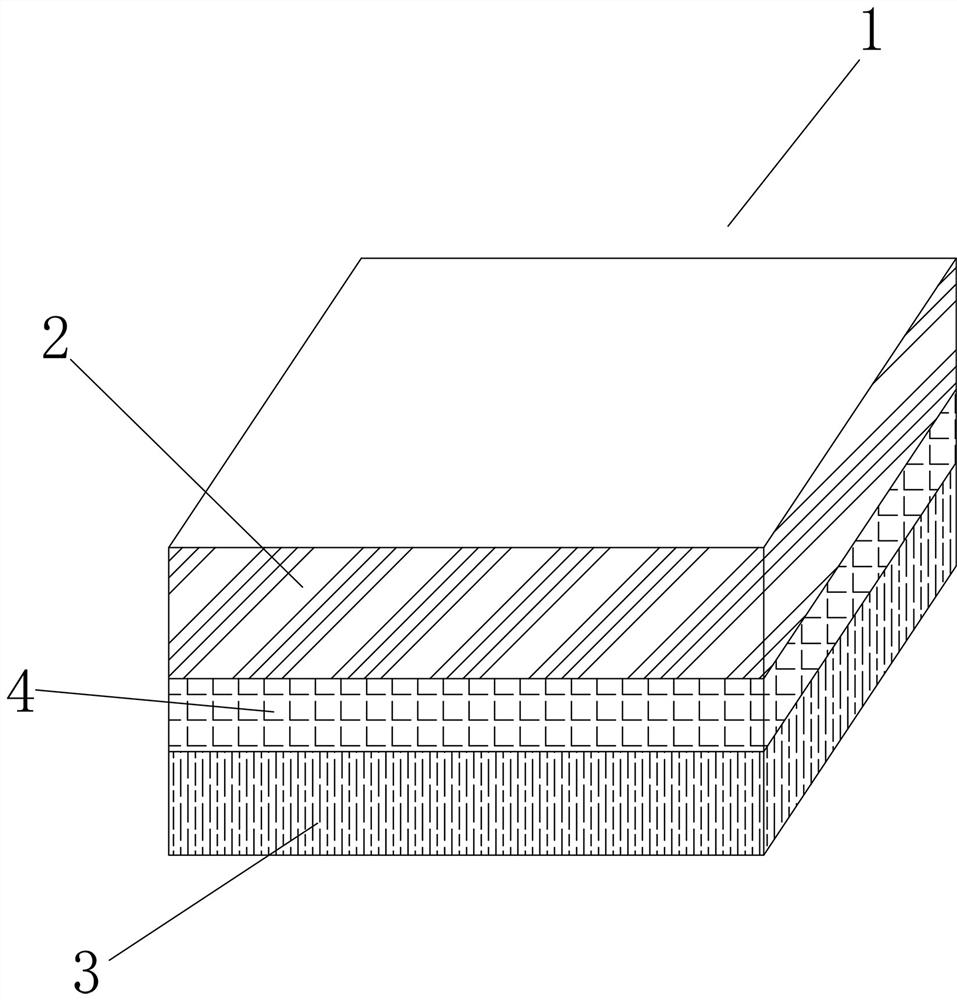

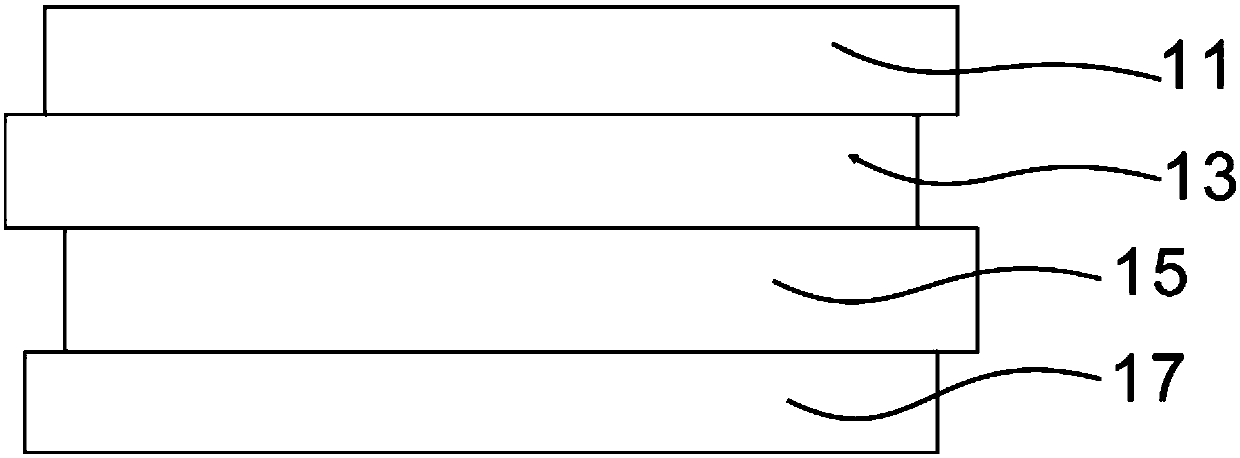

The invention discloses a screen inner rupture-proof film, and a preparation method thereof. The screen inner rupture-proof film is adhered to the inner surface of a screen glass cover plate so as to realize protection of the screen. The screen inner rupture-proof film comprises a base material; one surface of the base material is coated with a UV varnish adhesive layer, and the other surface of the base material is coated with an acrylic adhesive layer; the other surface of the acrylic adhesive layer is coated with a release film; the thickness of the base material ranges from 20 to 100<mu>m, and the base material is prepared from one ingredient selected from PET, OPP, and PE; the release film is a PET release film with a thickness ranging from 50 to 150<mu>m; and the release force ranges from 3 to 20gf. According to the preparation method, one surface of the screen inner rupture-proof film is provided with the UV vanish adhesive layer, so that the screen inner rupture-proof film possesses impressionability, the screen inner rupture-proof film is printed with the shape and the appearance of the screen, and then the screen inner rupture-proof film adhered to the inner surface of the screen glass cover plate. The visual effect of the screen is seldom influenced because that the light-admitting quality of the screen inner rupture-proof film is high, and the screen inner rupture-proof film is printed with the shape and the appearance of the screen, and at the same time protection effect on the screen and electronic components in the screen is realized.

Owner:NALI OPTICAL MATERIAL DONGGUAN

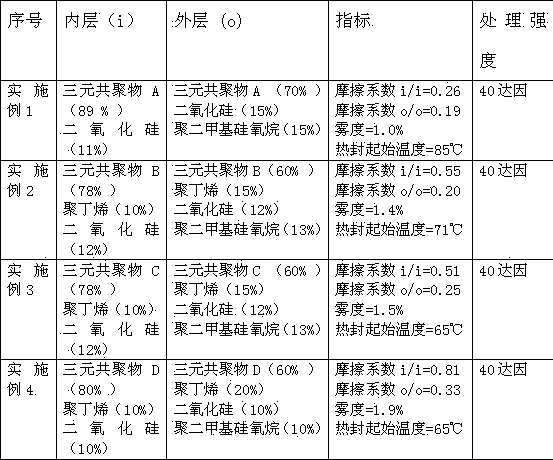

Printable double-faced heat sealing film, preparation method and application thereof

InactiveCN104527188AWith double-sided heat sealing performancePrintableFlexible coversWrappersMedium-density polyethyleneEthylene

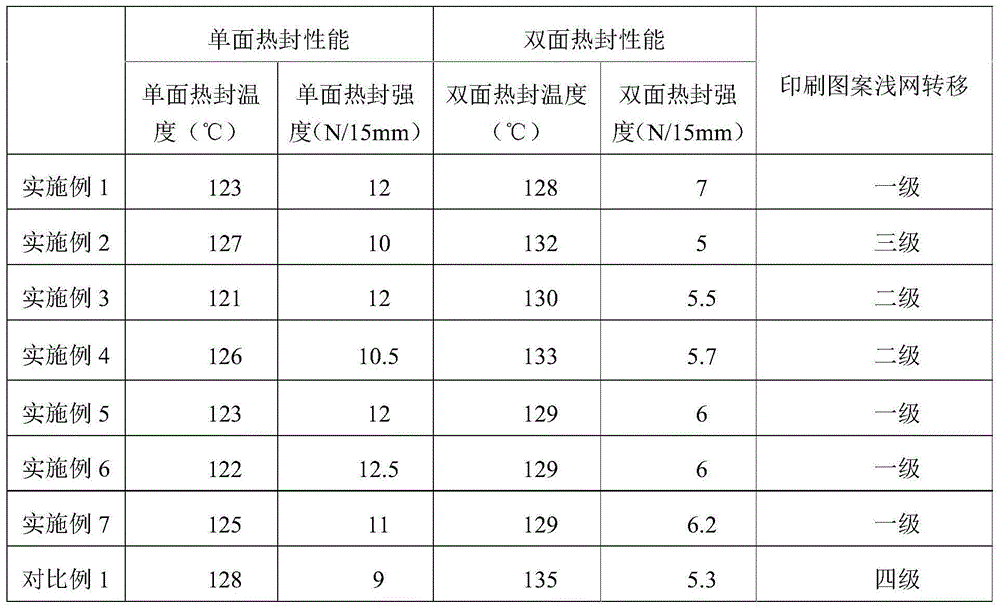

The invention provides a printable double-faced heat sealing film, a preparation method and an application thereof. The film sequentially comprises an outer layer, a middle layer and an inner layer, wherein the outer layer comprises the following raw materials in percentage by weight: 50-70% of first linear low density polyethylene, 15-25% of first low density polyethylene and 15-25% of first metallocene linear low density polyethylene; the middle layer comprises the following raw materials in percentage by weight: 70-80% of second linear low density polyethylene and 20-30% of medium density polyethylene; the inner layer comprises the following raw materials in percentage by weight: 40-60% of third linear low density polyethylene, 18-30% of second low density polyethylene and 18-30% of second metallocene linear low density polyethylene. The film has good double-faced heat sealing property. Meanwhile, after the resin materials in the layers of the thin are reasonably matched, the film further has printability.

Owner:ZHEJIANG CHENGDE PACKAGING

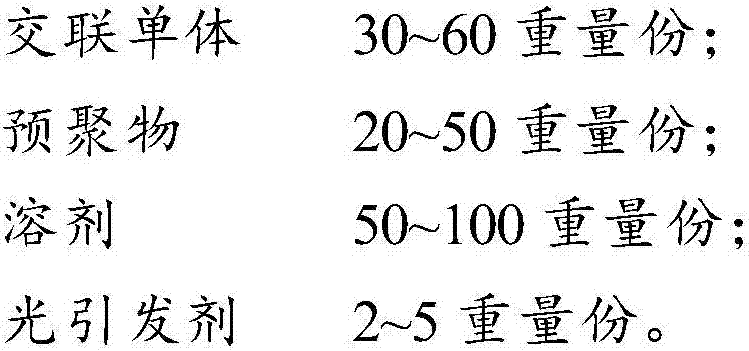

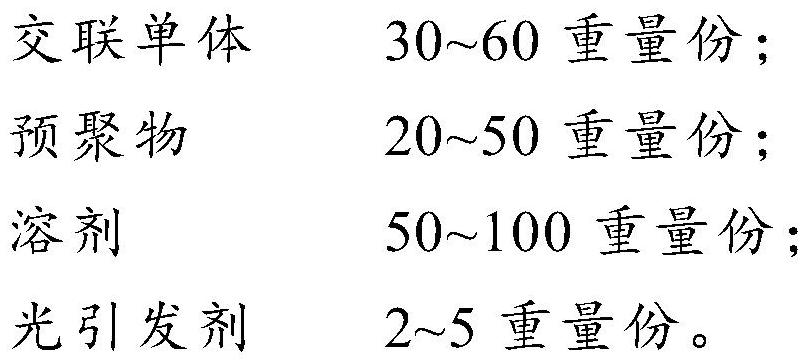

Method for preparing transparent hardening coat on surface of plastic plate

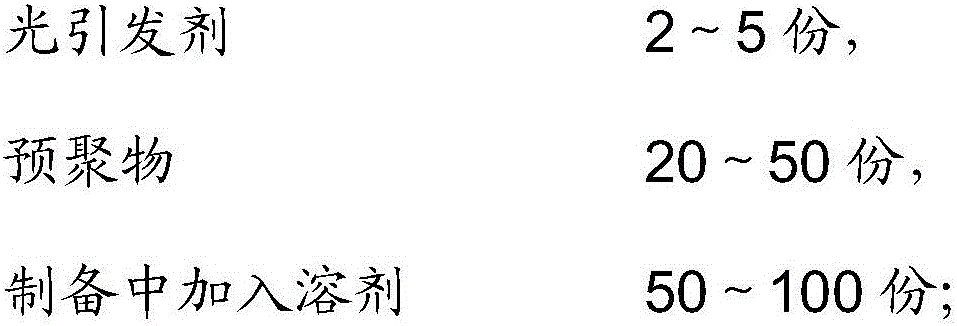

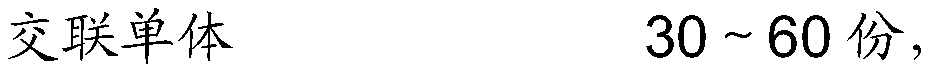

The invention discloses a method for preparing a transparent hardening coat on the surface of a plastic plate, using curtaining film making and UV radiation curing method, the steps are as follows: using acrylate oligomers, acrylic acid ester monomer and organic solvent, photoinitiator and auxiliary agent to prepare photo-cured coating; cleaning the surface of the plastic sheet; curtaining the photo-cured coating on the surface of the plastic sheet; naturally levelling the wet film on the plastic plate, then roasting and cooling; and curing the wet film on the plastic plate by UV to form transparent hardening coat. The method of the invention is simple, uses the curtaining method to form film, has low requirements on equipment and technology, and can be easily achieved on various plastic base materials, therefore, the surface of the obtained coat is transparent and smooth, the penetration is high, and the hardness can be enhanced by 6-8 levels than original sheets. The obtained hardening coat has excellent performances of impressionability, engravable and processable properties, film coating property, and the like, thereby being benefit for better protecting plastic base materials, and being adapted to the new developments of electronic products, electrical appliances and digital products.

Owner:杭州博纳特光电科技有限公司

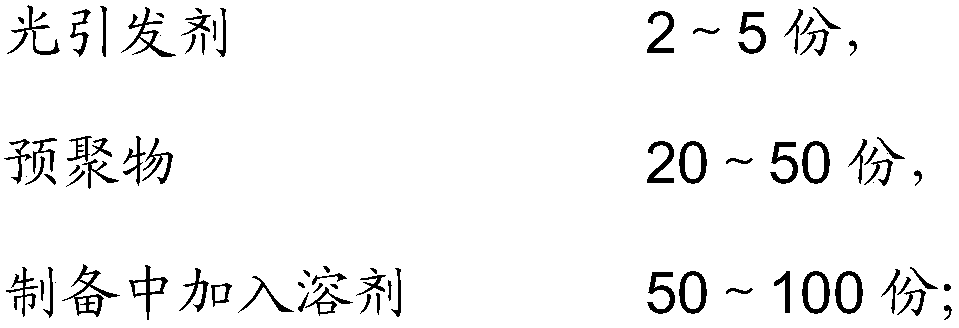

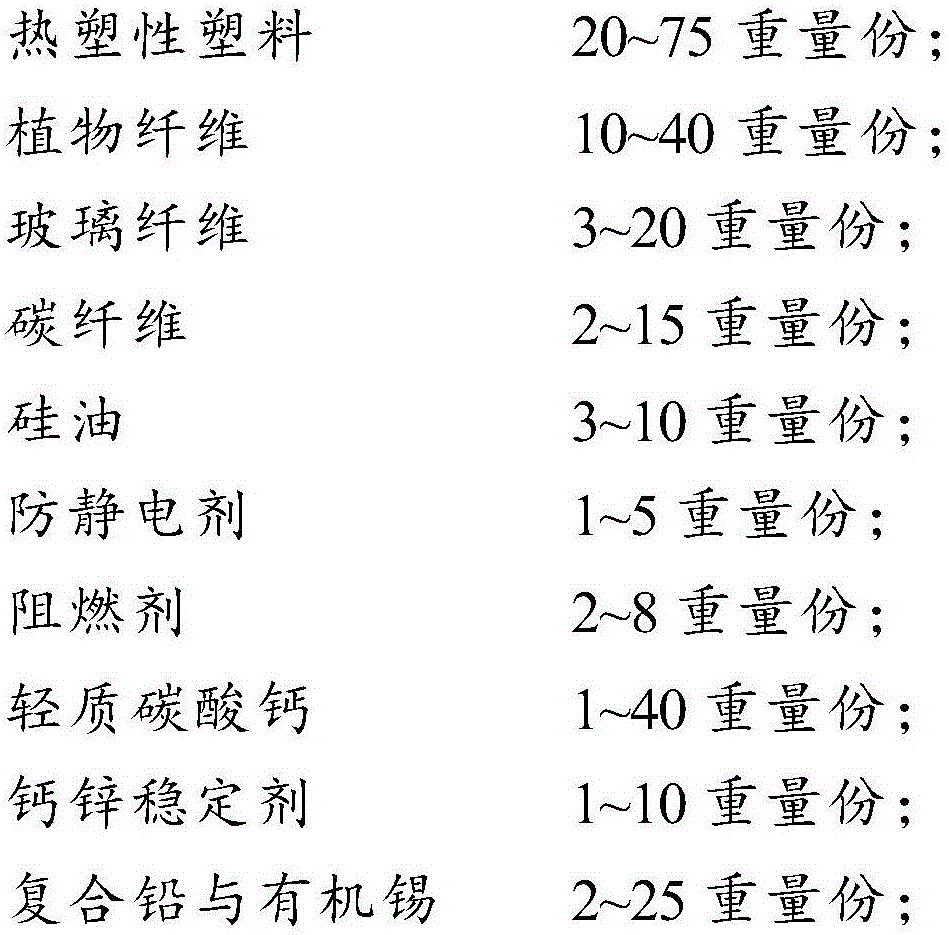

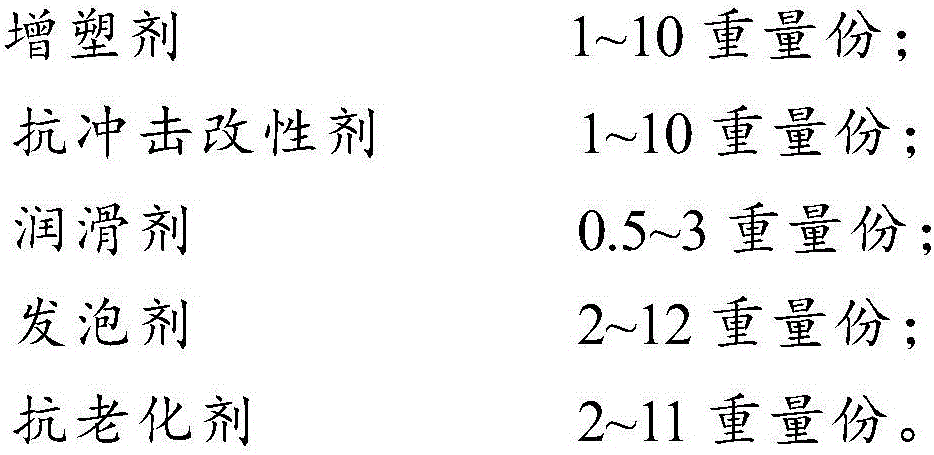

Wood-plastic composite material and preparation method thereof

The invention provides a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material is prepared from the following raw materials: thermoplastic, plant fiber, glass fiber, carbon fiber, an antistatic agent, a flame retardant, a logo printing adhesive agent, calcium carbonate, a heat stabilizer, a plasticizer, a foaming agent, an anti-impact modifier, a lubricant and an anti-ageing agent. Compared with the existing wood-plastic composite material, the logo printing adhesive agent is added to enhance the adhesion of the logo, so that the wood-plastic composite material has printability; the anti-static agent and flame retardant are added to endow the material with antistatic property and flame retardance; and glass fiber and carbon fiber are added to improve the physical and mechanical properties on the promise of ensuring good processing properties of the material.

Owner:重庆长江电工工业集团有限公司

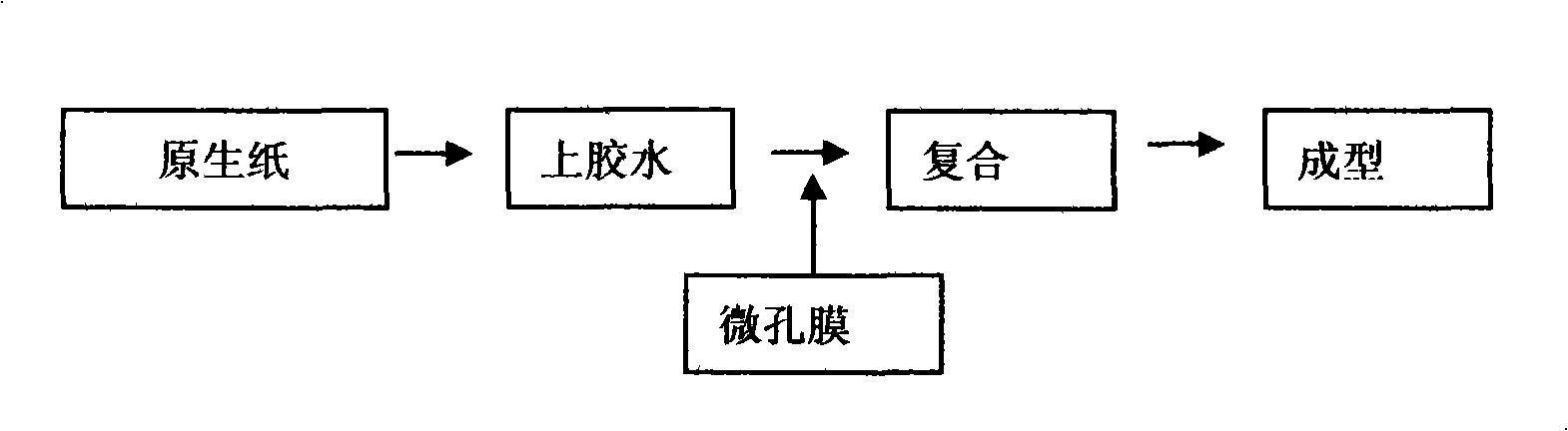

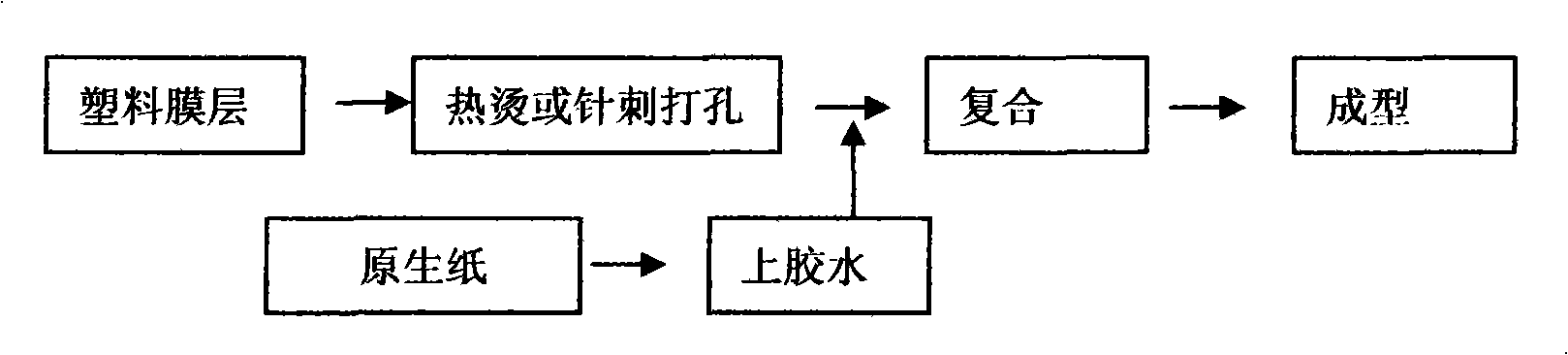

Alcohol antistaling agent wrapper paper and method for making same

InactiveCN101260633AStable, breathable and alcohol-permeableStable, breathable and wine-permeable performanceFlexible coversWrappersPaper sheetPlastic film

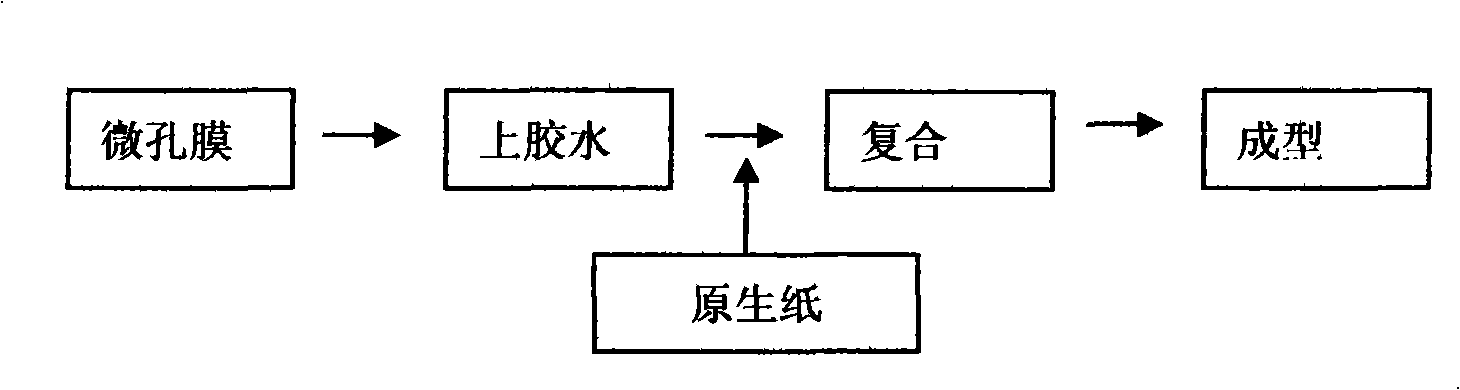

The invention discloses an alcohol antistaling agent wrapping paper aiming to provide the alcohol antistaling agent wrapping paper which has stable alcohol volatilizezing speed, is not lead or penetrate and has low cost and a preparation method thereof. The wrapping paper is formed by jointing a base paper layer on the surface layer and a plastic film layer, wherein, the plastic film layer is made of a material which has thermoplasticity and is selected from the polyolefine or the mixture of the polyolefine or a multipolymer, the plastic film layer is a microporous film formed by the microporous treatment in the manufacturing process, or is punching film which is formed by the direct blanching and pinprick processes in the manufacturing process.

Owner:GUANGDONG GUANGYI TECH IND

Tear-resistant packing material structure manufacture method and tear-resistant product

The invention provides a tear-resistant packing material structure manufacture method and a tear-resistant product. The tear-resistant packing material structure manufacture method comprises a first material preparing step, wherein the first material preparing step comprises a warp and weft direction fiber bundle weaving step and a first press fit step; a second material preparing step, wherein the second material preparing step comprises a second press fit step and a first coating step; a third press fit step; a second coating step; a fourth press fit step; a third coating step and a drying step; and therefore, the tear-resistant packing material structure which is provided with a heat-sealing layer, a transition layer, a film-similar tear-resistant layer, a junction layer and a paper layer in sequence from bottom to top. The tear-resistant packing material structure manufacture method can be realized by automated mechanical equipment, so that the production efficiency can be improved, and the manpower cost is lowered. The tear-resistant packing material structure provided by the invention has printability and deflection owned by the paper layer and also has the effects of bearing capacity, high strength, high toughness and the like of the tear-resistant layer.

Owner:FOMSON DEV ENTERPRISES

Liquid crystal temperature-sensitive anti-counterfeiting printing ink and preparation method thereof

InactiveCN111205701ARaw materials are easy to getLow raw material costLiquid crystal compositionsInksAntifoam agentPrinting ink

The invention provides liquid crystal temperature-sensitive anti-counterfeiting printing ink. The printing ink comprises the following components in parts by weight: 15-25 parts of cholesteric liquidcrystal and a microcapsule thereof, 10-15 parts of a water-soluble glue solution, 50-60 parts of a connecting material, 0.1-1 part of an antifoaming agent, 0.1-1 part of a leveling agent, and 0.1-3 parts of a viscosity regulator, wherein the cholesteric liquid crystal is a mixture of 4-cyano-4'-amyl biphenyl and cholesteric oleyl carbonate; the cholesteric liquid crystal microcapsule is a microsphere capsule prepared from the cholesteric liquid crystal and a water-soluble glue solution; and the water-soluble glue solution is a mixture of gelatin and Arabic gum. The a printing ink has the advantages of easily available raw materials, low raw material cost and simple preparation method, and is suitable for the field of anti-counterfeiting labels, the color of an anti-counterfeiting pattern can change due to the temperature change, defects of slow color change and poor contrast effect of a conventional temperature-sensitive ink are overcome, and thus the printing ink has a great application prospect in the field of anti-counterfeiting package.

Owner:深圳市旺盈彩盒纸品有限公司

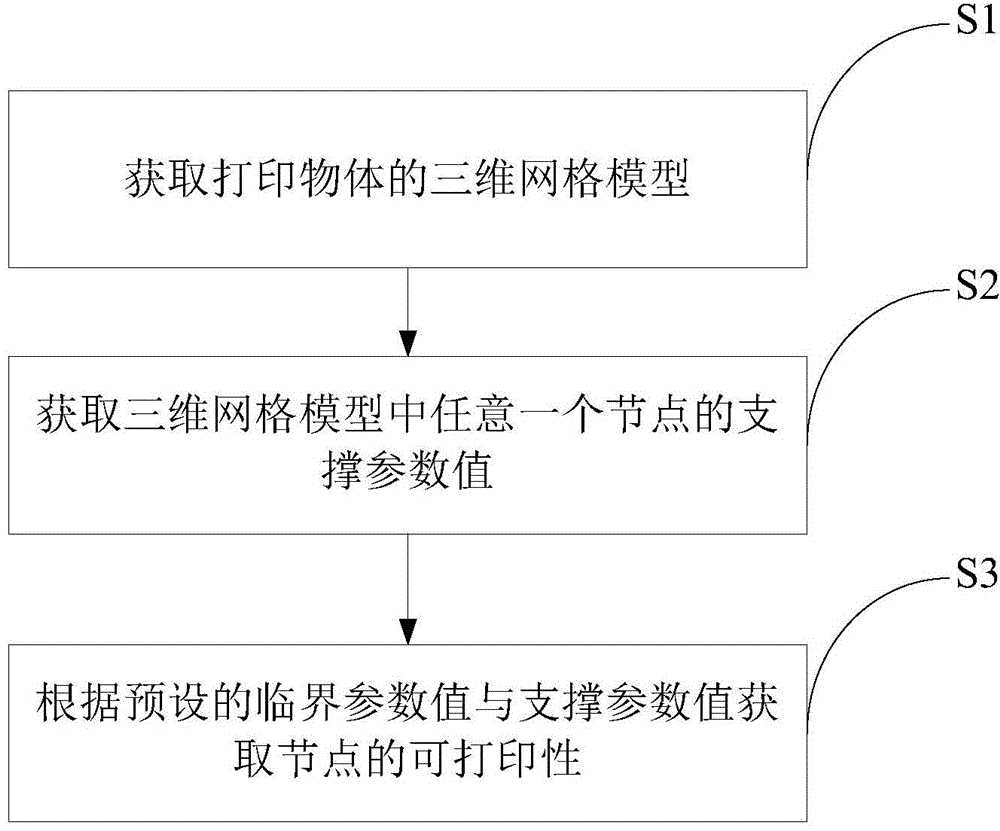

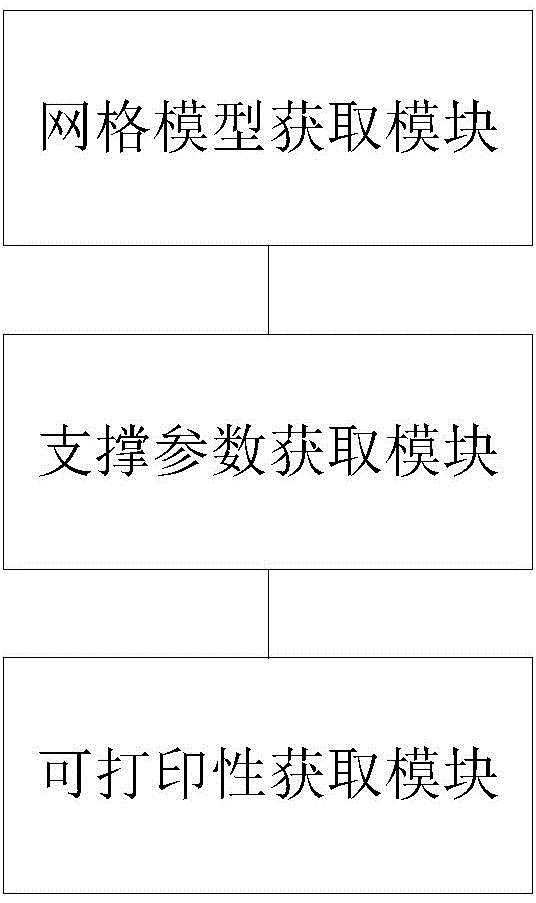

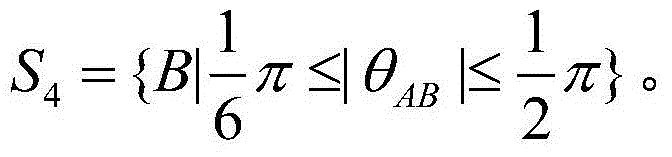

Printability acquisition method and system for three-dimensional printing

The invention discloses a printability acquisition method and system for three-dimensional printing. The printability acquisition method comprises the following steps: acquiring a three-dimensional grid model of a to-be-printed object, acquiring a supporting parameter value of any node on the three-dimensional grid model, and acquiring the printability of the node according to a preset critical parameter value and the supporting parameter value. The printability acquisition method and system disclosed by the invention has the advantages that one supporting parameter is endowed for each node on the three-dimensional grid model of the to-be-printed object and is used for balancing the supporting stability of the nodes, the supporting parameter values of all the nodes on the three-dimensional grid model are acquired according to an energy transfer idea, and whether the nodes have the printability is judged according to the relation between the preset printing critical value and the acquired supporting parameter values, so that the printability of the three-dimensional printing system can be accurately acquired.

Owner:GUANGDONG SANWEIJIA INFORMATION TECH CO LTD

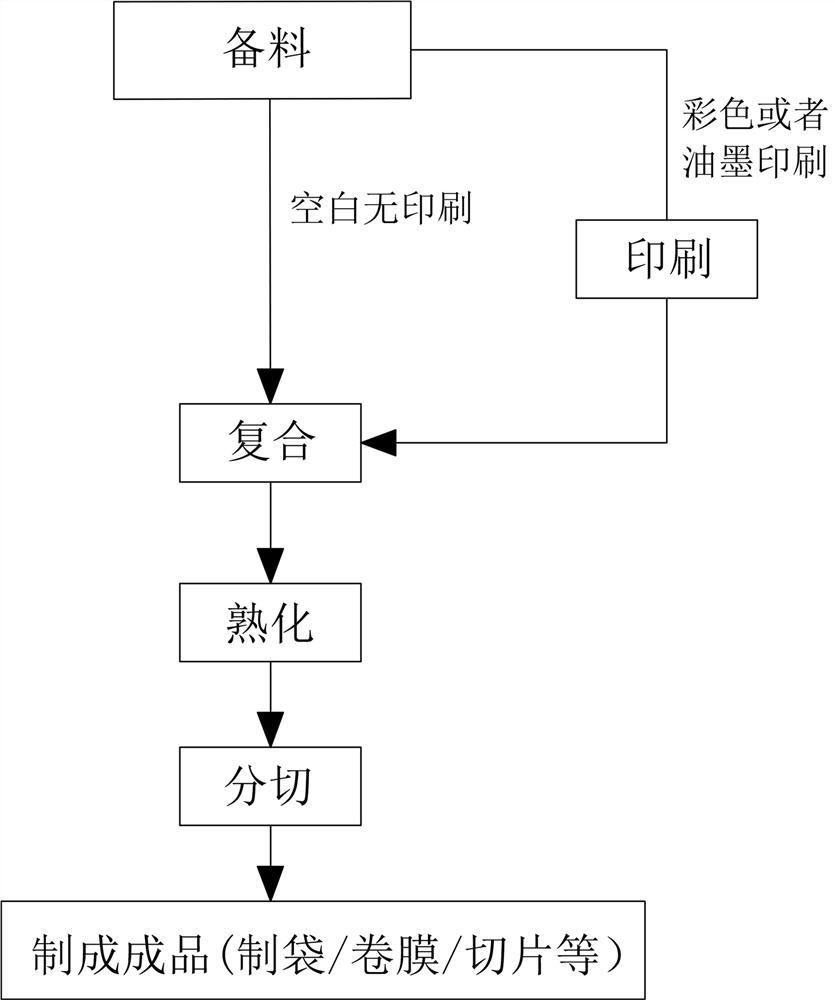

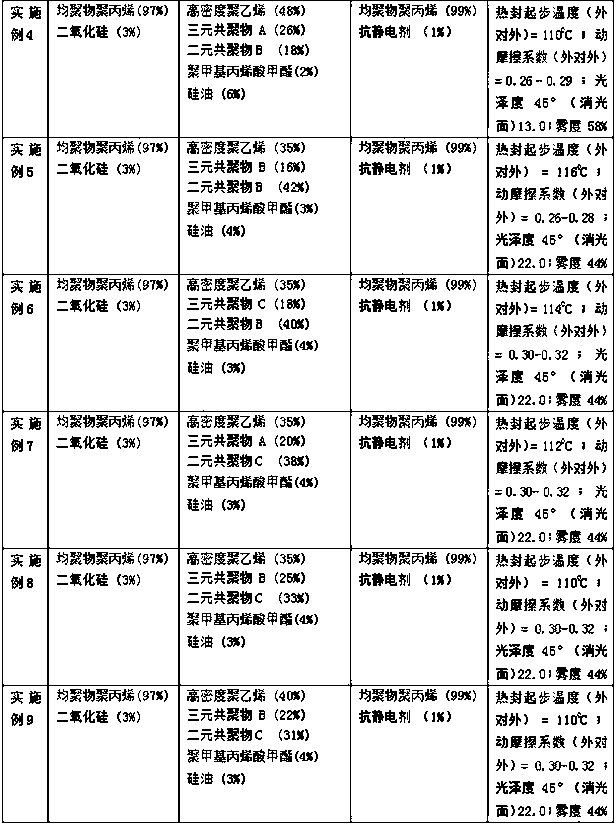

Cigarette logo permeable printing packaging film for replacing cigarette paper carton and preparation method of packaging film

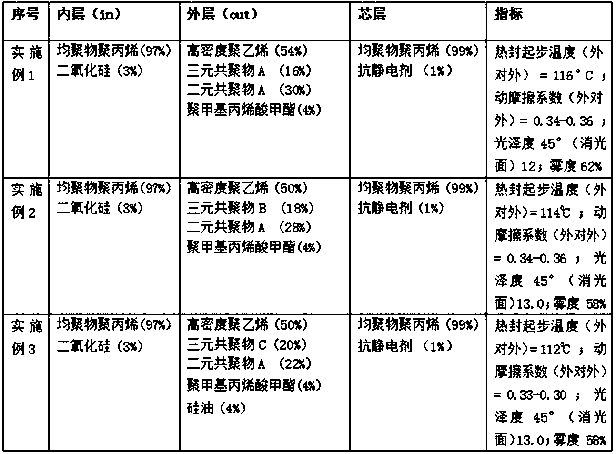

The invention discloses a cigarette logo permeable printing packaging film for replacing a cigarette paper carton and a preparation method of the packaging film. The packaging film comprises an outer layer, an inner layer and a core layer between the inner layer and the outer layer, wherein the core layer consists of polypropylene homopolymer, hydrocarbon resin and master batch; both the outer layer and the inner layer are made from low-temperature heat-seal films, and each low-temperature heat-seal film consists of master batch and a copolymer. The film disclosed by the invention is prepared by adopting a multi-layer coextrusion two-way stretching method, and the heat-seal temperature of the packaging film is 60-95 DEG C; when the cigarette carton is packaged through the packaging film, the inner layer is free from heat seal with a small box packaging outer layer, and simultaneously has a printable function. By using the packaging film disclosed by the invention, exiting cigarette paper carton packaging can be completely replaced, the adhesive consumption amount and the paper consumption are reduced in cigarette packaging, the packaging cost of a cigarette factory is reduced, and simultaneously purposes of energy conservation and environmental protection can be achieved.

Owner:YUNNAN KUNLENE FILM IND

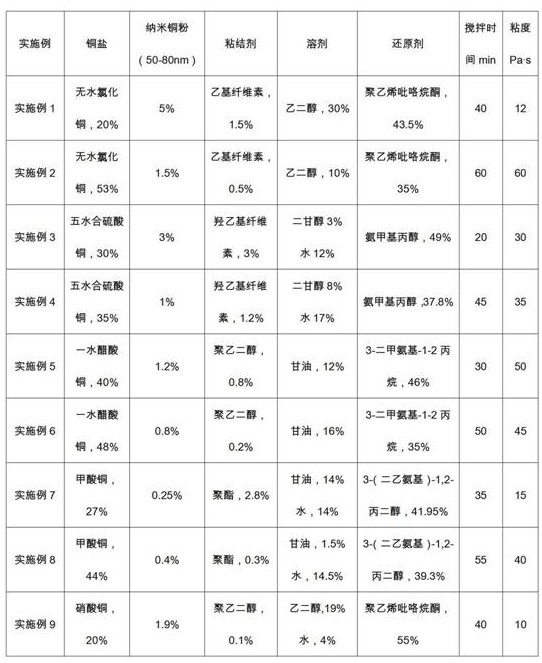

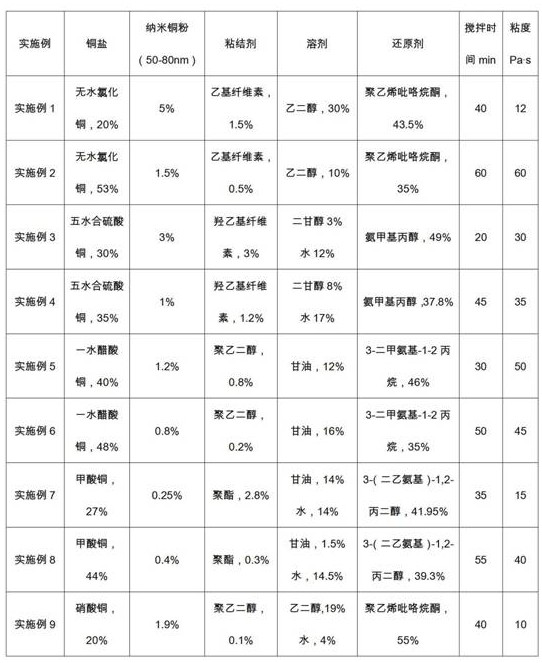

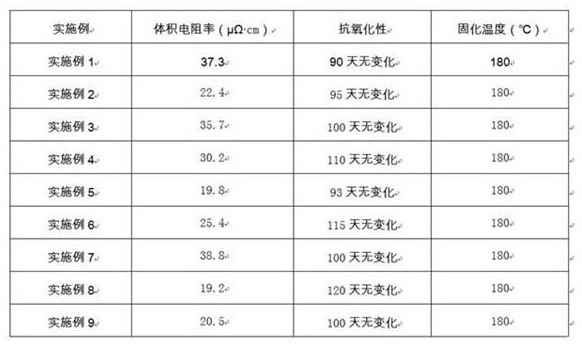

Preparation method of low-temperature curing conductive copper paste

ActiveCN113327721AImprove protectionHigh viscosityNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingNano copper

A preparation method of low-temperature curing conductive copper paste belongs to the field of flexible electronics. The conductive copper paste comprises the following raw materials by mass: 20%-53% of a copper salt, 0.25%-5% of nano copper powder, 0.1%-3% of a binder, 10%-30% of a solvent, and 35%-55% of a reducing agent. The preparation method comprises the following steps of: firstly adding the binder into the solvent to form a mixed solution, then adding the copper salt and the nano-copper powder into the mixed solution, finally adding the reducing agent to form mixed paste, and controlling the viscosity of the mixed paste to be 10 Pa.s to 60 Pa.s; adding the mixed paste into a planetary stirrer, stirring for 20-60 minutes, and carrying out primary dispersion; and adding the mixed paste obtained after primary dispersion into a three-roller mill for secondary dispersion. The obtained conductive copper paste can be subjected to low-temperature curing at the temperature of 180 DEG C or below and is suitable for circuit printing or electronic element preparation in flexible devices, all raw materials are nontoxic and harmless, and the green production requirement is met.

Owner:宁波维柔电子科技有限公司

Positive type photosensitive composition

InactiveCN1791837AAdhesion is sufficientFull adhesionThermographyPhotosensitive materials for photomechanical apparatusInfraredPositive type

A positive photosensitive composition which comprises (A) an alkali-soluble organic polymer substance having a phenolic hydroxyl group, (B) a light-heat conversion substance absorbing an infrared ray of an image exposure light source and converting it to heat, (C) at least one resin selected from the group consisting of a vinyl pyrrolidone / vinyl acetate copolymer and other specific polymers or resins, and (D) a dissolution inhibiting agent. The positive photosensitive composition does not require burning, provides necessary and sufficient adhesion in an application under a condition of a humidity in a working room of 25 to 60 %, allows the development which retains high sensitivity and is free of a residue, forms an image having a sharp outline, and provides a resist film which is so hard that its resistance to flawing is improved in the handling before development.

Owner:THINK LABORATORY CO LTD

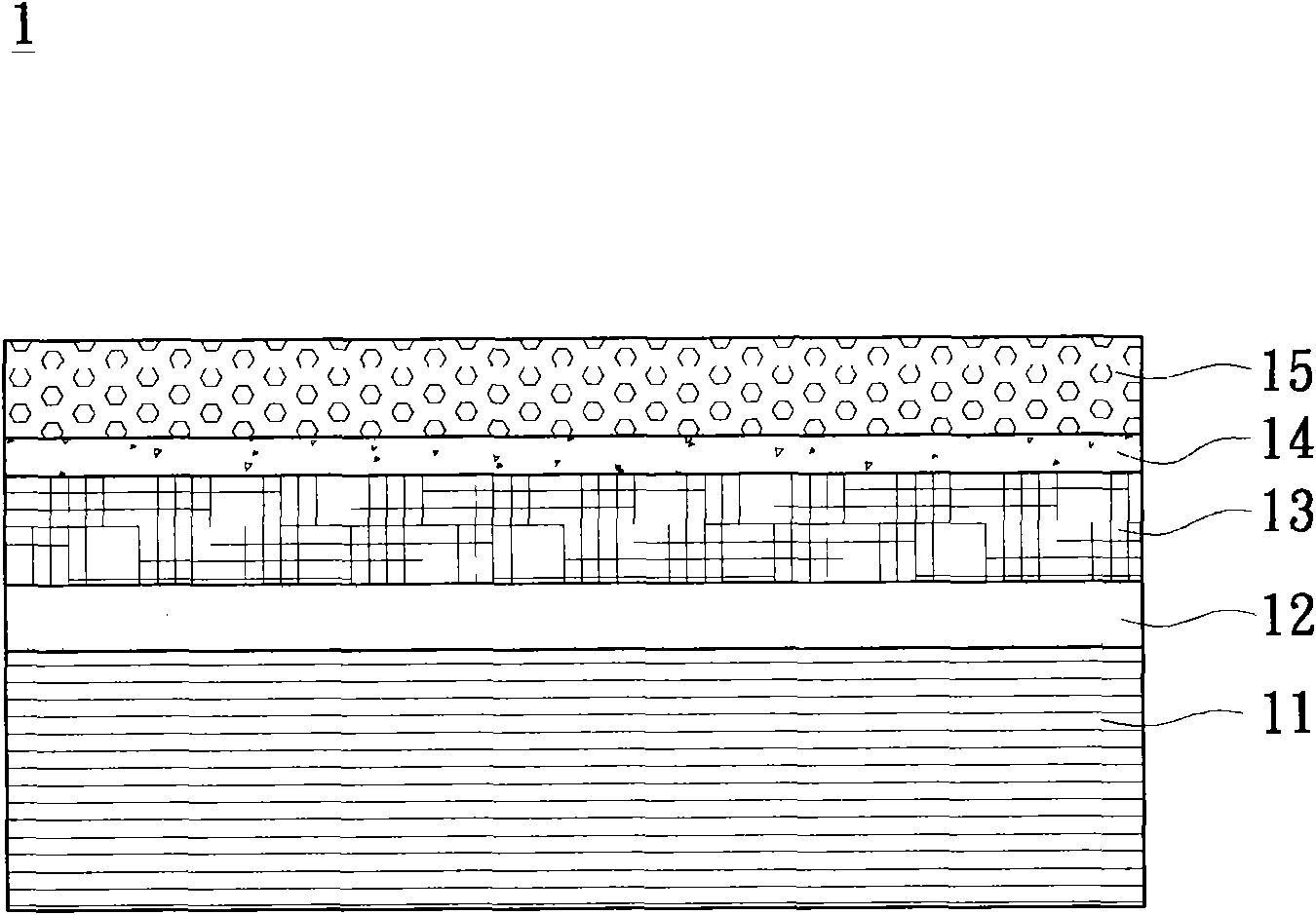

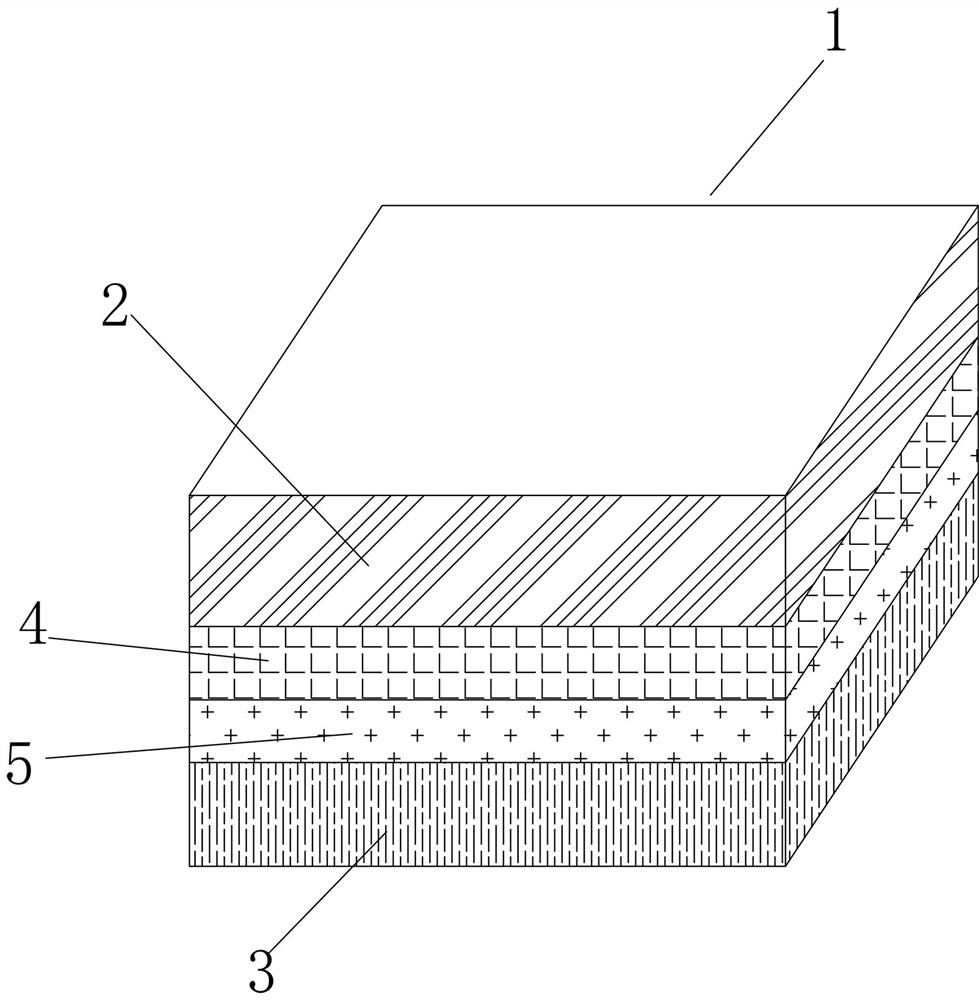

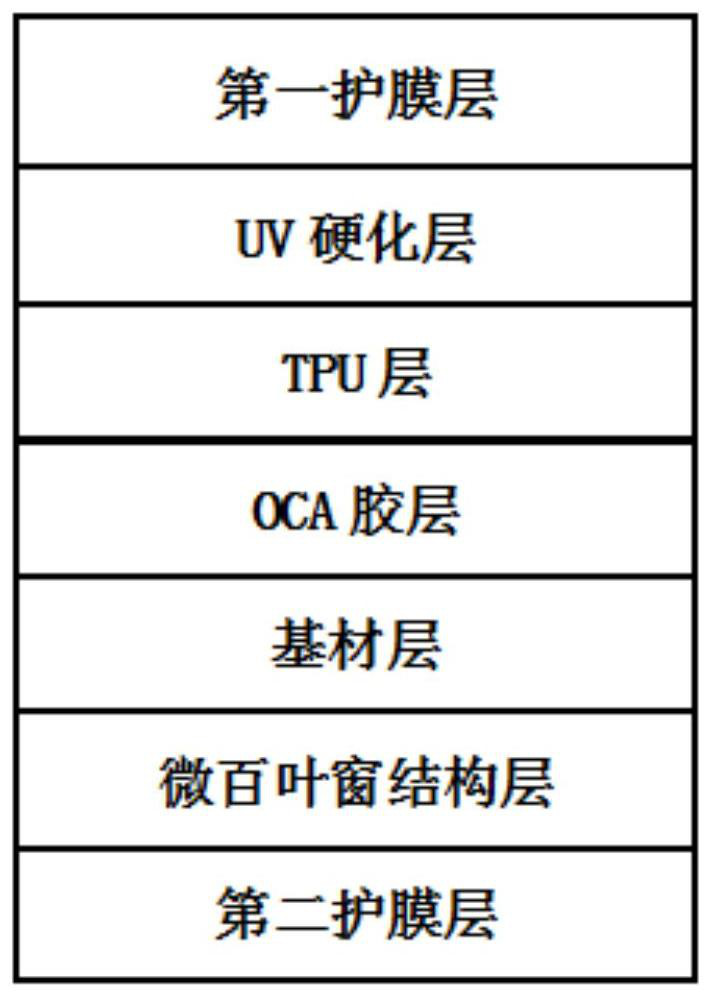

Peep-proof printable magnetic-resistant film and preparation method thereof

ActiveCN107142036AAvoid scratchesWith anti-magnetic effectFilm/foil adhesivesOrganic non-macromolecular adhesiveMagnetic effectConfidentiality

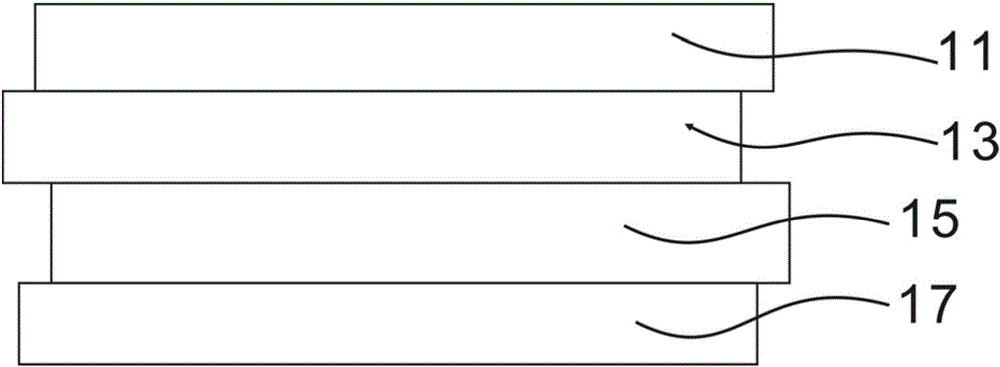

The invention provides a peep-proof printable magnetic-resistant film. The peep-proof printable magnetic-resistant film comprises a first protective film layer, an UV hardened layer composited to the first protective layer, a TPU layer composited on the UV hardened layer, an OCA adhesive layer composited on the TPU layer, a substrate layer combined on the OCA adhesive layer, a micro louver structure layer composited on the substrate layer and a second protective layer combined to the micro louver structure layer. The UV hardened layer is made of metal and oxide thereof, carbon conductive material and UV varnish glue. The UV hardened layer has an anti-magnetic effect and a printable function, the UV-hardened layer cooperates with the other layers to obtain the peep-proof printable magnetic-resistant film which has display confidentiality, the peep-proof layer is effectively prevented from being scratched, and the film has good printability and magnetic resistance and can meet customer's personal pursuit.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Biodegradable composite film material, preparation method thereof and packaging bag thereof

InactiveCN112092472APrintableGood surface wetting tensionFlexible coversWrappersCelluloseComposite film

The invention provides a biodegradable composite film material which comprises a PBAT layer, a natural cellulose layer and an adhesive layer clamped between the PBAT layer and the natural cellulose layer. The PBAT layer, the adhesive layer and the natural cellulose layer are combined together through a composite film forming technology. The natural cellulose layer with temperature resistance, printing adaptability, poor extensibility and no heat sealability and the PBAT layer with poor temperature resistance, heat sealability and extensibility are compounded together through the adhesive layer, and the properties of the natural cellulose layer and the PBAT layer are complementary to each other, so that the composite film material with good surface wetting tension, temperature resistance, heat sealability and capable of meeting the requirements of low-temperature freezing, water boiling and the like can be prepared. The composite film material can be printed and packaged as required; and the main raw materials are completely derived from biological raw materials, can be thoroughly degraded, and are energy-saving and environment-friendly.

Owner:珠海市辉丰包装材料有限公司

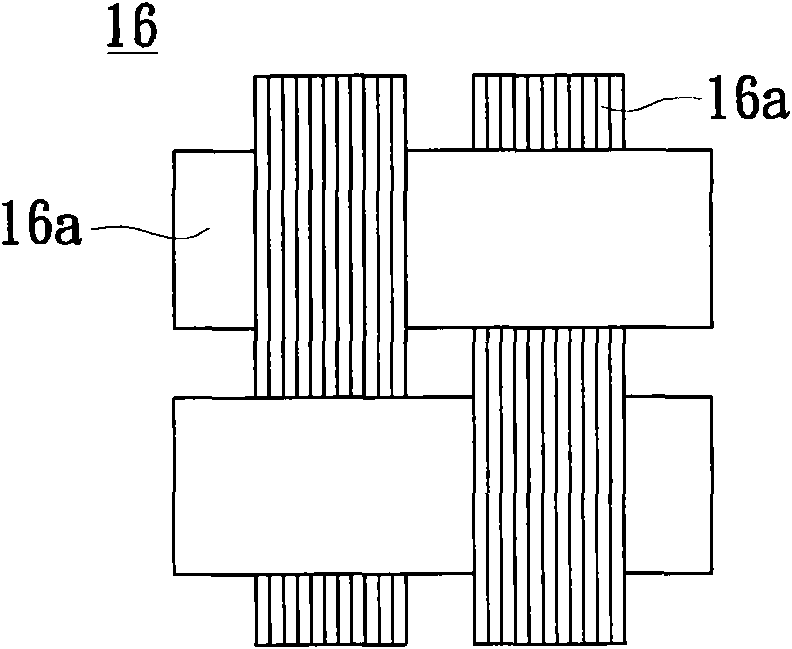

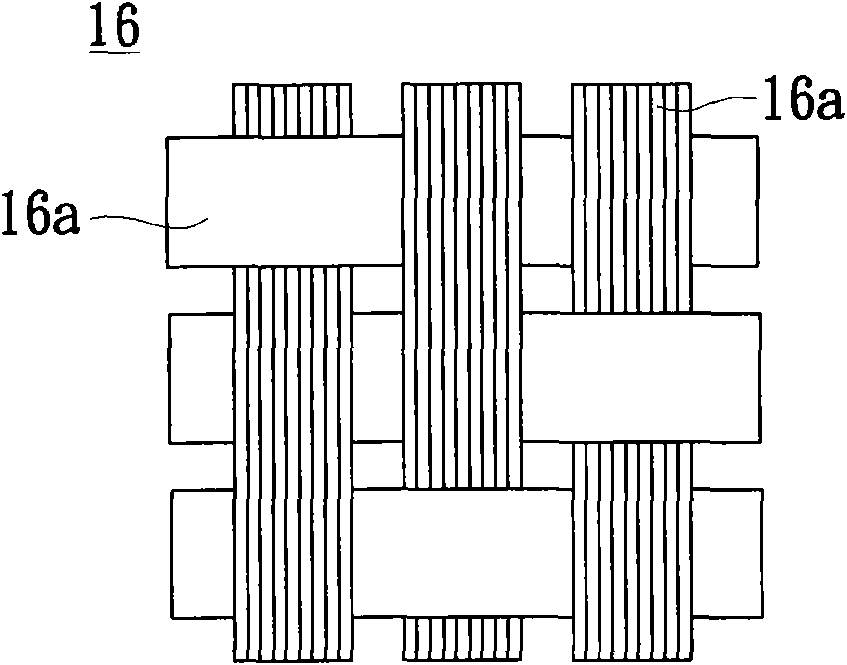

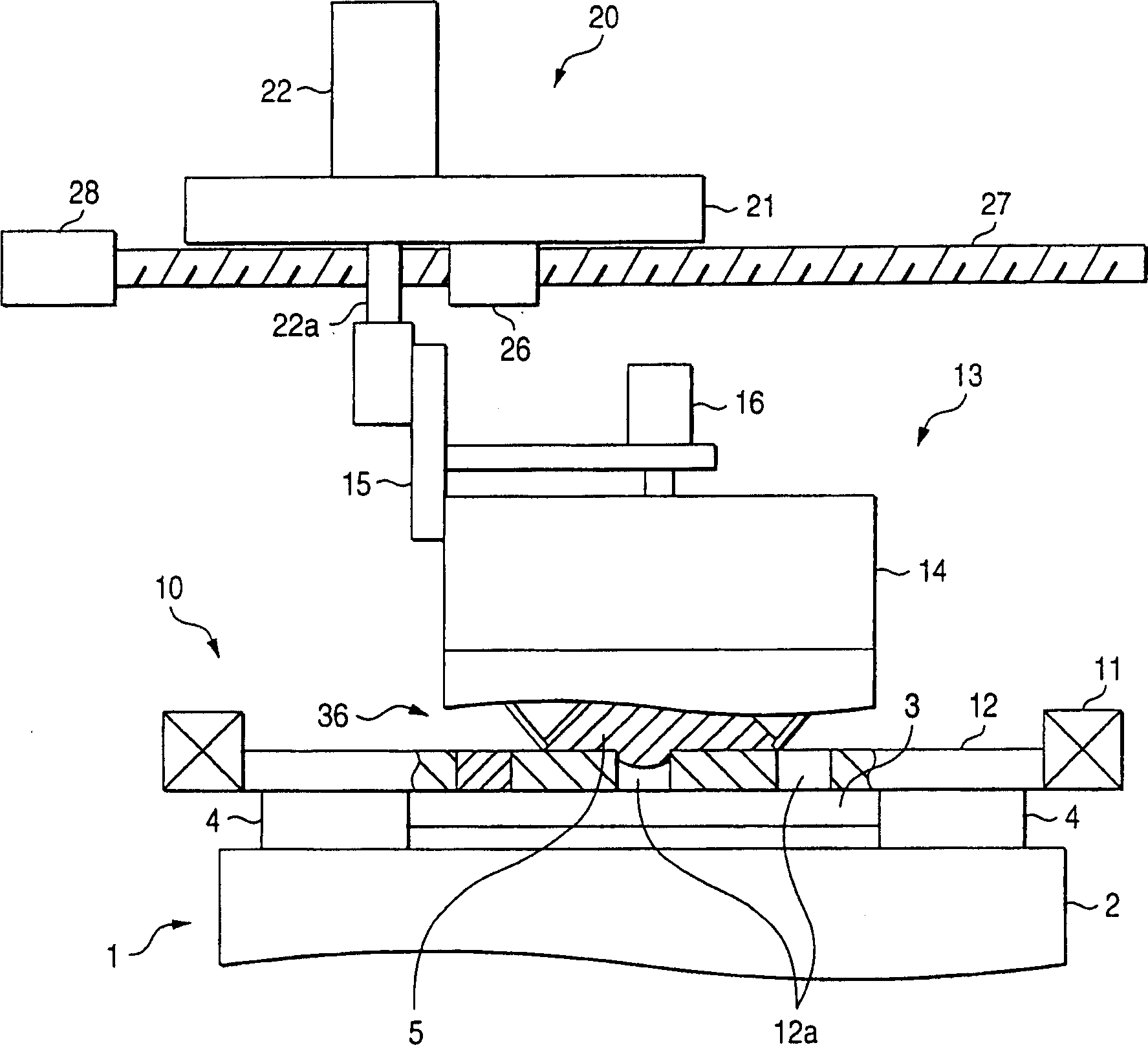

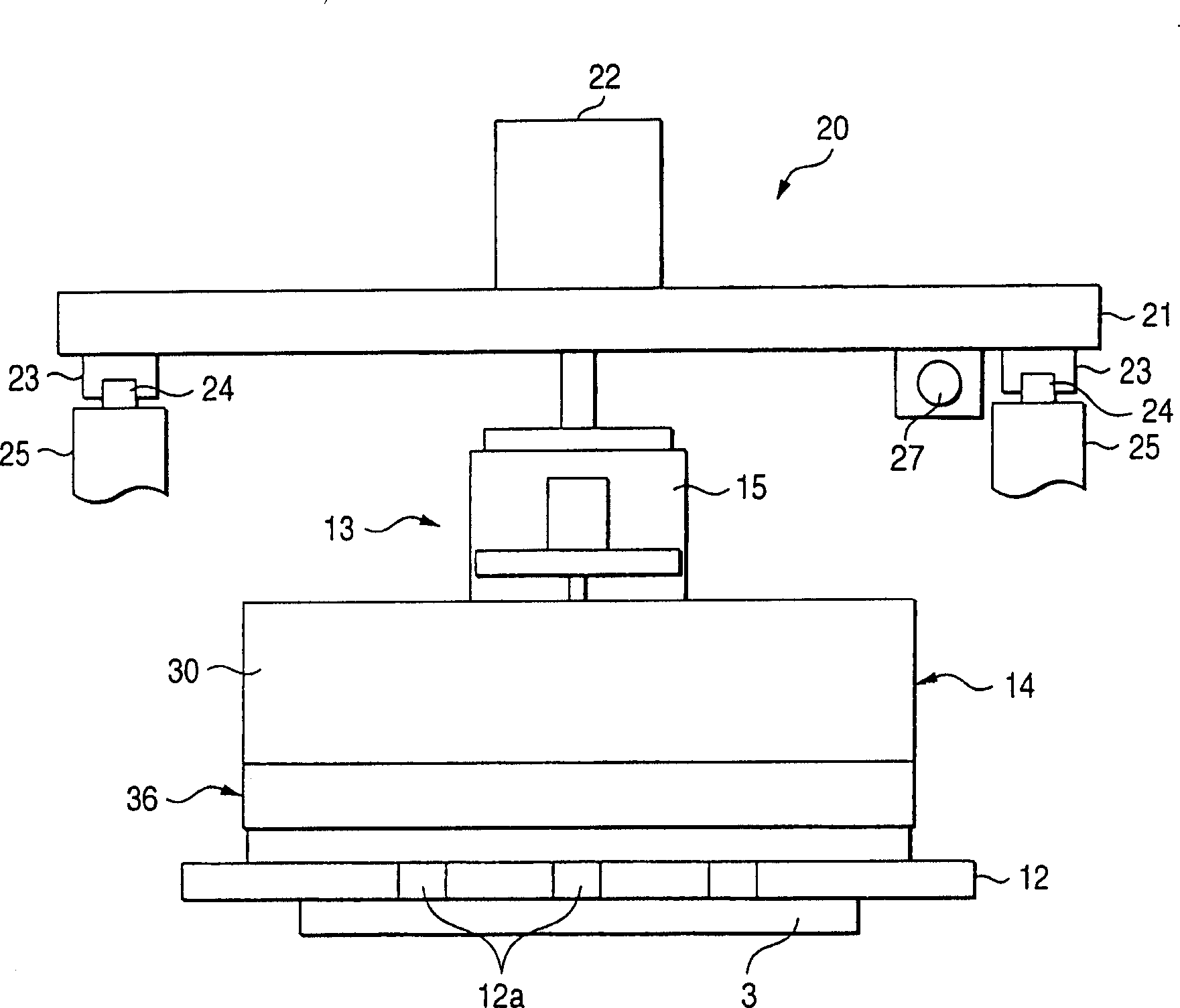

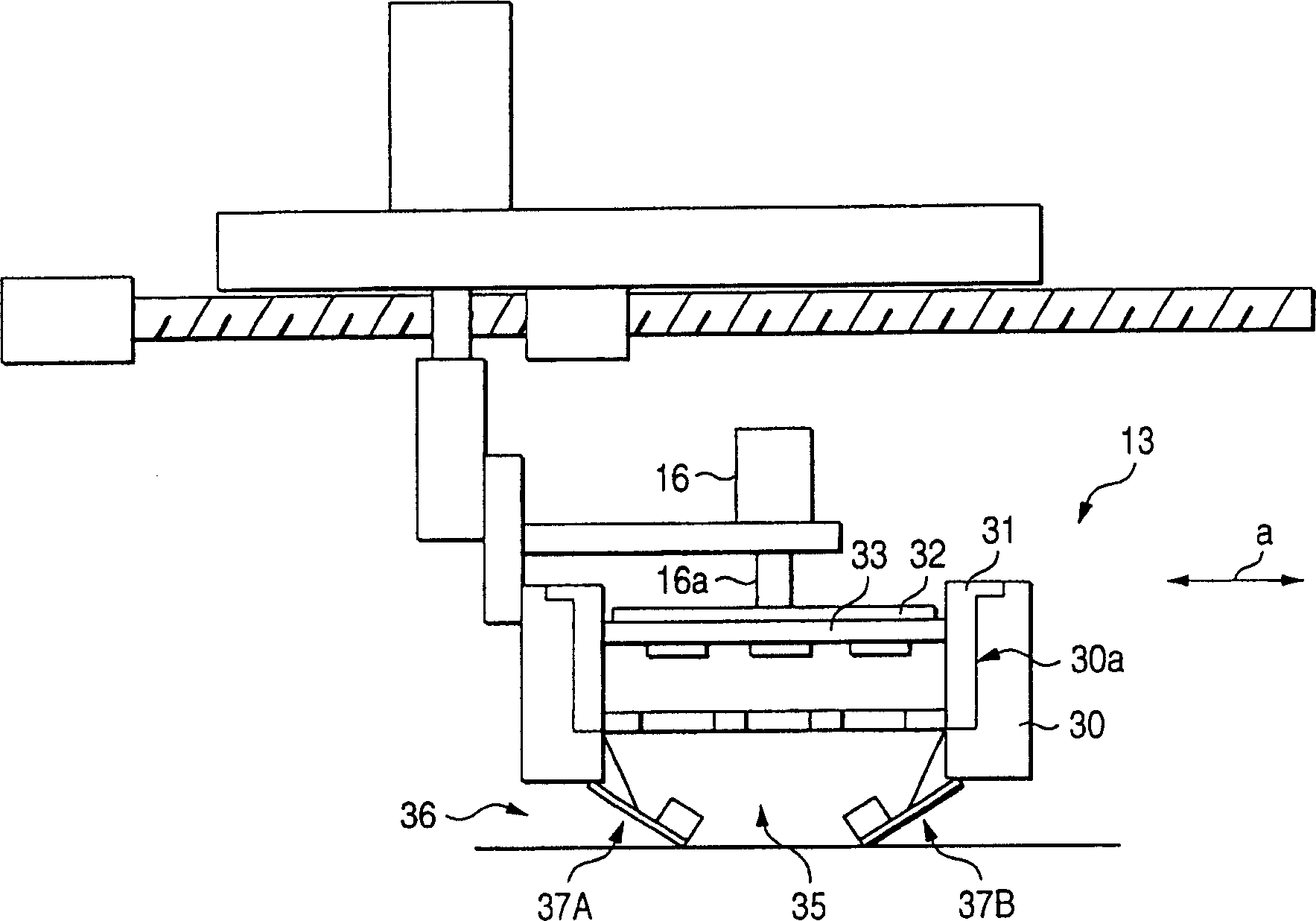

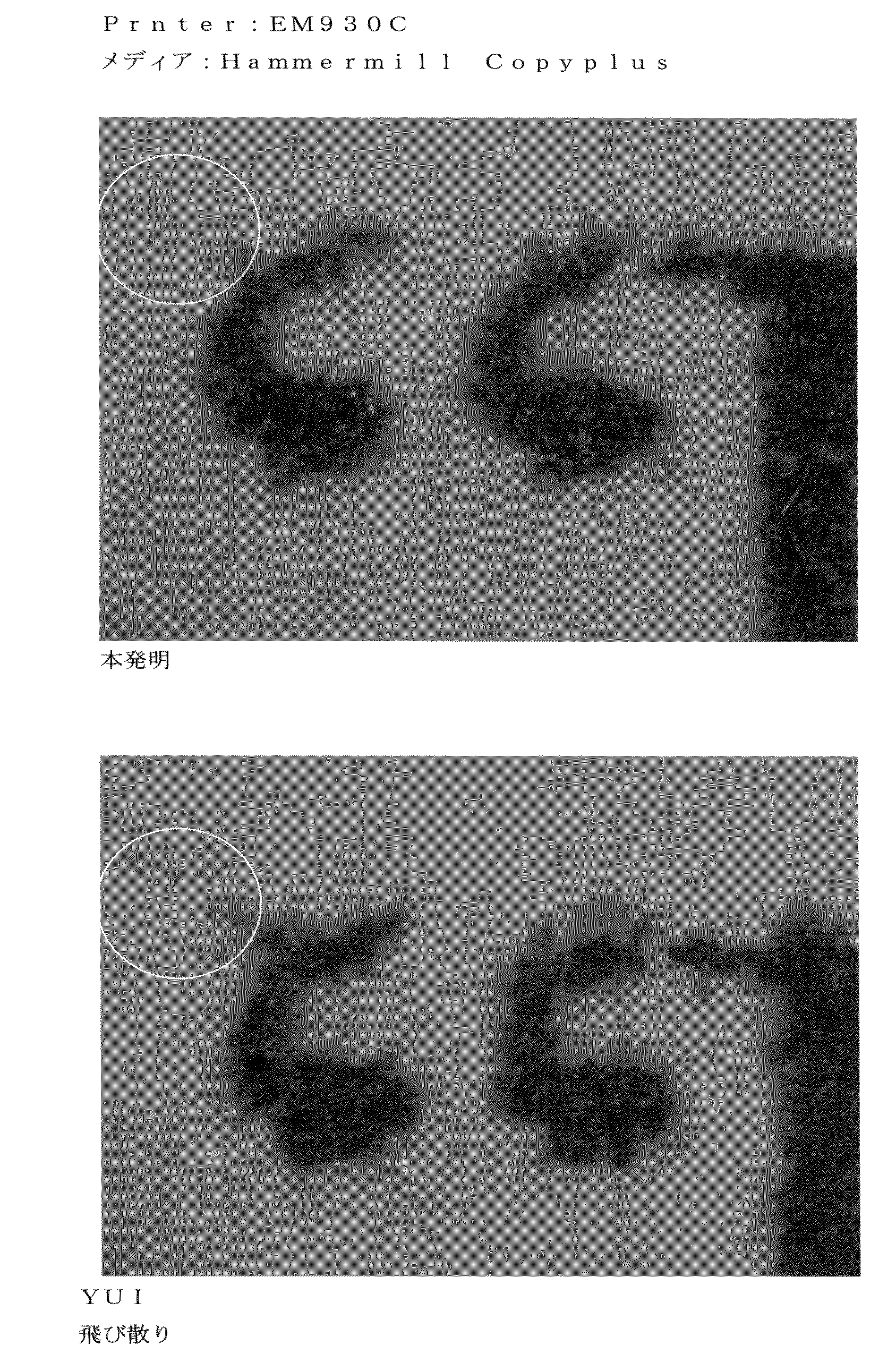

Screen printing apparatus

InactiveCN1582232AEliminates problems caused by leaksPrintablePrinted circuit assemblingScreen printersScreen printingAcute angle

A screen printing apparatus in which a squeegee head 13 is moved on a mask plate 12 thereby to print paste on a substrate through pattern holes 12a, slide contact portions 37A and 37B form respectively front and rear walls in the squeegeeing direction of a printing space 35 which reserves cream solder 5 therein and makes the cream solder contact with the surface of the mask plate 12 through an opening portion formed at the lower surface thereof. Each of the slide-contact portions is configured by a partition plate 39 for partitioning between the printing space 35 and the outside and a filling block 38 having a filling surface 38a which forms an acute angle with respect to the surface of the mask plate 12. In the squeegeeing operation, the filling surface 38a rolls the cream solder 5. Thus, the cream solder 5 can be filled into the pattern holes 12a without pressurizing the cream solder, and a problem caused by the leakage of the cream solder can be eliminated.

Owner:PANASONIC CORP

Composition of light-diffusing material and preparation method of composition

The invention discloses a composition of a light-diffusing material and a preparation method of the composition. The composition comprises, by weight, 30-45% of polycarbonate polymers, 55-65% of polystyrene polymers, 0.6-0.8% of light-diffusing agent, 0.5-5% of compatilizers, 0.3-0.8% of antioxidant and 0.2-0.6% of weather-proofing agent. The light-diffusing PC / PS alloy material has the advantagesof high mobility, light transmittance, haze and temperature resistance.

Owner:中山市华塑塑胶科技有限公司

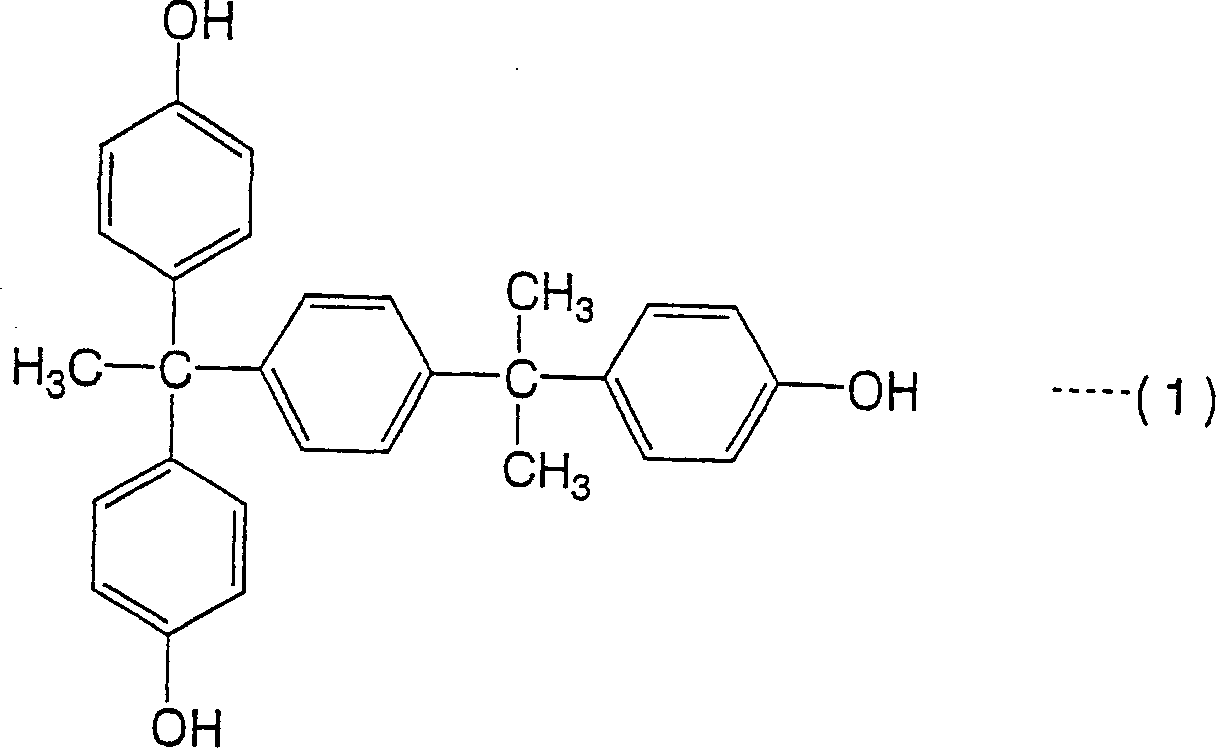

Saccharide-alkyleneoxy derivative and ink

InactiveUS7888406B2Improve permeabilityPrintableSugar derivativesDuplicating/marking methodsAlcohol sugarsOrganic chemistry

A saccharide-alkyleneoxy derivative comprising a compound represented by the following formula (1):A-(EP)n-OH (1)wherein A represents a skeleton of a saccharide selected from the group consisting of C3 to C12 aldoses, ketoses and sugar alcohols; EP represents an ethyleneoxy group and / or a propyleneoxy group; and n represents an average number of the repeating units. Also disclosed are a method for producing the saccharide alkyleneoxy derivative, and an ink containing the saccharide-alkyleneoxy derivative.

Owner:SEIKO EPSON CORP

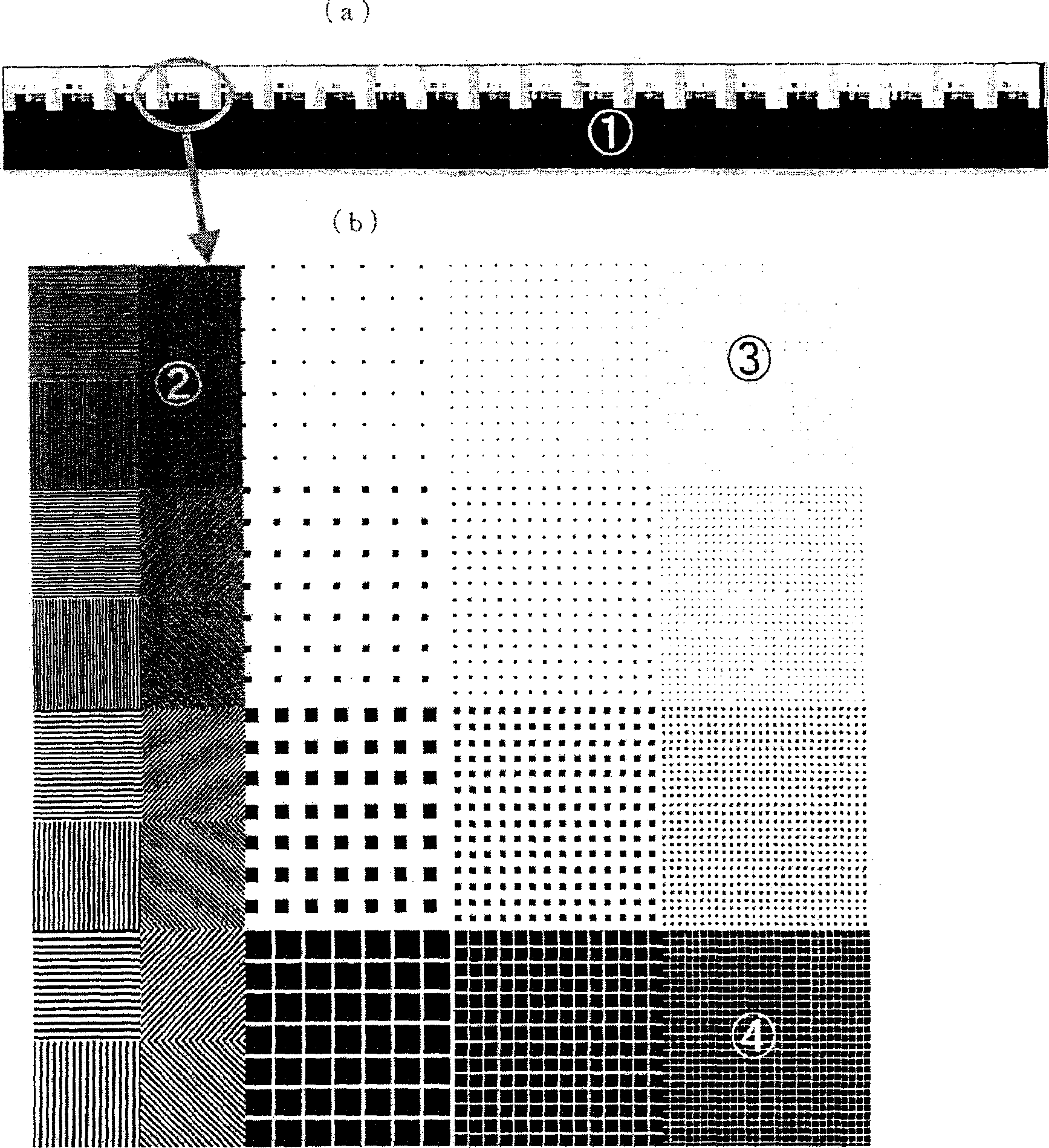

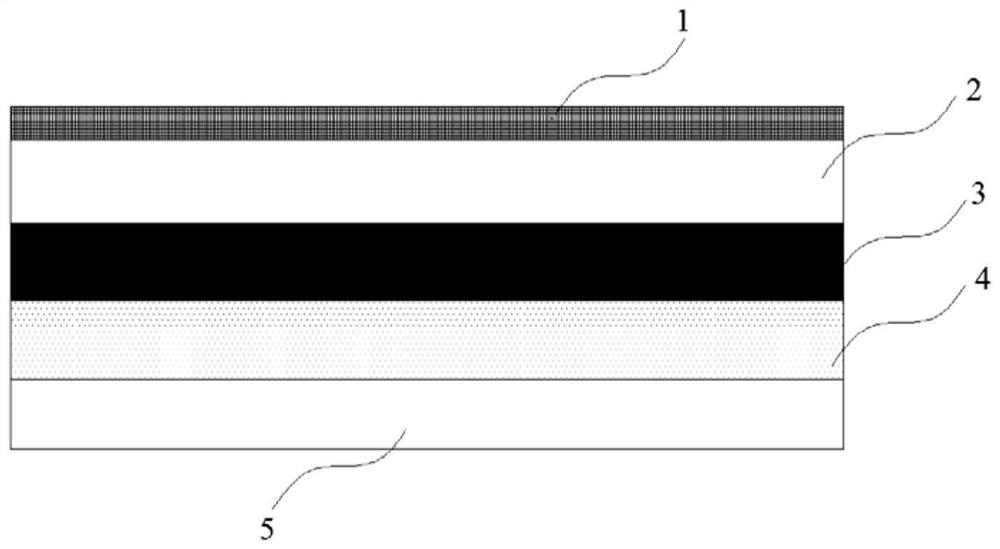

Print-ink stacked body

InactiveCN104918785AGood glossLess residual solventSynthetic resin layered productsInksPrepolymerDiamine

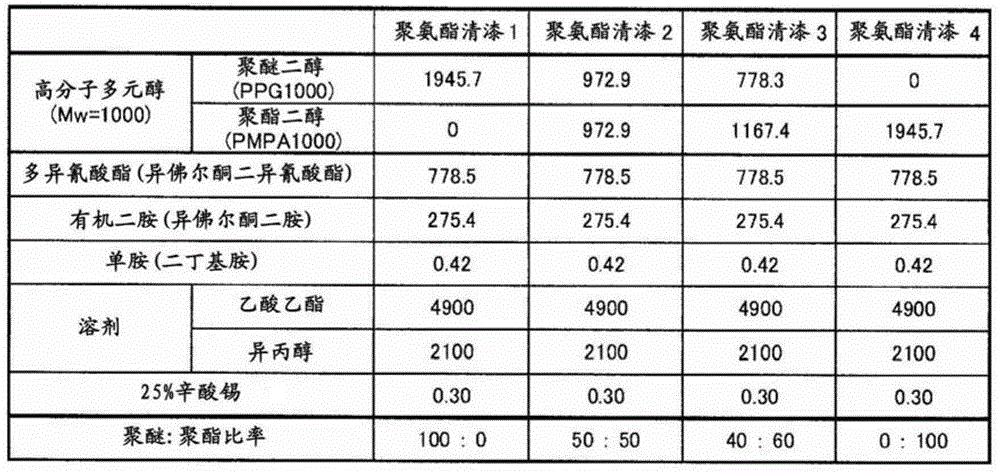

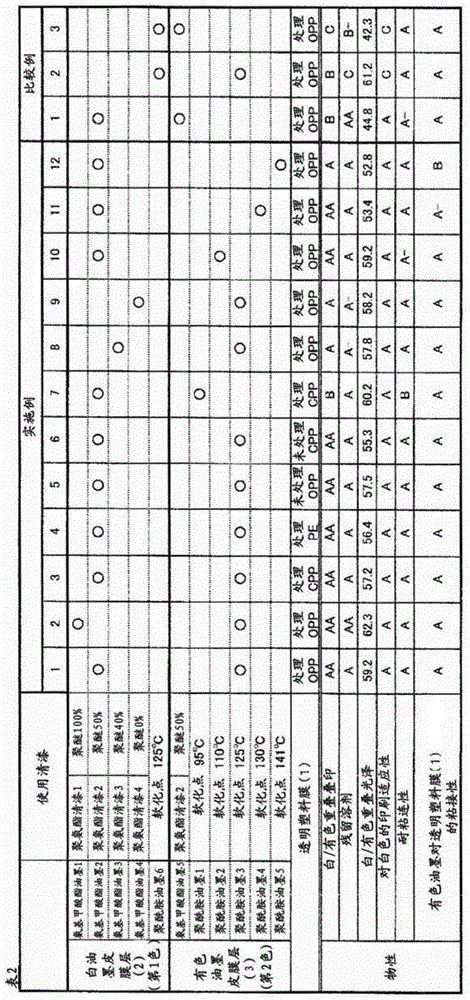

The present invention relates to a print-ink stacked body obtained by stacking, upon a transparent plastic film (1), a white ink film layer (2) formed using print ink including a polyurethane resin (A) and a white inorganic pigment, and a coloured ink film layer (3) formed using print ink including a polyamide resin (B) and an organic pigment, in that order, said print-ink stacked body wherein the polyurethane resin (A) is obtained by causing a reaction between an organic diamine and a urethane prepolymer having an isocyanate group at a terminal thereof, said urethane prepolymer being obtained by causing a reaction between a polymer polyol and polyisocyanate. According to the present invention, an ink stacking method can be used to produce an ink stacked body exhibiting, among other necessary properties, excellent white / colour-layer gloss, while reducing the usage amount of residual solvents.

Owner:TOYO INK SC HOLD CO LTD +1

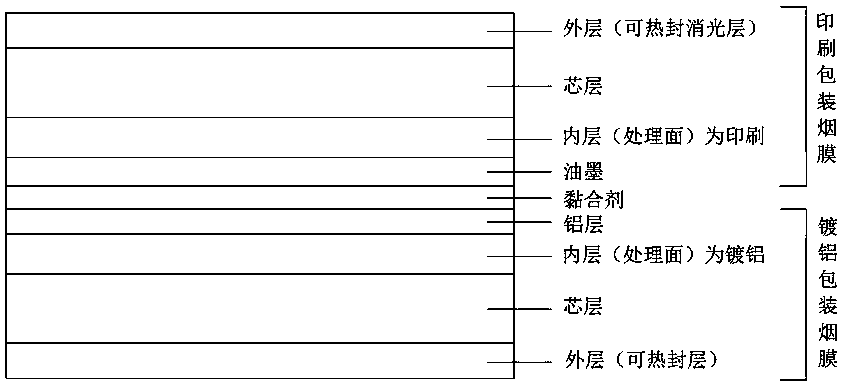

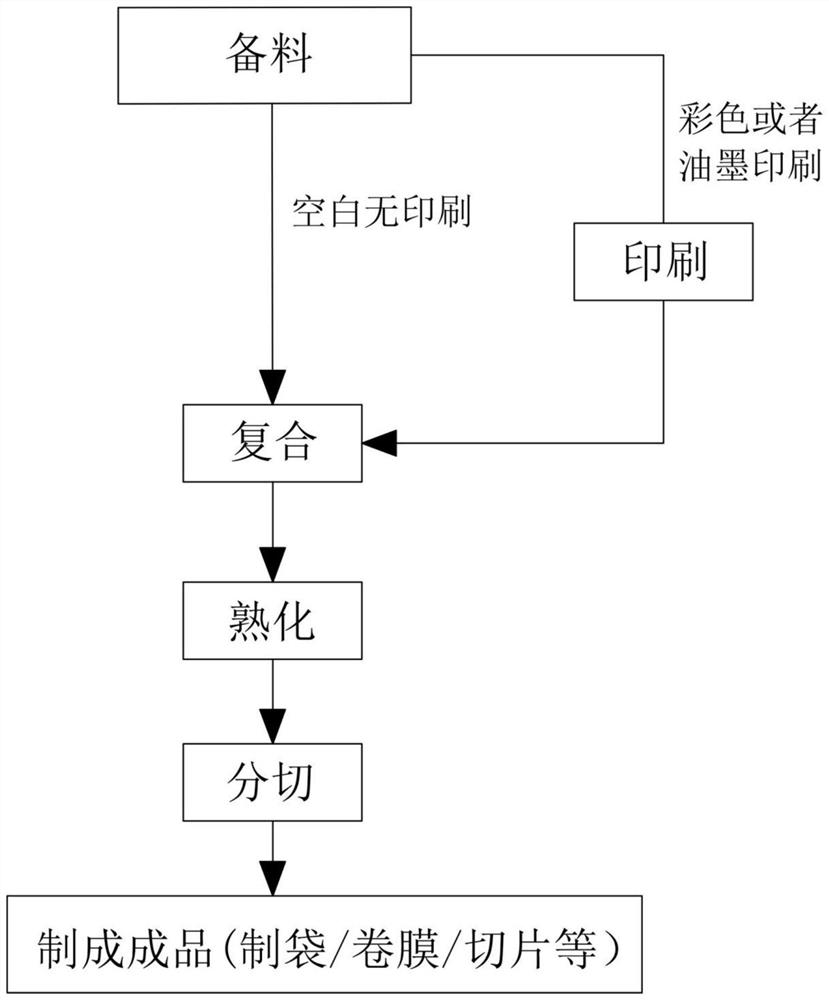

Heat-sealable matte aluminized printed composite packaging film for cigarettes and preparation method thereof

InactiveCN108656687ARealize the printing functionAvoid scratchingFlexible coversWrappersAluminiumHot-melt adhesive

The invention discloses a heat-sealable matte printed aluminized composite packaging film for cigarettes and a preparation method thereof. The composite packaging film comprises a printed matte film and an aluminized film which are laminated and processed by use of a binder or a hot melt adhesive, wherein the printed layer of the matte film can be laminated with the aluminized layer of the aluminized film to obtain the composite packaging film. The composite packaging film provided by the invention has the following advantages: a heat-sealable matte film is creatively proposed to be adopted asa printed packaging film; after inner printing of the inner surface of the matte film, the printed layer of the matte film is laminated with the surface of the aluminized layer of the aluminized film, so the problem of additional coating of a matting coating on the surface of a conventional cigarette packaging film is solved; meanwhile, the matted layer and the aluminized film have medium-and-low-temperature heat sealability, so a film can be packaged and bonded without the need of using a glue when a cigarette is subsequently packaged on a machine; and the composite packaging film provided by the invention realizes medium-and-low-temperature heat sealability and matte effects on the basis of guaranteeing conventional functions, effectively reduces energy consumption, is friendly to the environment, and has a matte metal texture.

Owner:SUZHOU KUNLENE FILM IND CO LTD +1

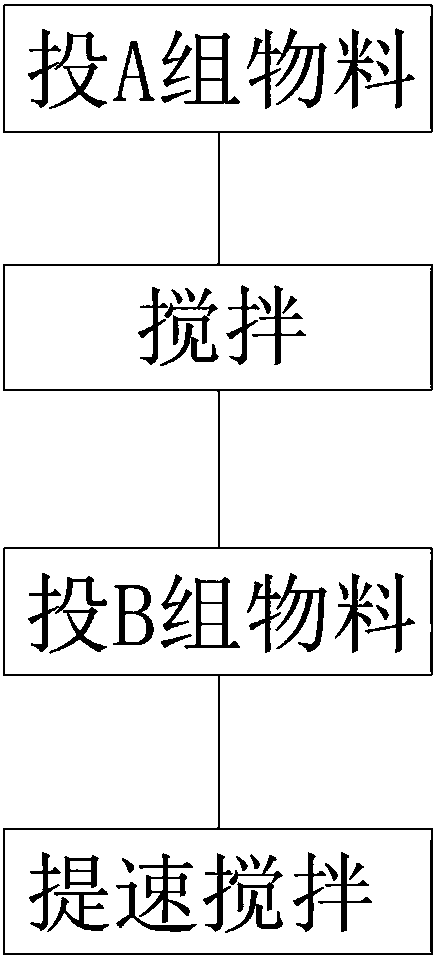

A kind of preparation method of low-temperature curing conductive copper paste

ActiveCN113327721BImprove protectionHigh viscosityNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingSlurry

A preparation method for low-temperature curing conductive copper paste, which belongs to the field of flexible electronics. The raw material composition of the conductive copper paste is as follows in terms of mass percentage: copper salt 20%~53%, nano copper powder 0.25%~5%, binder 0.1% ~3%, solvent 10%~30%, reducing agent 35%~55%; first add binder to the solvent to form a mixed solution, then add copper salt and nano-copper powder to the mixed solution, and finally add reducing agent to form Mix the slurry, control the viscosity of the mixed slurry to 10Pa·s~60Pa·s; add the mixed slurry to the planetary mixer and stir for 20-60 minutes for a dispersion; add the mixed slurry after the first dispersion to the three-roll mill After secondary dispersion, the obtained conductive copper paste can be cured at a low temperature below 180°C, which is suitable for circuit printing in flexible devices or the preparation of electronic components, and all raw materials are non-toxic and harmless, meeting the requirements of green production.

Owner:宁波维柔电子科技有限公司

Heat-sensitive recording material

The present invention provides a heat-sensitive recording material, which is a heat-sensitive recording material in which a heat-sensitive recording layer containing a colorless or light-colored basic leuco dye and a color developer as main components is provided on a support, and is characterized in that In that, the thermosensitive recording layer contains an acrylic polymer obtained by copolymerizing alkyl acrylate, alkyl methacrylate, and vinyl silane as monomer components, and colloidal silica, and the colloidal silica Silicon has a chain structure.

Owner:NIPPON PAPER IND CO LTD

Saccharide-alkyleneoxy derivative and ink

InactiveUS20080163791A1Improve permeabilityGenerates cloggingCosmetic preparationsLiquid surface applicatorsAlcohol sugarsSugar alcohol

A saccharide-alkyleneoxy derivative comprising a compound represented by the following formula (1):A−(EP)n−OH (1)wherein A represents a skeleton of a saccharide selected from the group consisting of C3 to C32 aldoses, ketoses and sugar alcohols; EP represents an ethyleneoxy group and / or a propyleneoxy group; and n represents an average number of the repeating units. Also disclosed are a method for producing the saccharide alkyleneoxy derivative, and an ink containing the saccharide-alkyleneoxy derivative.

Owner:SEIKO EPSON CORP

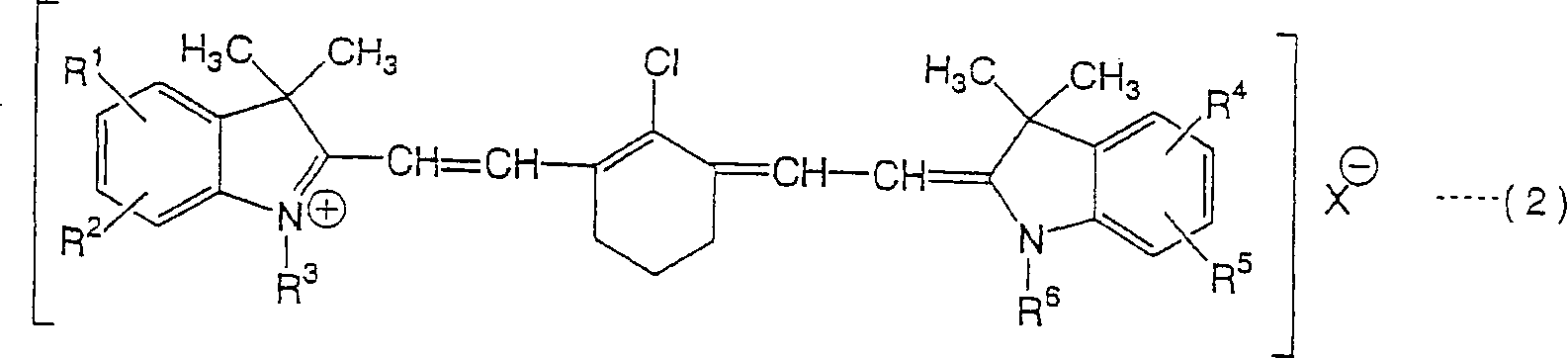

Aqueous gravure gold ink and preparation method thereof

The invention discloses aqueous gravure gold ink and a preparation method thereof. The aqueous gravure gold ink is prepared from the following components in parts by weight: 10-15 parts of water, 50-60 parts of an aqueous acrylic copolymer, 20-30 parts of ethanol, 30-40 parts of bronze powder, 1-2 parts of ethanol amine, 10-20 parts of acrylic modified chlorinated polyolefin, 0.2-0.5 part of [1-methyl-4-(4-diethylaminobenzoazo) pyridinium] and 0.2-1.0 part of modified polysiloxane. By only taking water and ethanol as solvents, pollution on the environment caused by emission of volatile organiccompounds (VOCs) is reduced, and human health hazard is reduced. The product is designed for meeting the pursuit of a presswork on a special printing effect, and meanwhile, the product has a printingeffect and printing adaptability of ester dissolved gravure metals.

Owner:YUNNAN HONGTA INK CO LTD

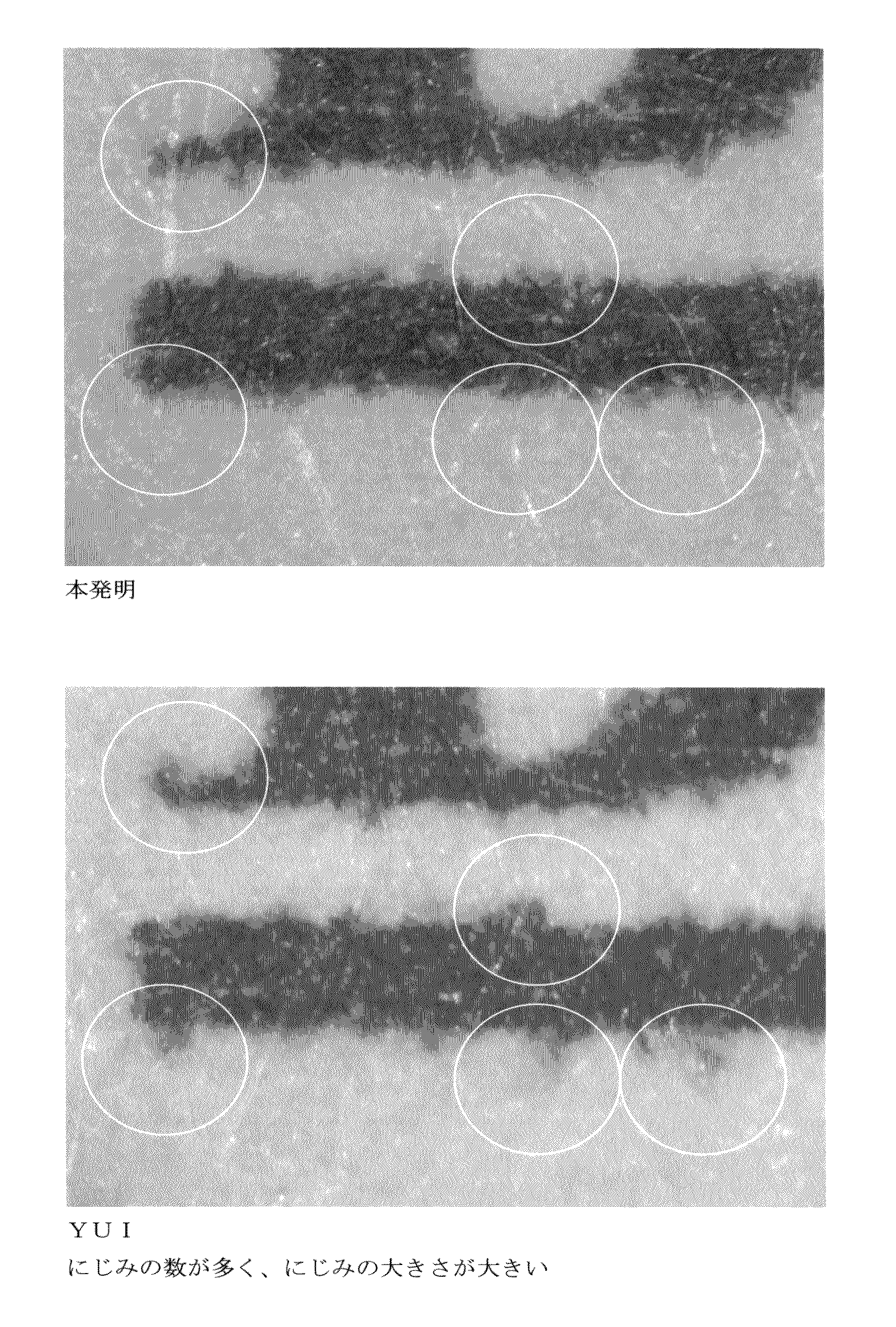

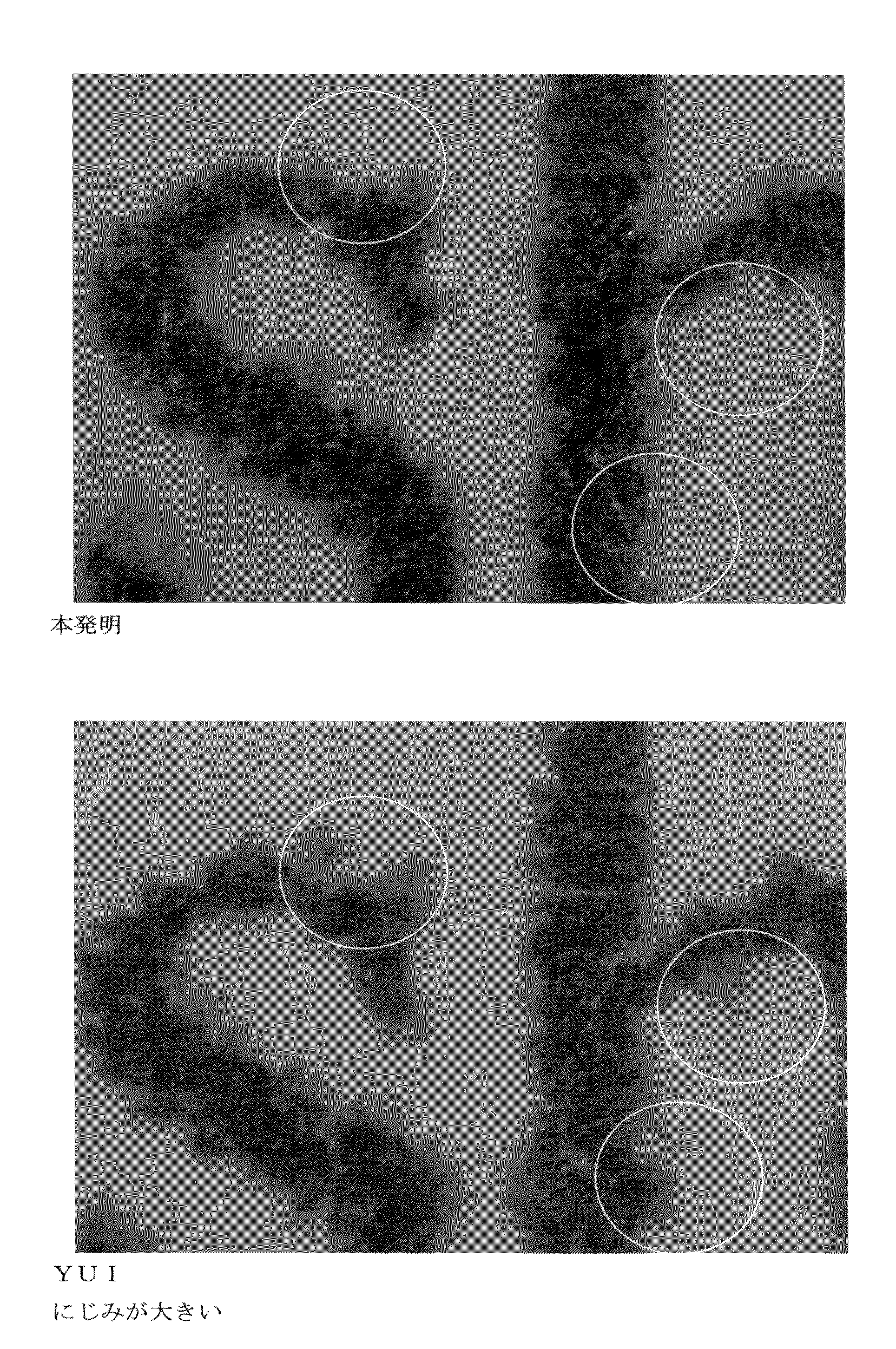

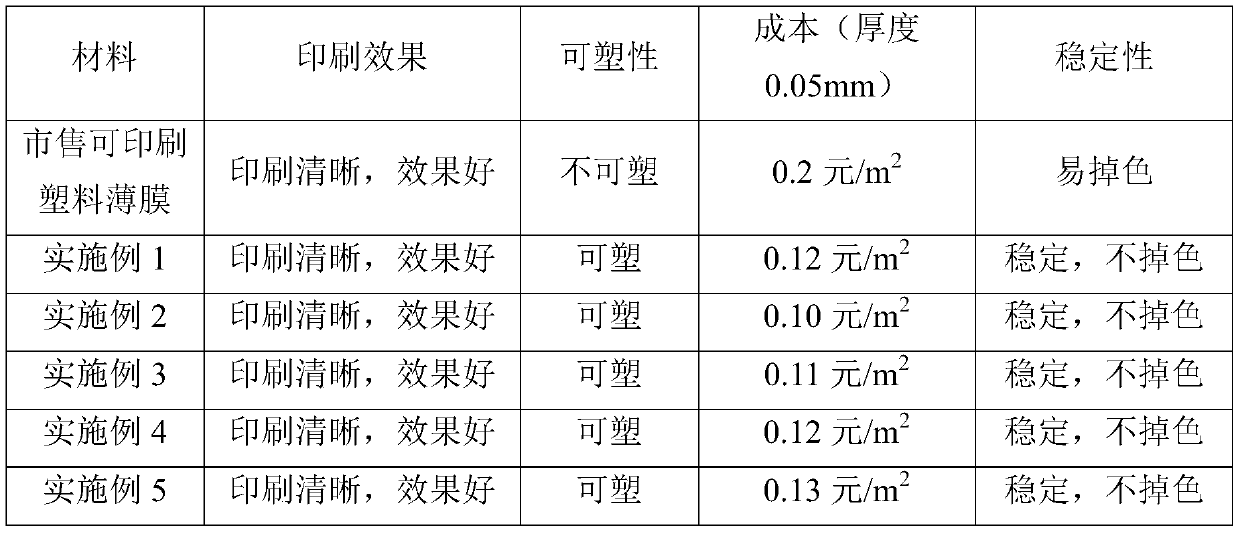

Printable plastic film and preparation method thereof

The invention discloses a printable plastic film and a preparation method thereof. Raw materials of the printable plastic film comprise 85-95 wt% of a resin material, 3-10 wt% of a conductive materialand 2-5 wt% of an oily material; raw materials for preparing the resin material include 70-80 wt% of polyethylene or polypropylene and 20-30 wt% of C5 petroleum resin; and raw materials for preparingthe conductive material include 10-20 wt% of carbon black, 15-25 wt% of graphite, 15-25 wt% of ferriferrous oxide, 15-25 wt% of carbon nanotubes and 20-30 wt% of metal powder. The printable plastic film prepared in the invention has the advantages of good printability, good stability and low production cost, and the preparation method has the advantages of simplicity, easiness in process operation, and suitableness for large-scale promotion.

Owner:ZHEJIANG CHENGDE PACKAGING

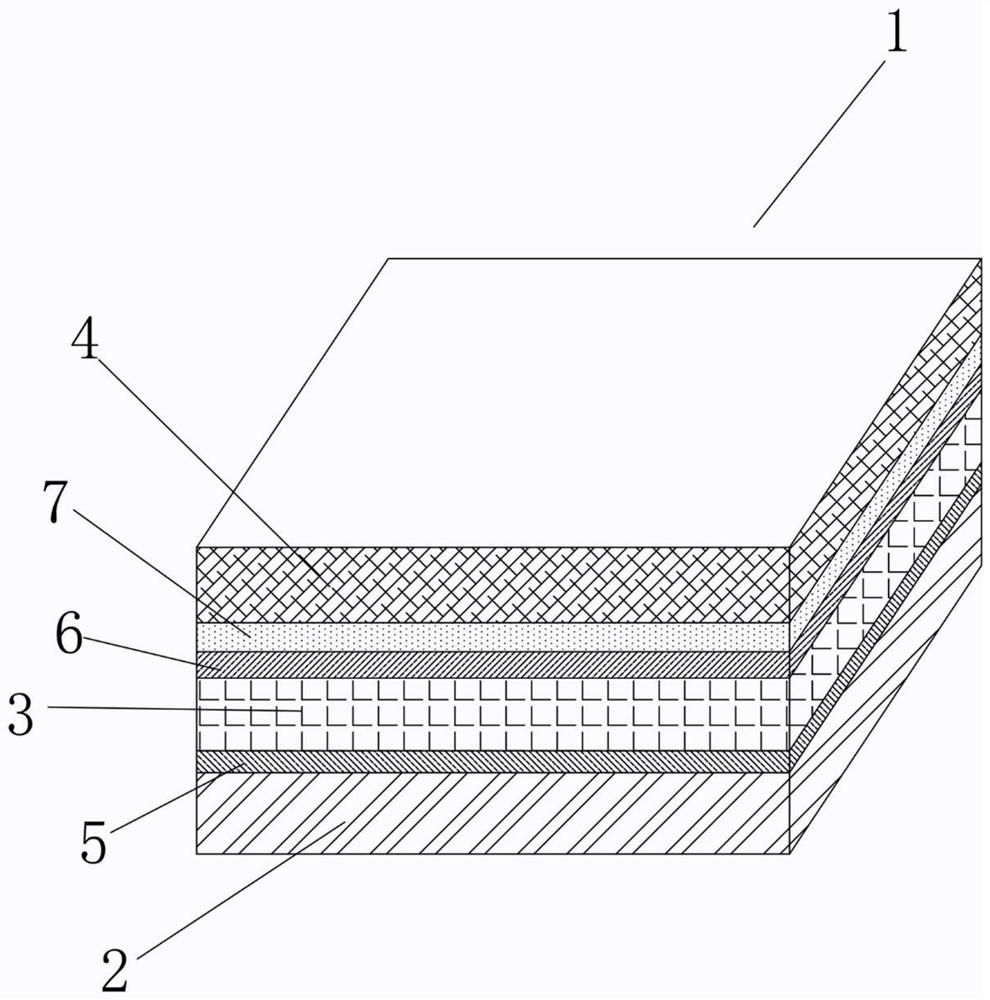

Biodegradable high-barrier composite film material structure and packaging bag thereof

PendingCN112937045APrintableTemperature resistantBio-packagingSynthetic resin layered productsCelluloseComposite film

The invention provides a biodegradable high-barrier composite film material structure. The composite film material sequentially comprises a cellulose layer, a pure aluminum layer, a PBAT layer, a first adhesive layer clamped between the PBAT layer and the pure aluminum layer, and a second adhesive layer clamped between the pure aluminum layer and the cellulose layer from top to bottom, wherein the PBAT layer, the first adhesive layer, the pure aluminum layer, the second adhesive layer and the cellulose layer are combined together through a composite film forming technology. The cellulose layer with printing adaptability, temperature resistance, poor extensibility and no heat sealability and the pure aluminum with high barrier property are compounded together through the second adhesive layer, and then are compounded together with the PBAT layer with heat sealability and extensibility through the first adhesive layer, so that the properties of the cellulose layer and the PBAT layer are complementary, and the composite film material which is good in surface wetting tension, resistant to temperature, capable of being subjected to heat sealing and capable of meeting the performance requirements of low-temperature freezing, high-barrier conditions and the like can be prepared. The degradation rate of the degradable part is 90% or above, and energy saving and environment friendliness are achieved.

Owner:珠海横琴辉泽丰包装科技有限公司

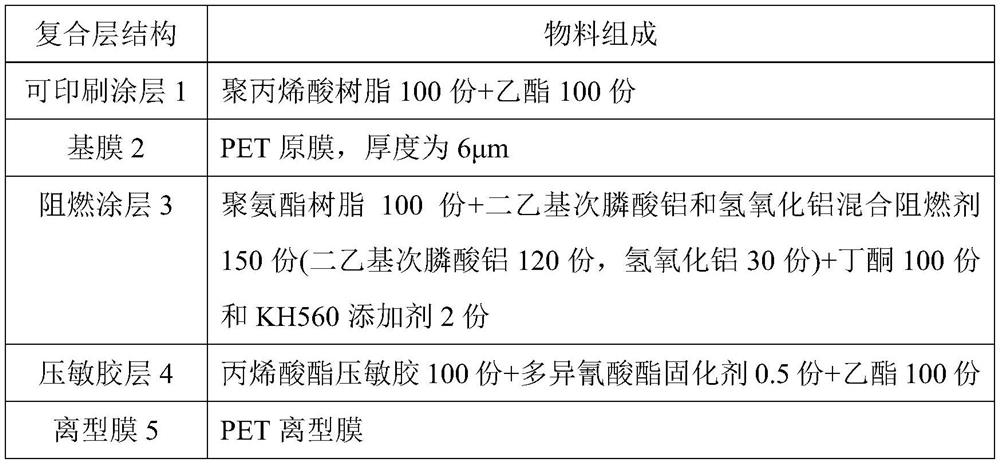

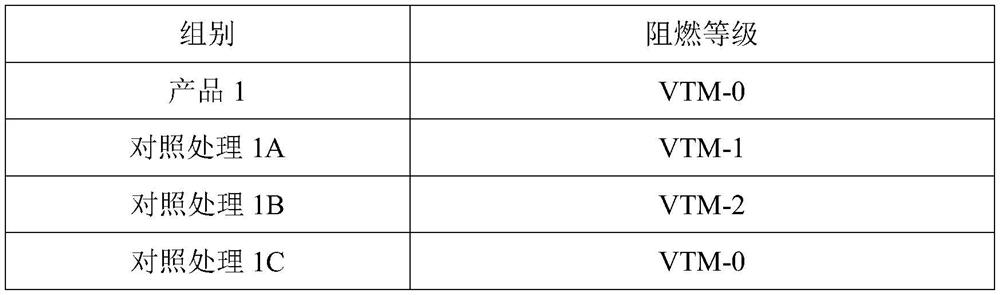

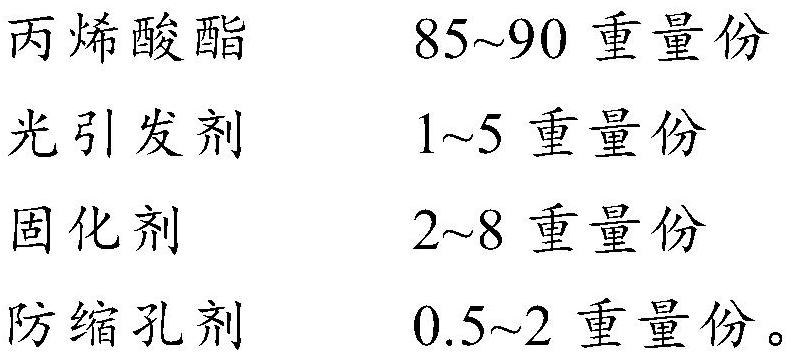

Flame-retardant adhesive tape capable of being used for wrapping lithium ion battery and preparation method of flame-retardant adhesive tape

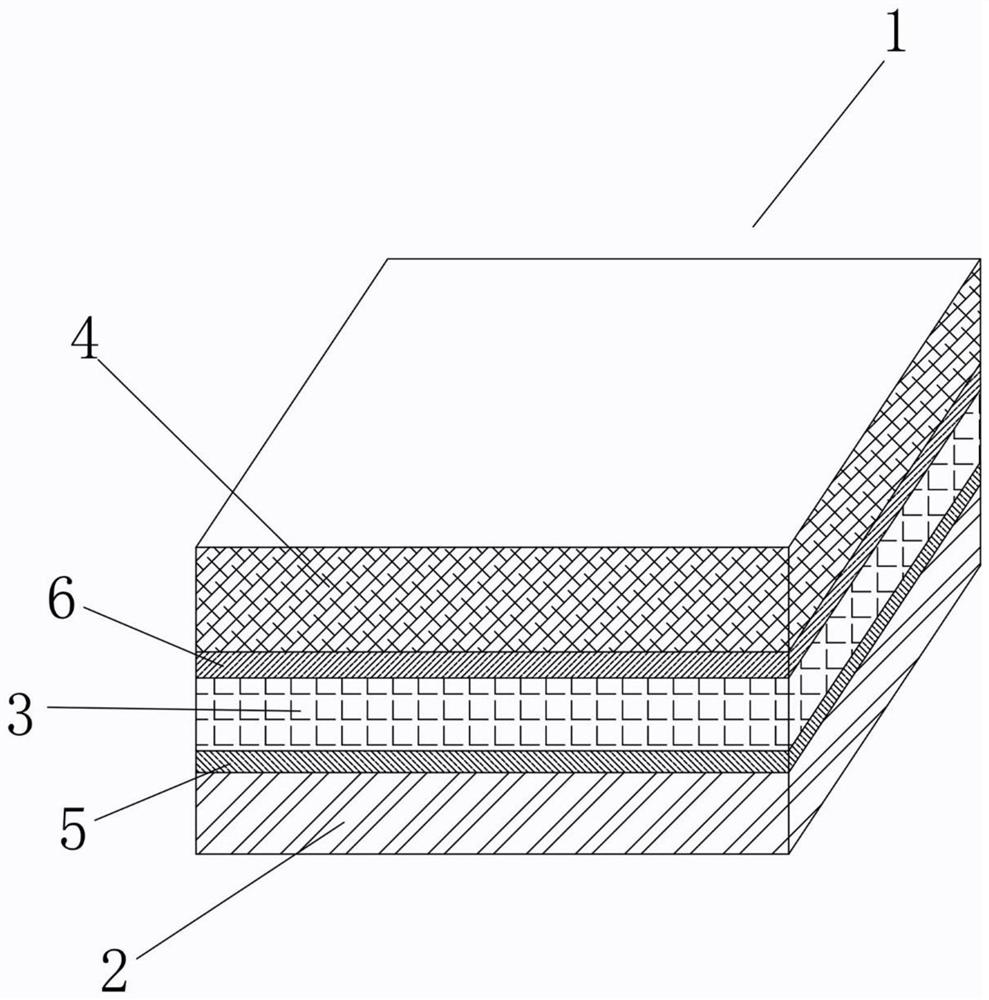

ActiveCN113088210APrintableFilm/foil adhesive primer layersFinal product manufactureAdhesiveSilicone tape

The invention provides a flame-retardant adhesive tape capable of being used for wrapping a lithium ion battery. The flame-retardant adhesive tape comprises a printable coating, a base film layer, a flame-retardant coating and a pressure-sensitive adhesive layer which are sequentially compounded, wherein the total thickness of the flame-retardant adhesive tape is not more than 45 microns; the flame-retardant coating comprises the following components in parts by mass: 100 parts of flame-retardant resin, 100-200 parts of a flame retardant and 1-10 parts of an additive; and the pressure-sensitive adhesive layer comprises the following components in parts by mass: 80-120 parts of a polyacrylate pressure-sensitive adhesive and 0.01-2 parts of a cross-linking agent, the total mass of the polyacrylate pressure-sensitive adhesive and the cross-linking agent accounts for not less than 98% of the mass of the pressure-sensitive adhesive layer, and the balance is unavoidable impurities. The flame-retardant adhesive tape provided by the invention has the characteristics of printability, ultra-thinness, high transparency, good flame-retardant effect and high bonding strength, and has a good application prospect.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

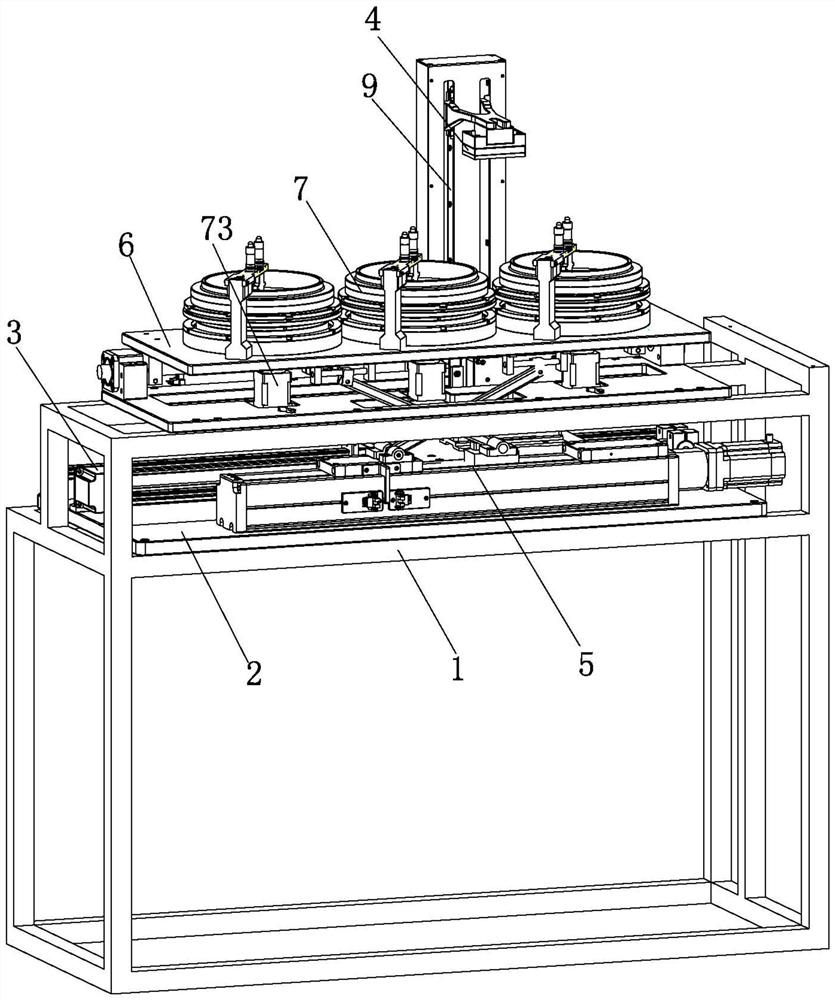

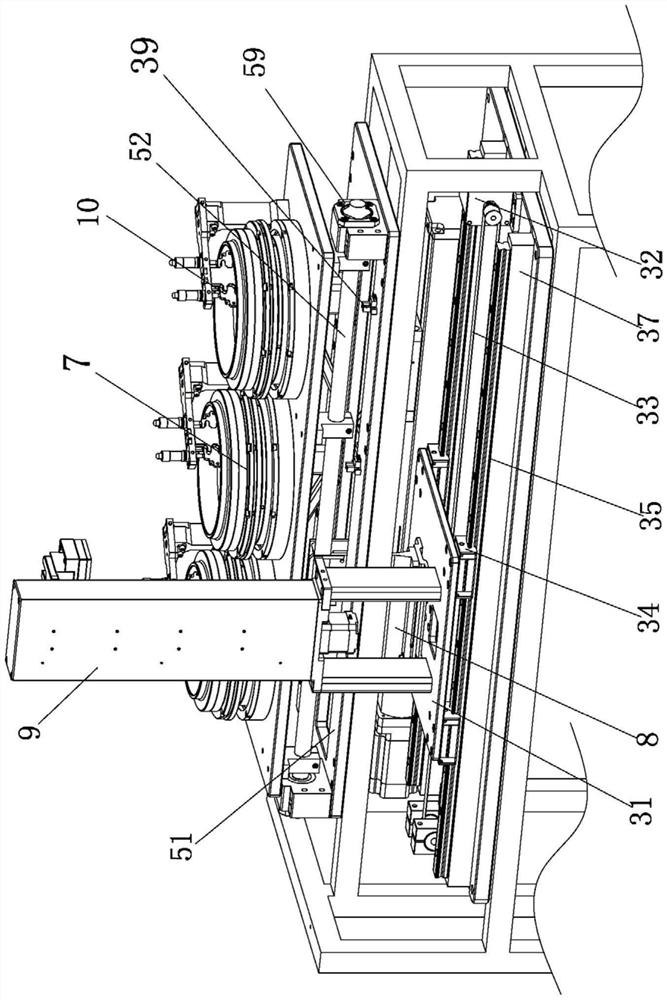

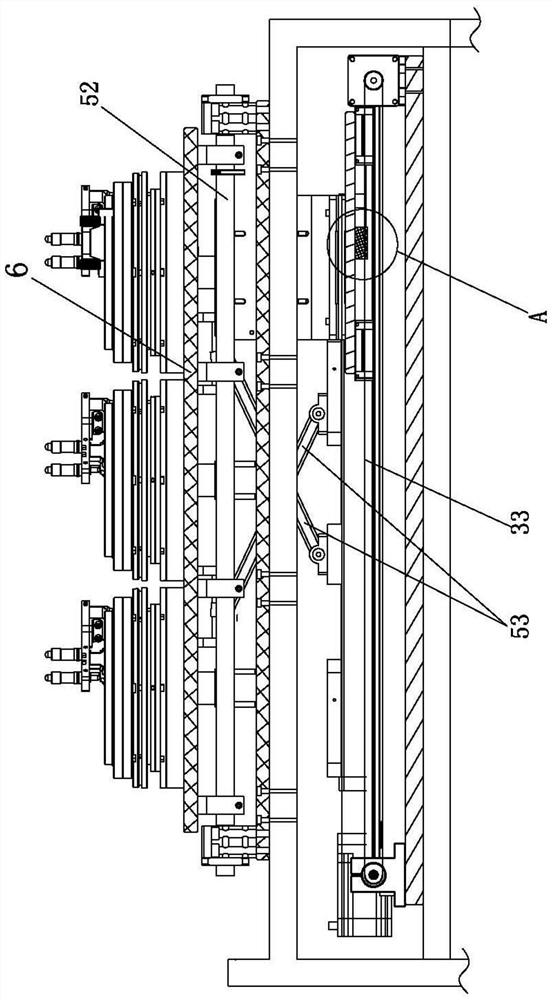

A multi-material 3D printer

ActiveCN110757798BPrecise positioningNo misalignmentManufacturing enclosuresAdditive manufacturing with liquidsComputer printing3d printer

The invention relates to a multi-material 3D printer, comprising a frame, a bottom plate, a Z-axis translation mechanism, a printing platform, an oblique drawing mechanism, a mounting plate and at least two material holding mechanisms; the bottom plate is fixedly mounted on the frame; the The Z-axis translation mechanism is supported on the bottom plate and can move relative to the bottom plate; an optical machine is installed on the Z-axis translation mechanism, and the light machine can move to the bottom of any material holding mechanism along with the Z-axis translation mechanism; the printing platform is installed on On the Z-axis translation mechanism, it can lift up and down and move horizontally; the bottom end of the oblique pulling mechanism is installed on the bottom plate, and the top end is connected to the mounting plate, which can drive the mounting plate to turn over; the material holding mechanism is arranged side by side on the mounting plate ; The printing platform can be translated to the top of each material holding mechanism along the arrangement direction of the material holding mechanism, so as to realize multi-material printing by using different printing materials in each material holding mechanism. The invention can realize the printing of various materials, and the printing demoulding is fast, and can effectively solve the problem that the printing materials cannot be printed.

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD

Anti-peeping printable antimagnetic film and preparation method thereof

ActiveCN107142036BAvoid scratchesWith anti-magnetic effectSynthetic resin layered productsLaminationMagnetic effectAdhesive glue

The invention provides a peep-proof printable magnetic-resistant film. The peep-proof printable magnetic-resistant film comprises a first protective film layer, an UV hardened layer composited to the first protective layer, a TPU layer composited on the UV hardened layer, an OCA adhesive layer composited on the TPU layer, a substrate layer combined on the OCA adhesive layer, a micro louver structure layer composited on the substrate layer and a second protective layer combined to the micro louver structure layer. The UV hardened layer is made of metal and oxide thereof, carbon conductive material and UV varnish glue. The UV hardened layer has an anti-magnetic effect and a printable function, the UV-hardened layer cooperates with the other layers to obtain the peep-proof printable magnetic-resistant film which has display confidentiality, the peep-proof layer is effectively prevented from being scratched, and the film has good printability and magnetic resistance and can meet customer's personal pursuit.

Owner:NALI OPTICAL MATERIAL DONGGUAN

A kind of explosion-proof film in the screen and its preparation method

ActiveCN106244037BPrintableDoes not affect the visual effectNon-macromolecular adhesive additivesFilm/foil adhesivesGlass coverAdditive ingredient

The invention discloses a screen inner rupture-proof film, and a preparation method thereof. The screen inner rupture-proof film is adhered to the inner surface of a screen glass cover plate so as to realize protection of the screen. The screen inner rupture-proof film comprises a base material; one surface of the base material is coated with a UV varnish adhesive layer, and the other surface of the base material is coated with an acrylic adhesive layer; the other surface of the acrylic adhesive layer is coated with a release film; the thickness of the base material ranges from 20 to 100<mu>m, and the base material is prepared from one ingredient selected from PET, OPP, and PE; the release film is a PET release film with a thickness ranging from 50 to 150<mu>m; and the release force ranges from 3 to 20gf. According to the preparation method, one surface of the screen inner rupture-proof film is provided with the UV vanish adhesive layer, so that the screen inner rupture-proof film possesses impressionability, the screen inner rupture-proof film is printed with the shape and the appearance of the screen, and then the screen inner rupture-proof film adhered to the inner surface of the screen glass cover plate. The visual effect of the screen is seldom influenced because that the light-admitting quality of the screen inner rupture-proof film is high, and the screen inner rupture-proof film is printed with the shape and the appearance of the screen, and at the same time protection effect on the screen and electronic components in the screen is realized.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Polyester ink for ultra-thin colored film and method for making ultra-thin colored film

ActiveCN104263067BIncrease the variety of functionsMeet needsSynthetic resin layered productsInksPolyethylene terephthalateColor film

The invention discloses a polyester ink for an ultrathin colored film, which is prepared from the following raw materials in parts by mass: polyester resin, pigment, matting powder, dispersing agent, diluter and curing agent. The invention also discloses a manufacturing method of the ultrathin colored film, which comprises the following steps: 1) coating a release agent on a PET (polyethylene terephthalate) substrate, drying and curing to obtain a release layer; 2) coating the polyester ink on the release layer, drying and curing; and peeling the base film. Otherwise, the manufacturing method of the ultrathin colored film comprises the following steps: 1) coating a release agent on a PET substrate, drying and curing to obtain a release layer; 2) coating protective gloss oil on the release layer to form an ink protective layer; 3) coating the polyester ink on the ink protective layer, drying and curing to form an ink layer; and peeling the base film. The manufacturing method can be used for flexibly producing the film of any thickness or color, and can be used for preparing the polyester films with different tensile strengths and percentages of elongation; and the added ink protective layer can promote the diversification of the product functions.

Owner:DONGGUAN WEISHI ELECTRONICS MATERIALS TECH

A kind of wood-plastic composite material and preparation method thereof

The invention provides a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material is prepared from the following raw materials: thermoplastic, plant fiber, glass fiber, carbon fiber, an antistatic agent, a flame retardant, a logo printing adhesive agent, calcium carbonate, a heat stabilizer, a plasticizer, a foaming agent, an anti-impact modifier, a lubricant and an anti-ageing agent. Compared with the existing wood-plastic composite material, the logo printing adhesive agent is added to enhance the adhesion of the logo, so that the wood-plastic composite material has printability; the anti-static agent and flame retardant are added to endow the material with antistatic property and flame retardance; and glass fiber and carbon fiber are added to improve the physical and mechanical properties on the promise of ensuring good processing properties of the material.

Owner:重庆长江电工工业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com