Alcohol antistaling agent wrapper paper and method for making same

A preservative and wrapping paper technology, applied in wrapping paper, wrapping paper, packaging, etc., can solve the problems of unstable alcohol volatilization rate, difficult control of wrapping paper hole depth, food contamination, etc. Excellent alcohol permeability, stable breathability and alcohol permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

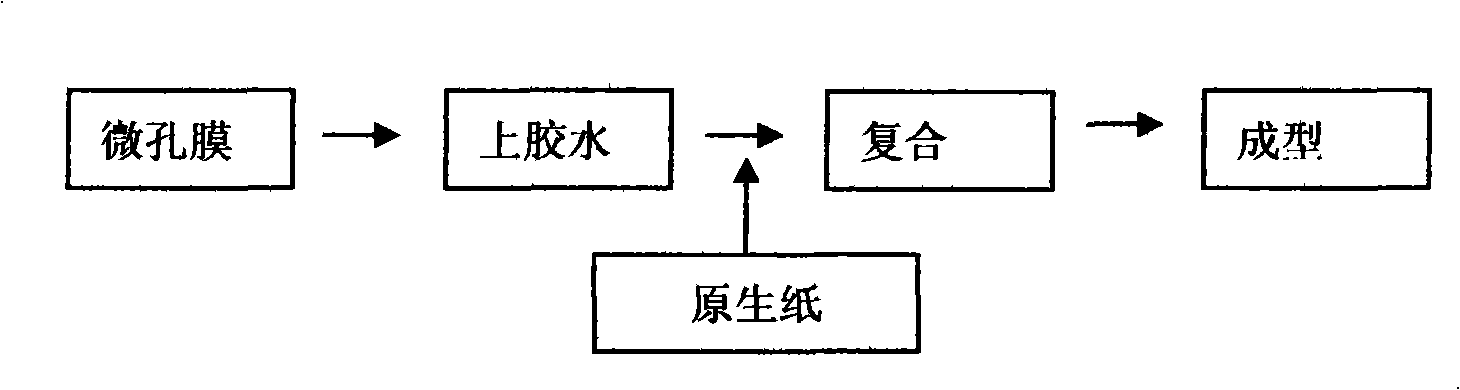

[0024] refer to figure 1 , provide a kind of wrapping paper for alcohol antistaling agent, it is formed by laminating base paper layer and plastic film layer on the surface layer, wherein the plastic film layer is made of thermoplastic material selected from polyolefin and its mixture or copolymer, so The plastic film layer is a microporous film formed through microporous treatment during the production process.

[0025] The plastic film layer can use one of the following plastics with heat-sealing properties or a mixture thereof as the substrate: ethylene vinyl acetate, ethylene ethyl acrylate, ethylene acrylic acid, linear low-density polyethylene, high-density polyethylene, polyolefin plastic, Polyvinyl alcohol, polyacrylonitrile, ethylene-propylene elastomer mixture; and during the production process, one or more fillers of the following substances with an average particle size of about 0.1-10 microns are added for stretching to produce uniform micropores , Microporous fi...

Embodiment 2

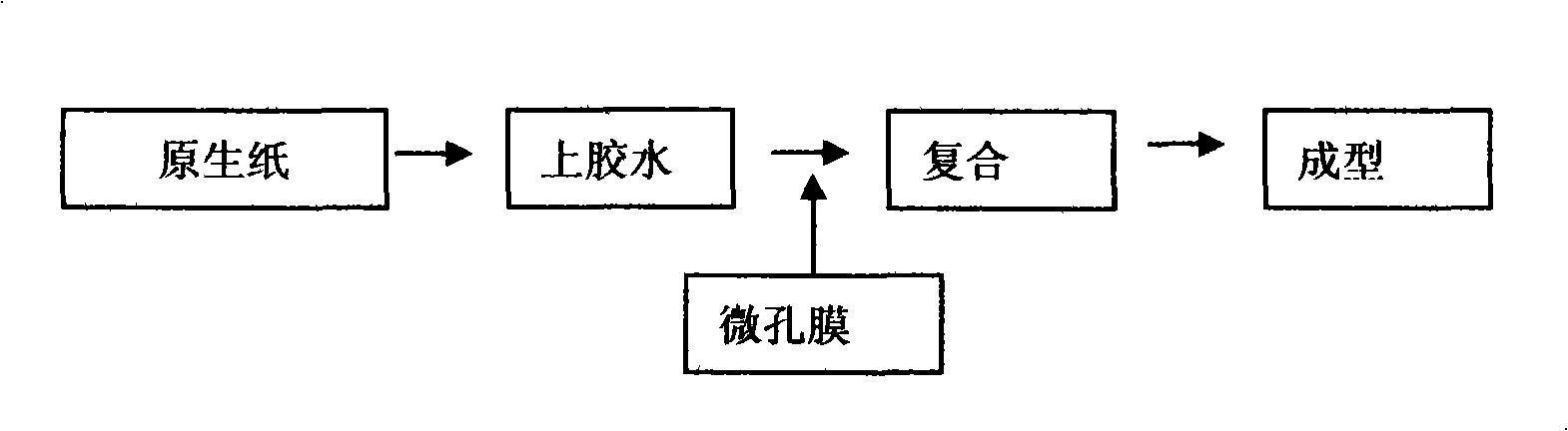

[0029] refer to figure 2 , apply glue on the original paper layer and then compound it with the microporous membrane prepared in the above way, and finally form it, and the rest are the same as in Example 1.

Embodiment 3

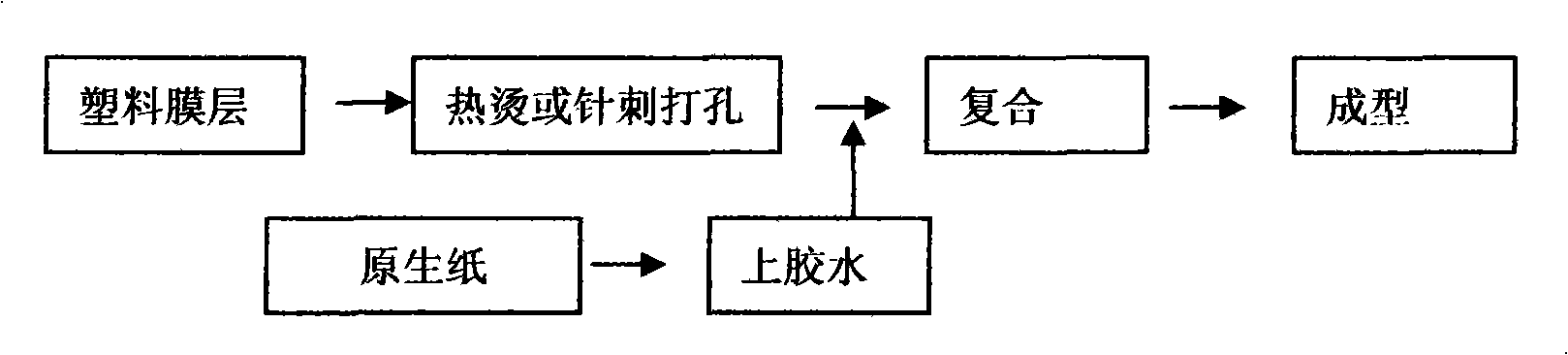

[0031] refer to image 3 , Alcohol preservative wrapping paper is also formed by laminating the surface base paper layer and the plastic film layer, and the plastic film layer is a perforated film formed by directly scalding and acupuncture treatment during the production process.

[0032] The perforated film also adopts one of the following plastics with heat-sealing properties or a mixture thereof as a substrate: ethylene vinyl acetate, ethylene ethyl acrylate, ethylene acrylic acid, linear low-density polyethylene, high-density polyethylene, polyethylene Olefin plastics, polyvinyl alcohol, polyacrylonitrile, ethylene-propylene elastomer blends.

[0033] Take the following preparation methods:

[0034] The perforated film is obtained by scalding or needle-punching on the plastic film layer, and at the same time, glue is applied on the original paper layer, and then the two are compounded and finally formed.

[0035] refer to Figure 4 Carry out blanching or acupuncture pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com