Patents

Literature

43results about How to "Heat sealable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer chlorine-free film with polyester barrier layer and ostomy pouches formed therefrom

InactiveUS6258423B1Good odor barrier propertyMinimal noiseSynthetic resin layered productsColostomyLow noisePolyethylene terephthalate glycol

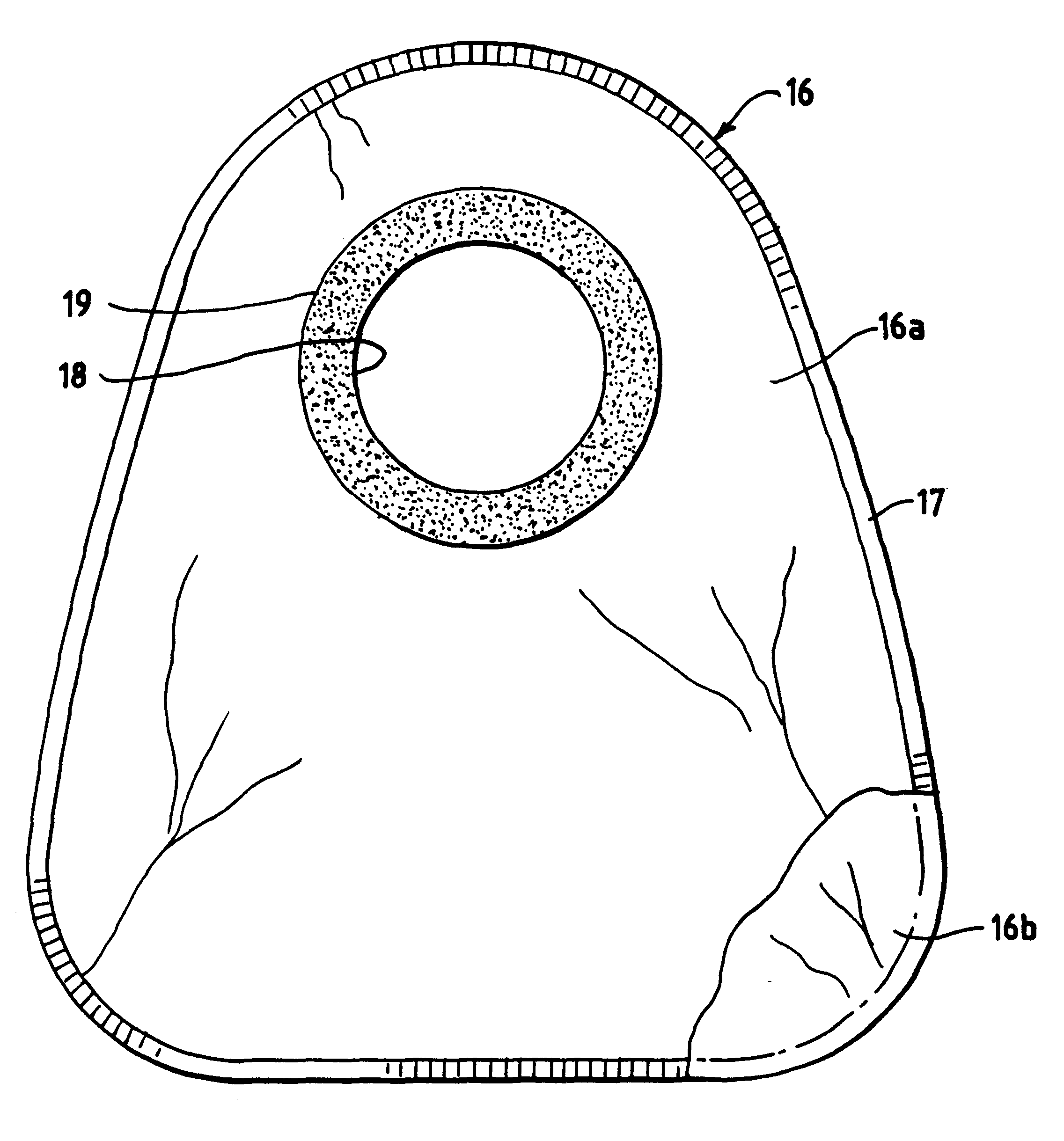

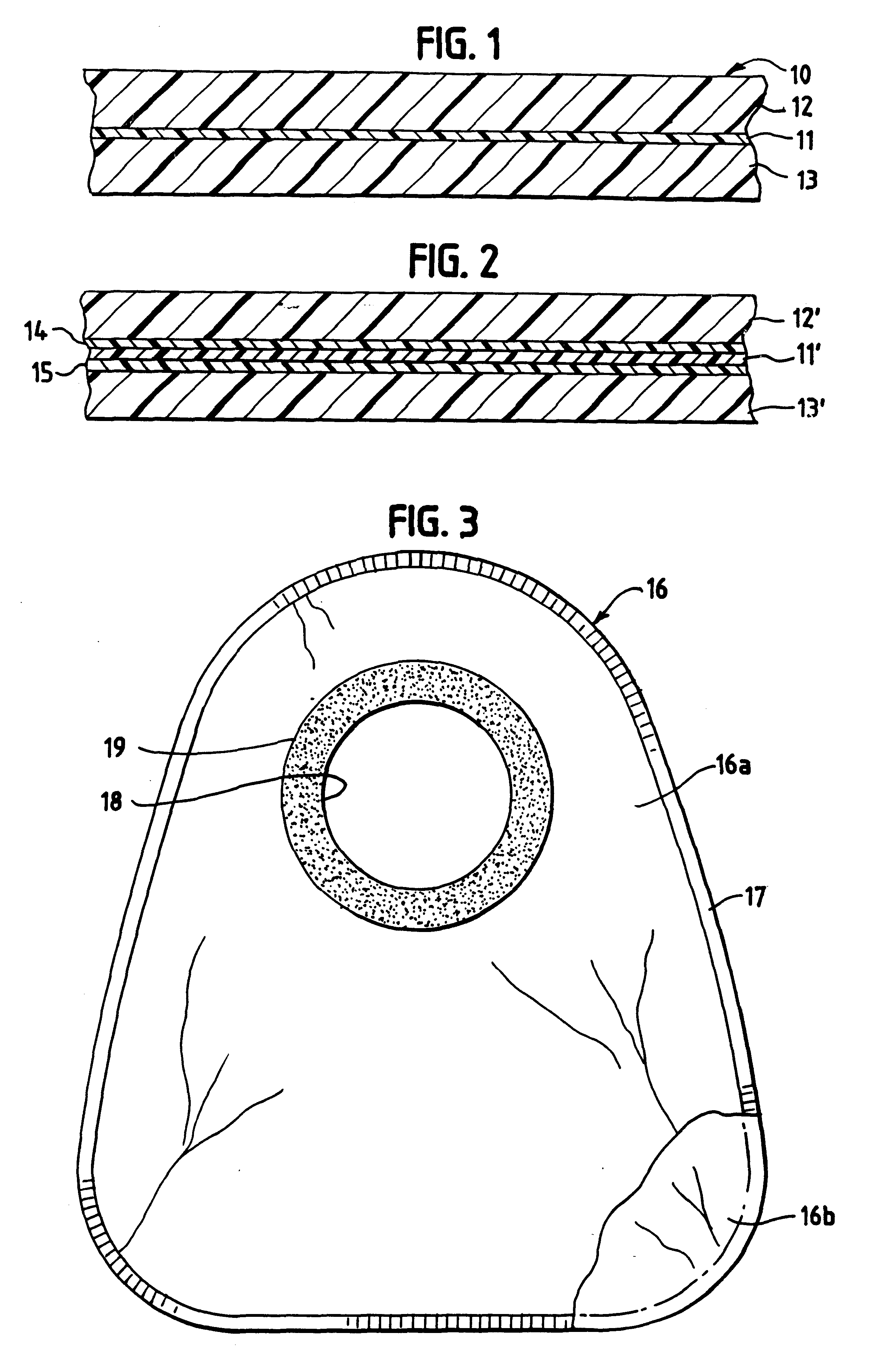

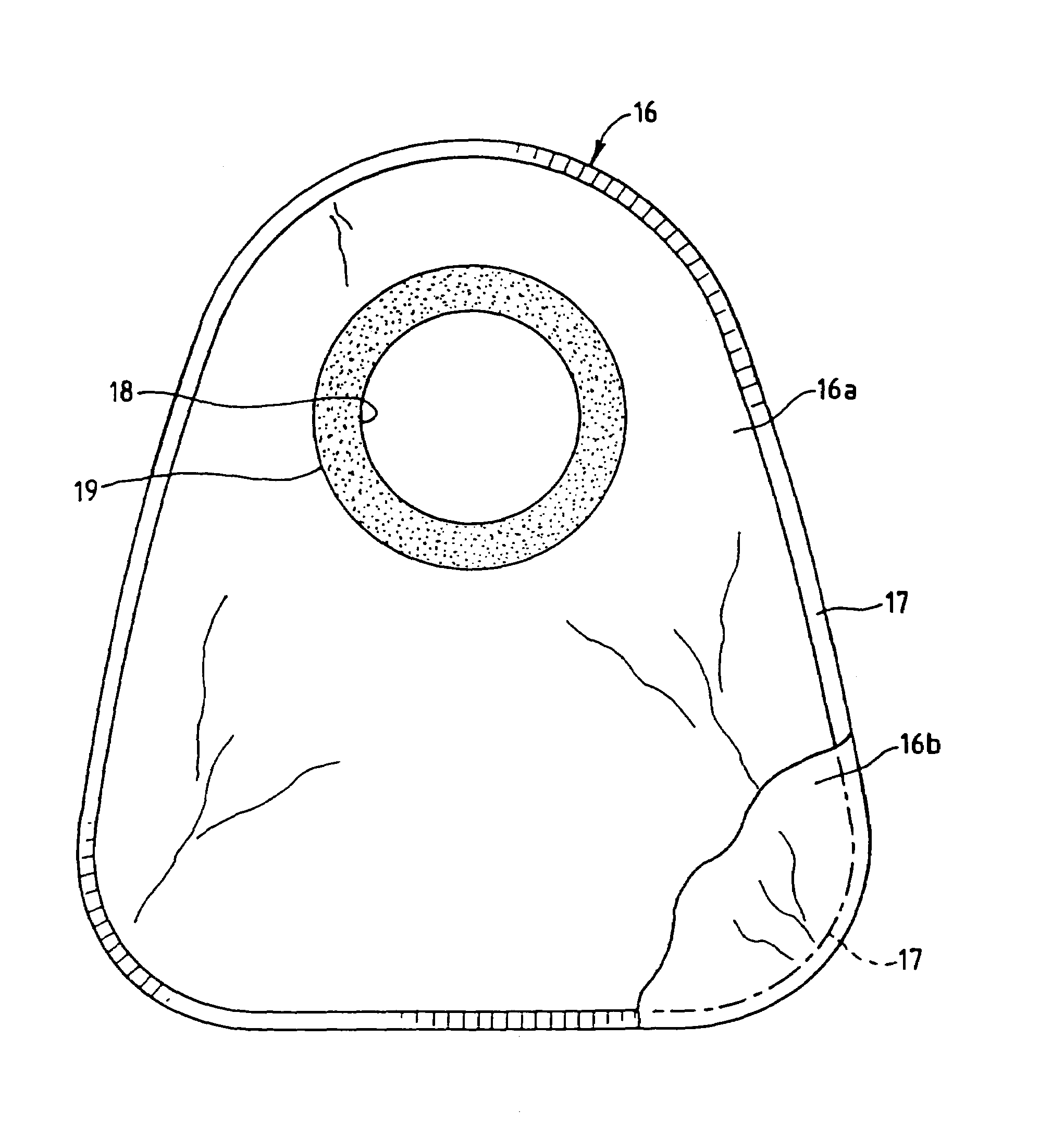

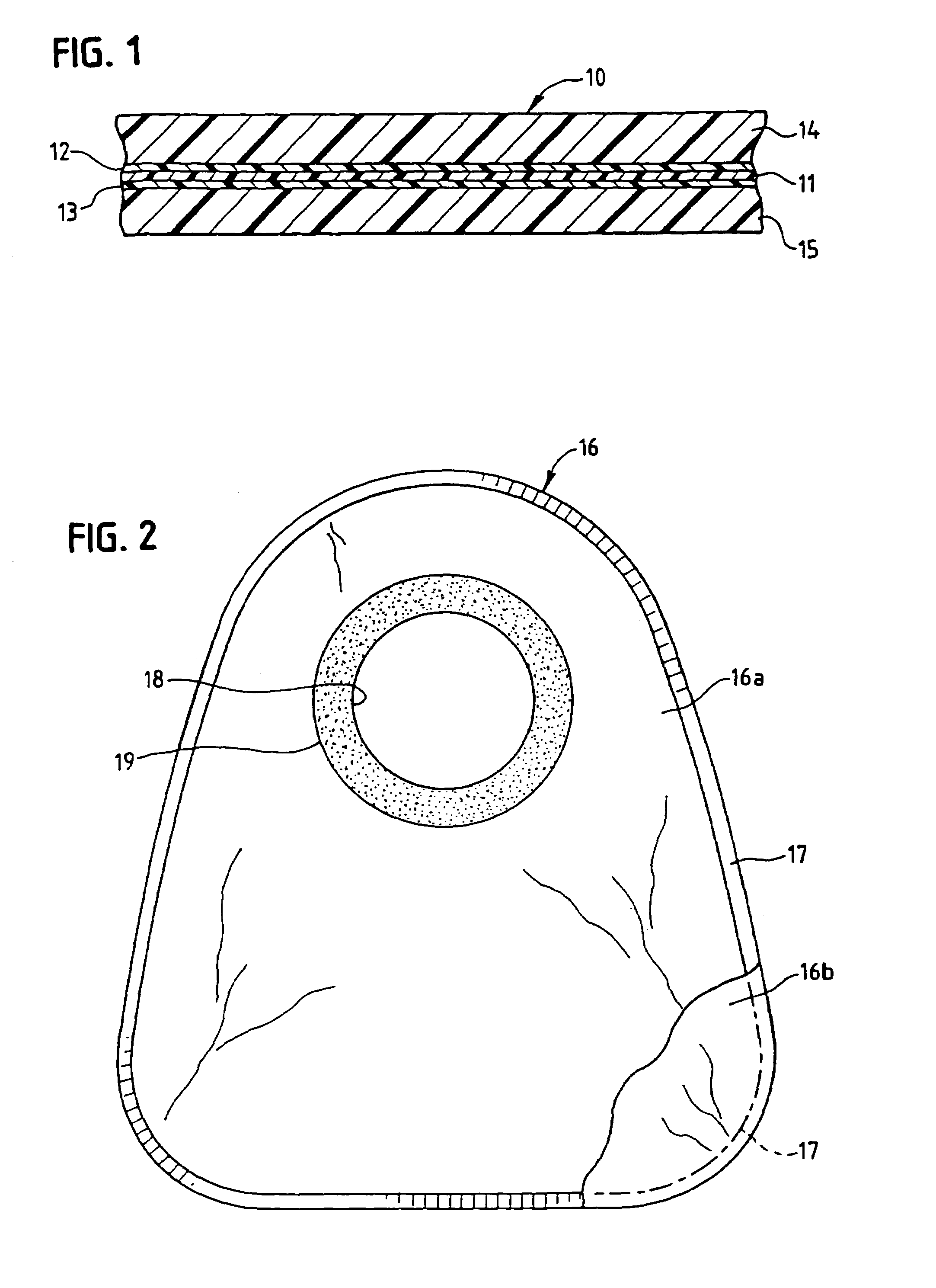

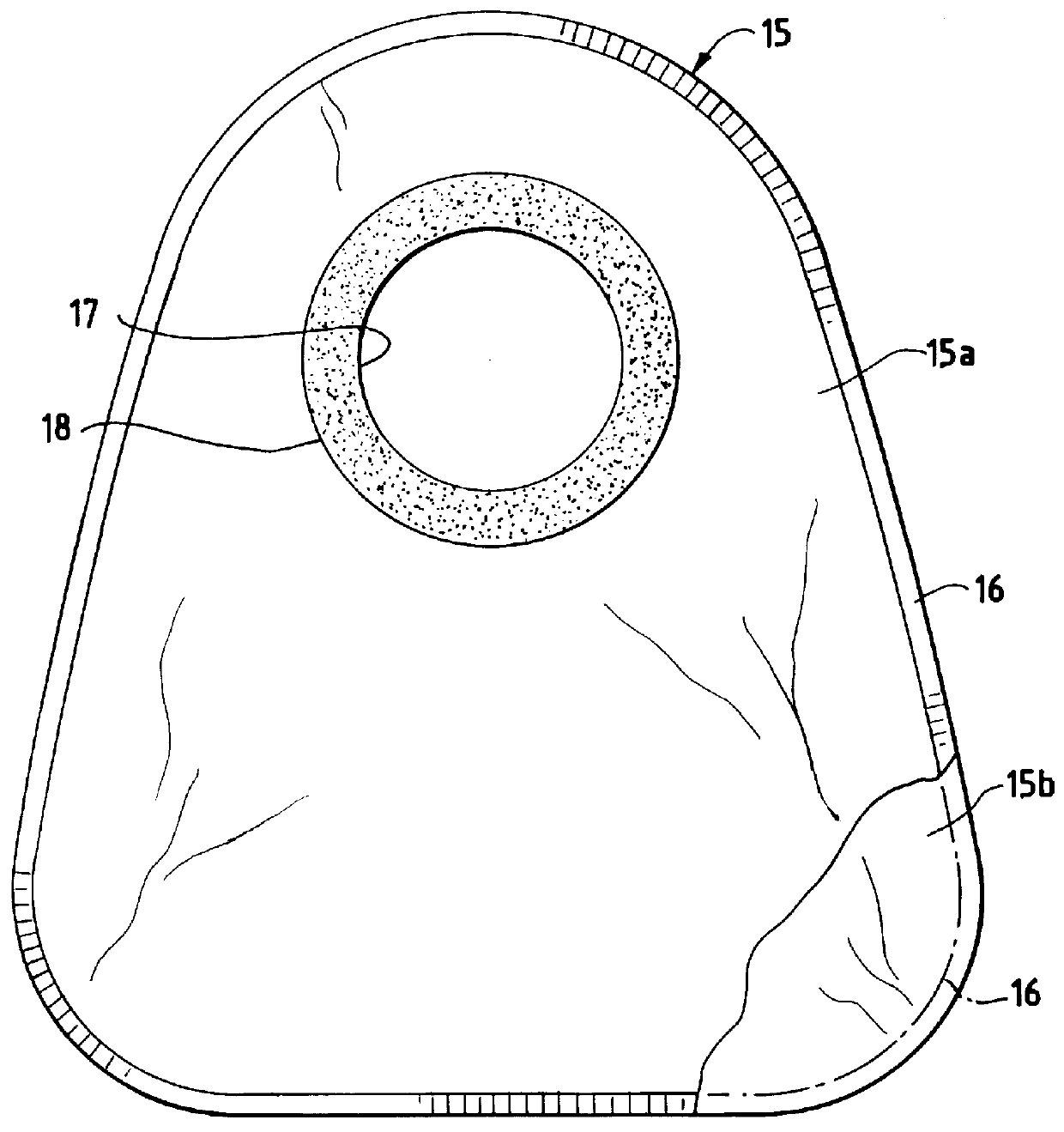

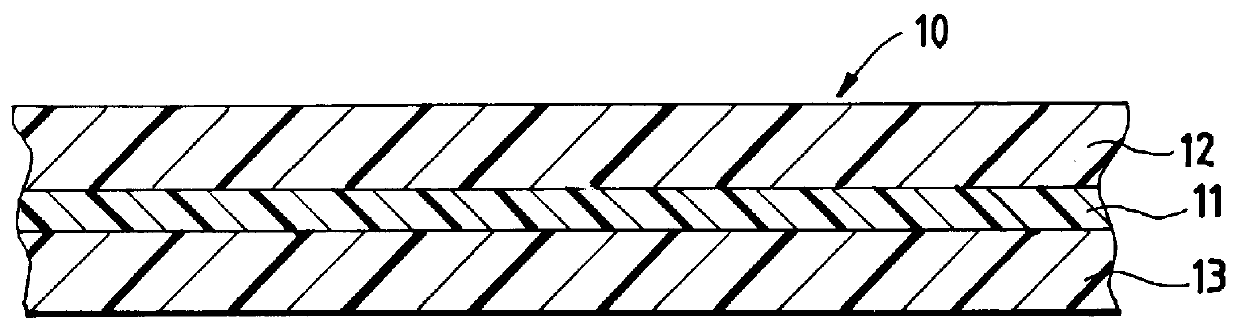

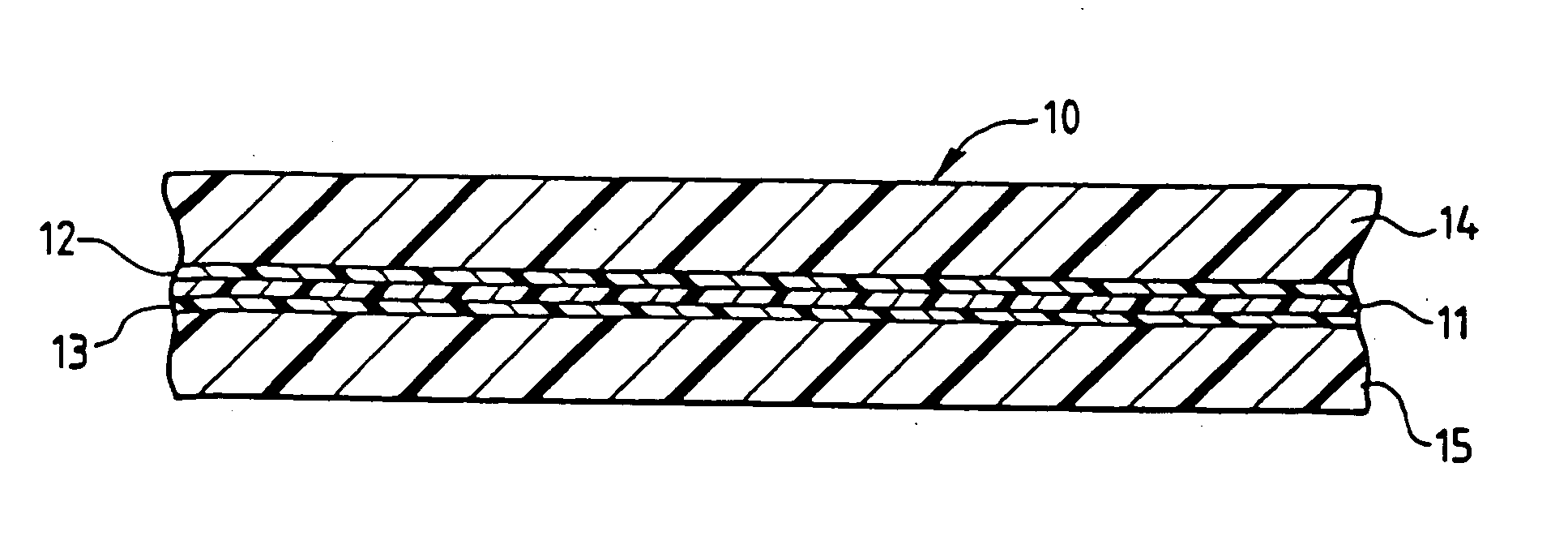

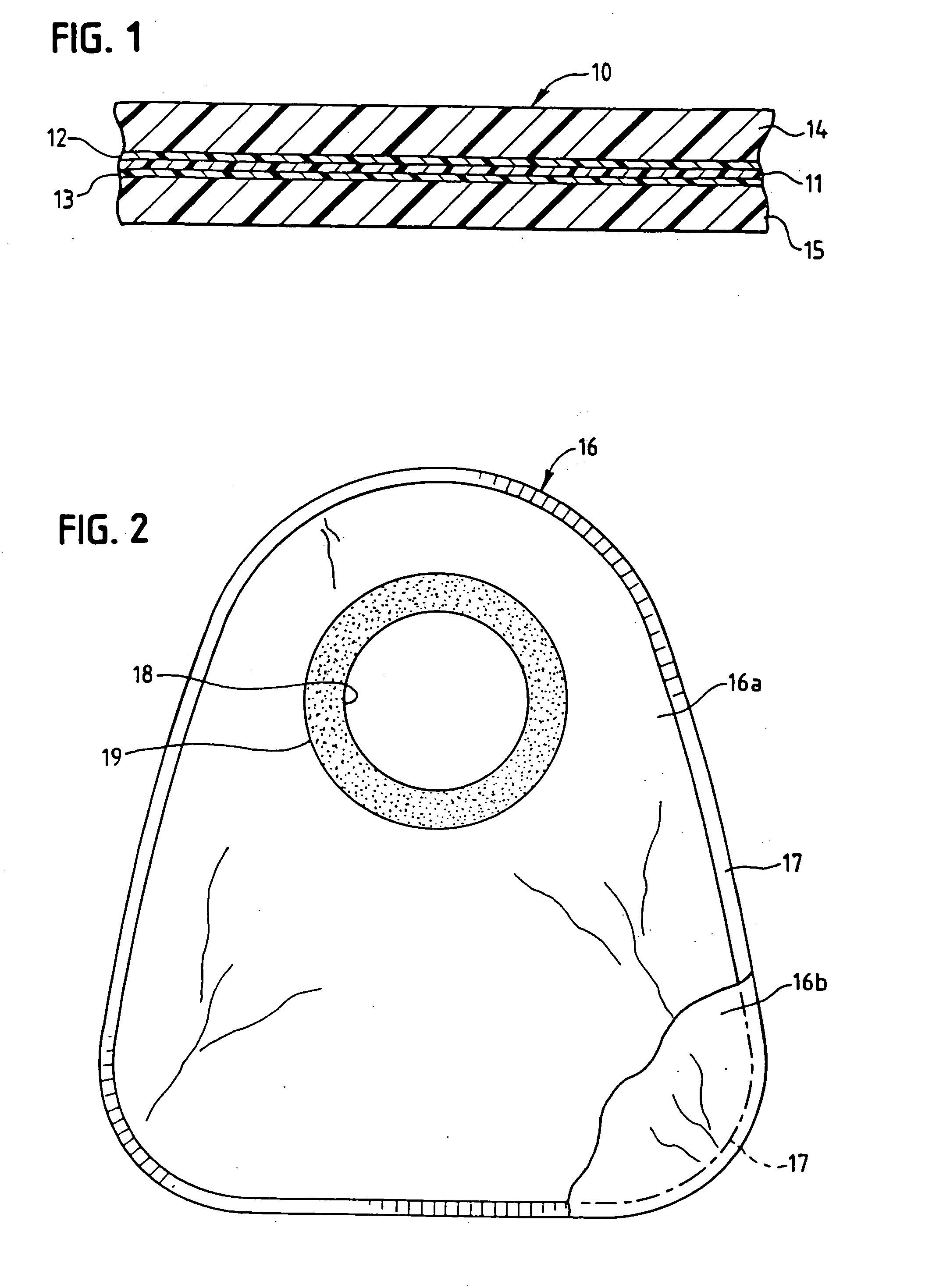

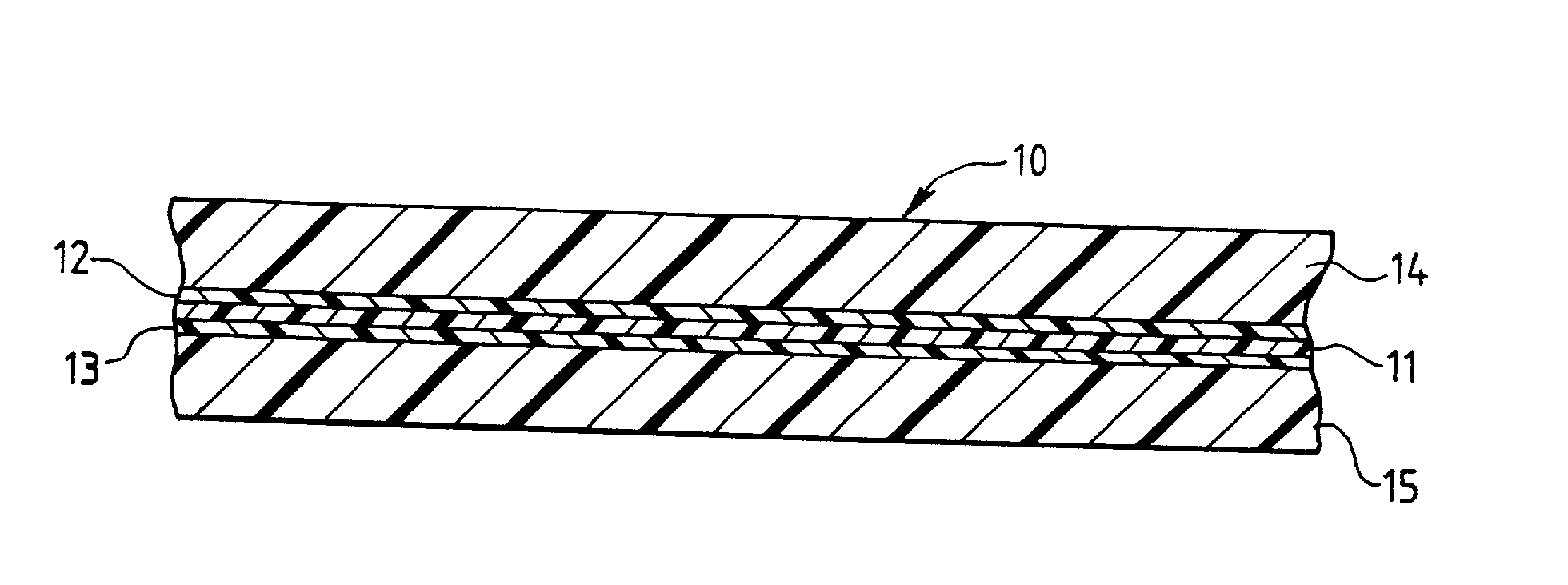

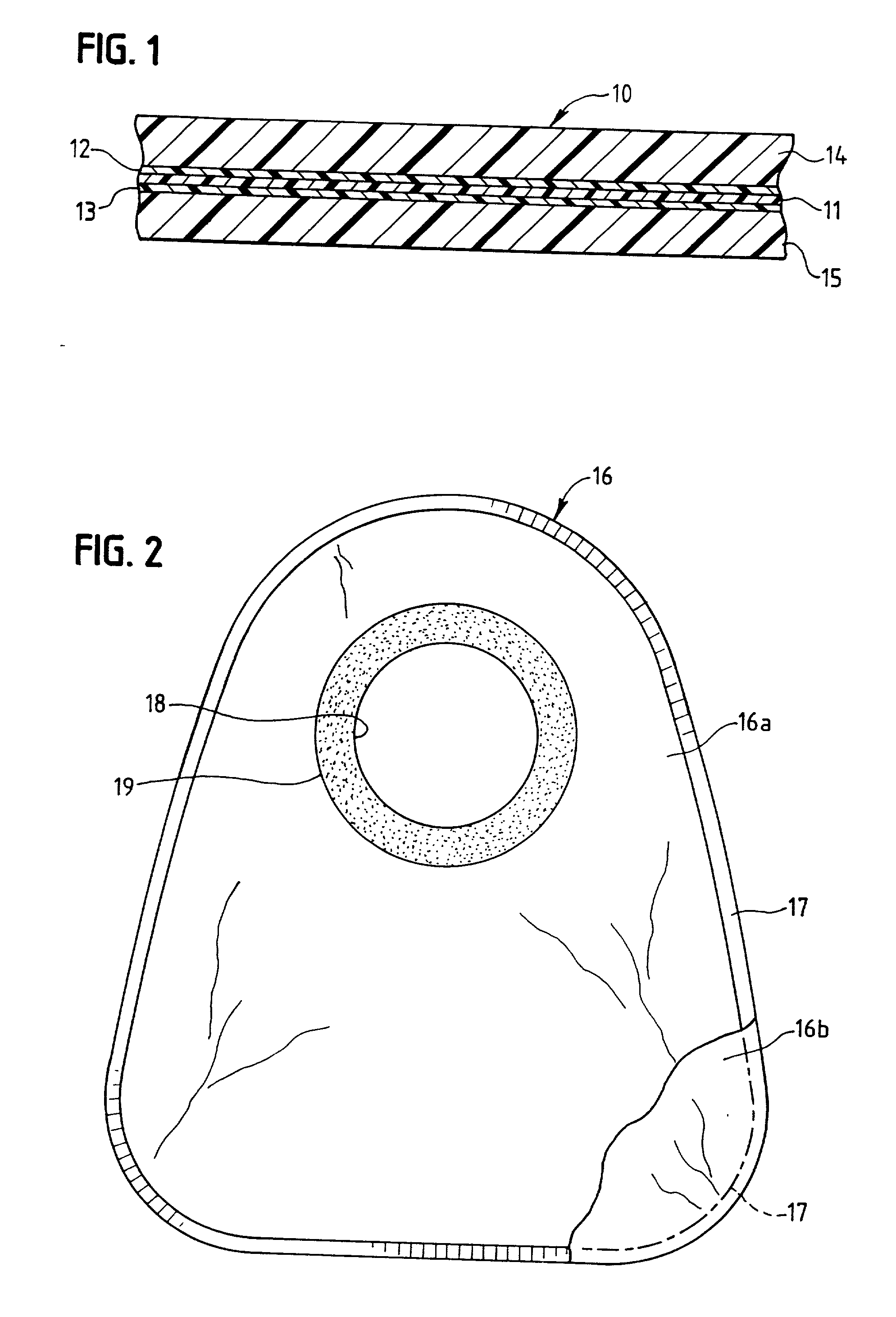

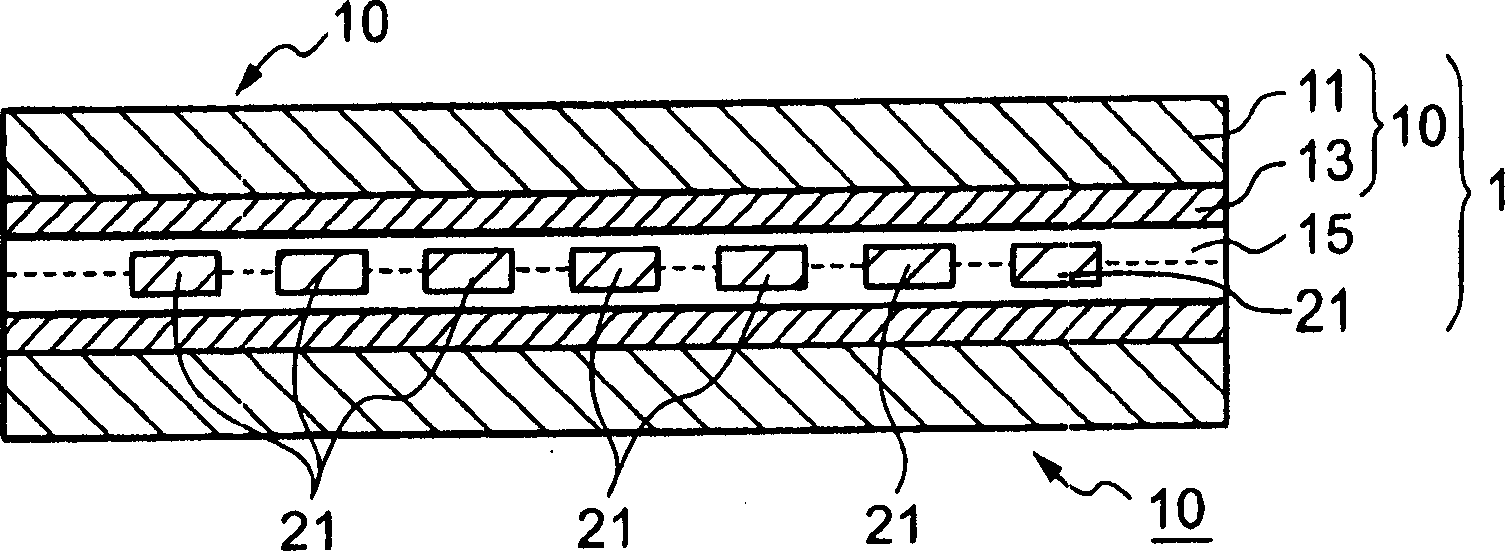

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of polyester resin and at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of a homopolymer of ethylene or a copolymer of ethylene and an alpha-olefin or an ester-containing monomer. In a preferred embodiment, the odor barrier layer is formed of polyethylene terephthalate and adhesive tie layers are interposed between the odor barrier layer and the skin layers, resulting in a multilayer film of five layers. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

Multilayer chlorine-free film with barrier layer of a polyamide blend and ostomy pouches formed therefrom

InactiveUS7270860B2Good odor barrier propertyMinimal noiseEnvelopes/bags making machineryLayered product treatmentPolyamideEthylene Polymers

A multilayer heat-sealable chlorine-free odor barrier film having relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of an amorphous polyamide resin blended with an anhydride-modified olefinic polymer or copolymer. The film also includes at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of an ethylene polymer or copolymer. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

Multilayer chlorine-free film with barrier layer of a polyamide blend and ostomy pouches formed therefrom

InactiveUS6143383AGood odor barrier propertyMinimal noiseSynthetic resin layered productsBagsHigh resistanceLow noise

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film includes an odor barrier layer and at least one directly adjoining heat-sealable skin layer. The barrier layer is composed of either an aliphatic or partially aromatic polyamide resin, or a blend thereof, blended with an ionomer resin consisting essentially of a partially neutralized ethylene-methacrylic acid copolymer, and the heat-sealable skin layer or layers bonded directly to the barrier layer are composed of copolymers of ethylene and an ester-containing comonomer. High resistance to delamination of the barrier layer and skin layer(s) is achieved without tie layers therebetween. Pouches formed of such multilayer chlorine-free films are also disclosed.

Owner:HOLLISTER INCORPORAED

Multilayer chlorine-free film with barrier layer of a polyamide blend and ostomy pouches formed therefrom

InactiveUS20040228992A1Good barrier propertyGood resistance to odor transmissionEnvelopes/bags making machineryLayered product treatmentLow modulusOlefin polymerization

A multilayer heat-sealable chlorine-free odor barrier film having relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of an amorphous polyamide resin blended with an anhydride-modified olefinic polymer or copolymer. The film also includes at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of an ethylene polymer or copolymer. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

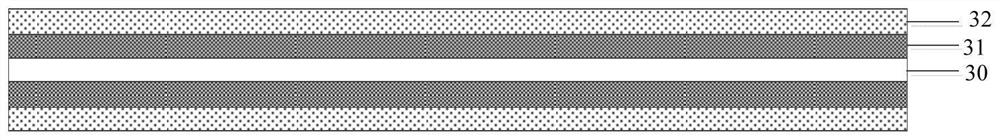

VMPET coated thin film, and production method

InactiveCN101092069AGood heat sealingImprove barrier propertiesFlexible coversWrappersPolyvinyl alcoholRaw material

The invention relates to a novel coated film and the producing method thereof. And it is a VMPET coated film, produced by coating PVDC, PVOH and AC as main raw materials on VMPET.

Owner:海南现代高科实业有限公司

Multilayer chlorine-free film with barrier layer of morphous polyamide blended with anhydride-modified olefinic polymer and ostomy pouches formed therefrom

InactiveUS20030064182A1Good odor barrier propertyMinimal noiseSynthetic resin layered productsMedical devicesPolyamideOlefin polymerization

A multilayer heat-sealable chlorine-free odor barrier film having relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of an amorphous polyamide resin blended with an anhydride-modified olefinic polymer or copolymer. The film also includes at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of an ethylene polymer or copolymer, and an adhesive tie layer between each skin layer and the odor barrier layer. Pouches formed of such multilayer films are also disclosed.

Owner:GIORI CLAUDIO

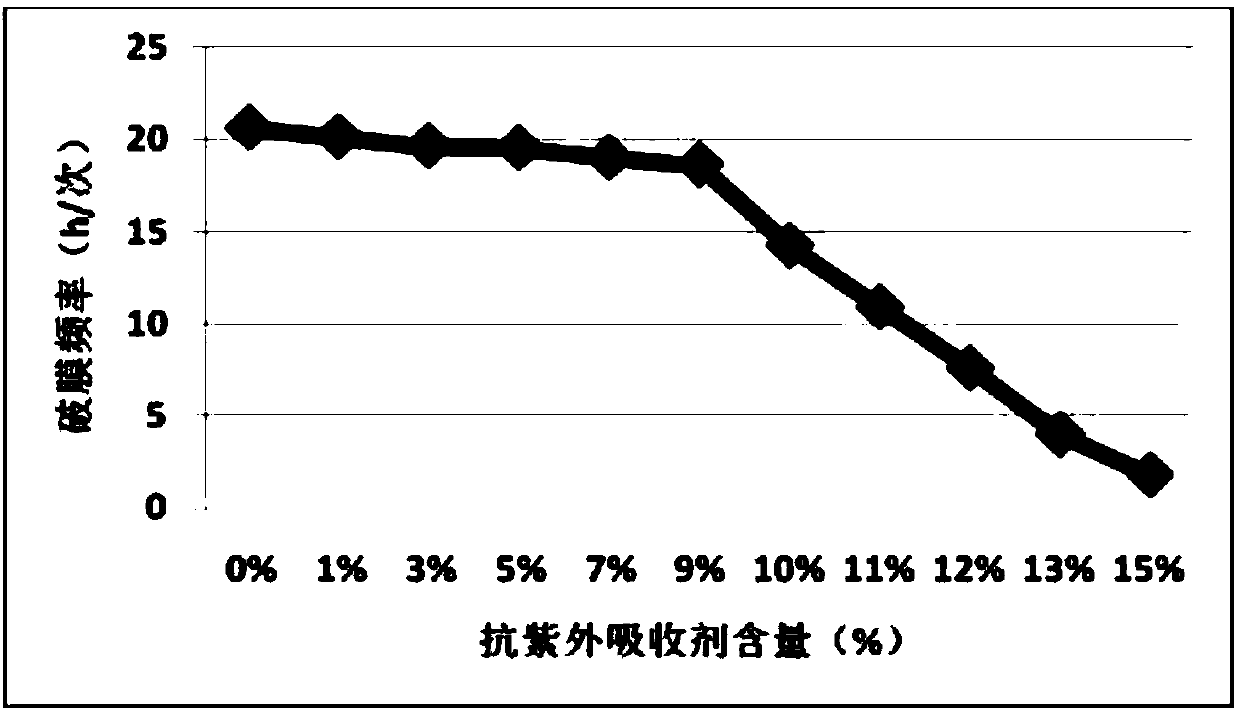

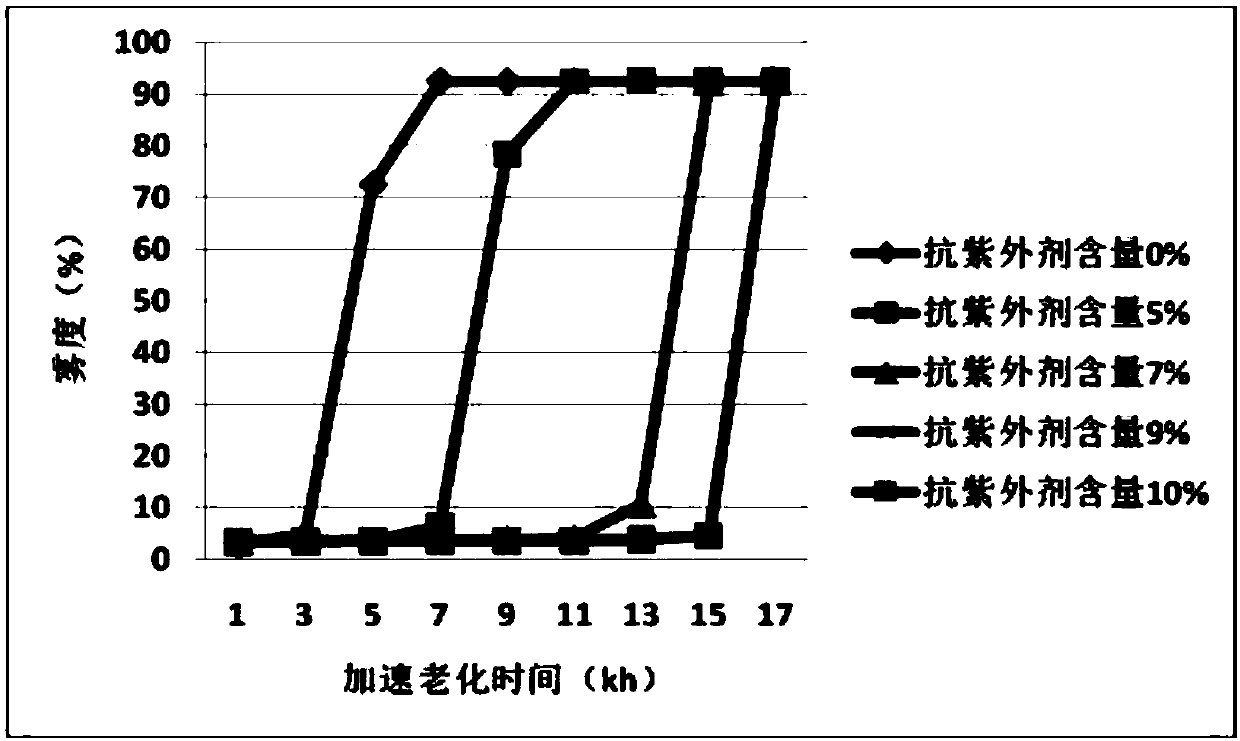

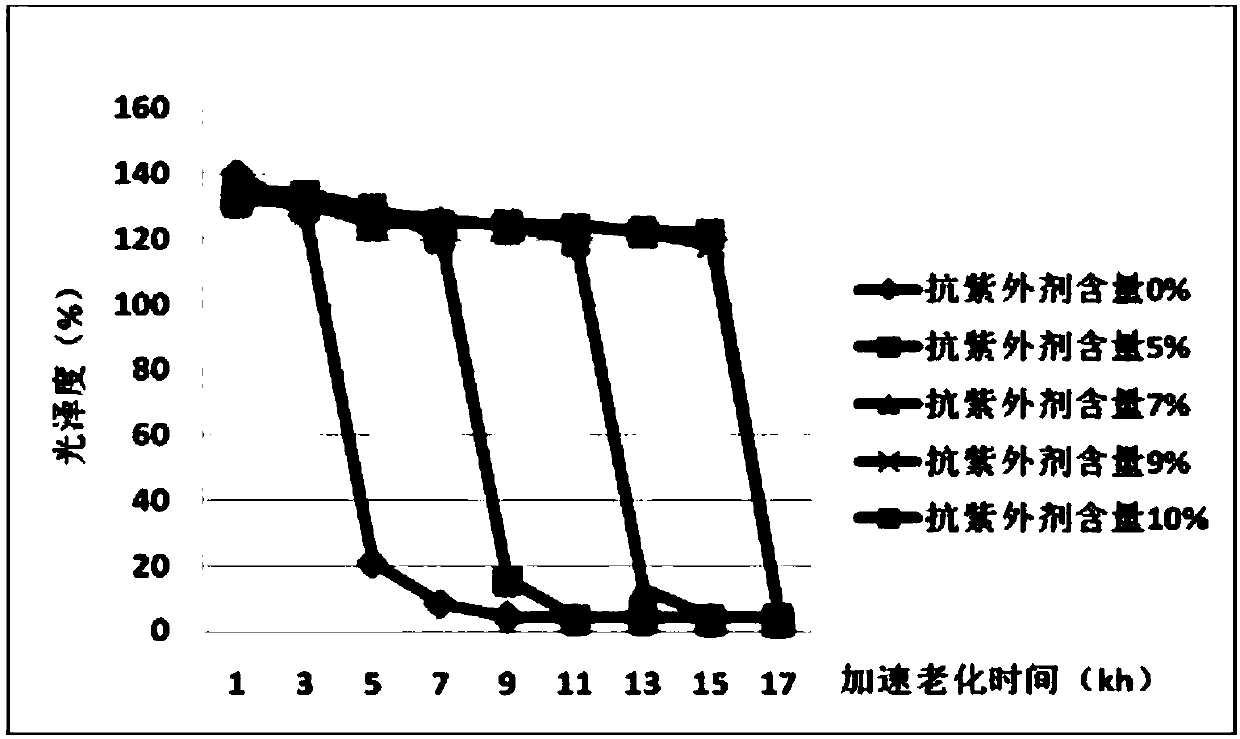

Anti-ultraviolet bidirectional stretching polyester film and preparation method thereof

InactiveCN107839323AImprove product performanceEnhanced anti-aging effectSynthetic resin layered productsFlat articlesPolyesterChemistry

The invention relates to an anti-ultraviolet bidirectional stretching polyester film and a preparation method thereof. The an anti-ultraviolet bidirectional stretching polyester film is composed of anupper surface layer, a core layer, and a lower surface layer. The core layer is composed of an anti-ultraviolet absorbent and polyethylene glycol terephthalate slice; the upper surface layer is composed of the anti-ultraviolet absorbent, an anti-adhesion agent, and the polyethylene glycol terephthalate slice; and the lower surface layer is composed of the anti-adhesion agent and the modified polyethylene glycol terephthalate slice. The product has the characteristics of UV resistance, heat sealing, high intensity, hydrolysis resistance, corrosion resistance, and high thermostability, can be widely used in the fields of outdoor product package and building, and belongs to the functional film, performance is outstanding, cost is low, and the method has a wide application prospect.

Owner:ANHUI GUOFENG PLASTIC

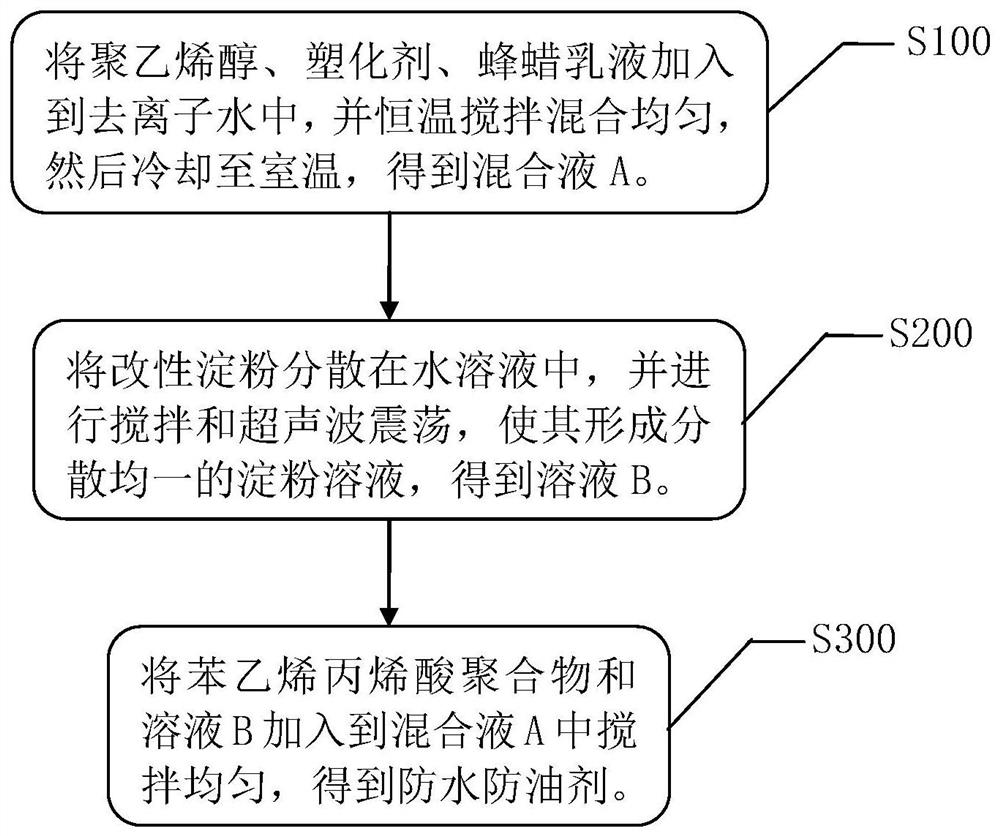

Waterproof and oilproof agent as well as preparation method and application thereof

InactiveCN111749042AGood film formingImproved water and oil repellencyNon-macromolecular organic additionPaper coatingPolymer sciencePolyvinyl alcohol

The invention relates to a waterproof and oilproof agent as well as a preparation method and application thereof. The waterproof and oilproof agent is prepared from the following components in percentage by weight: 30%-50% of styrene acrylic polymer, 5%-10% of beeswax emulsion, 2.5%-4.5% of polyvinyl alcohol, 2%-5.5% of modified starch, 0.5%-2% of plasticizer and 28%-60% of deionized water. The waterproof and oilproof agent is good in film-forming property; beeswax emulsion in a formed coating and the styrene-acrylic acid polymer are combined to form a hydrophobic and oleophobic surface layer;meanwhile, the hydrophobic and oleophobic surface layer is compounded with the modified starch, so that the waterproof and oilproof effects of the waterproof and oilproof coating on food-grade raw paper are obviously improved; the waterproof and oilproof properties of the waterproof and oilproof agent are extremely good; the waterproof and oilproof agent can completely replace traditional waxing,silicon coating and laminating processes; and the paper can directly enter a papermaking pulping system to be recycled when being recycled, the pollution of the laminated paper to the environment isreduced; and therefore, the waterproof and oilproof agent is an environment-friendly material.

Owner:ZHONGSHAN TIAN JIA PAPER PROD

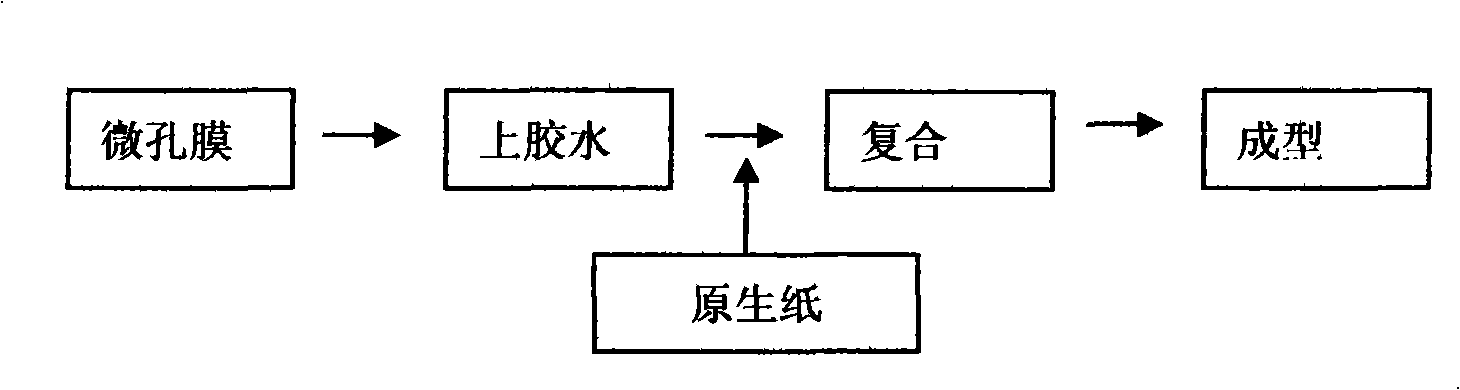

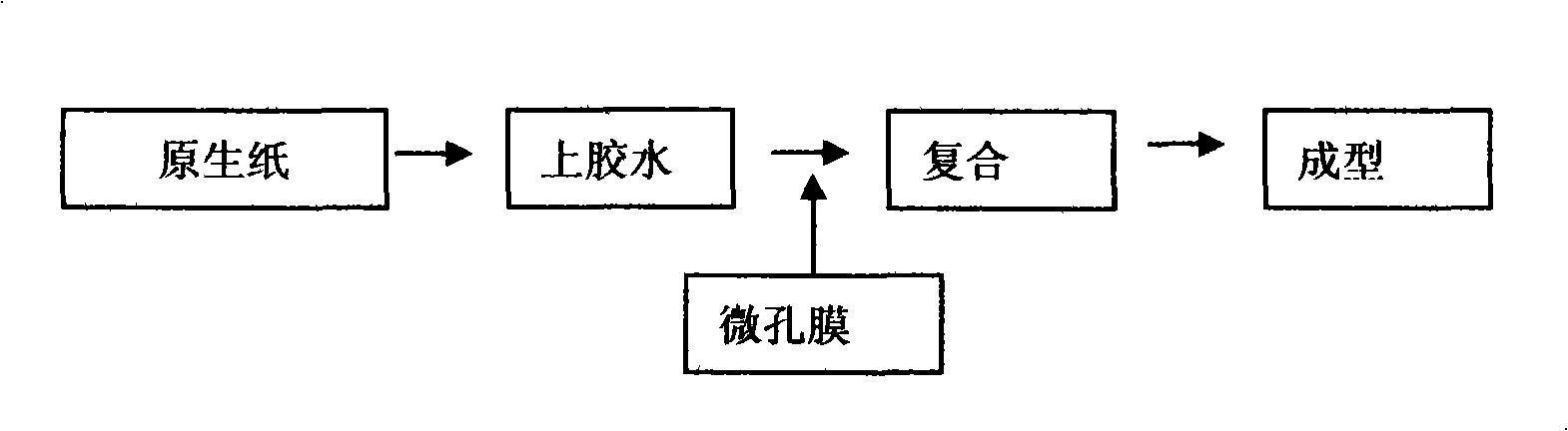

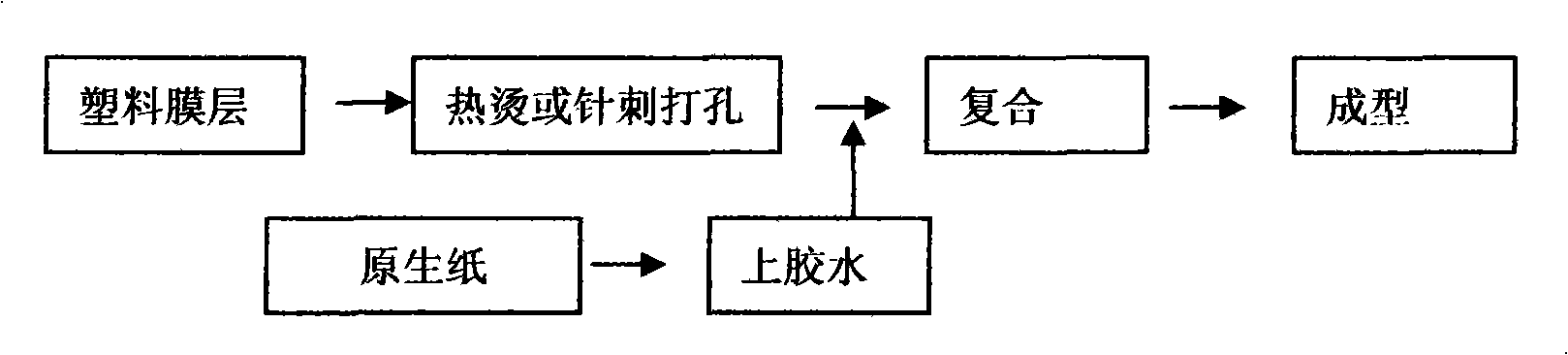

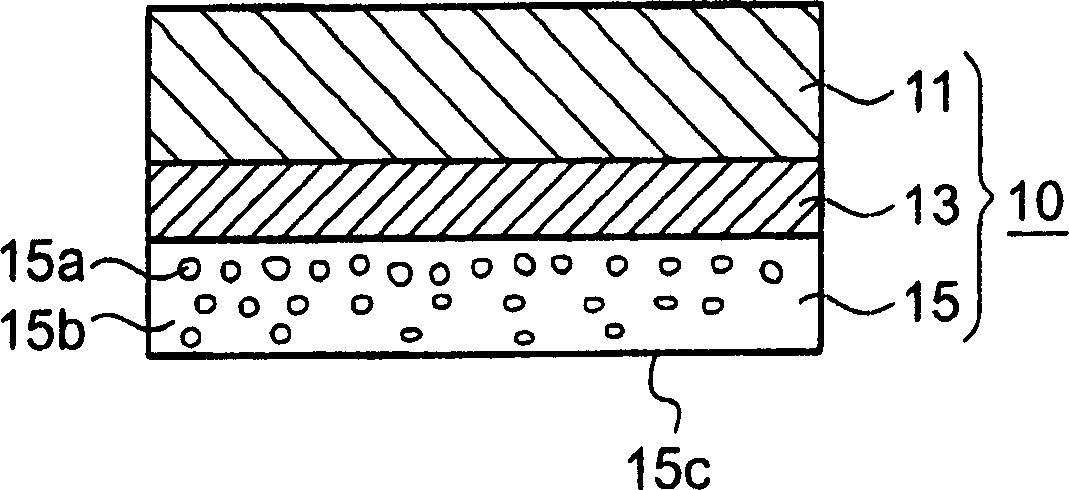

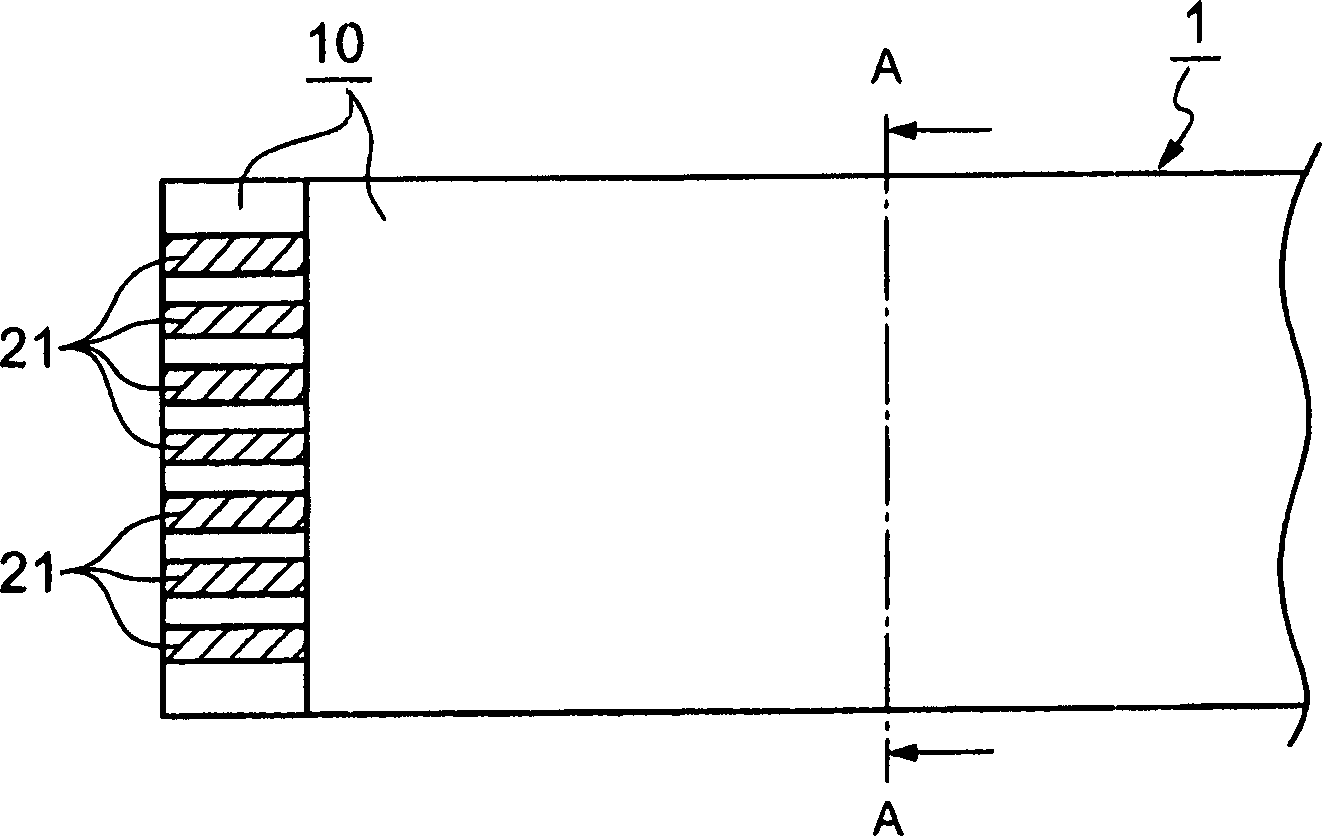

Alcohol antistaling agent wrapper paper and method for making same

InactiveCN101260633AStable, breathable and alcohol-permeableStable, breathable and wine-permeable performanceFlexible coversWrappersPaper sheetPlastic film

The invention discloses an alcohol antistaling agent wrapping paper aiming to provide the alcohol antistaling agent wrapping paper which has stable alcohol volatilizezing speed, is not lead or penetrate and has low cost and a preparation method thereof. The wrapping paper is formed by jointing a base paper layer on the surface layer and a plastic film layer, wherein, the plastic film layer is made of a material which has thermoplasticity and is selected from the polyolefine or the mixture of the polyolefine or a multipolymer, the plastic film layer is a microporous film formed by the microporous treatment in the manufacturing process, or is punching film which is formed by the direct blanching and pinprick processes in the manufacturing process.

Owner:GUANGDONG GUANGYI TECH IND

Flat-cable-coating material and flat cable

InactiveCN1806297AFlame retardantHeat-sealablePlastic/resin/waxes insulatorsNon-macromolecular adhesive additivesThermal adhesiveMaterials science

A flat cable covering material which has a base material film and, provided on one surface thereof, a thermal adhesive layer (P + V) containing at least a filler (P) and a thermoplastic resin (V), wherein the mass proportion (P) / (P + V) is distributed in a graduated manner in the direction of the thickness of the thermal adhesive layer, preferably, is gradiatedly distributed in such a manner that the mass proportion decreases from the base material film side to the side of the surface of the thermal adhesive layer in the range of (P) / (P + V) = 90 to 50 mass %, or wherein the filler (P) component comprises a hydrated metal compound (P1) and the mass proportion (P1) / (P) is gradiatedly distributed in such a manner that the mass proportion (P1) / (P) decreases from the base material film side to the side of the surface of the thermal adhesive layer in the range of (P1) / (P) = 80 to 0 mass %.

Owner:DAI NIPPON PRINTING CO LTD

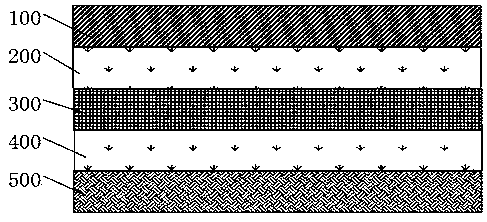

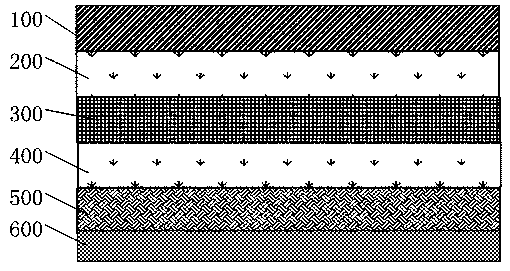

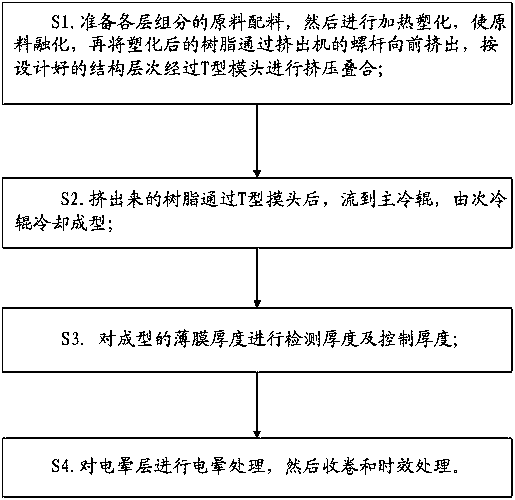

Undrawn polyethylene film and preparation method thereof

ActiveCN106739359AHigh tensile strengthMoisture permeability Reduced air permeabilityFlexible coversWrappersUltimate tensile strengthFilm material

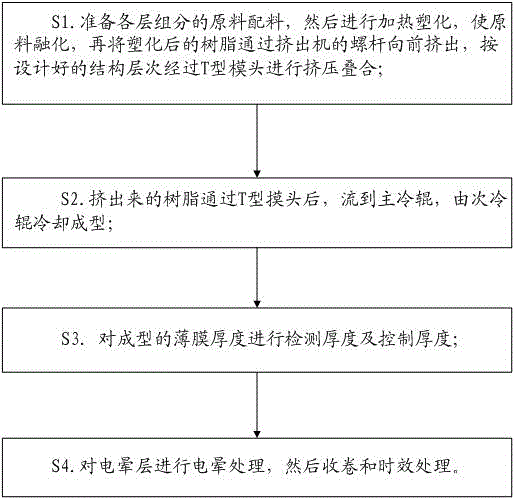

The invention discloses an undrawn polyethylene film and a preparation method thereof, and relates to the technical field of packaging film materials. The preparation method comprises the following steps: performing heating plastification on different layers of prepared components and raw materials, extruding, preparing a laminated-structure material by using a T-shaped mold head, and performing later treatment, thereby obtaining the undrawn polyethylene film finally. The undrawn polyethylene film comprises five layers, namely, a thermal sealing layer, a first middle layer, an auxiliary layer, a second middle layer and a corona layer for plating an aluminum membrane in sequence. The undrawn polyethylene film disclosed by the invention is large in strength, low in air permeability, low in damp permeability, good in plated aluminum adhesion property and good in thermal sealing property.

Owner:广东铭丰新材料科技有限公司

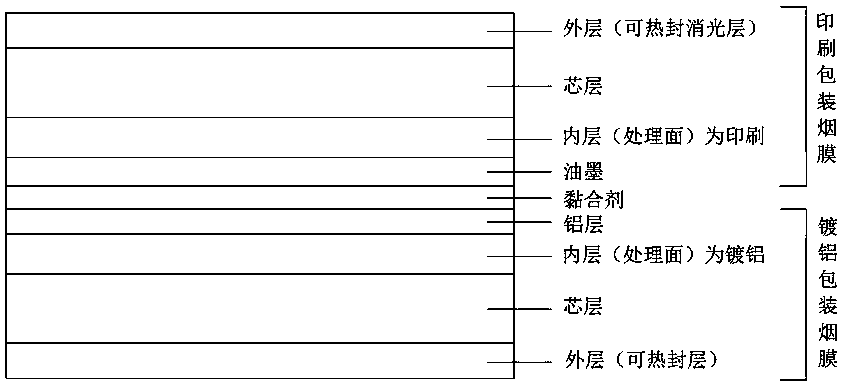

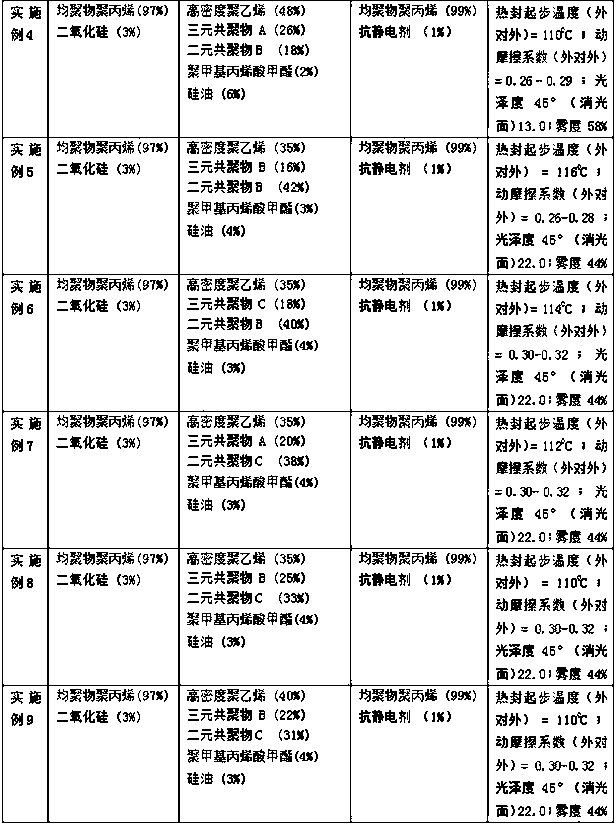

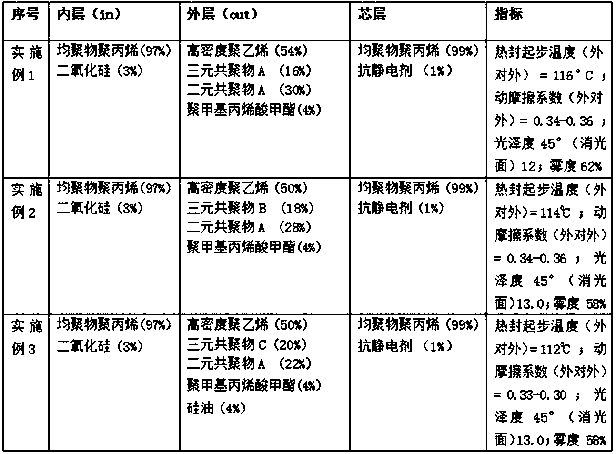

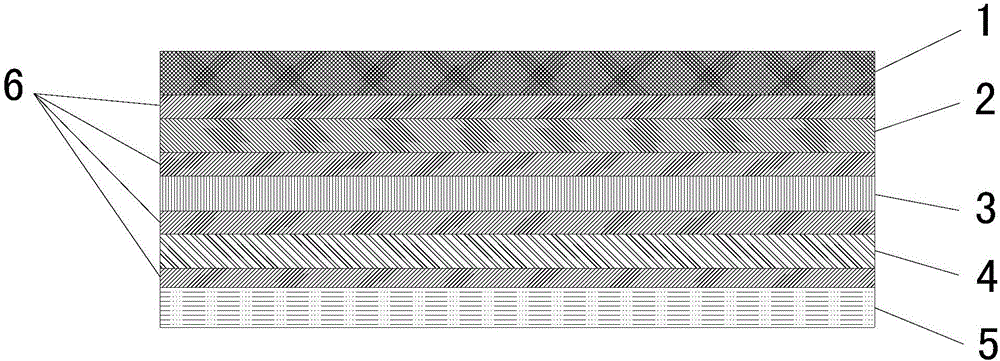

Heat-sealable matte aluminized printed composite packaging film for cigarettes and preparation method thereof

InactiveCN108656687ARealize the printing functionAvoid scratchingFlexible coversWrappersAluminiumHot-melt adhesive

The invention discloses a heat-sealable matte printed aluminized composite packaging film for cigarettes and a preparation method thereof. The composite packaging film comprises a printed matte film and an aluminized film which are laminated and processed by use of a binder or a hot melt adhesive, wherein the printed layer of the matte film can be laminated with the aluminized layer of the aluminized film to obtain the composite packaging film. The composite packaging film provided by the invention has the following advantages: a heat-sealable matte film is creatively proposed to be adopted asa printed packaging film; after inner printing of the inner surface of the matte film, the printed layer of the matte film is laminated with the surface of the aluminized layer of the aluminized film, so the problem of additional coating of a matting coating on the surface of a conventional cigarette packaging film is solved; meanwhile, the matted layer and the aluminized film have medium-and-low-temperature heat sealability, so a film can be packaged and bonded without the need of using a glue when a cigarette is subsequently packaged on a machine; and the composite packaging film provided by the invention realizes medium-and-low-temperature heat sealability and matte effects on the basis of guaranteeing conventional functions, effectively reduces energy consumption, is friendly to the environment, and has a matte metal texture.

Owner:SUZHOU KUNLENE FILM IND CO LTD +1

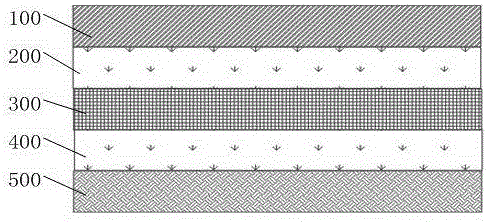

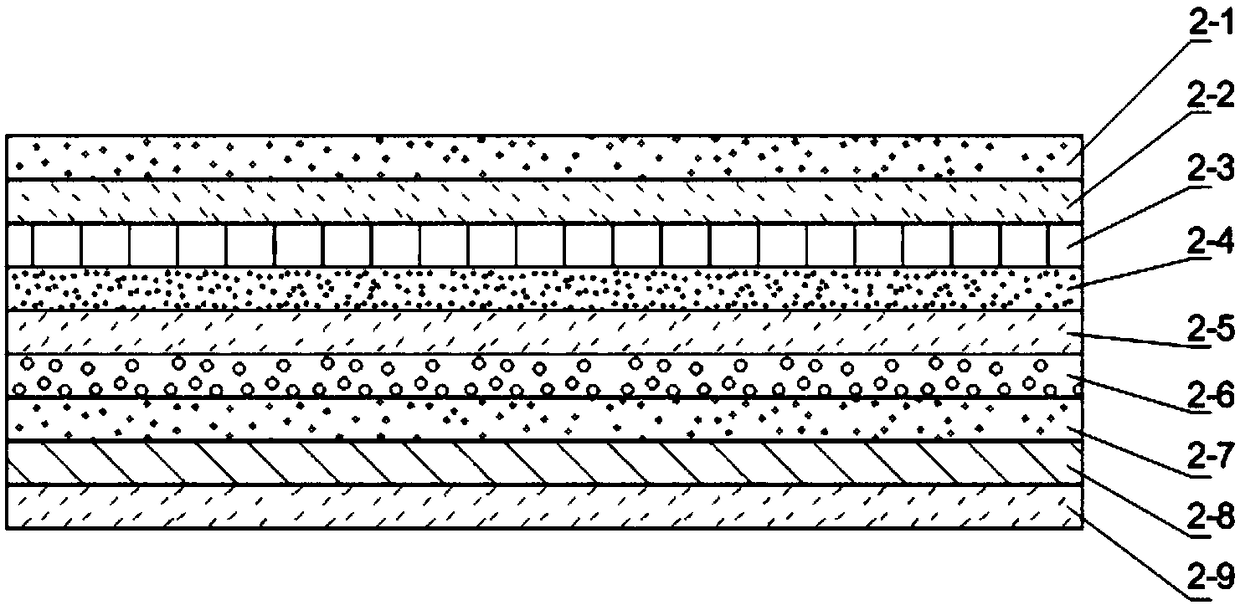

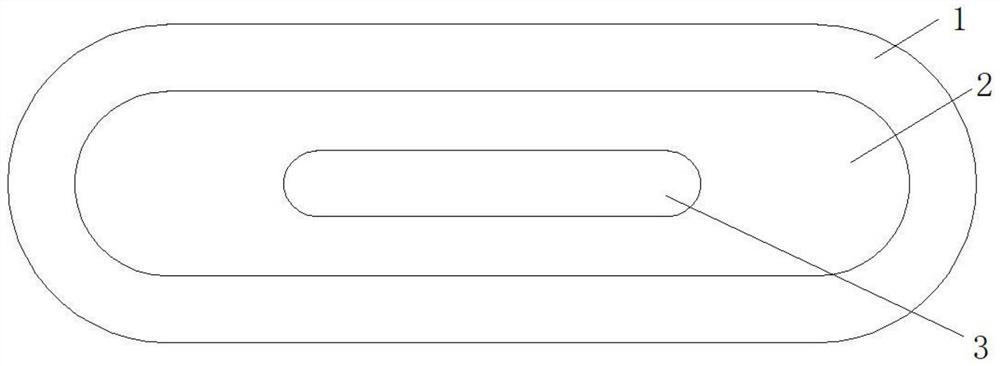

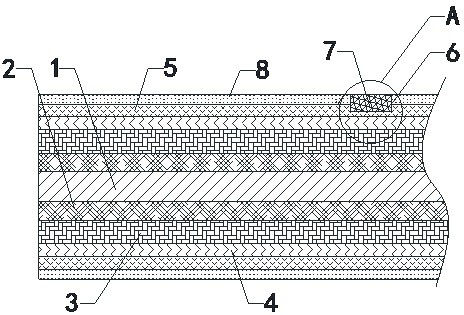

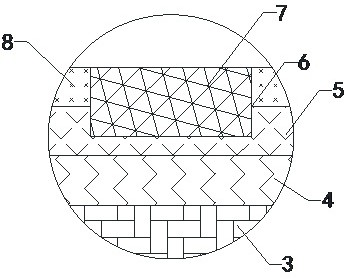

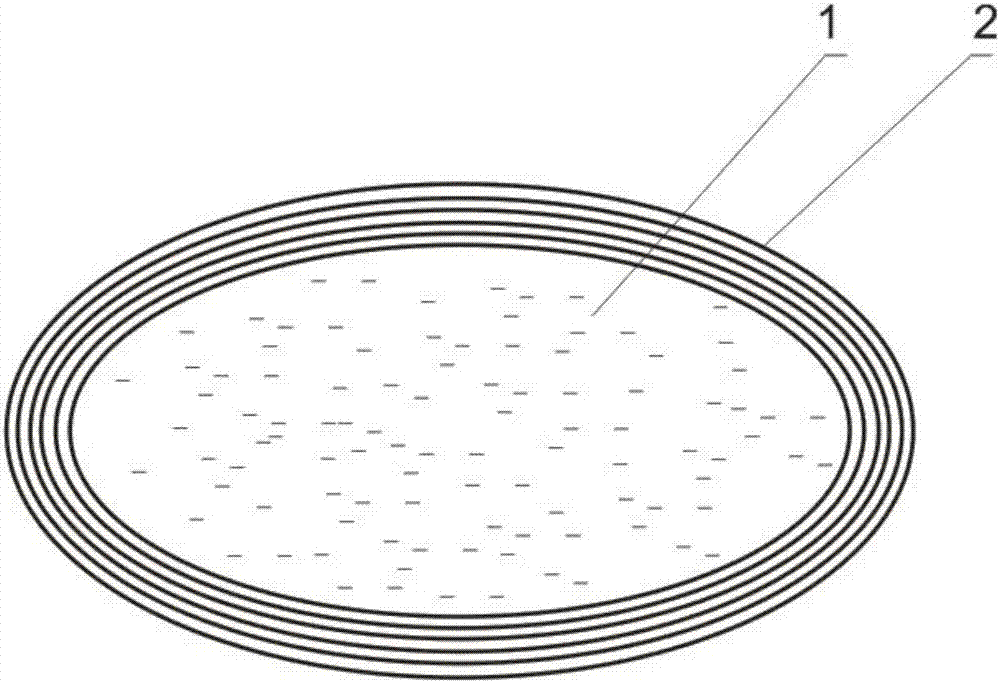

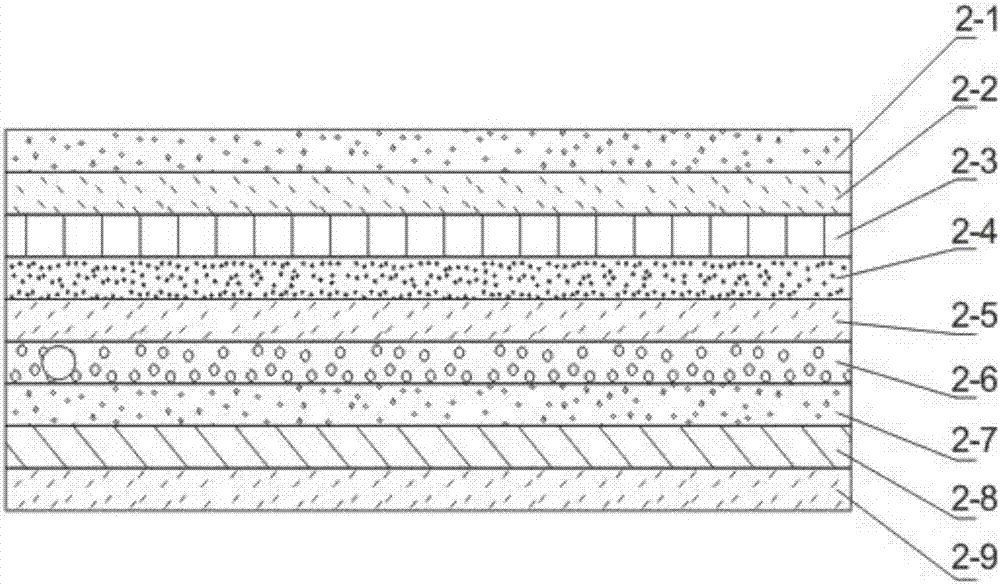

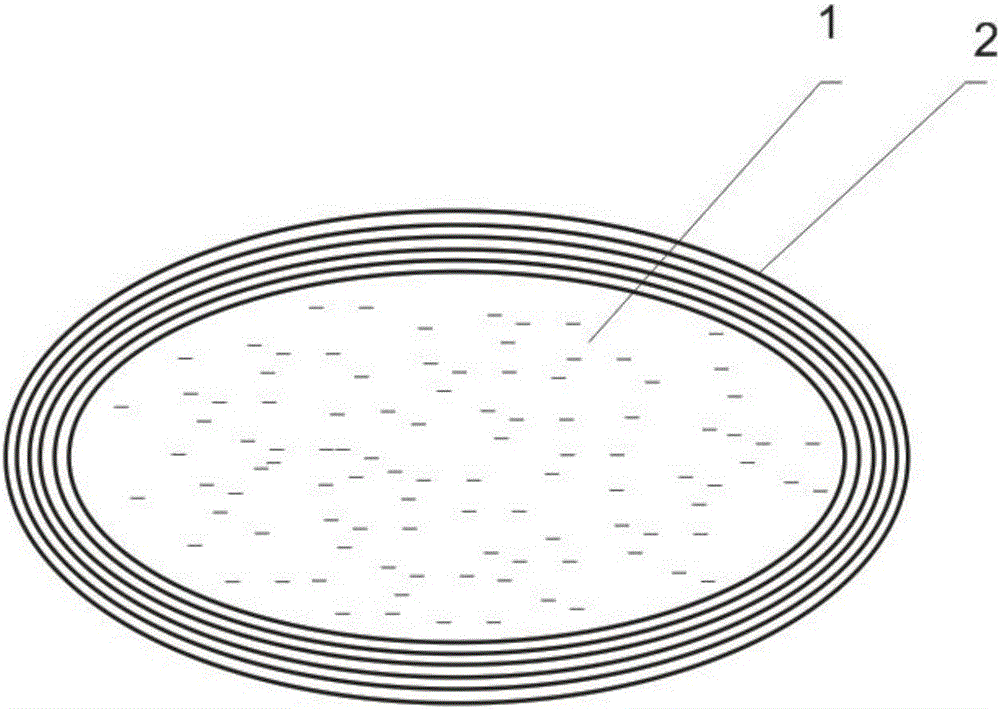

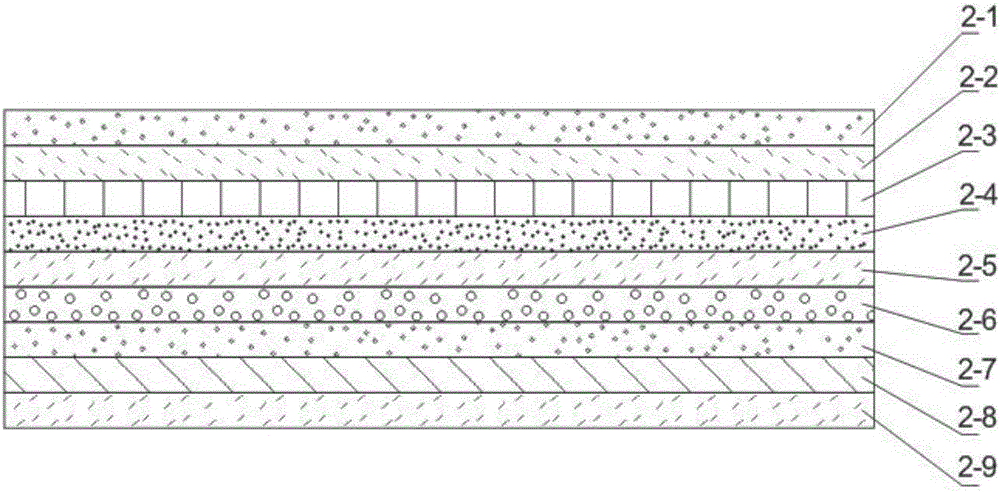

High-barrier-property multilayer-co-extrusion packaging film

The invention discloses a high-barrier-property multilayer-co-extrusion packaging film which includes a surface layer, an inner layer and a core layer, wherein the core layer includes a first core layer, a second core layer and a third core layer which are successively bonded to each other through adhesive layers. The thickness ratio of the three core layers is (1-3):(1-5):(1-4). The adhesive layers are also used for respectively bonding the first core layer with the surface layer and the third core layer with the inner layer. The first core layer is a polyamide layer, the second core layer is an ethylene-vinyl alcohol co-polymer layer and the third core layer is a polyvinylidene chloride layer. The third core layer includes a mixture composed of 98 wt% of polyvinylidene chloride and 2 wt% of a processing aid, wherein the polyvinylidene chloride is a vinylidene chloride-maleic anhydride co-polymer, is 150 DEG C in melt point and is 1.7 g / cm<3> in density, and the processing aid is epoxidized soybean oil. In the invention, a polyvinylidene chloride core layer which is single in the prior art is improved, wherein the core layer is formed by compositing three functional core layers including polyamide, the ethylene-vinyl alcohol co-polymer and the polyvinylidene chloride according to the certain thickness ratio, so that the packaging film can improve air-barrier property and is further reduced in production cost by 25-30%.

Owner:SUZHOU TIPACK

Outer composite bag infusion bag

PendingCN108501483ALeaked in timeBreak the tensionSynthetic resin layered productsPharmaceutical containersDrug utilisationLiquid layer

The invention relates to an outer composite bag infusion bag, which comprises a package and a drug liquid in the package, wherein the package comprises a drug liquid layer, a leakage detection layer and a gas barrier layer, the drug liquid layer is a non-PVC plastic film with characteristics of liquid barrier property and compatibility with the drug liquid, the leakage detection layer is vacuum, and the gas barrier layer is a plastic film having gas barrier property. According to the present invention, with the outer composite bag infusion bag, the possibly existing micro-pore leakage liquid can be observed and found out, and the outer composite bag infusion bag can be subjected to industrial batch production; by setting the vacuum degree of the leakage detection layer, the tension of thedrug liquid in the leakage hole of the drug liquid layer is broken through, such that the drug liquid can timely leak and can be observed; the gas barrier layer can effectively control the vacuum degree and the vacuum degree attenuation change in the leakage detection layer; and the production cost can be reduced, the infusion bag with the leakage hole can be effectively prevented from leaving thefactory, and the safety of medication can be ensured.

Owner:张杰 +1

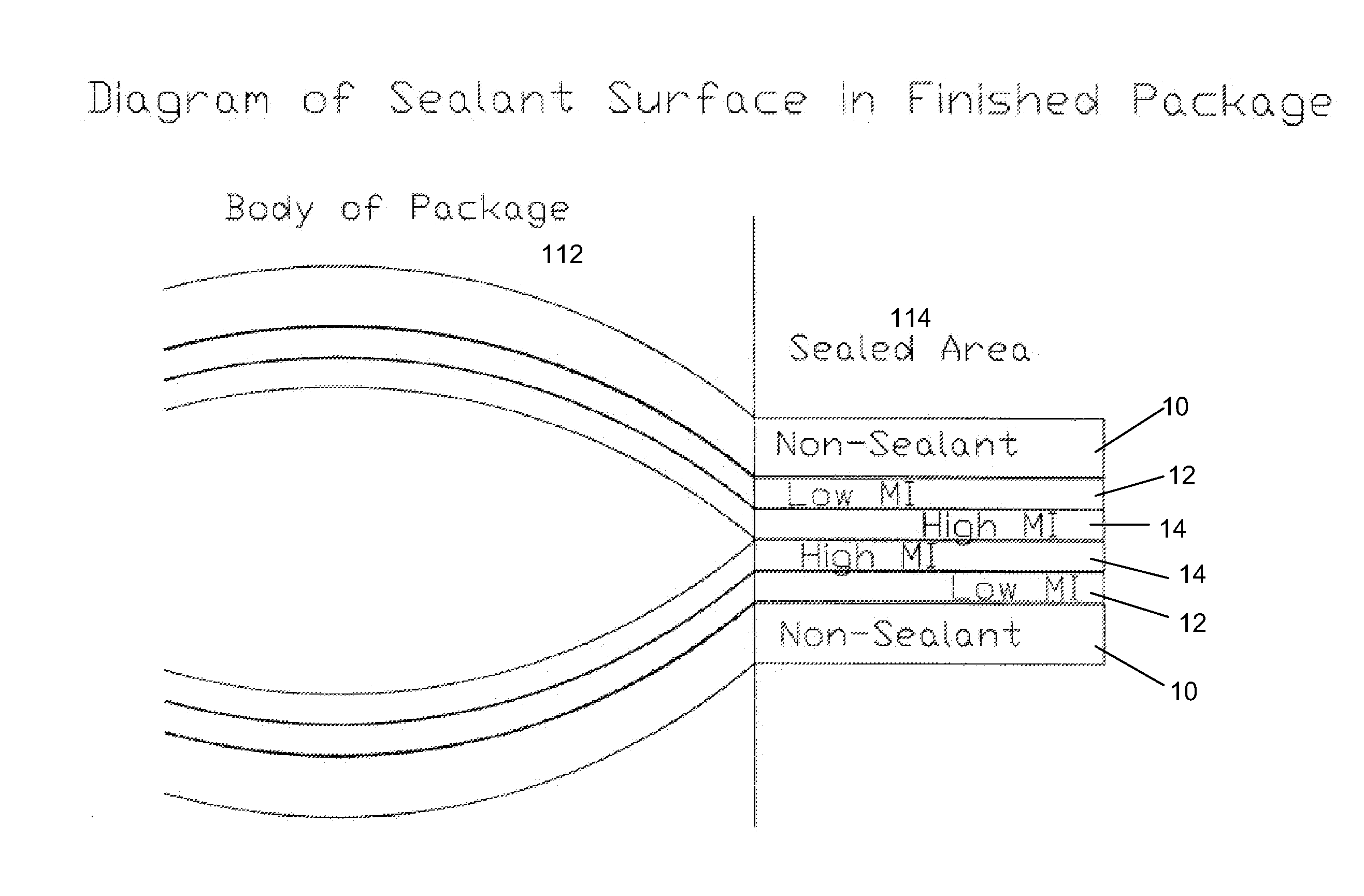

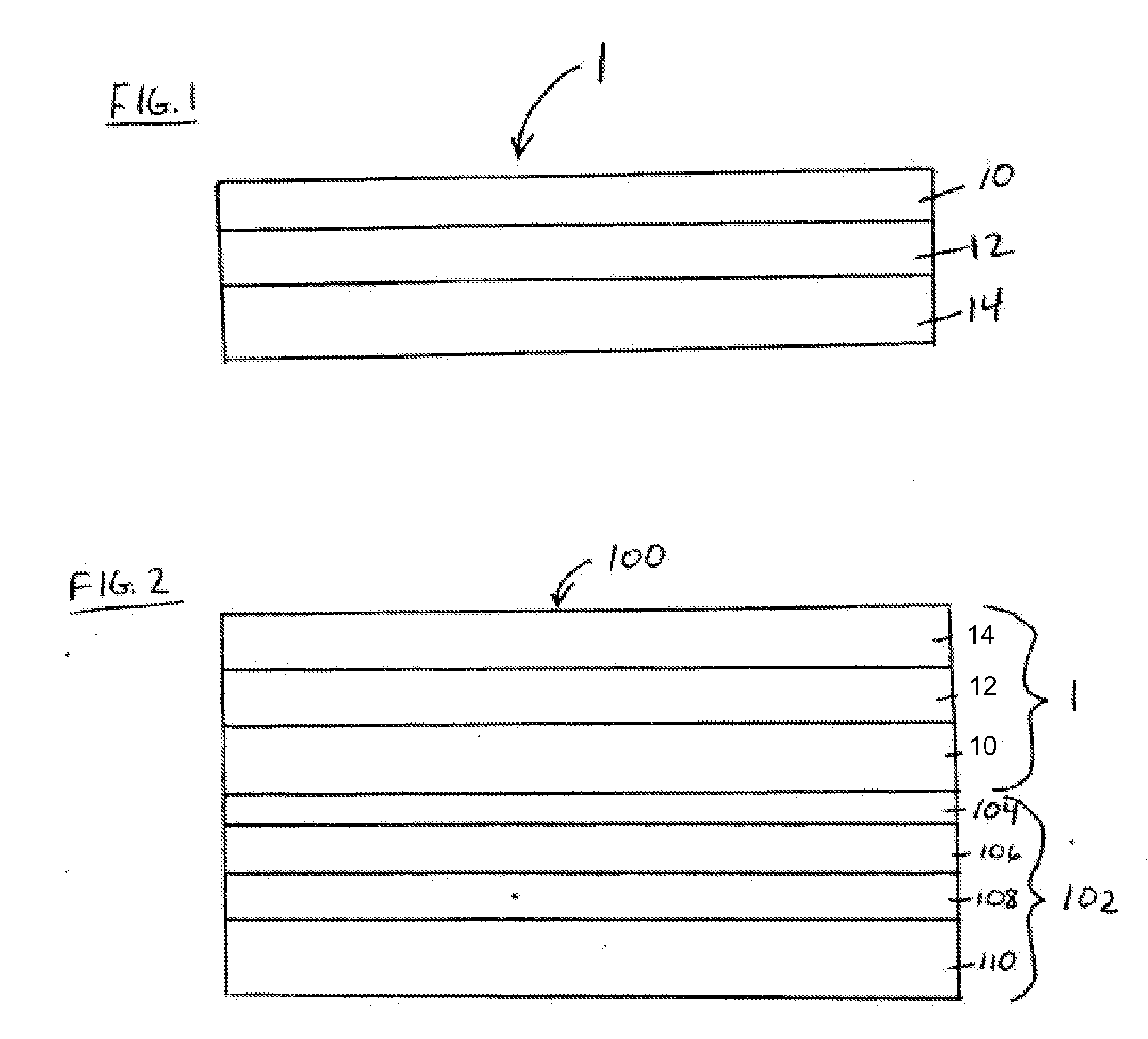

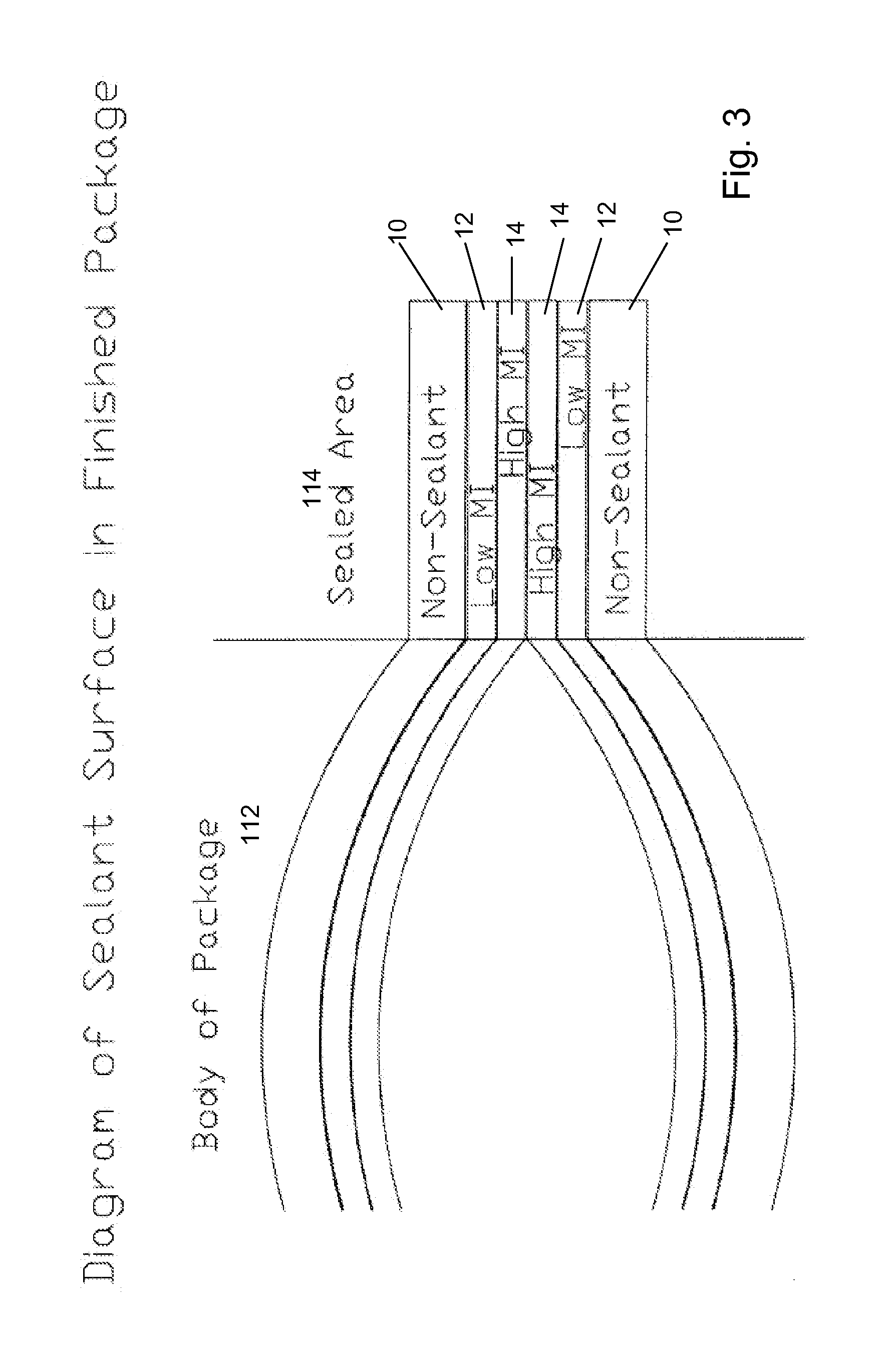

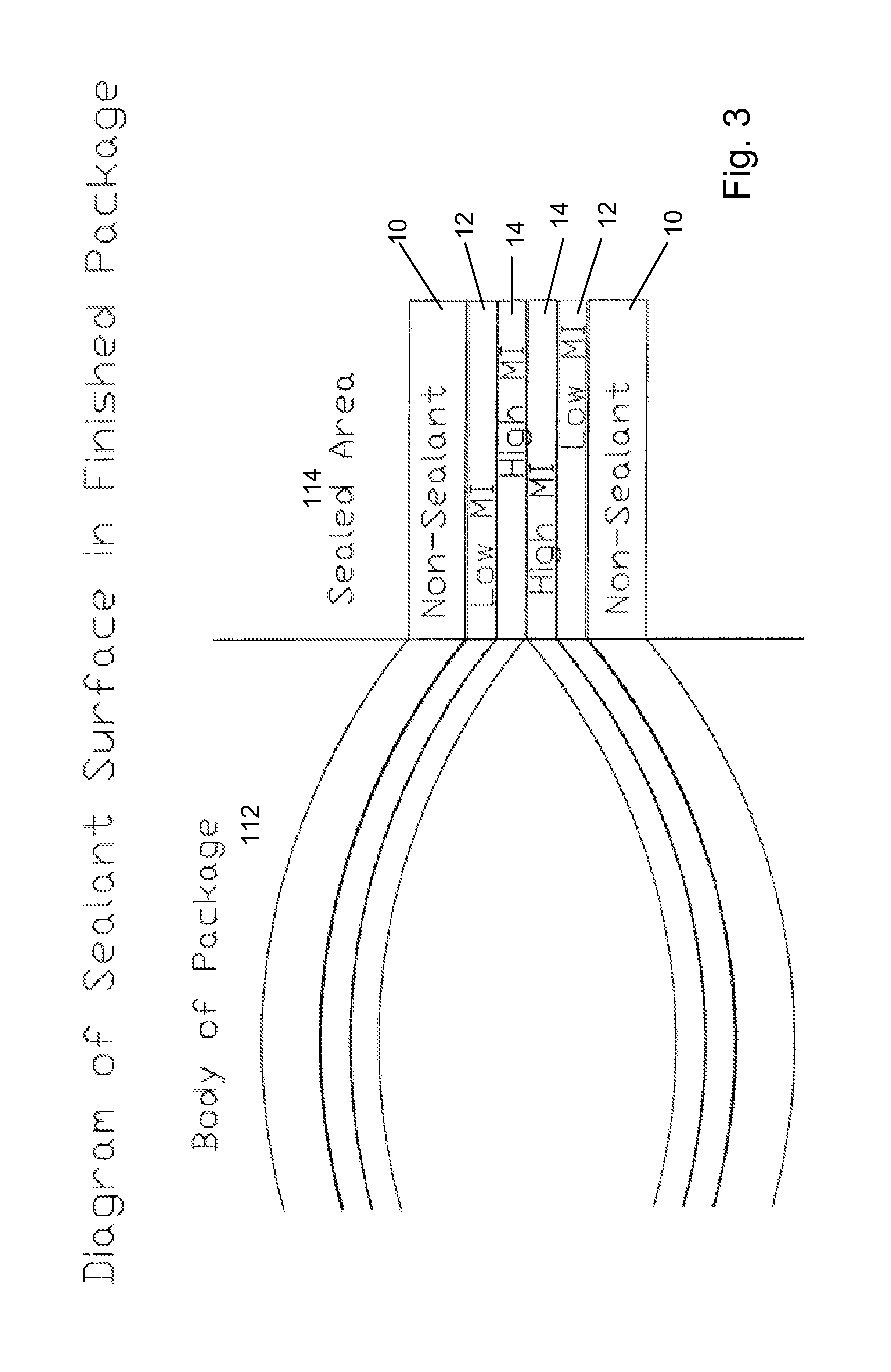

Multilayer heat sealant structures, packages and methods of making the same

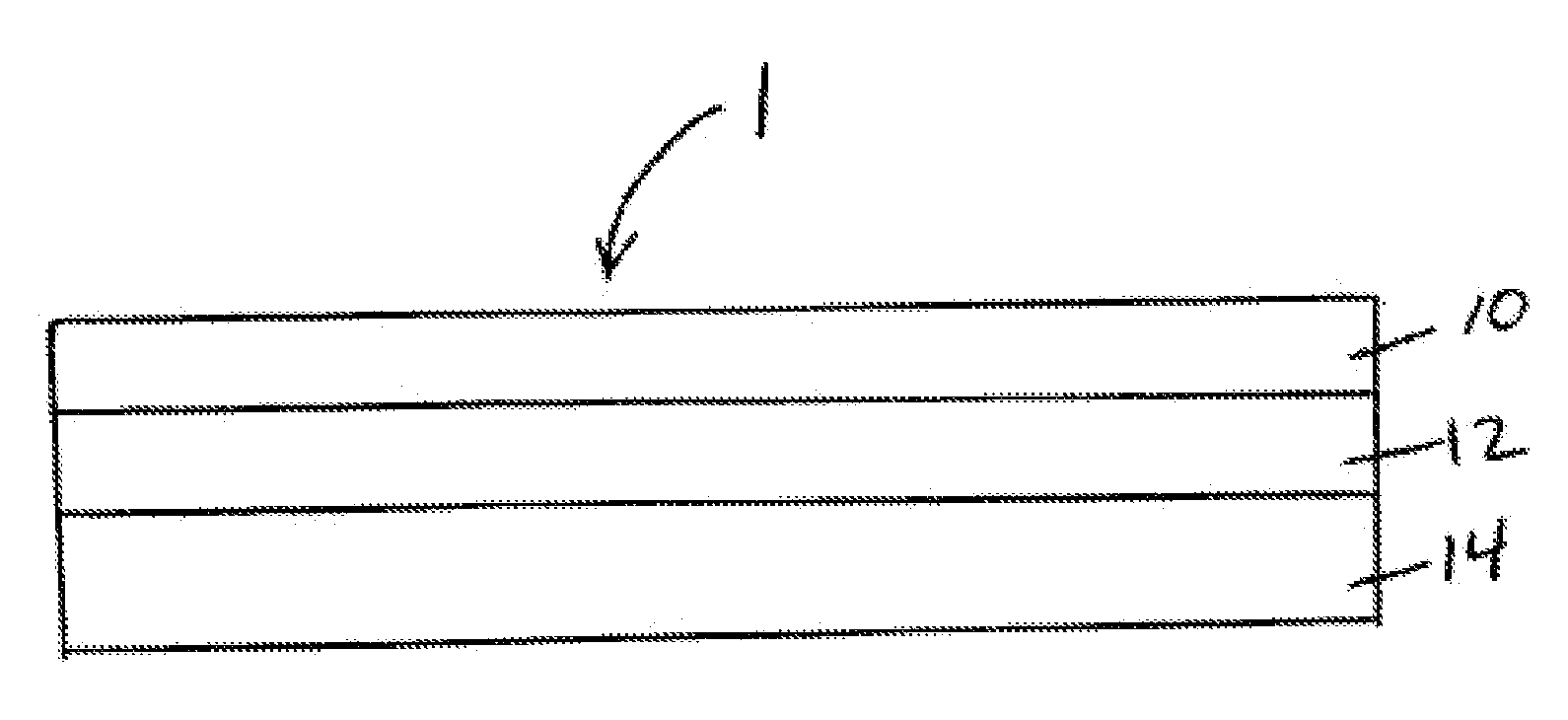

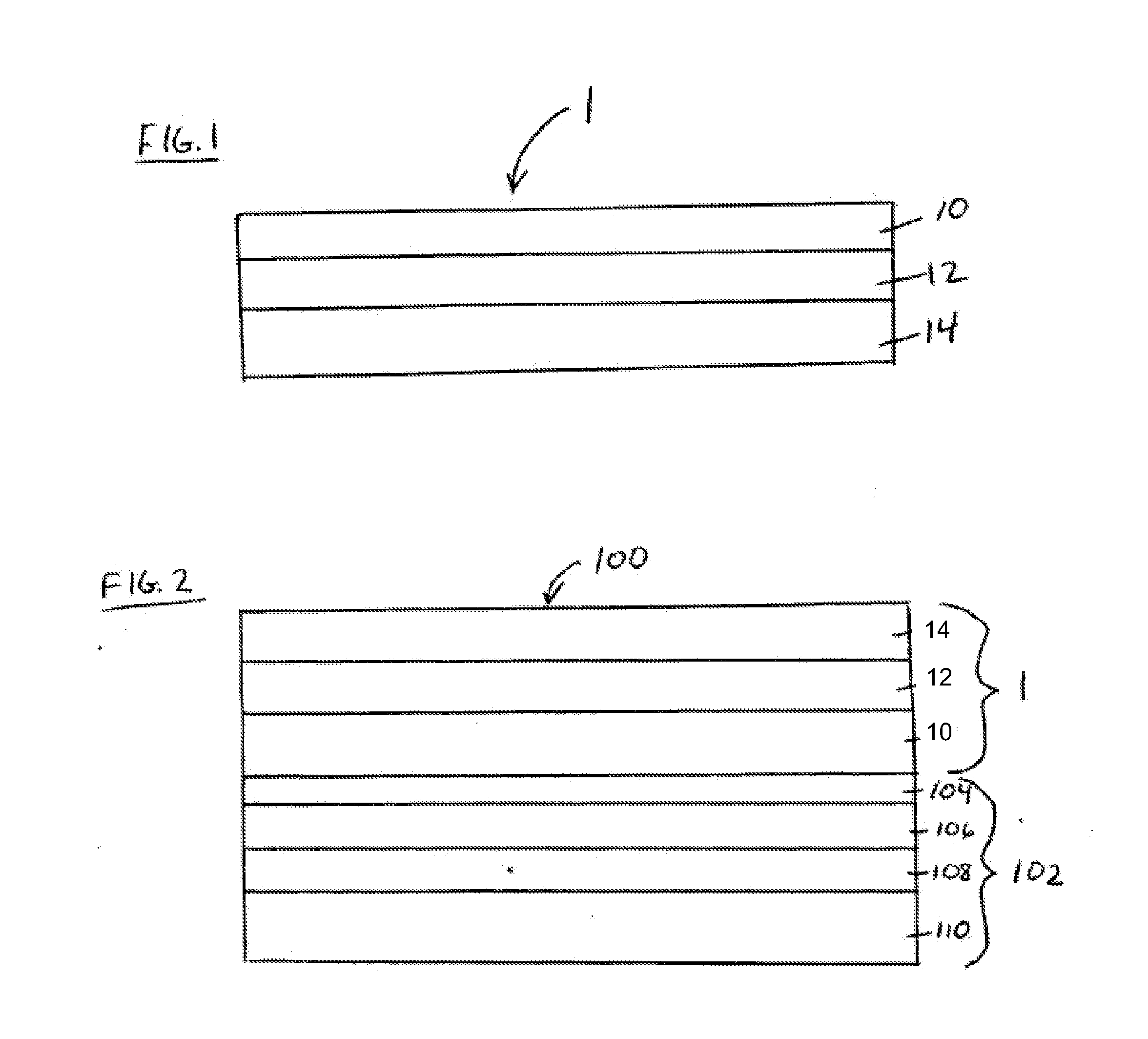

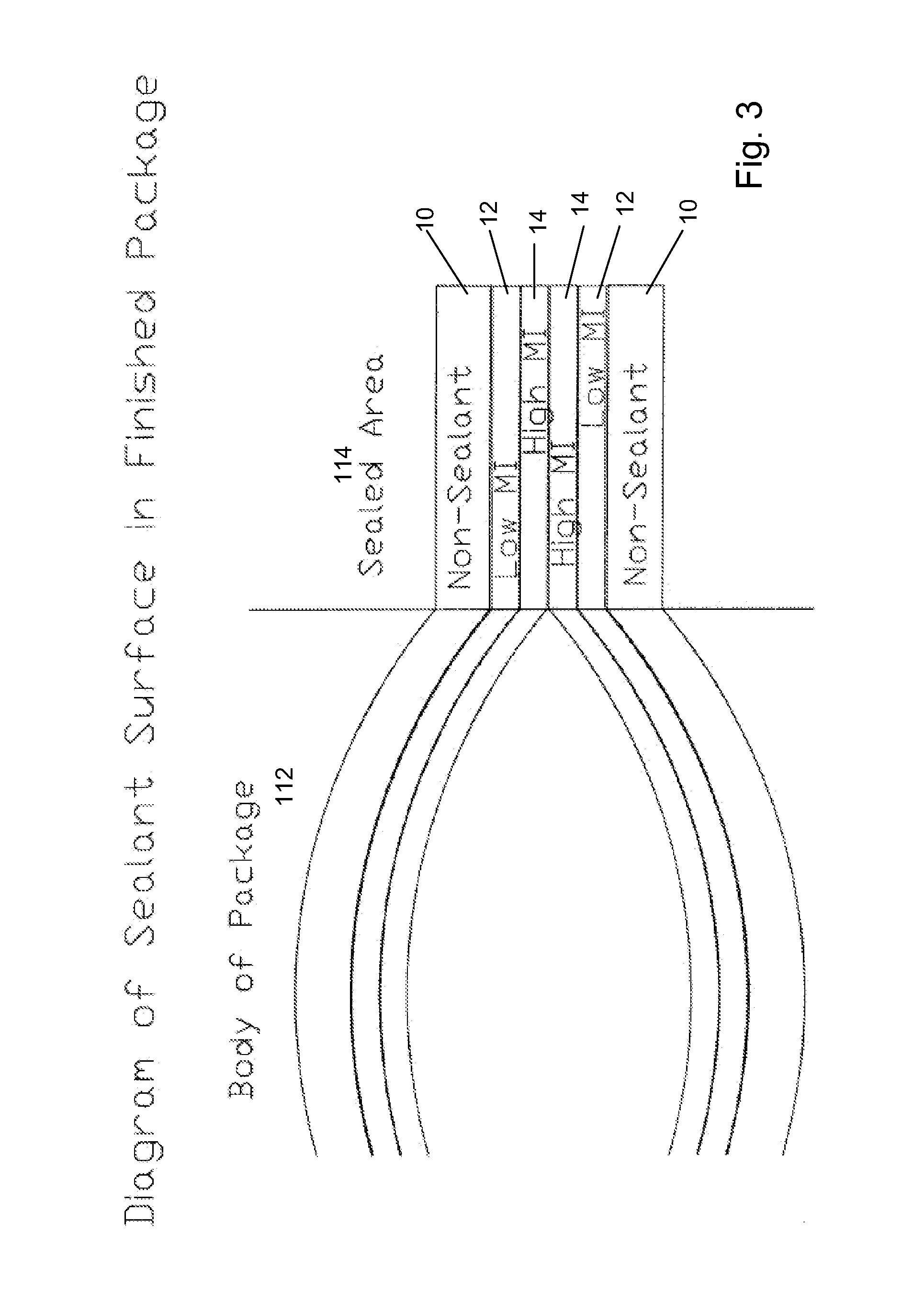

InactiveUS20120009370A1Easy to tearHeat sealablePipe laying and repairSynthetic resin layered productsPolymer scienceSealant

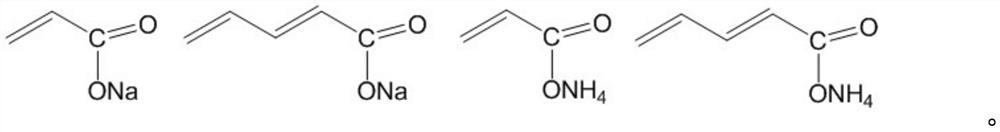

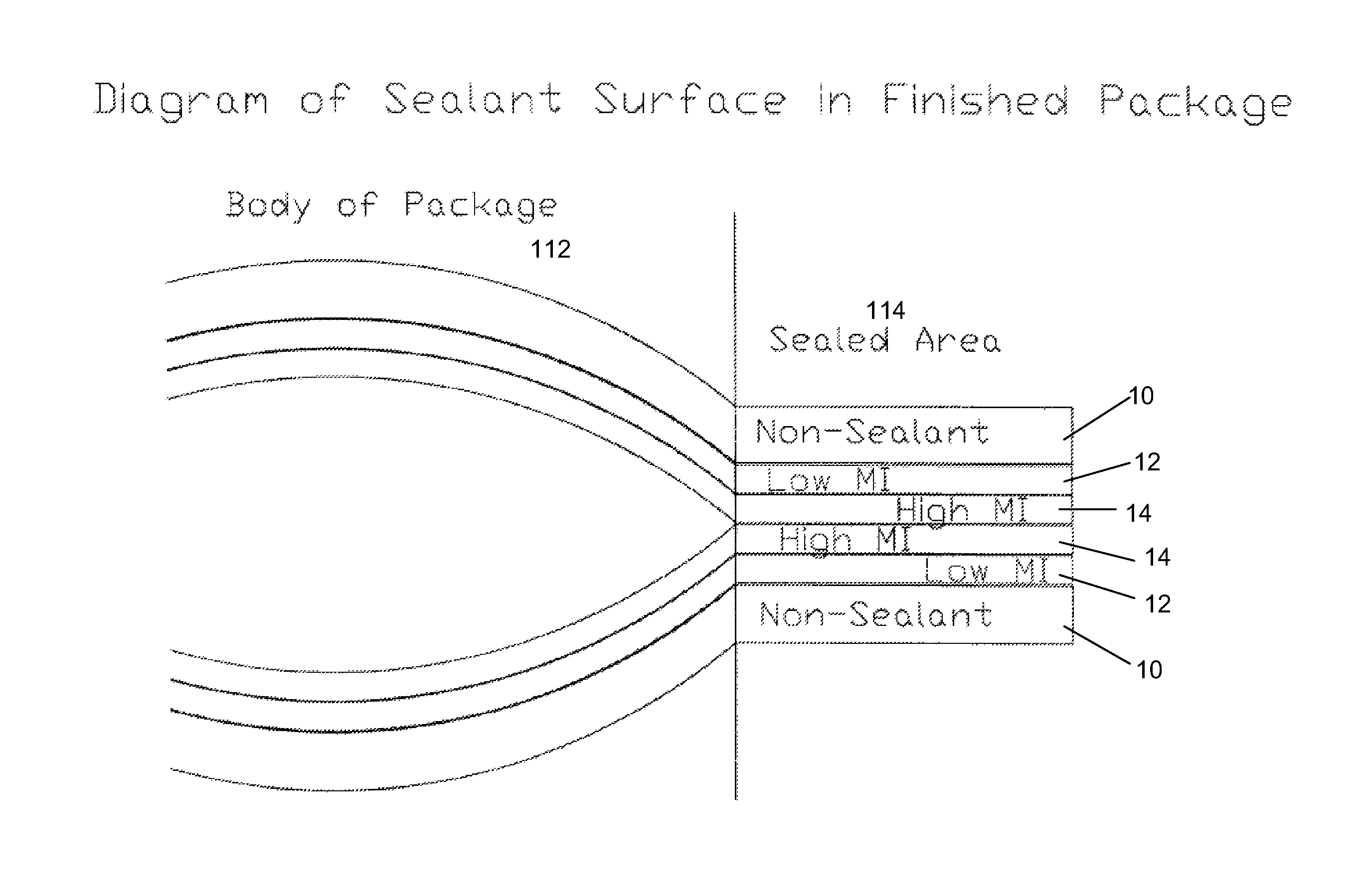

The embodiments of the present invention relate to multilayer thermoplastic structures having improved sealability and tearability. More specifically, the present invention relates to a multilayer heat sealant structure having at least three layers that may be coextrusion coated or otherwise laminated to a substrate, such as metallized polymeric material, foil, or other substrates.

Owner:BEMIS COMPANY INC

PETG cast film and preparation process thereof

InactiveCN106317796ASatisfy the production and use requirementsIncrease wetting tensionCoatingsAntistatic agentShrinkage rate

The invention discloses a PETG cast film and a preparation process thereof. The components of the substrate include: 98.0-99.3 wt% of PETG resin, 0.5-1.0 wt% of antioxidant, 0.1-0.5wt % of antistatic agent, and 0.1-0.5wt % of ultraviolet absorbent. The antioxidant is at least one of hindered phenols; the antistatic agent is at least one of ethoxylated alkyl amines; and the ultraviolet absorbent is 2-hydroxy-4-n-octyloxybenzophenone. The product is high in wetting tension and low in shrinkage rate and thickness deviation, the appearance defect is few, the heat seal and heat transfer function can be achieved, and the percent of pass is up to 90%, the requirements in the fields of cards, anti-counterfeiting films, packaging films, decorative films and the like can be met. The technological process is simple and feasible, industrial production is easy to realize, and the method has excellent industrial application value.

Owner:JIANGSU HUAXIN NEW MATERIAL

Alginate soft capsule and preparation method thereof

InactiveCN112675144AHeat-sealableCondensation formabilityInorganic non-active ingredientsCapsule deliveryChemistryDigestive canal

The invention discloses an alginate soft capsule. A capsule material comprises thermal reversible gel, and the alginate soft capsule is prepared by dissolving a monovalent alginate salt and the thermal reversible gel in water in parts by mass and treating obtained thermal reversible gel liquid through a dropping or pressing process of the soft capsule. Through the thermal reversible gel, the capsule material has heat sealability and condensation formability, and meanwhile, the capsule material has feasibility of further carrying out a cross-linking reaction with a thermal irreversible gel initiator; a thermal irreversible gel layer can be accurately regulated and controlled by accurately regulating and controlling the thermal irreversible gel initiator; as a protective layer, the thermal irreversible gel layer can achieve a disintegration effect of the soft capsule on different parts of a digestive tract; and the thermal reversible gel layer can realize wrapping forming and instant dissolution of contents of the soft capsule. The alginate soft capsule disclosed by the invention can be completed by adopting a dropping method or a pressing method in an existing gelatin soft capsule production process; and a preparation method is simple, the cost is low, new process equipment does not need to be added, and quite high practicability and wide applicability are achieved.

Owner:南京健辉生物科技有限公司

BOPP film

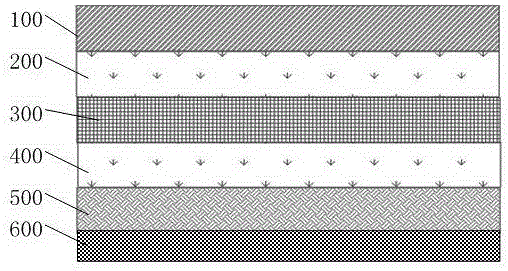

PendingCN113147140AHigh tensile strengthHeat-sealableSynthetic resin layered productsPolymer scienceThin membrane

The invention relates to the technical field of BOPP film technology, in particular to a BOPP film, which can have good heat sealability, improve the printing effect of the thin film, enhance the anti-counterfeiting property of the thin film, enable the thin film not to be easily counterfeited and reduce the use limitation. The BOPP film comprises a base layer film, two groups of tensile layer films, two groups of heat sealing glue layers, two groups of corona layer films, two groups of ink layer films and an anti-counterfeiting coating, one ends of the two groups of tensile layer films are fixedly connected with the top end and the bottom end of the base layer film respectively, and one ends of the two groups of heat sealing glue layers are fixedly connected with the other ends of the two groups of tensile layer films respectively; one ends of the two sets of ink layer films are fixedly connected with the other ends of the two sets of corona layer films respectively, one ends of the two sets of anti-fake grooves are fixedly connected with the other ends of the two sets of ink layer films respectively, the anti-fake grooves are formed in the ink layer films above the base layer film, and the anti-fake coatings are fixedly installed in the anti-fake grooves. The surface of the anti-fake coating is parallel to the end face of the ink layer film.

Owner:上海翰册塑料科技有限公司

Scratch-resistant degradable licence card base material and preparation technology thereof

ActiveCN105799283ASatisfy the production and use requirementsHigh light transmittanceSynthetic resin layered productsCoatingsPolymer sciencePlasticizer

The invention discloses a scratch-resistant degradable licence card base material and a preparation technology thereof. The base material comprises an upper layer and a lower layer. The upper layer comprises 92.8-97.8wt% of PMMA resin, 2-5wt% of a plasticizer, 0.1-0.7wt% of a lubricant, 0.1-0.5wt% of an anti-oxidant, 0-0.5wt% of an ultraviolet ray absorber and 0-0.5wt% of an antistatic agent. The lower layer comprises 90.1-94.4wt% of PHA resin, 5-8wt% of a plasticizer, 0.4-0.8wt% of a lubricant, 0.2-0.6wt% of an anti-oxidant and 0-0.5wt% of an antistatic agent. The base material has good scratch resistance, high light transmittance and good heat dimensional stability and can be used for heat seal card preparation. The preparation technology has simple and easy processes and can be industrialized easily. The base material has excellent industrial application value.

Owner:江苏华信高新材料有限公司

Multilayer Heat Sealant Structures, Packages And Methods Of Making The Same

ActiveUS20080057239A1Easy to tearHeat sealablePipe laying and repairSynthetic resin layered productsSealantMaterials science

The embodiments of the present invention relate to multilayer thermoplastic structures having improved sealability and tearability. More specifically, the present invention relates to a multilayer heat sealant structure having at least three layers that may be coextrusion coated or otherwise laminated to a substrate, such as metallized polymeric material, foil, or other substrates.

Owner:BEMIS COMPANY INC +1

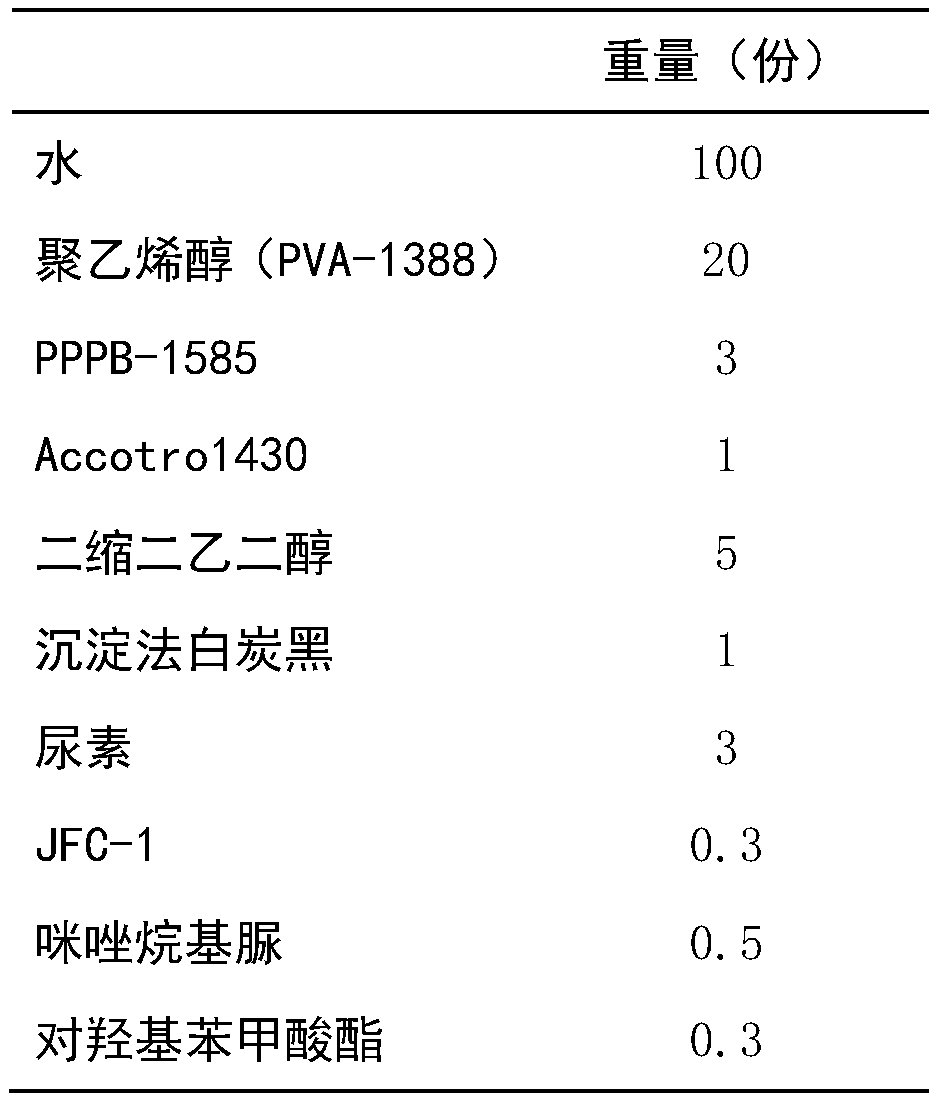

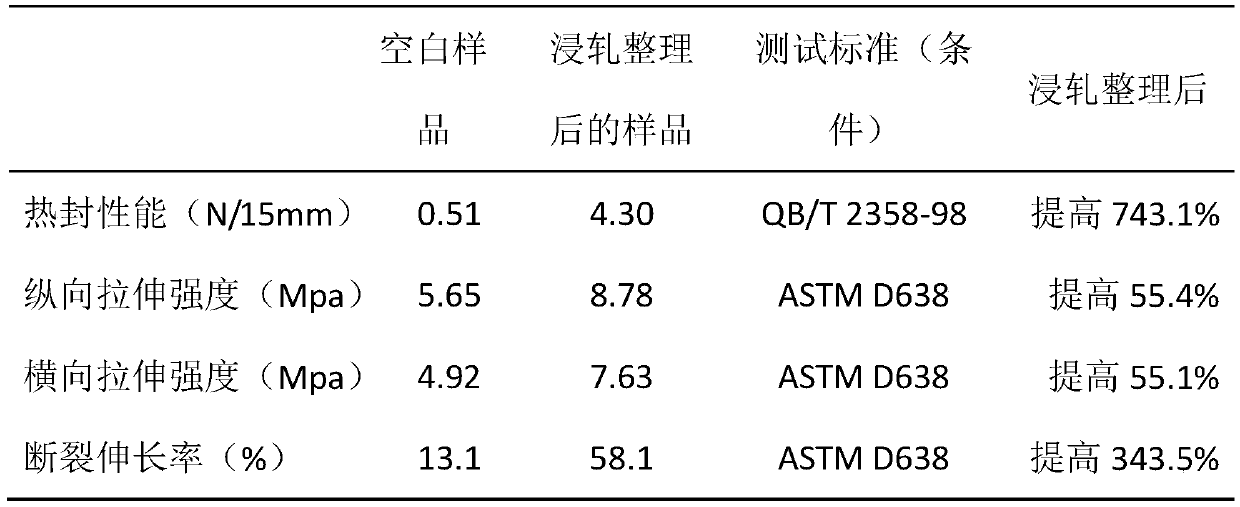

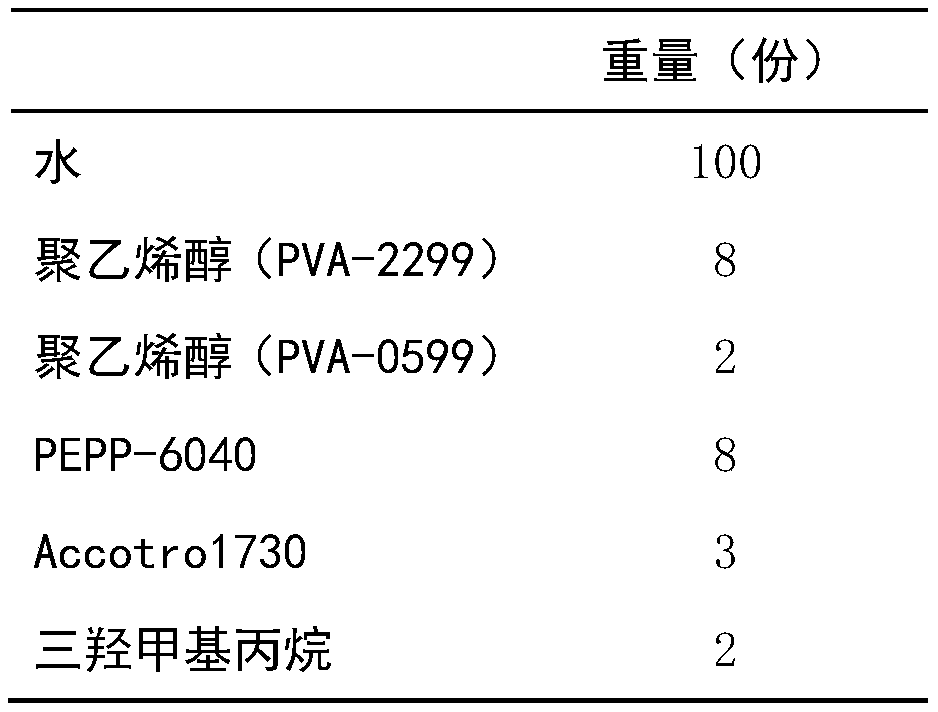

A kind of preparation method of machine-made water-soluble polyvinyl alcohol non-woven shopping bag

ActiveCN109371681BImprove processing efficiencyHeat-sealableGrip property fibresBenzoic acidPolymer science

Disclosed is a method for preparing a machine-made water-soluble polyvinyl alcohol nonwoven fabric shopping bag. The preparation method specifically involves: (1) preparing a sizing finishing agent, wherein the sizing finishing agent comprises the following raw material components, in parts by weight: 10-20 parts of polyvinyl alcohol; 3-8 parts of a polyol copolymer polyether; 1-3 parts of a polyacrylamide hydrolysate; 2-5 parts of a polyol; 1-3 parts of an inorganic filler; 1-3 parts of urea; 0.1-0.3 part of a wetting agent; 0.2-0.5 part of an imidazolidinyl urea; 0.1-0.3 part of a p-hydroxybenzoate; and 100 parts of water; and these components are mixed to prepare the sizing finishing agent; (2) applying the sizing finishing agent to padding finishing and coating finishing processes for a polyvinyl alcohol nonwoven fabric; and (3) subjecting the polyvinyl alcohol nonwoven fabric, which has been padded or coated and sized, to mechanized automatic hot-seal bagmaking to obtain the shopping bag. The shopping bag provided by the present invention has excellent heat sealability and mechanical properties and a good hand feeling. By means of the method, the processing efficiency is improved, and the production cost is reduced.

Owner:SHENGZHEN SAILONG FIBERGLASS CO LTD

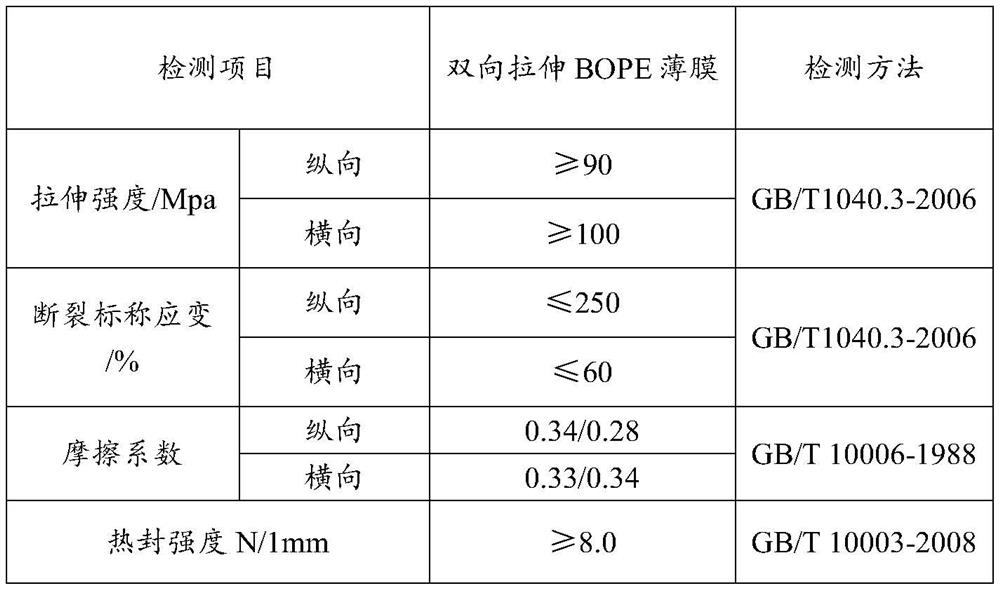

Biaxially-oriented BOPE film and preparation method thereof

InactiveCN111941970AReduce heat sealing temperatureReduce secondary composite processingSynthetic resin layered productsAntistatic agentPlasticulture

The invention relates to a biaxially-oriented BOPE film and a preparation method thereof. The biaxially-oriented BOPE film comprises a surface layer I, a core layer and a surface layer II, wherein thecore layer is located between the surface layer I and the surface layer II; the surface layer I is composed of a heat sealing material and an anti-sticking agent; the surface layer II is composed ofpolyethylene and an anti-sticking agent; and the core layer is made of polyethylene and an antistatic agent. Raw materials for the three layers are respectively subjected to extrusion, strip casting,longitudinal stretching, transverse stretching, traction, corona treatment and rolling after melt plastification so as to obtain a product, namely the biaxially-oriented BOPE film. According to the film, the novel heat-sealing material is used on the surface layer I, so the heat-sealing temperature of the film is reduced to a very low temperature, the secondary composite processing of downstream customers is reduced, and wasting is reduced. According to a detection result, the product has heat sealing performance at 92 DEG C; the heat sealing strength of the film can reach 8.9 N / mm at 95 DEG C; and the film is very suitable for printing and compounding through corona treatment.

Owner:GETTEL GRP TONGCHENG PLASTIC IND

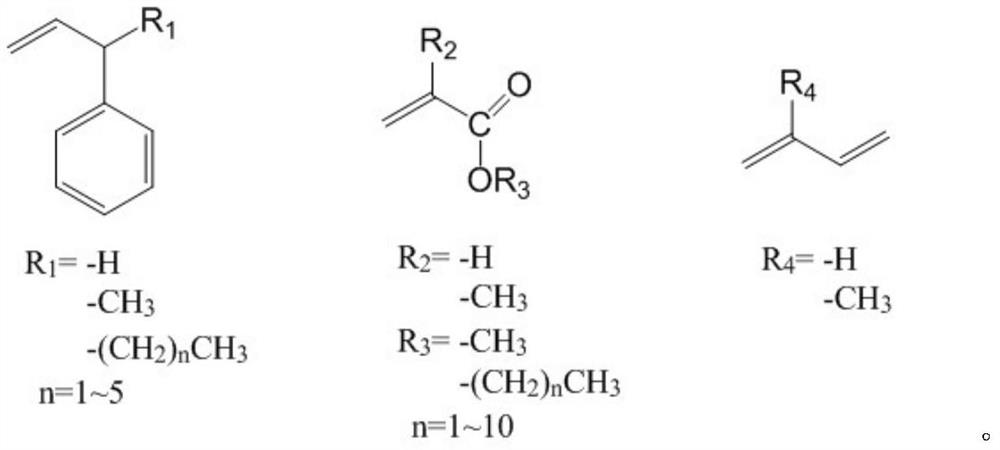

Waterproof and oil-proof agent and application thereof

ActiveCN113463431AWaterproofWaterproof and oil-proofPackage recyclingWater-repelling agents additionThermoplasticPolymer science

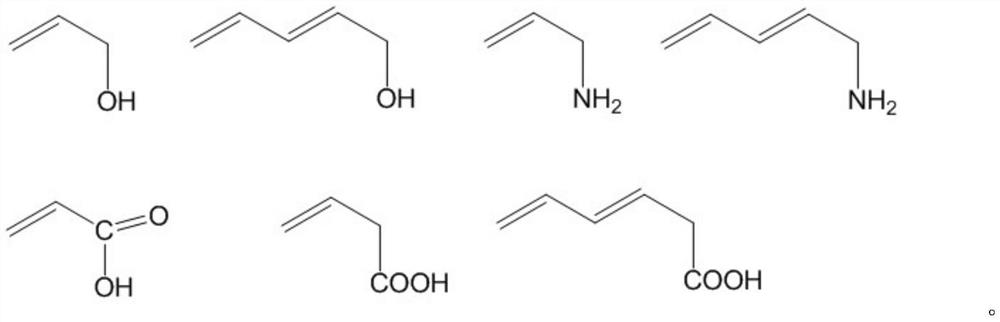

The invention discloses a waterproof and oil-proof agent. The waterproof and oil-proof agent comprises thermoplastic waterproof and oil-proof acrylic resin and thermoplastic reinforced acrylic resin, the thermoplastic waterproof and oil-proof acrylic resin contains a waterproof monomer and an oil-proof monomer; the waterproof monomer comprises an acrylate monomer and a styrene monomer; the oil-proof monomer is an acrylate monomer containing at least one of hydroxyl, amino and carboxyl; and the thermoplastic reinforced acrylic resin contains a self-crosslinking group. According to the waterproof and oil-proof agent, domestic acrylic resin is adopted, the cost is lower, two kinds of acrylic resin with different functions are adopted, the double-acrylic resin is scientifically compounded, a coating can be endowed with waterproof, oil-proof, temperature-resistant, non-sticky and peelable functions, when the waterproof and oil-proof agent is applied to paper-based packaging, a paper base can be re-pulped and recycled, and the adopted acrylic resin has heat sealability, so that the paper material of which the surface is coated with the waterproof and oil-proof agent can be directly heat-sealed and molded into various paper-based packages, and the paper material does not contain fluorine, and is non-toxic and odorless.

Owner:佛山市鼎茂科技有限公司

Multilayer heat sealant structures, packages and methods of making the same

ActiveUS8048521B2Easy to tearHeat sealablePipe laying and repairSynthetic resin layered productsSealantPolymer

The embodiments of the present invention relate to multilayer thermoplastic structures having improved sealability and tearability. More specifically, the present invention relates to a multilayer heat sealant structure having at least three layers that may be coextrusion coated or otherwise laminated to a substrate, such as metallized polymeric material, foil, or other substrates.

Owner:BEMIS COMPANY INC +1

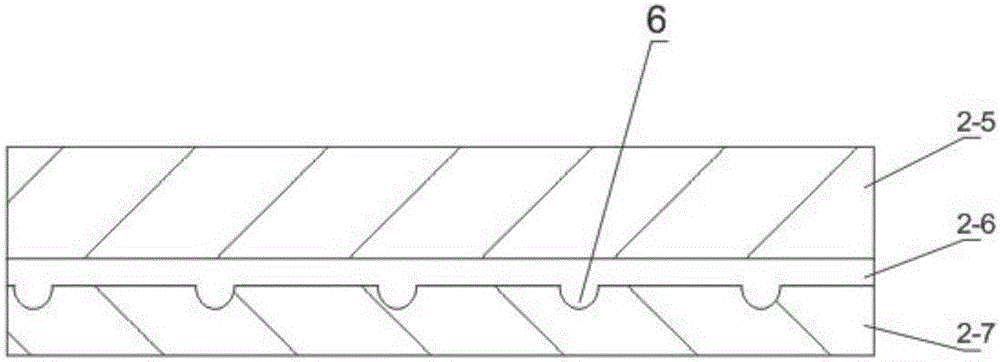

Outer barrier flushing fluid bag filled with inert gas

ActiveCN106515162BAvoid destructionImprove barrier propertiesFlexible coversWrappersMedical unitPolyester

The invention provides a flushing solution with an external barrier bag filled with inert gas. The flushing solution is formed by a package and the flushing solution in the package, wherein materials in the package are respectively PP (Poly Propylene) resin on a heat sealing layer, POE (Polyolefin Elastomer) resin on a membrane layer, POE resin on a strength layer, POE resin on an adhesion layer, thermoplastic resin on a heat-resisting layer, negative-pressure gas in a gas layer, PP resin on a hot adhesion layer, polyamide resin on a strengthening layer and PET (Polyester) resin on a barrier layer in sequence from inside to outside; the gas layer is internally filled with the inert gas. According to the flushing solution with the external barrier bag filled with the inert gas, provided by the invention, a liquid medicine layer can meet integration with the flushing solution and high barrier performance on liquid; the gas layer is internally filled with the inert gas, oxygen is prevented from remaining in the gas layer, the oxygen is prevented from entering the liquid medicine to damage the liquid medicine, and meanwhile, the oxygen in the air permeating and entering the gas layer from an external sealing layer can be resisted; longitudinal grooves are formed in the inner surface of the external sealing layer, and the inert gas is even everywhere in the gas layer; the percent of pass of finished products leaving a factory of flushing solution packaging bags is increased, more guaranteed flushing solution is provided for medical units, and medication safety of patients is ensured.

Owner:SICHUAN TAIPINGYANG PHARMA

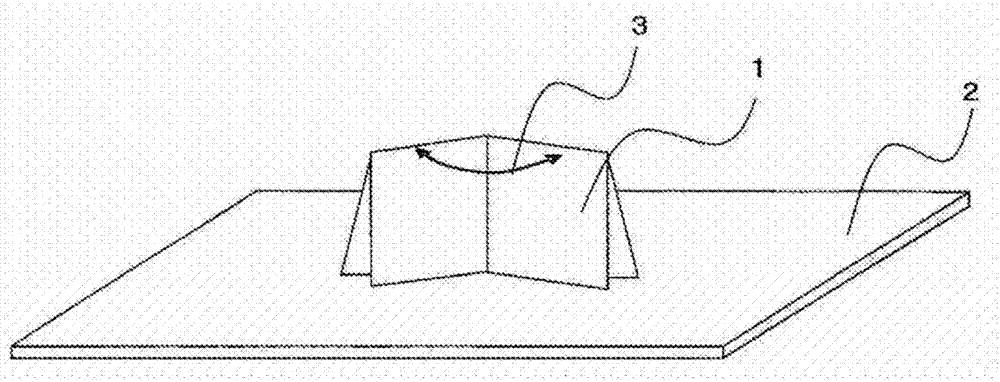

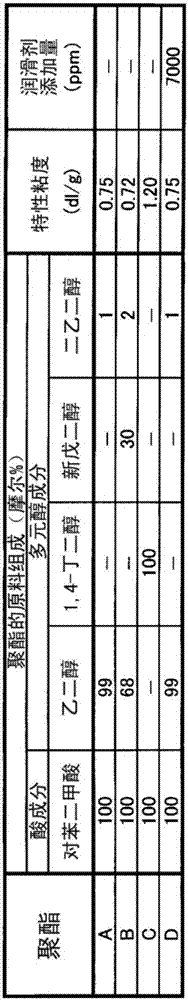

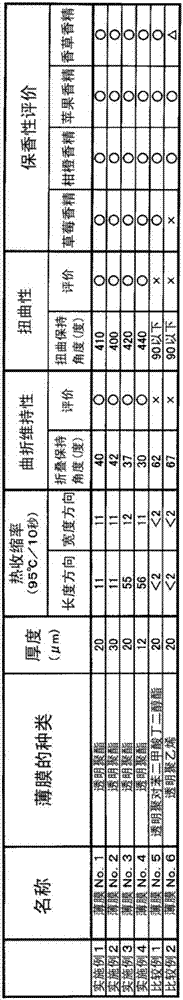

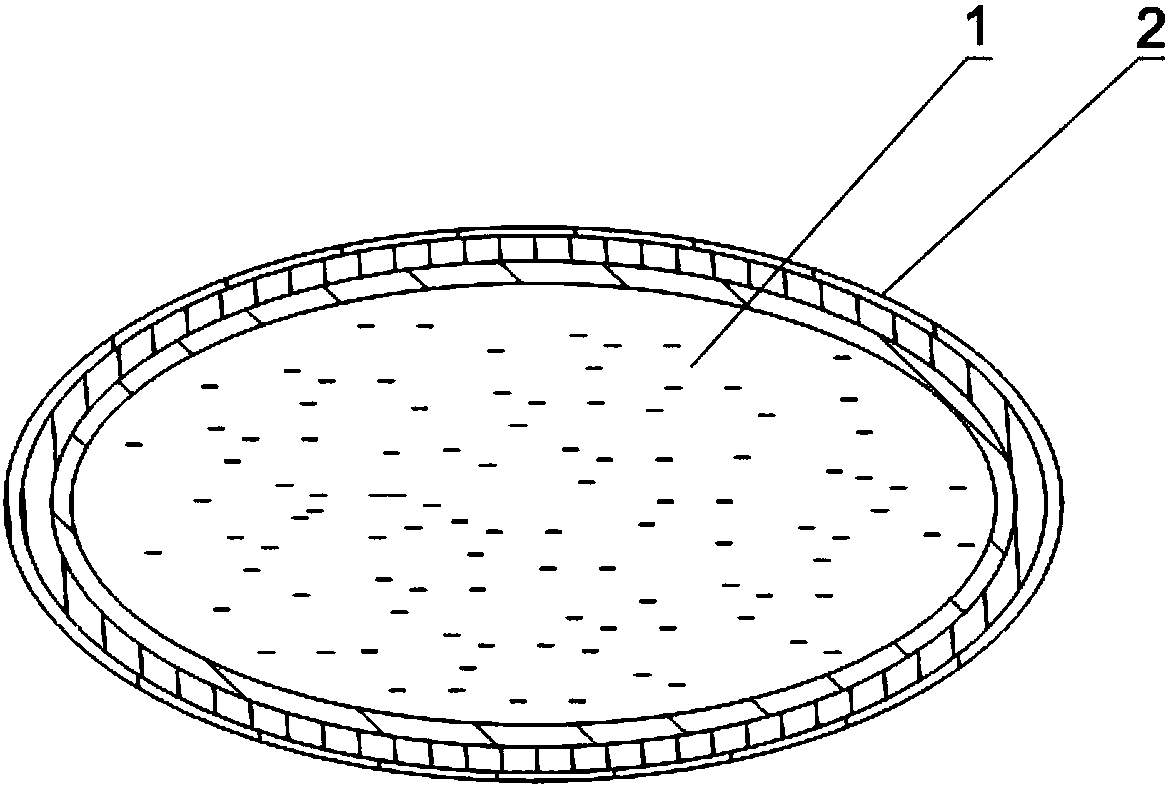

Film for packaging and packaging bag

Provided is a film for packaging, when an object is placed at the center of the film, wrapped by twisting the ends of the film above the object and then allowed to stand for a preset period of time, said film being capable of retaining the twisted state and thus preventing the diffusion of an offensive smell. The film according to the present invention is characterized in that the film is a film for packaging that is formed of a resin film and has a twisting retention angle of 400 degrees or greater.

Owner:TOYOBO CO LTD

Outer barrier bag flushing liquid bag

PendingCN108498328ALeaked in timeBreak the tensionSynthetic resin layered productsPharmaceutical containersMedical unitPass rate

The invention provides an outer barrier bag flushing liquid bag which is constituted by a package and flushing liquid in the package. The package comprises a liquid medicine layer, a leakage observinglayer and a gas barrier layer, and is particularly and sequentially provided with PP resin serving as a thermal-bonding layer, POE resin serving as a diaphragm layer, POE resin serving as a strengthlayer, POE resin serving as a bonding layer, thermoplastic resin serving as a thermal-resisting layer, negative pressure gas serving as the leakage observing layer, PP resin serving as a thermal sticky layer, nylon resin serving as a reinforcing layer, and PET resin serving as a barrier layer. The integration of the outer barrier bag flushing liquid bag and the flushing liquid and the high barrierproperty to liquid are achieved; if the liquid medicine layer generates micro pores, the leakage observing layer can absorb the micro-leakage flushing liquid, and water spots are generated on the leakage observing layer, so that the micro-leakage flushing liquid is advantageously removed through quality testing; and the pass rate of factory finished products of the flushing liquid packing bag isincreased, the more guaranteed flushing liquid is provided for a medical unit, and the medication safety of patients is ensured.

Owner:张杰 +1

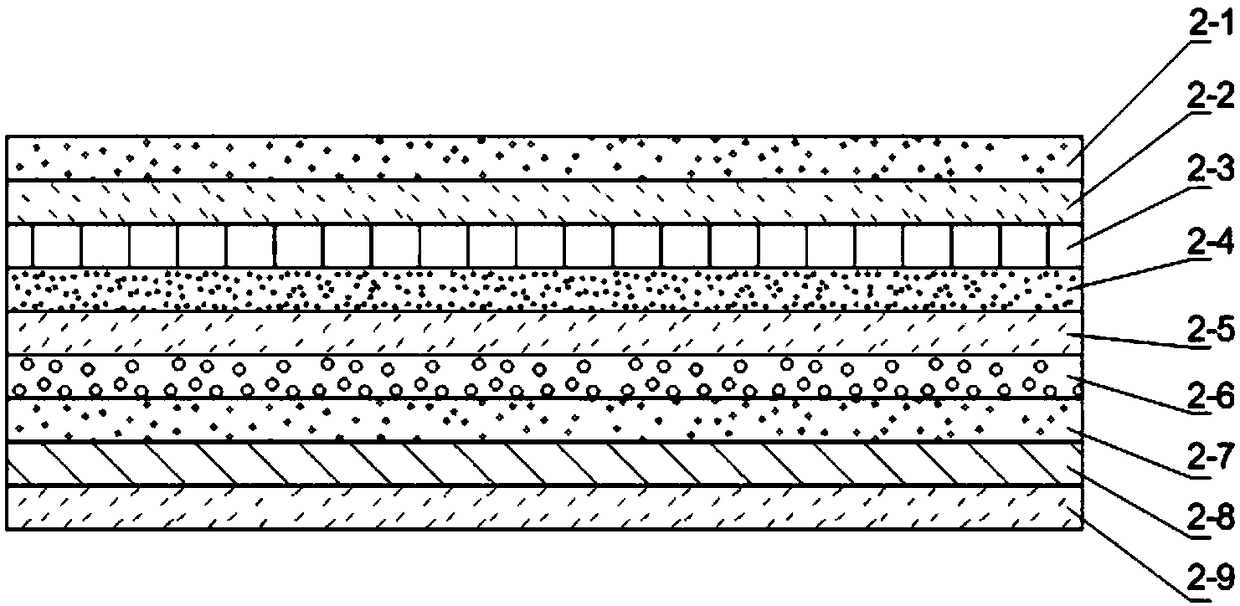

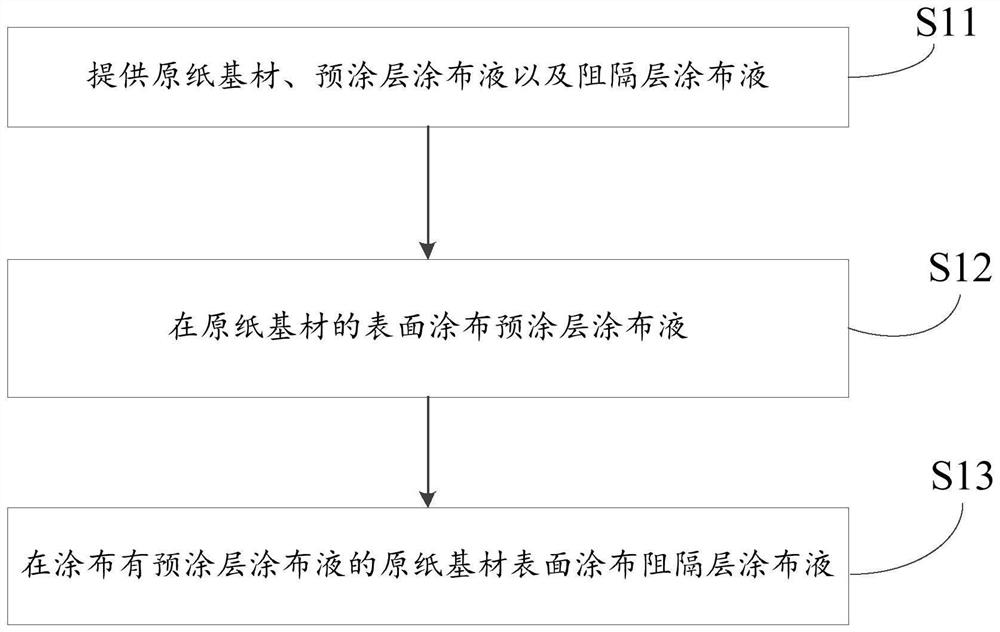

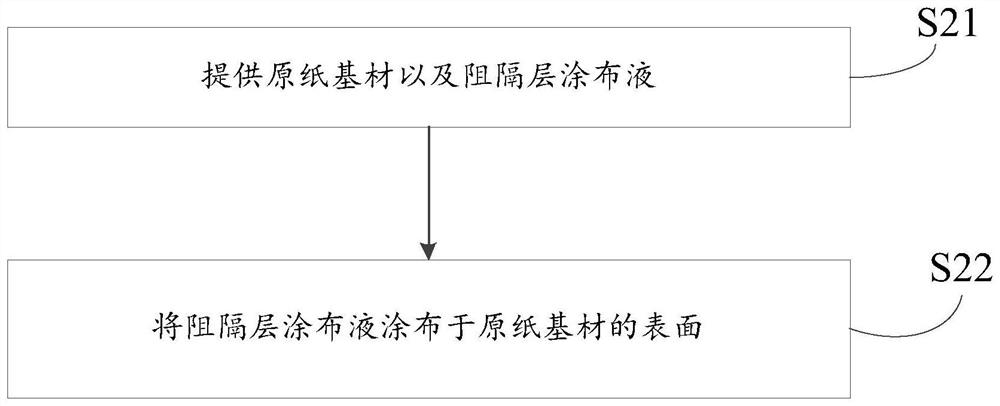

Preparation method of paper bag and environment-friendly paper bag

PendingCN114381971AHeat-sealableWater resistantCoatings with pigmentsFiltration separationPaper basedPolymer

The invention relates to a preparation method of a paper bag and an environment-friendly paper bag, and the preparation method of the paper bag comprises the following steps: providing a raw paper base material, a pre-coating layer coating liquid and a barrier layer coating liquid; coating the pre-coating layer coating liquid on the surface of the raw paper base material; coating the surface of the raw paper base material coated with the pre-coating layer coating liquid with the barrier layer coating liquid to obtain the degradable paper bag; wherein the barrier layer coating liquid comprises an olefin polymer elastic dispersion which can be heat-sealed. By means of the method, the prepared environment-friendly paper bag replaces a traditional plastic bag, and environment pollution caused by plastic is reduced.

Owner:GOLD EAST PAPER JIANGSU

A kind of unstretched polyethylene film and preparation method thereof

ActiveCN106739359BHigh tensile strengthMoisture permeability Reduced air permeabilityFlexible coversWrappersPolymer scienceUltimate tensile strength

The invention discloses an undrawn polyethylene film and a preparation method thereof, and relates to the technical field of packaging film materials. The preparation method comprises the following steps: performing heating plastification on different layers of prepared components and raw materials, extruding, preparing a laminated-structure material by using a T-shaped mold head, and performing later treatment, thereby obtaining the undrawn polyethylene film finally. The undrawn polyethylene film comprises five layers, namely, a thermal sealing layer, a first middle layer, an auxiliary layer, a second middle layer and a corona layer for plating an aluminum membrane in sequence. The undrawn polyethylene film disclosed by the invention is large in strength, low in air permeability, low in damp permeability, good in plated aluminum adhesion property and good in thermal sealing property.

Owner:广东铭丰新材料科技有限公司

Infusion bag with outer barrier bag filled with inert gas

PendingCN106511078AAvoid destructionImprove barrier propertiesSynthetic resin layered productsPharmaceutical containersEngineeringOxygen

The invention discloses an infusion bag with an outer barrier bag filled with inert gas. The infusion bag comprises a package and liquid medicine in the package. Hot melting edge sealing is conducted on the periphery of the package, and the package is a multi-layer package sequentially comprising a heat seal layer, a membrane layer, a strength layer, an adhesive layer, a heat-resistant layer, a gas layer, a hot bonding layer, a reinforcing layer and a barrier layer from inside to outside. The gas layer is filled with inert gas and internally provided with a humidity indicator. The gas layer serving as the infusion middle layer is filled with inert gas, oxygen is prevented from being left in the gas layer, and when a liquid medicine layer bag slightly leaks, oxygen can be prevented from entering the liquid medicine and damaging the liquid medicine. Meanwhile, oxygen, permeating and entering an outer sealing layer, in air can be removed. Longitudinal grooves are formed and form a road net for flowing of the inert gas, the inert gas is evenly distributed in the gas layer, and no bubbles are generated.

Owner:SICHUAN TAIPINGYANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com