Biaxially-oriented BOPE film and preparation method thereof

A biaxial stretching and longitudinal stretching technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems that ordinary BOPE optical films cannot meet the needs of consumers and increase costs, and achieve The effect of reducing secondary composite processing, reducing waste, and reducing heat sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

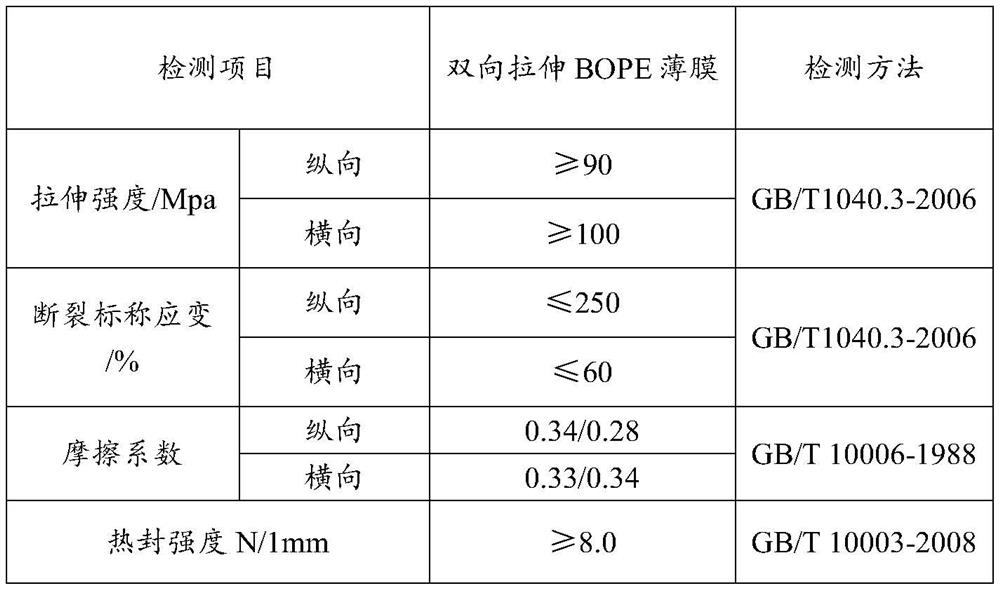

Examples

Embodiment 1

[0021] A method for preparing a 25-micron biaxially stretched BOPE film. The film includes a surface layer I, a core layer, and a surface layer II. The core layer is located between the surface layer I and the surface layer II. The surface layer I includes 97 parts of heat-sealing material and 3 parts of anti-sticking agent; The surface layer II includes 98.5 parts of polyethylene, 2.5 parts of anti-sticking agent, and the core layer includes 99 parts of polyethylene and 1 part of antistatic agent. The thickness of the surface layer I is about 2 microns; the thickness of the surface layer II is about 1 micron, and the thickness of the core layer is about 22.5 microns, and the raw materials used are purchased from outside.

[0022] The preparation process of biaxially stretched BOPE film is as follows:

[0023] S1: Add the raw materials of surface layer I, core layer and surface layer II to the corresponding high-speed mixer and mix for 25 minutes. After mixing evenly, the core...

Embodiment 2

[0032] A method for preparing a 25-micron biaxially stretched BOPE film. The film includes a surface layer I, a core layer, and a surface layer II. The core layer is located between the surface layer I and the surface layer II. The surface layer I includes 96 parts of heat-sealing material and 4 parts of anti-sticking agent; The surface layer II includes 98 parts of polyethylene, 2 parts of anti-sticking agent, and the core layer includes 98 parts of polyethylene and 2 parts of antistatic agent. The thickness of the surface layer I is about 2 microns; the thickness of the surface layer II is about 1 micron, and the thickness of the core layer is about 22.5 microns. Among them, polyethylene is a special material supplied by Sinopec, the heat sealing material is SP0540, the antistatic agent is MS10E, and the antisticking agent is WE-05BE are purchased products.

[0033] Its preparation method is the same as embodiment 1.

Embodiment 3

[0035] A method for preparing a 25-micron biaxially stretched BOPE film. The film includes a surface layer I, a core layer, and a surface layer II. The core layer is located between the surface layer I and the surface layer II. The surface layer I includes 95 parts of heat-sealing material and 5 parts of anti-sticking agent; The surface layer II includes 97 parts of polyethylene, 3 parts of anti-sticking agent, and the core layer includes 97 parts of polyethylene and 3 parts of antistatic agent. The thickness of the surface layer I is about 2 microns; the thickness of the surface layer II is about 1 micron, and the thickness of the core layer is about 22.5 microns. Among them, polyethylene is a special material supplied by Sinopec, the heat sealing material is SP0540, the antistatic agent is MS10E, and the antisticking agent is WE-05BE are purchased products.

[0036] Its preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com