Polyolefin bidirectional stretching surface hanging film and preparation method thereof

A technology of biaxial stretching and polyolefin, which is applied in the direction of chemical instruments and methods, flat products, and other household appliances, etc. It can solve the problems of slippage, heat sealing and lack of transparency, affect production efficiency, and weak sealing, etc., to achieve Meet the needs of high-speed packaging, improve transparency and heat-sealability, and have the effect of wide heat-sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

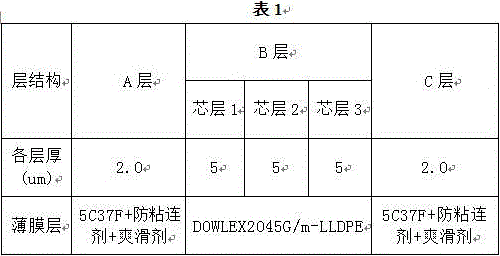

Image

Examples

Embodiment Construction

[0029] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

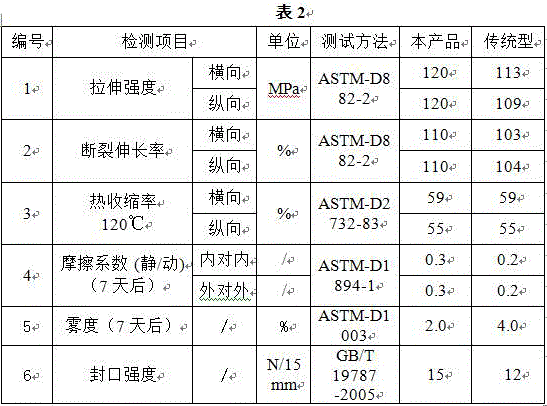

[0030] At present, in order to ensure the opening of the general film, it is necessary to achieve a high degree of slip, while improving the slip, it reduces the heat sealability and transparency of the material. During high-speed packaging, it is prone to poor sealing and affects the appearance, which affects production efficiency. After long-term practice, slipperiness, transparency and heat-sealing temperature are three important parameters of the performance of the linen film. Through long-term production practice and rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com