Three-layer co-extrusion heavy packaging film and preparation method thereof

A three-layer co-extrusion, packaging film technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of poor stiffness and thermal deformation, high heat sealing temperature, package rupture, etc., and achieve good stiffness. , The effect of high friction coefficient and low heat sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

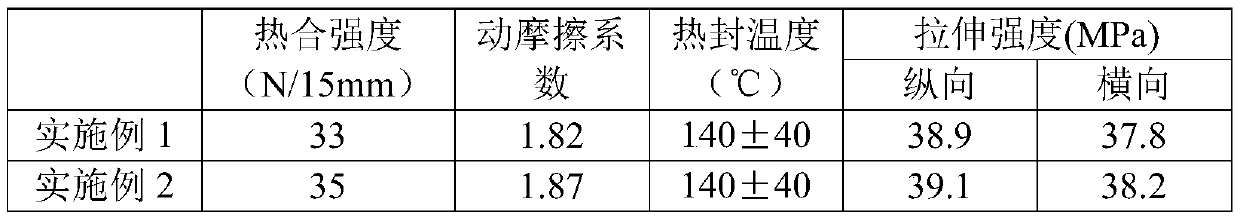

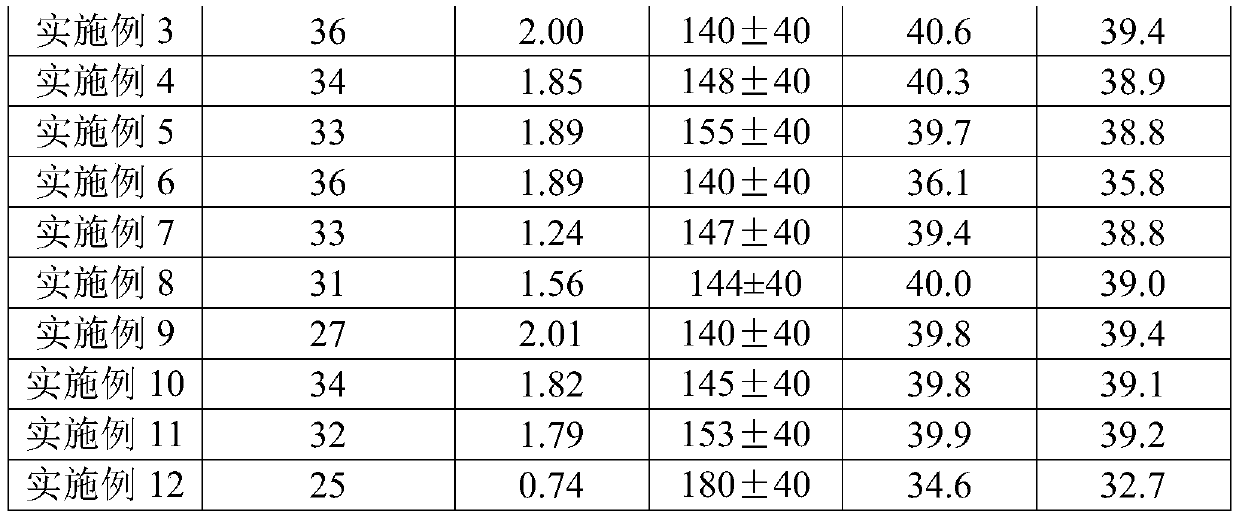

Examples

preparation example Construction

[0071] The preparation raw materials of the inner layer, the middle layer and the outer layer of the present invention are weighed and configured separately to obtain the mixture of the inner layer, the middle layer and the outer layer, and then the inner layer mixture and the middle layer are mixed according to the weight ratio of the inner layer, the middle layer and the outer layer material and outer layer mixture.

[0072] The standards of the parts by weight of the inner layer, the middle layer and the outer layer are different in the present invention.

[0073] The second aspect of the present invention provides a method for preparing a three-layer co-extrusion heavy-duty packaging film, which includes: respectively transporting the preparation raw materials of the inner layer, the middle layer and the outer layer to three extruders. After being plasticized in the exiting machine, they are transported to the same three-layer blown film die head, and the inner layer, midd...

Embodiment 1

[0078] Embodiment 1 of the present invention provides a kind of three-layer co-extrusion heavy packaging film, and it comprises inner layer, middle layer and outer layer three parts that are arranged sequentially from inside to outside; By weight, the preparation raw material of described inner layer comprises 20 parts of low-density polyethylene, 30 parts of metallocene polyethylene, 15 parts of polyolefin elastomer, 0.5 part of open smooth masterbatch; by weight, the preparation raw materials of the middle layer include 10 parts of metallocene polyethylene, 10 parts of Low-density polyethylene, 5 parts of high-density polyethylene, 2 parts of color masterbatch; by weight, the preparation raw materials of the outer layer include 20 parts of low-density polyethylene, 30 parts of metallocene polyethylene, 15 parts of polyolefin elastic body.

[0079] In the inner layer, the melt index of the low-density polyethylene is 0.25g / 10min, which is purchased from Shanghai Kaiyi Plastic...

Embodiment 2

[0085]Embodiment 2 of the present invention provides a kind of three-layer co-extrusion heavy packaging film, and it comprises inner layer, middle layer and outer layer three parts that are arranged sequentially from inside to outside; By weight, the preparation raw material of described inner layer comprises 50 parts of low-density polyethylene, 31.5 parts of metallocene polyethylene, 45 parts of polyolefin elastomer, 5 parts of open smooth masterbatch; by weight, the preparation raw materials of the middle layer include 40 parts of metallocene polyethylene, 30 parts of Low-density polyethylene, 35 parts of high-density polyethylene, 10 parts of color masterbatch; by weight, the preparation raw materials of the outer layer include 50 parts of low-density polyethylene, 31.5 parts of metallocene polyethylene, 45 parts of polyolefin elastic body.

[0086] In the inner layer, the melt index of the low-density polyethylene is 0.75g / 10min, which is purchased from Suzhou Pengran Pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com