Ion exchange membrane with high current efficiency, and preparation method and application thereof

An ion-exchange membrane and high-current technology, applied in the field of ion-exchange membranes, can solve problems such as high tank pressure and complex ion membrane preparation process, and achieve the effects of low cost, improved peeling defects, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

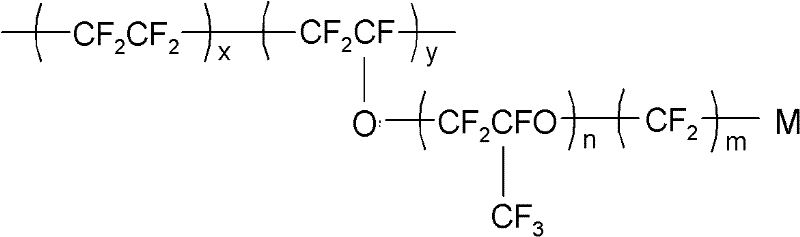

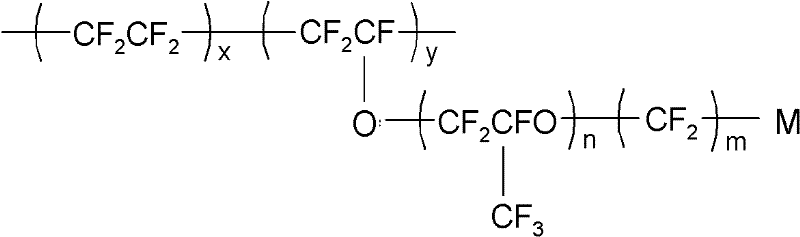

[0041]The short-chain perfluorosulfonic acid resin (A layer raw material) of IEC=1.12mmol / g (x=4.5, n=0, m=3 in the general formula), the long-chain perfluorosulfonic acid of IEC=0.85mmol / g Resin (B layer raw material) (x=7.3, n=1, m=3) and IEC=1.20mmol / g long-chain perfluorocarboxylic acid resin (C layer raw material) (x=3.9, n=1, m= 3) According to a certain ratio, it is composited into a film by co-extrusion casting, wherein the thickness of the A layer is 100 microns, the thickness of the B layer is 10 microns, and the thickness of the C layer is 8 microns; then, the PFA fiber web (thickness 65 microns) The A layer (80% of the thickness of the PFA fiber web is embedded in the A layer) of the three-layer composite membrane is compounded by a hot pressing process (temperature 150°C) to form a reinforced ionic membrane, and the composite ionic membrane is hydrolyzed in 25wt% KOH aqueous solution at 90°C 10-15 hours for transformation treatment, and then ZrO containing 3-5wt% ...

Embodiment 2

[0043] The ionic membrane with high current efficiency in the chlor-alkali tank as described in embodiment 1, difference is to adopt the short-chain perfluorinated sulfonic acid resin (A layer raw material) (x=3.5, n=of IEC=1.26mmol / g) 0, m=2), IEC=0.77mmol / g long-chain perfluorosulfonic acid resin (B layer material) (x=8.5, n=1, m=4) and IEC=1.00mmol / g short-chain perfluorosulfonic acid resin Fluorocarboxylic acid resin (material for layer C) (x=5.5, n=0, m=3). Among them, the thickness of layer A is 120 microns, the thickness of layer B is 10 microns, and the thickness of layer C is 6 microns; then, the polytetrafluoroethylene fiber mesh (thickness 70 microns) is composited into a three-layer composite by hot pressing (temperature 120 °C) The A layer of membrane (90% embedding A layer of polytetrafluoroethylene fibrous web thickness) forms reinforced ionic membrane, and after this composite ionic membrane is described in embodiment 1 transformation, after hydrophilic coating...

Embodiment 3

[0045] The ionic membrane with high current efficiency in the chlor-alkali tank as described in embodiment 1, difference is to adopt the short-chain perfluorinated sulfonic acid resin (A layer raw material) (x=3.0, n=of IEC=1.35mmol / g) 0, m=5), IEC=0.95mmol / g long-chain perfluorosulfonic acid resin (B layer raw material) (x=6.1, n=1, m=2) and IEC=1.18mmol / g long-chain perfluorosulfonic acid resin Fluorocarboxylic acid resin (raw material for layer C) (x=4.0, n=1, m=3). Among them, the thickness of layer A is 100 microns, the thickness of layer B is 20 microns, and the thickness of layer C is 10 microns; then, the polyperfluoroethylene propylene fiber mesh (thickness 55 microns) is composited into three layers by hot pressing (temperature 140 °C) The A layer of the composite membrane (the full thickness of the polyperfluoroethylene propylene fiber net is embedded in the A layer) forms a reinforced ionic membrane. After the composite ionic membrane is transformed and treated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com