Polyolefin / polycarbonate alloy film for meltable asphalt packing bag and production method thereof

A polycarbonate and alloy film technology, applied in the field of asphalt packaging bags, can solve the problems of inconvenient construction, low limit temperature, and packaging bags cannot be completely mixed and melted, and achieve the effect of reducing labor intensity and lowering processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

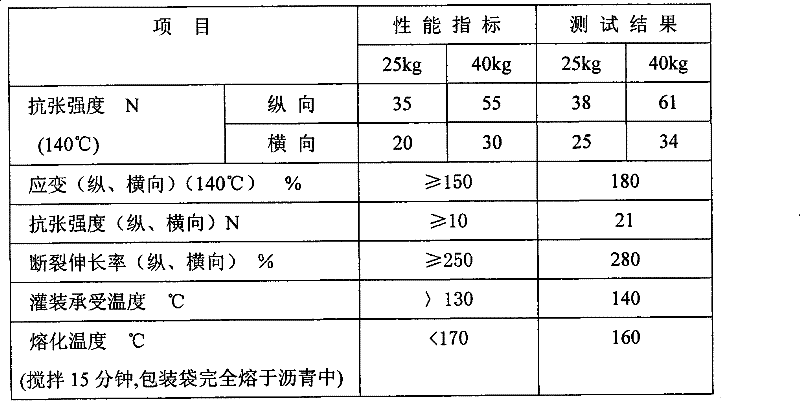

Image

Examples

Embodiment 1

[0043] (1) Melt kneading: Premix the formula component raw materials determined by the polyolefin / polycarbonate alloy film embodiment for the above-mentioned meltable asphalt packaging bag, and then send the fully mixed raw materials into two parallel sets The extruder is melted and kneaded, and the temperature of the melted kneading is controlled at about 185°C;

[0044] (2) Extrusion of film blanks: After fully kneading and melting, the two parts of the melt enter the machine head in the direction of crossing each other, and the two parts of the melt are brought together in the machine head to form a double melt flow direction crossing each other. Layer-composite melt, the film embryo is extruded from the die mouth of the machine head as a cylindrical melt, and the temperature of the machine head is controlled at about 180°C;

[0045] (3) Blown film forming: The cylindrical melt film embryo extruded from the die of the machine head is blown film by the down-blown film method...

Embodiment 2

[0049] (1) Melt mixing: Premix the raw materials of the formula components determined in the polyolefin / polycarbonate alloy film embodiment for the above-mentioned meltable bitumen packaging bag, and then send the fully mixed raw materials into the double-unit extruder Carry out melt kneading, and the melt kneading temperature is controlled at about 180°C;

[0050] (2) Thin film embryo extrusion: After fully kneading and melting, the two parts of the melt enter the machine head in the direction perpendicular to each other, and the two parts of the melt are brought together in the machine head to form a double melt flow direction perpendicular to each other. Layer-composite melt, the film embryo is extruded from the die mouth of the machine head as a cylindrical melt, and the temperature of the machine head is controlled at about 175°C;

[0051] (3) Blown film forming: The cylindrical melt film embryo extruded from the die of the machine head is blown by the down-blown film met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com