Outer material for power storage device, external case for power storage device and power storage device

A technology for electrical storage equipment and outer packaging, which is applied to battery box/cover materials, electronic equipment, battery boxes/coats, etc., which can solve the problems of reduced surface slippage and inability to form the sealing layer, so as to reduce the amount of seepage, Reduced contact area and good sliding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

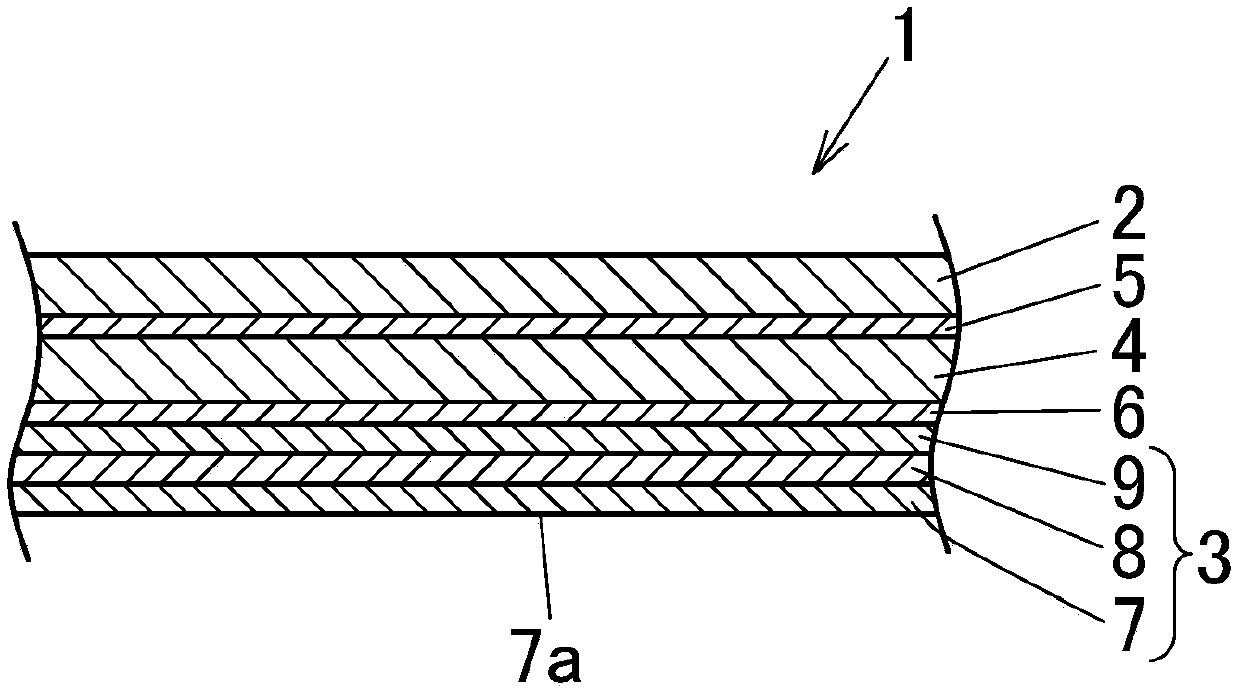

[0119] A chemical conversion treatment liquid containing phosphoric acid, polyacrylic acid (acrylic resin), chromium (III) salt compound, water, and alcohol is applied to both sides of an aluminum foil 4 with a thickness of 35 μm, and then dried at 180° C. to form a chemical conversion treatment solution. film. The amount of chromium attached to the chemical conversion coating is 10mg / m per side 2 .

[0120] Next, a biaxially stretched nylon 6 film 2 with a thickness of 5 μm is dry-laminated (laminated) on the aluminum foil that has undergone the above-mentioned chemical conversion treatment through a two-component curing type urethane adhesive 5 4 on one side.

[0121] Next, the first heat-sealable resin unstretched film 7 (which contains ethylene-propylene random copolymer, 1000 ppm of erucamide (lubricant), 2000 ppm of silica particles (average The particle size is 1.0 μ m; non-compatible particles)), the thickness is 21 μ m second unstretched film 8 of heat-sealable res...

Embodiment 2

[0124] The content of the silica particles (non-compatible particles) in the first heat-meltable resin layer (innermost layer) 7 and the third heat-meltable resin layer 9 was changed from 2000 ppm to 1000 ppm, the same as in Example 1 Do the same, get figure 1 An outer packaging material 1 for an electrical storage device having the configuration shown in the figure.

Embodiment 3

[0126] The content of the silica particles (non-compatible particles) in the first heat-meltable resin layer (innermost layer) 7 and the third heat-meltable resin layer 9 was changed from 2000 ppm to 6000 ppm, and it was the same as in Example 1. Do the same, get figure 1 An outer packaging material 1 for an electrical storage device having the configuration shown in the figure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com