High-barrier antiskid packaging film and preparation method thereof

A packaging film and high-barrier technology, applied in the field of packaging materials, can solve the problems of poor barrier performance, low friction coefficient on the surface of large packaging bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

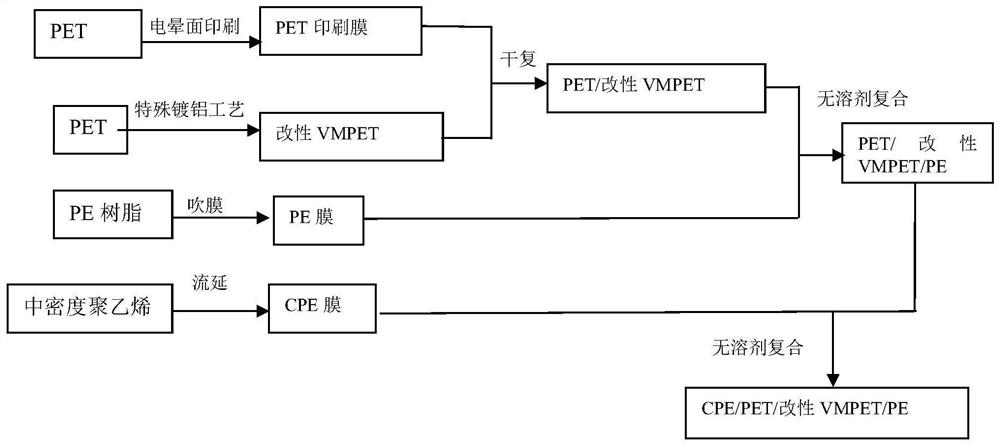

Method used

Image

Examples

Embodiment 1

[0039] The film with the structure of "12PET / 12 ordinary VMPET / 125PE" is prepared by ordinary aluminum plating process:

[0040] S1. Preparation of PET printing film: Print on the corona surface of the PET film. The printing parameters are: machine speed 250±10m / min, unwinding tension 110±5N, feeding tension 130±5N, traction tension 150 ±5N, the winding tension is 80±5N, and the PET printing film is obtained;

[0041] S2. Preparation of ordinary VMPET film: Use Leybold aluminum plating machine to carry out aluminum plating process on PET film. Aluminum plating process parameters: plasma power is 3kw, Alubondx oxygen flow rate is 3.5SCCM, unwinding roller tension is 420±30kg, winding The roller tension is 200±30kg to make ordinary VMPET film;

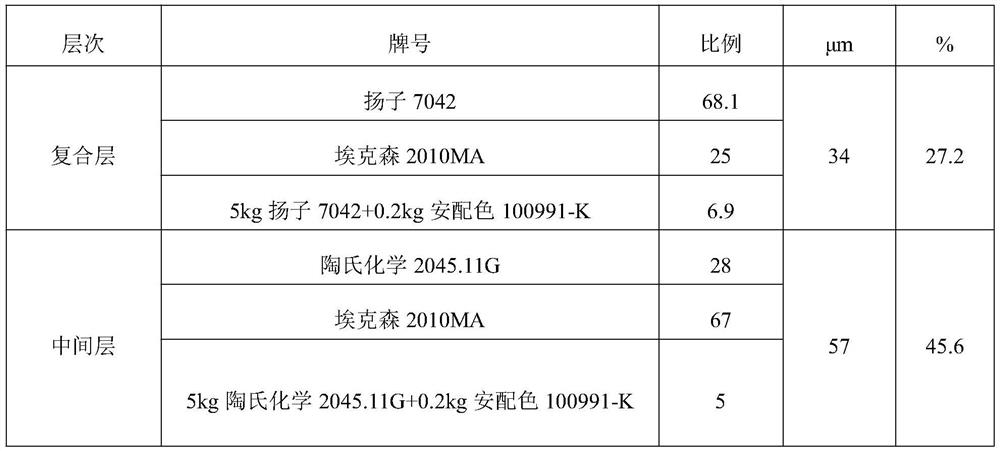

[0042] S3. Preparation of PE film: Weigh the materials of each layer of PE film according to the stated component ratio, and add them to the corresponding hopper in the multi-layer co-extrusion casting machine respectively, and form the...

Embodiment 2

[0049] The film with the structure of "30CPE / 12PET / 12 ordinary VMPET / 95PE" is prepared by reverse aluminum plating process:

[0050] S1. Preparation of PET printing film: Corona surface printing is carried out on one side of the PET film. The printing parameters are: machine speed 250±10m / min, unwinding tension 110±5N, feeding tension 130±5N, traction tension: 150±5N, the winding tension is 80±5N, and the PET printing film is obtained;

[0051] S2. Preparation of ordinary VMPET film: Use Leybold aluminum plating machine to carry out aluminum plating process on PET film. Aluminum plating process parameters: plasma power is 3kw, Alubondx oxygen flow rate is 3.5SCCM, unwinding roller tension is 420±30kg, winding The roller tension is 200±30kg to make ordinary VMPET film;

[0052] S3. Preparation of PE film: Weigh the materials of each layer of PE film according to the stated component ratio, and add them to the corresponding hopper in the multi-layer co-extrusion casting machine...

Embodiment 3

[0064] The film with the structure of "30CPE / 12PET / 12 modified VMPET / 95PE" was prepared by reverse aluminum plating process:

[0065] S1. Preparation of PET printing film: Corona surface printing is carried out on one side of the PET film. The printing parameters are: machine speed 250±10m / min, unwinding tension 110±5N, feeding tension 130±5N, traction tension: 150±5N, the winding tension is 80±5N, and the PET printing film is obtained;

[0066]S2. Preparation of modified VMPET film: use BOBST metallizer to carry out reverse aluminum plating process on PET film, aluminum plating process parameters: plasma power is 3kw, Alubondx oxygen flow rate is 3.5SCCM, unwinding roller tension is 340±30kg , the winding roller tension is 210±30kg, and the modified VMPET film is prepared;

[0067] S3. Preparation of PE film: Weigh the materials of each layer of PE film according to the stated component ratio, and add them to the corresponding hopper in the multi-layer co-extrusion casting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com