Scratch-resistant degradable licence card base material and preparation technology thereof

A preparation process and scratch-resistant technology, applied in the field of thermoplastic polyester, can solve the problems of reduced wetting tension on the surface of the material, unfavorable secondary processing of punching and carding, and overall brittleness of the material, so as to achieve a simple and easy process and easy industrial production. , Good scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

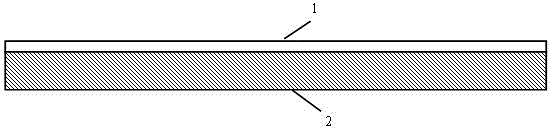

Image

Examples

Embodiment 1

[0034] Example 1: Differential injury can be deducted from the derivative card and its preparation process

[0035] Material recipe: upper layer: PMMA resin 92.8WT%, plasticizer citric acid triate 5WT%, lubricant hard fatty acid glycerin 0.7WT%, antioxidant sanybin ester 0.5WT%, ultraviolet absorbent 2-0.5WT%of the hydroxyl-4-olive oxygenylbenzylene ketone, and 0.5WT%of the antistatic agent sigmohydramine.Below: PHA resin 90.1WT%, plasticizer acetyl citrate triaxotate 8WT%, lubricant ethylene glycol monolithic acid ester 0.8WT%, antioxidant subcarcitic acid triathin 0.6WT%, antistatic agent0.5WT%of steroxidamine.

[0036] Molding:

[0037] A. Raw material preparation: Take the raw materials according to the formula, PMMA, PHA resin is dry to 0.3%of the moisture content;

[0038] B. Material hybrid: use high -speed mixed machines to perform two sections of the material.Upper PMMA: High -speed mixed segment: material temperature 70 ° C, spindle speed 1500rpm, mixed time of 30min; lo...

Embodiment 2

[0044] Example 2: Differential injury can be deducted from the derivative card and its preparation process

[0045] Material recipe: upper layer: PMMA resin 97.8WT%, plasticizer citric acid triate 2WT%, lubricant hard fatty acid glyceride 0.1WT%, antioxidant sanybolic sink -. 0.1WT%.Lower layer: PHA resin 90.6WT%, plasticizer acetyl citrate tria -butyl 5WT%, citric acid triacosine 3WT%, lubricant ethylene alcohol monocolite 0.8WT%, antioxidant sub -phosphoric acid triple sinkEtate 0.6WT%.

[0046] Molding:

[0047] A. Raw material preparation: Take the raw materials according to the formula, PMMA, PHA resin is dry to 0.3%of the moisture content;

[0048] B. Material hybrid: use high -speed mixed machines to perform two sections of the material.Upper PMMA: High -speed mixed segment: material temperature 70 ° C, spindle speed 1500rpm, mixed time of 30min; low -speed mixed segment: material temperature 40 ° C, spindle speed 80rpm, mixed time 15min; lower layer PHA: high -speed mixed ...

Embodiment 3

[0054] Example 3: Differential injury can be degraded to degrade the derivative card and its preparation process

[0055] Material recipe: upper layer: PMMA resin 92.8WT%, plasticizer citric acid triate 5WT%, lubricant hard fatty acid glycerin 0.5WT%, ethylene glycol diic acid ester 0.2WT%, antioxidant subcunal phosphoric acidTrigemon ester 0.2WT%, triteromylphotate 0.3WT%, ultraviolet absorbers 2-hydroxyl-4-olive oxygenyl dietthone 0.5WT%, anti-static agent sigmonidamine 0.3WT%, Ethyl oxidation duoline 0.2WT%.Below: PHA resin 94.4WT%, plasticizer acetyl citrate triaxotate 5WT%, lubricant ethylene glycol monolithic acid ester 0.3WT%, solid glycerin 0.1WT%, antioxidant sub -phosphoric acid triple differenceCinded 0.2WT%.

[0056] Molding:

[0057] A. Raw material preparation: Take the raw materials according to the formula, PMMAA, PHA resin is dry to 0.3%of the moisture content;

[0058] B. Material hybrid: use high -speed mixed machines to perform two sections of the material.Uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com