A scratch-resistant degradable card substrate and its preparation process

A preparation process and scratch-resistant technology, applied in the field of thermoplastic polyester, can solve the problems of reduced wetting tension on the surface of the material, unfavorable secondary processing of punching and carding, and overall brittleness of the material, so as to achieve a simple and easy process and easy industrial production. , Good scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

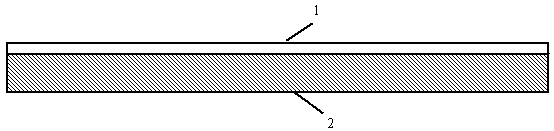

[0034] Example 1: Scratch-resistant degradable card substrate and its preparation process

[0035] Material formula: upper layer: PMMA resin 92.8wt%, plasticizer tributyl citrate 5wt%, lubricant stearin 0.7wt%, antioxidant triisooctyl phosphite 0.5wt%, ultraviolet absorber 2 -Hydroxy-4-n-octyloxybenzophenone 0.5 wt%, antistatic agent ethoxylated oleylamine 0.5 wt%. Lower layer: PHA resin 90.1 wt%, plasticizer acetyl tributyl citrate 8wt%, lubricant ethylene glycol monostearate 0.8wt%, antioxidant triisooctyl phosphite 0.6wt%, antistatic agent Ethoxylated oleylamine 0.5 wt%.

[0036] Molding:

[0037] A. Raw material preparation: Weigh raw materials according to the formula, dry PMMA and PHA resins to a moisture content of 0.3%;

[0038] B. Material mixing: Use high-speed mixer to carry out two-stage mixing process for materials. Upper layer PMMA: high-speed mixing section: material temperature 70°C, spindle speed 1500rpm, mixing time 30min; low-speed mixing section: materi...

Embodiment 2

[0044] Example 2: Scratch-resistant degradable card substrate and its preparation process

[0045] Material formula: upper layer: PMMA resin 97.8wt%, plasticizer tributyl citrate 2wt%, lubricant stearin 0.1wt%, antioxidant triisooctyl phosphite 0.1wt%. Lower layer: PHA resin 90.6wt%, plasticizer acetyl tributyl citrate 5wt%, tributyl citrate 3wt%, lubricant ethylene glycol monostearate 0.8wt%, antioxidant triisooctyl phosphite Esters 0.6wt%.

[0046] Molding:

[0047] A. Raw material preparation: Weigh raw materials according to the formula, dry PMMA and PHA resins to a moisture content of 0.3%;

[0048] B. Material mixing: Use high-speed mixer to carry out two-stage mixing process for materials. Upper layer PMMA: high-speed mixing section: material temperature 70°C, spindle speed 1500rpm, mixing time 30min; low-speed mixing section: material temperature 40°C, spindle speed 80rpm, mixing time 15min; lower layer PHA: high-speed mixing section: material temperature 70°C, spin...

Embodiment 3

[0054] Example 3: Scratch-resistant degradable card substrate and its preparation process

[0055] Material formula: upper layer: PMMA resin 92.8wt%, plasticizer tributyl citrate 5wt%, lubricant stearin 0.5wt%, ethylene glycol distearate 0.2wt%, antioxidant phosphorous acid Tri-isooctyl ester 0.2wt%, triethyl phosphite 0.3wt%, UV absorber 2-hydroxy-4-n-octyloxybenzophenone 0.5wt%, antistatic agent ethoxylated oleylamine 0.3wt %, ethoxylated dodecylamine 0.2 wt %. Lower layer: PHA resin 94.4 wt %, plasticizer acetyl tributyl citrate 5 wt %, lubricant ethylene glycol monostearate 0.3 wt %, glyceryl stearate 0.1 wt %, antioxidant triisophosphite Octyl ester 0.2wt%.

[0056] Molding:

[0057] A. Raw material preparation: Weigh the raw materials according to the formula, dry the PMMAA and PHA resins to a moisture content of 0.3%;

[0058] B. Material mixing: Use high-speed mixer to carry out two-stage mixing process for materials. Upper layer PMMA: high-speed mixing section: m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com