Outer barrier flushing fluid bag filled with inert gas

A technology of inert gas and flushing liquid, applied in the direction of flexible coverings, packaging, layered products, etc., can solve the problems of uncontrollable micro-leakage, damage to micro-leakage packaging, damage, etc., to achieve convenient heat sealing and high-temperature disinfection, strengthen The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention and corresponding drawings.

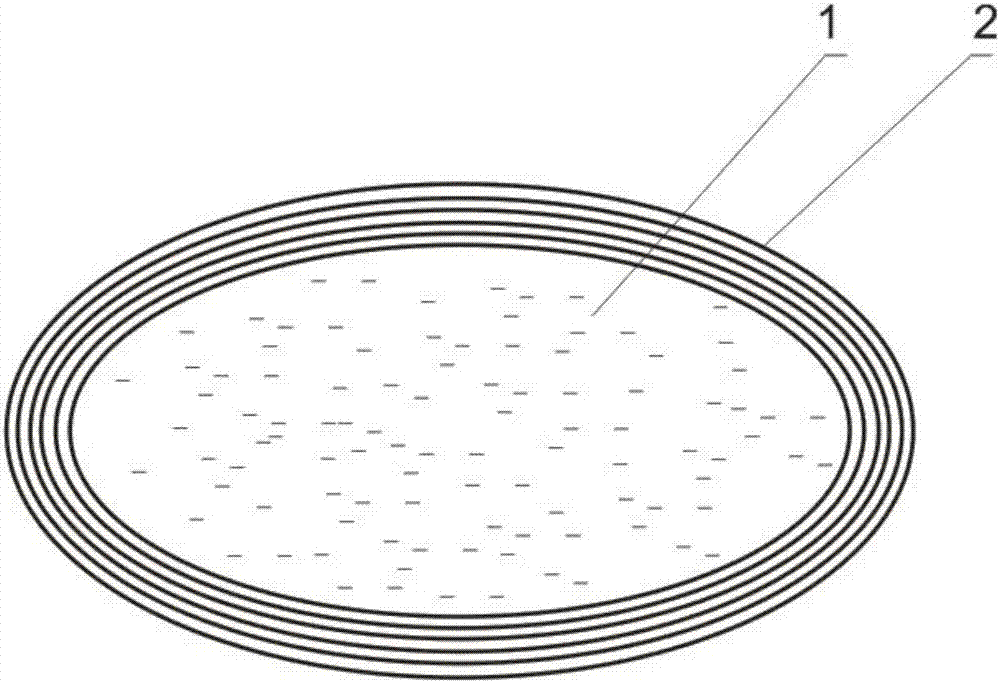

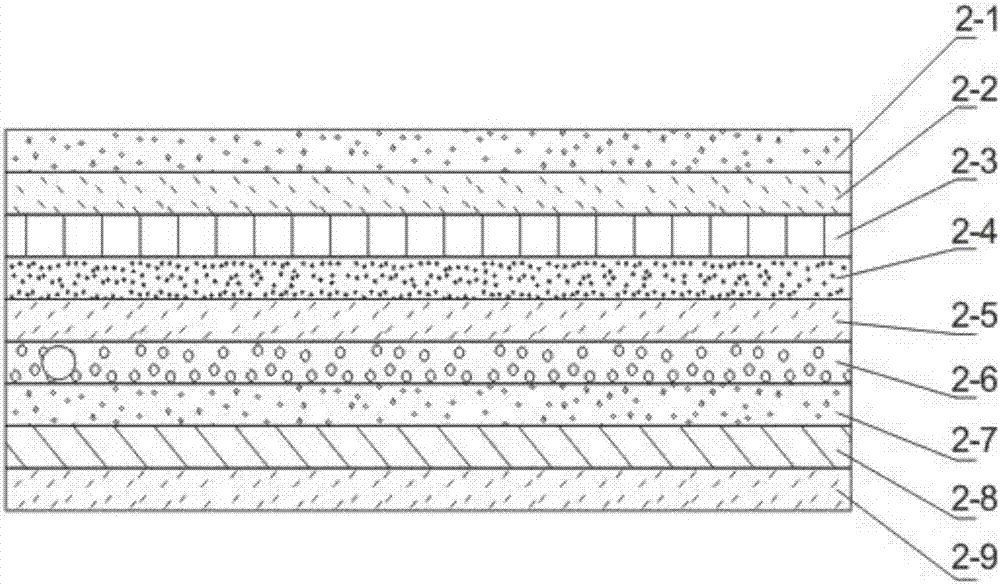

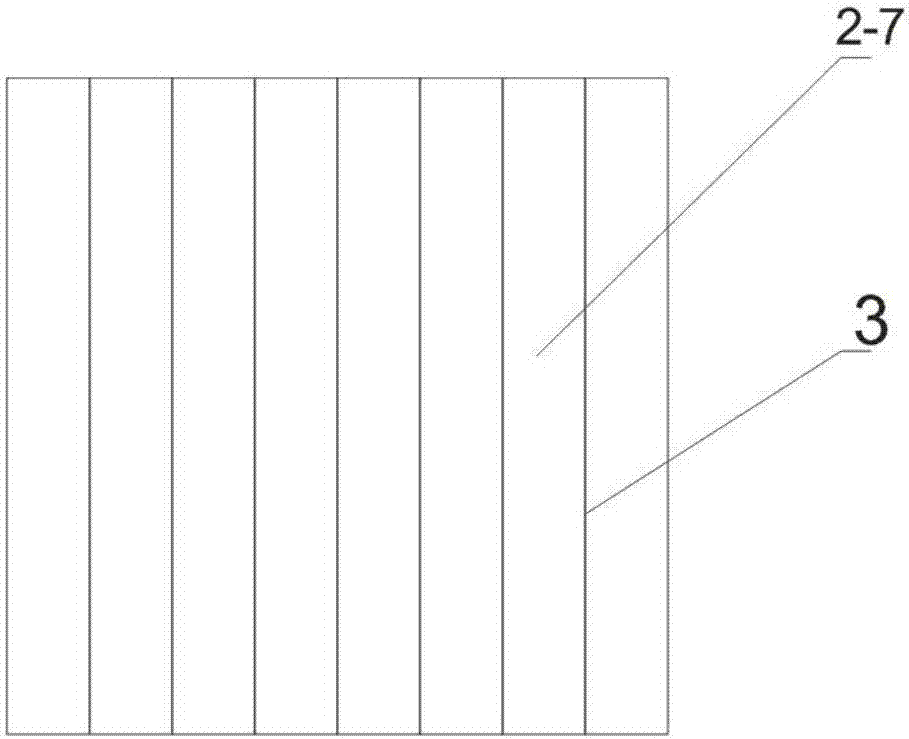

[0031] Refer to attached figure 1 , figure 2 , the packaging of the present invention is mainly divided into three parts: from the inside to the outside, it is a liquid medicine layer, a gas layer, and an outer sealing layer; , the gas layer separates the liquid medicine layer from the outer sealing layer, and applies negative pressure to the liquid medicine layer, and the outer sealing layer is made of a material with gas barrier properties.

[0032] 1. The innermost layer is the liquid medicine layer that is in direct contact with the flushing liquid. The liquid medicine layer is a total of five layers of materials. During processing, a five-layer co-extrusion process is used for bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com