A kind of unstretched polyethylene film and preparation method thereof

A technology of polyethylene film and high-pressure polyethylene, which is applied in chemical instruments and methods, flexible coverings, types of packaging items, etc., can solve the problems of fragile heat-sealed ports, unfavorable food safety, and insufficient strength, etc., and achieve air permeability Reduce, avoid puncture or scratch, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

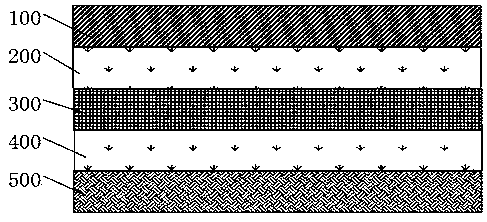

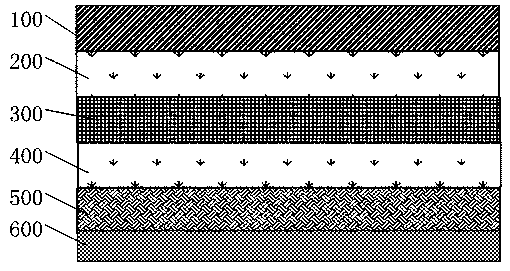

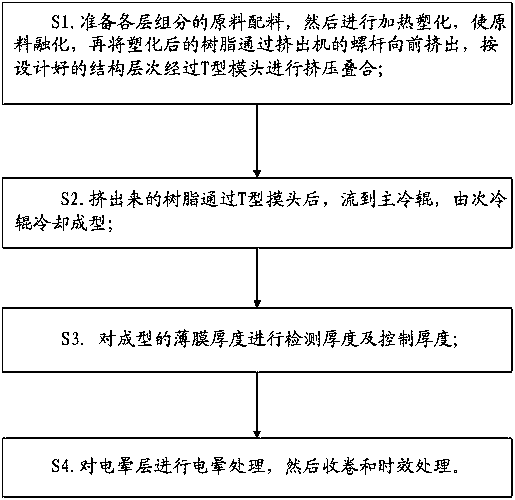

[0031]In the unstretched polyethylene film, the thickness percentages of the heat-sealing layer 100, the first intermediate layer 200, the auxiliary layer 300, the second intermediate layer 400, and the corona layer 500 are respectively: 20%, 17.5% , 20%, 17.5%, 25%. Specifically, the heat-sealing layer 100 includes components by mass percentage: 20% high-pressure polyethylene, 30% linear polyethylene, 48% metallocene polyethylene, and 2% opening agent; the first intermediate layer 200 and the second The mass percentages of the components included in the second middle layer 400 are: 20% high pressure polyethylene, 30% low pressure polyethylene, 50% metallocene polyethylene; the mass percentages of the components included in the auxiliary layer 300 are: 40% high pressure polyethylene, 40% linear polyethylene 50% ethylene, 10% low-pressure polyethylene; the corona layer 500 includes components by mass percentage: 24% high-pressure polyethylene, 50% linear polyethylene, 25.8% met...

Embodiment 2

[0033] In the unstretched polyethylene film, the thickness percentages of each layer among the heat-sealing layer 100, the first intermediate layer 200, the auxiliary layer 300, the second intermediate layer 400, and the corona layer 500 are respectively: 20%, 20%, 20%, 15%, 25%. Specifically, the heat-sealing layer 100 includes the following mass percentages: 33% high-pressure polyethylene, 33% linear polyethylene, 33% metallocene polyethylene, and 1% anti-blocking agent; the first intermediate layer 200 and the second The mass percentages of the components included in the second middle layer 400 are: high pressure polyethylene 33%, low pressure polyethylene 33%, metallocene polyethylene 33%; the components mass percentages of the auxiliary layer 300 are: high pressure polyethylene 45%, linear polyethylene 50% ethylene, 5% low-pressure polyethylene; the corona layer 500 includes 25.9% high-pressure polyethylene, 50% linear polyethylene, 24% metallocene polyethylene and 0.1% t...

Embodiment 3

[0035] In the unstretched polyethylene film, the thickness percentages of each layer among the heat-sealing layer 100, the first intermediate layer 200, the auxiliary layer 300, the second intermediate layer 400, and the corona layer 500 are respectively: 25%, 15%, 20%, 15%, 25%. Specifically, the heat-sealing layer 100 includes the following mass percentages: 20% high-pressure polyethylene, 50% linear polyethylene, 25% metallocene polyethylene, and 5% anti-blocking agent; the first intermediate layer 200 and the second The mass percentage of components included in the second middle layer 400 is: 20% high pressure polyethylene, 50% low pressure polyethylene, 30% metallocene polyethylene; the mass percentage of components included in the auxiliary layer 300 is: 40% high pressure polyethylene, 40% linear polyethylene 50% ethylene, 10% low-pressure polyethylene; the corona layer 500 includes 30% high-pressure polyethylene, 39.82% linear polyethylene, 30% metallocene polyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com