Alginate soft capsule and preparation method thereof

An alginate and soft capsule technology, which is applied in the directions of capsule delivery, pharmaceutical formulations, and non-active ingredients medical preparations, can solve the problems of uneven thickness of the capsule, deformation of the soft capsule, and lack of heat-sealing properties. Avoid local deformation or even leakage of capsule material, precise fixed-point disintegration function, and protect the gastrointestinal tract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

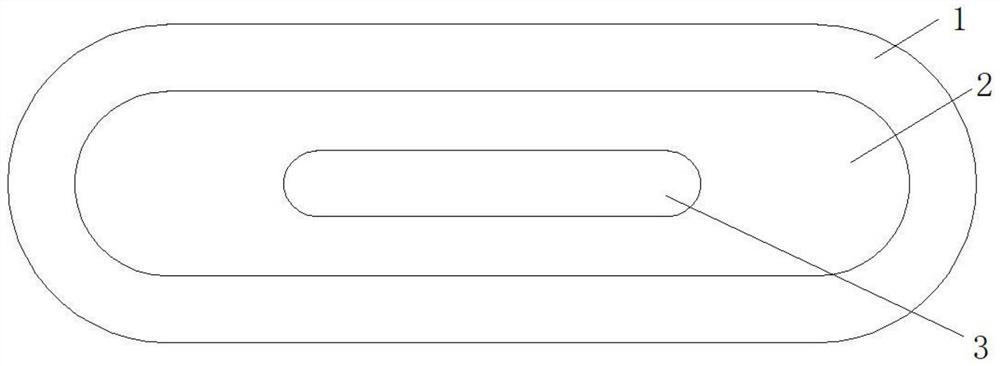

Image

Examples

Embodiment 1

[0046]A alginate soft capsule, prepared, including the following steps:

[0047]S1, potassium alginate 1 kg, 50 grams of endozogene, dissolved in 100 kg of purified water at 80 ° C, forming a transparent gel fluid;

[0048]S2, using fully automatic drip soft capsule production equipment (RDW-P type drip soft capsule machine, Beijing Xinhang Science Technology Development Co., Ltd.), content object is soybean oil, gel fluid and contents in double tap The outer layer flows out at different speeds, dripped into liquid paraffin, gradually cooled, solidified into spherical soft capsules (thermal reverse gel), alcohol to clean the surface of the soft capsule after collecting liquid paraffin;

[0049]S4, the cage is dried at room temperature, and the product made is oral disintegration or rapidly disintegration soft capsule.

[0050]Oral disintegration or rapid disintegration refers to disintegrating within 10 minutes in neutral water.

[0051]In this embodiment, since the crosslinking reaction is not re...

Embodiment 2

[0053]A algarate soft capsule, based on the components and preparation methods of Example 1, further comprising step S3, the soft capsule (thermocracked gelatin) collected by step S2 in Example 1 is 0.1% calcium with a mass concentration of 0.1%. The aqueous solution was soaked for 5 minutes;

[0054]Then, the product made by step S4 is a small intestinal collapsed soft capsule.

[0055]Small intestinal collapsed soft capsules refer to a soft capsule that is not disintegrated in neutral water and 120 minutes in artificial gastric juice, in 30 minutes within 30 minutes of artificial medium.

[0056]In this embodiment, in step S3, a multivalent metal ion crosslinking treatment of a relatively short time of a lower concentration is transmitted, and the multivalent metal ion is diffused into the superficial outer layer of thermoformed gel, soft capsules. The outer layer of the capsule forms a thinner thermal irreversible gel. The inner layer of the capsule is still a heat-reversible gel that doe...

Embodiment 3

[0058]An alginate soft capsule, based on the components and preparation methods of Example 1, further comprising step S3, a soft capsule (thermocracked gel) collected in Example 1 with a mass concentration of 5% chlorine Soak for 20 minutes;

[0059]Then, the product made by step S4 is a colon disintegration soft capsule.

[0060]Colon disintegration soft capsules refer to neutralized water, artificial gastric liquid, artificial intestinal fluid each 120 minutes without disintegration, in a 30-minute soft capsule that is 30 minutes in artificial colon liquid.

[0061]In this embodiment, the multivalent metal ion can diffuse into the deeper ,,,,,,,,,,,,,,,,,,,,,,,,,,, The outer layer of the capsule forms a layer of thick thermal irreversible gelatin, and the inner layer of the capsule is still a heat-reversible gel without the multivalent metal ion reaction, and the capsule material produced by step S4 is contained in the capsule material produced by step S4. More multivalent metal ions, thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com