Anti-ultraviolet bidirectional stretching polyester film and preparation method thereof

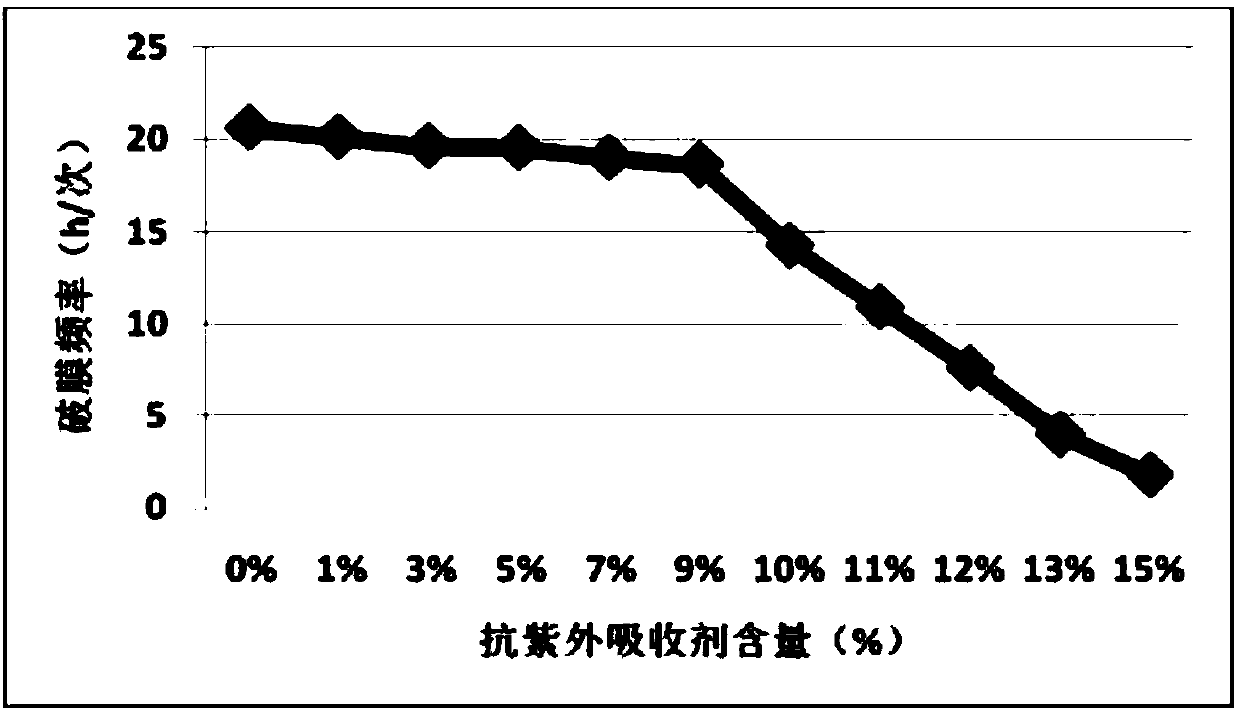

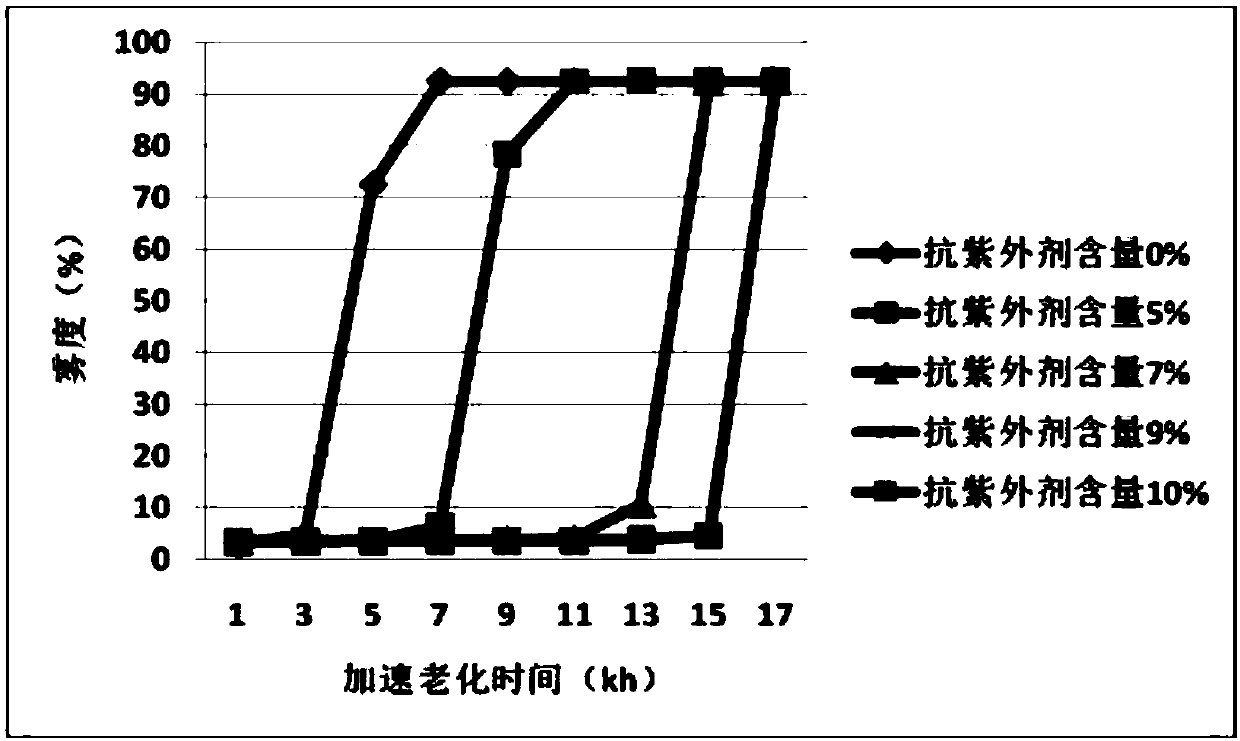

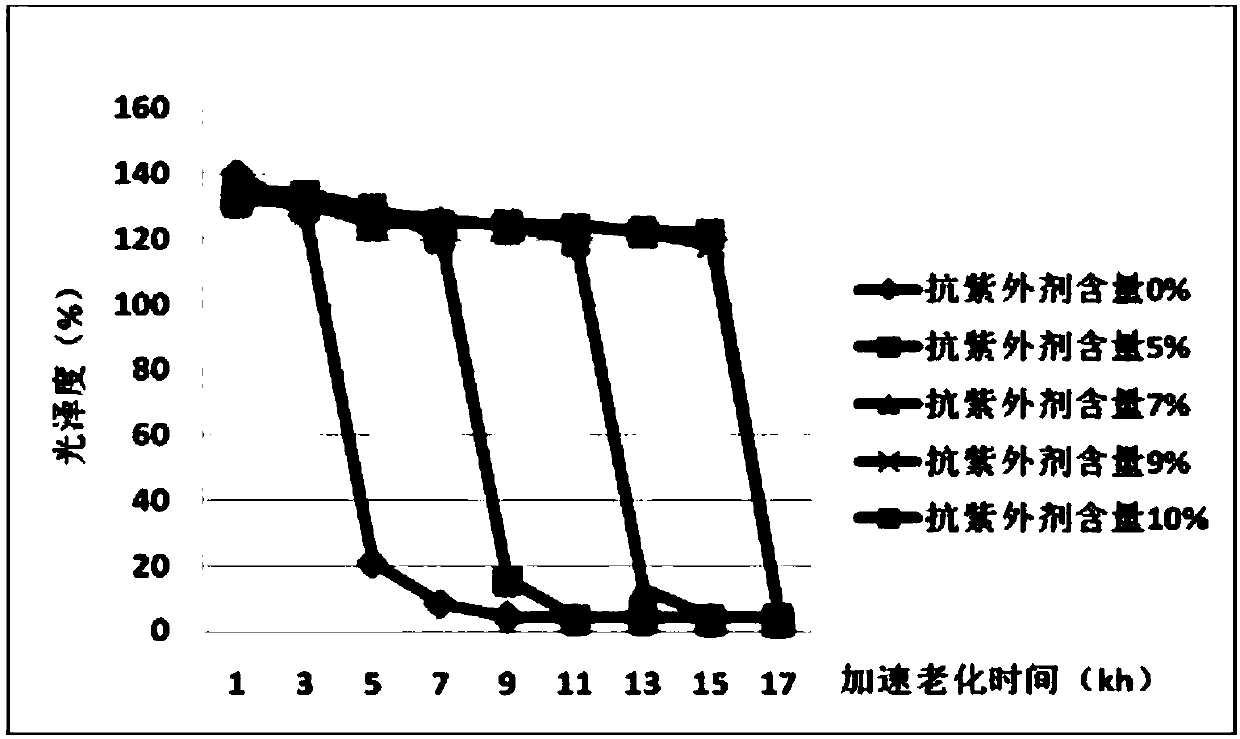

A technology of biaxially stretched polyester and anti-ultraviolet absorber, which is applied in the direction of chemical instruments and methods, applications, household appliances, etc., can solve the problem that the PET film has not yet met the customer's expected requirements, the mechanical strength and the nominal strain at break are reduced, and the gloss Reduce the temperature and other problems, achieve excellent UV resistance, excellent heat sealing performance, and reduce the effect of aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mix polyethylene terephthalate slices and anti-ultraviolet absorbing agent, and dry them on a fluidized bed at 130°C for 40 minutes, and then dry them in a drying tower at 130°C for 2 hours; The moisture content of the slices is 50ppm;

[0037] (2) Add the mixed chips dried in step (1) into the main extruder and heat them into a molten state as the main extruded melt of the core layer. The temperature of the main extruder is 265°C; Disc filter filter;

[0038] (3) Add polyethylene terephthalate slices, anti-ultraviolet absorbers and anti-blocking agents into the auxiliary extruder to obtain the upper surface melt after melting and vacuuming. The temperature of the auxiliary extruder is 265 ℃;

[0039] (4) Add modified polyethylene terephthalate slices and anti-blocking agent into the auxiliary extruder to obtain the lower surface melt after melting and vacuuming, and the temperature of the auxiliary extruder is 230°C;

[0040] (5) The main extruded melt, the uppe...

Embodiment 2

[0047] (1) Mix the polyethylene terephthalate chips and the anti-ultraviolet absorbing agent, and dry them on a fluidized bed at 150°C for 41 minutes, and then dry them in a drying tower at 150°C for 6 hours; The moisture content of the slices is 45ppm;

[0048] (2) Add the mixed chips dried in step (1) into the main extruder and heat them into a molten state as the main extruded melt of the core layer. The temperature of the main extruder is 285°C; Disc filter filter;

[0049] (3) Add polyethylene terephthalate slices, anti-ultraviolet absorbers and anti-blocking agents into the auxiliary extruder to obtain the upper surface melt after melting and vacuuming. The temperature of the auxiliary extruder is 285 ℃;

[0050] (4) Add the modified polyethylene terephthalate chips and anti-blocking agent into the auxiliary extruder to obtain the lower surface melt after melting and vacuuming, and the temperature of the auxiliary extruder is 260 ° C;

[0051] (5) Merge the main extru...

Embodiment 3

[0058] (1) Mix the polyethylene terephthalate chip and the anti-ultraviolet absorber, and dry it on a fluidized bed at 180°C for 42 minutes, and then dry it in a drying tower at 180°C for 8 hours; The moisture content of the slices is 40ppm;

[0059] (2) Add the mixed chips dried in step (1) into the main extruder and heat them into a molten state as the main extruded melt of the core layer. The temperature of the main extruder is 305°C; Disc filter filter;

[0060] (3) Add polyethylene terephthalate slices, anti-ultraviolet absorbers and anti-blocking agents into the auxiliary extruder to obtain the upper surface melt after melting and vacuuming. The temperature of the auxiliary extruder is 305 ℃;

[0061] (4) Add the modified polyethylene terephthalate chips and anti-blocking agent into the auxiliary extruder to obtain the lower surface melt after melting and vacuuming, and the temperature of the auxiliary extruder is 290 ° C;

[0062] (5) The main extruded melt, the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com