VMPET coated thin film, and production method

A coating and film technology, which is applied in the field of VMPET series coating films, can solve the problems of decreased barrier performance of the aluminized layer, restricted application, and failure to achieve barrier effects, etc., to achieve reduced production costs, excellent heat sealing performance, and excellent printing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

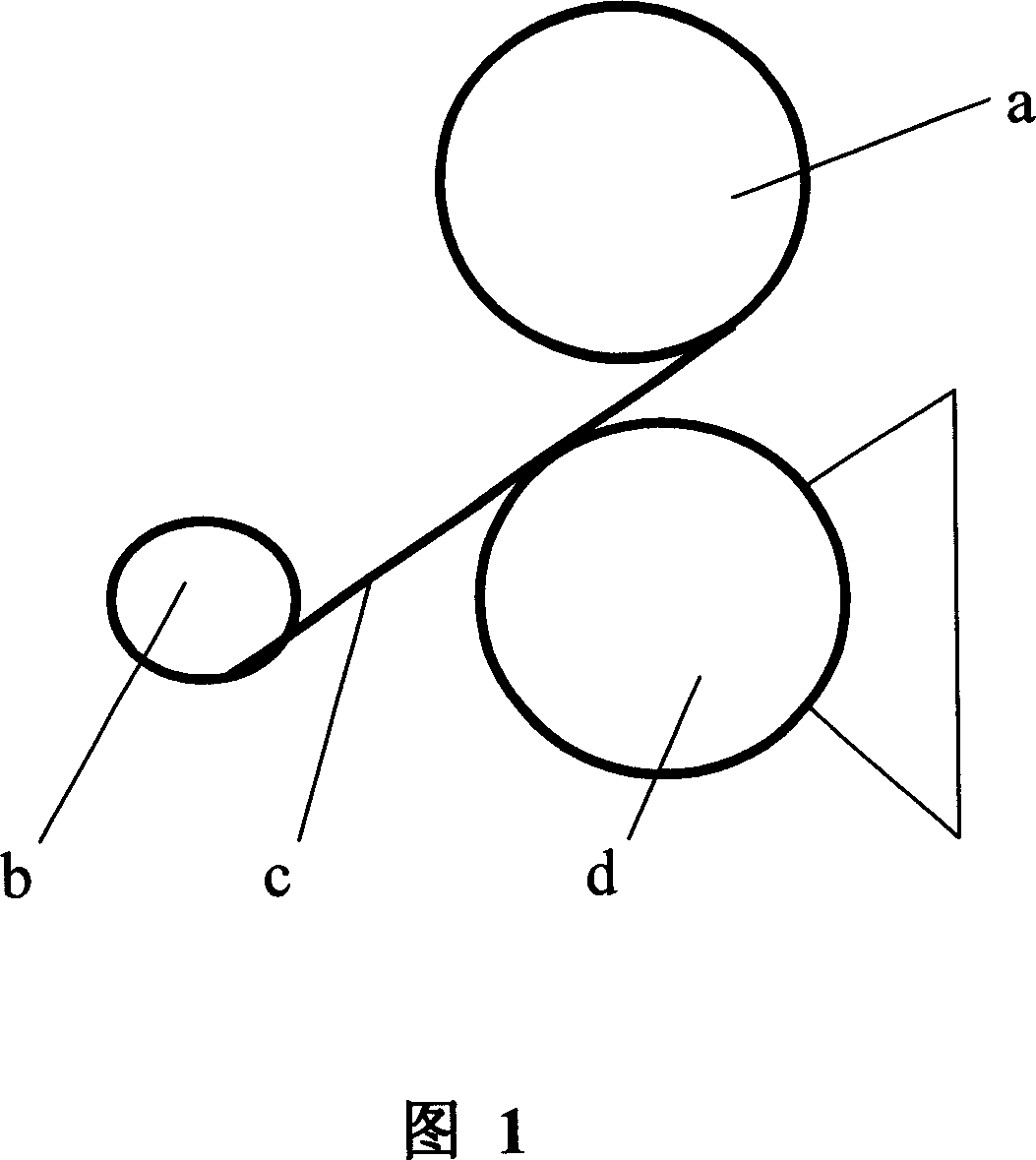

Image

Examples

Embodiment

[0025] Embodiment (1) AC coating / primer 1 / PET-AL / primer 2 / PVDC coating. Primer 1 coating amount is 0.3g / m 2 , the coating amount of primer 2 is 0.8g / m 2 , PVDC coating amount is 4.0g / m 2 , AC coating weight is 1.0g / m 2 , Cured for 2 days at 42°C. The coating speed is 200m / min; the drying temperature is 130°C; the drying time is 8 seconds. In addition, the primer is dried with hot air, and the top coat is dried with a combination of far-infrared heating and hot air. Coating material formula: (1) Primer coating material formula (both surfaces are the same primer formula) - weigh 20kg of polyurethane adhesive (solid content 55%), curing agent 4kg (solid content 55%), mix and stir evenly . (2) PVDC coating material formula for surface coating—weigh 250kg of PVDC emulsion (solid content 49%), wax emulsion 14.7kg (solid content 25%), anti-adhesive agent 1.2kg (solid content 10%), soft water 14.8kg , mix and stir evenly; surface coating AC coating material formula - weigh AC e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com