Outer composite bag infusion bag

A technology of infusion bags and composite bags, which is applied in the field of infusion bags, can solve problems such as inability to obtain tests, and achieve the effects of convenient heat sealing and high-temperature disinfection, low material cost, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention and corresponding drawings.

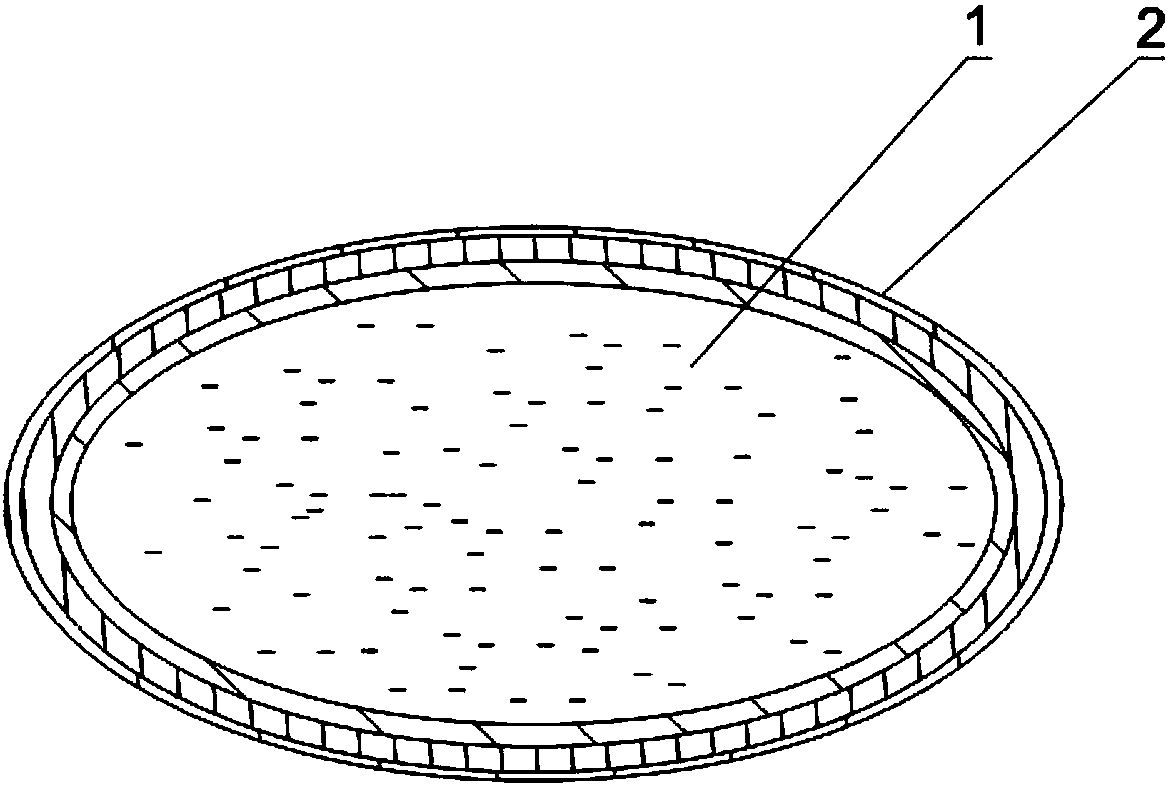

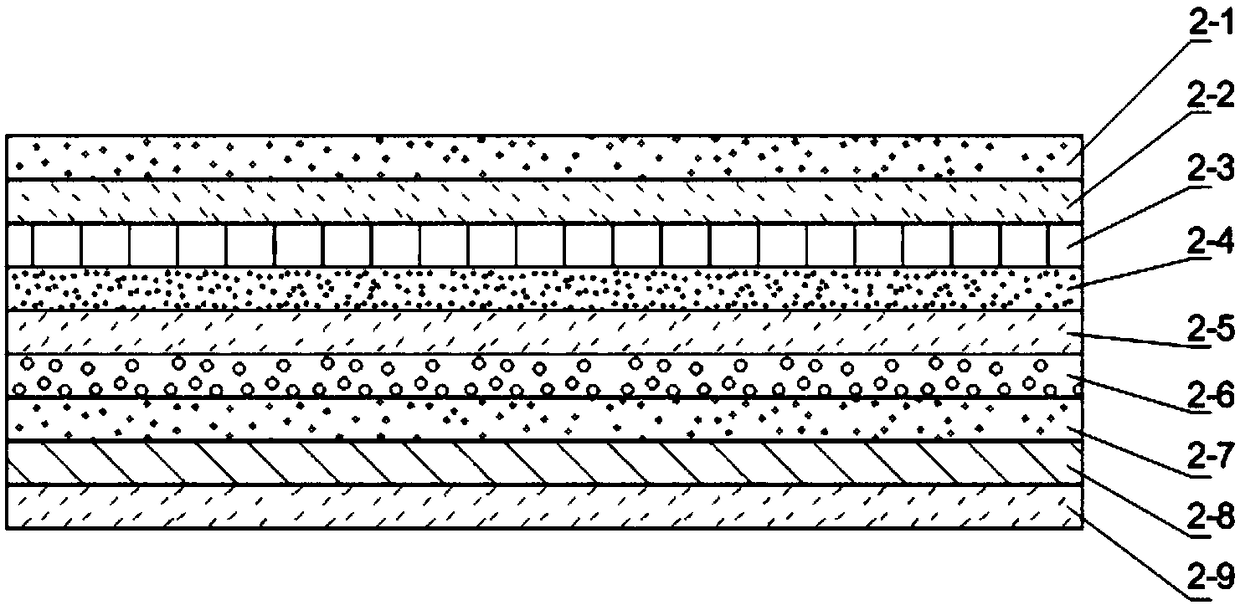

[0032] Refer to attached figure 1 , the packaging of the present invention is mainly divided into three parts: a liquid medicine layer, a leakage detection layer, and a gas barrier layer.

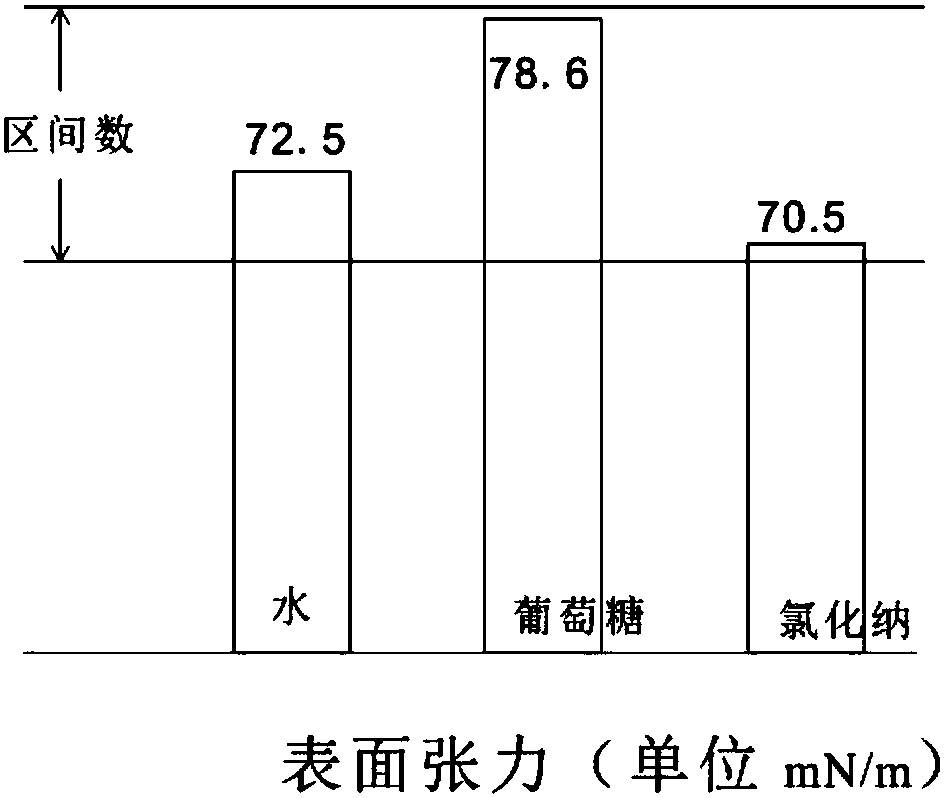

[0033] 1. The innermost layer is the liquid medicine layer in direct contact with the liquid medicine. The oxygen transmission rate, water vapor transmission rate, and nitrogen gas transmission rate of the liquid medicine layer determine the basic requirements of the membrane material. If the transmission rate is high, it cannot withstand the vacuum requirement of the leak detection layer. , the liquid medicine is likely to penetrate the liquid medicine layer; so it is necessary to seek the best bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com