Shredder

A chopper and chopping technology, applied in grain processing and other directions, can solve the problems of high food waste rate, poor chopping effect, easy clogging, etc., to achieve low food waste rate, ensure chopping efficiency, and not block Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

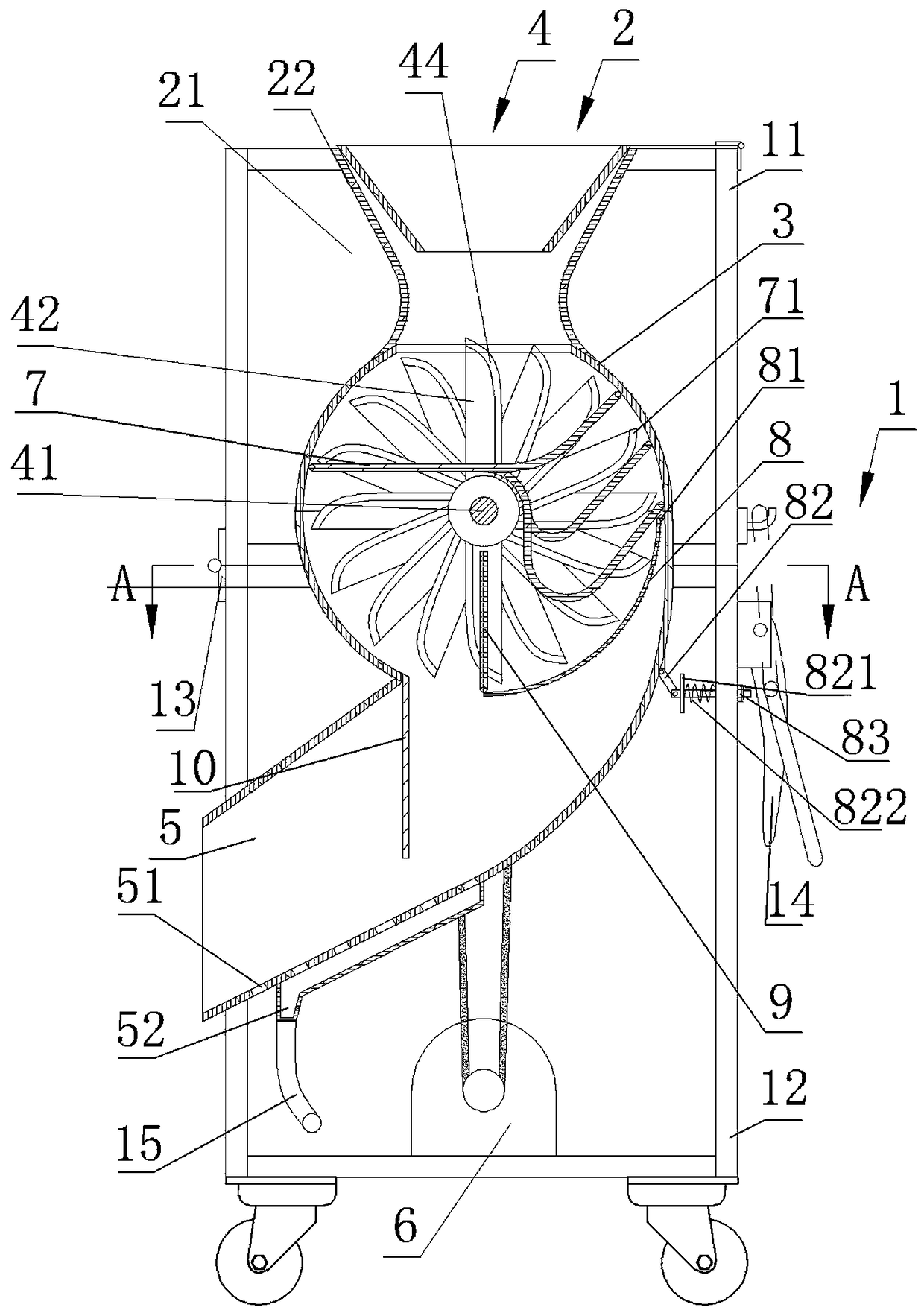

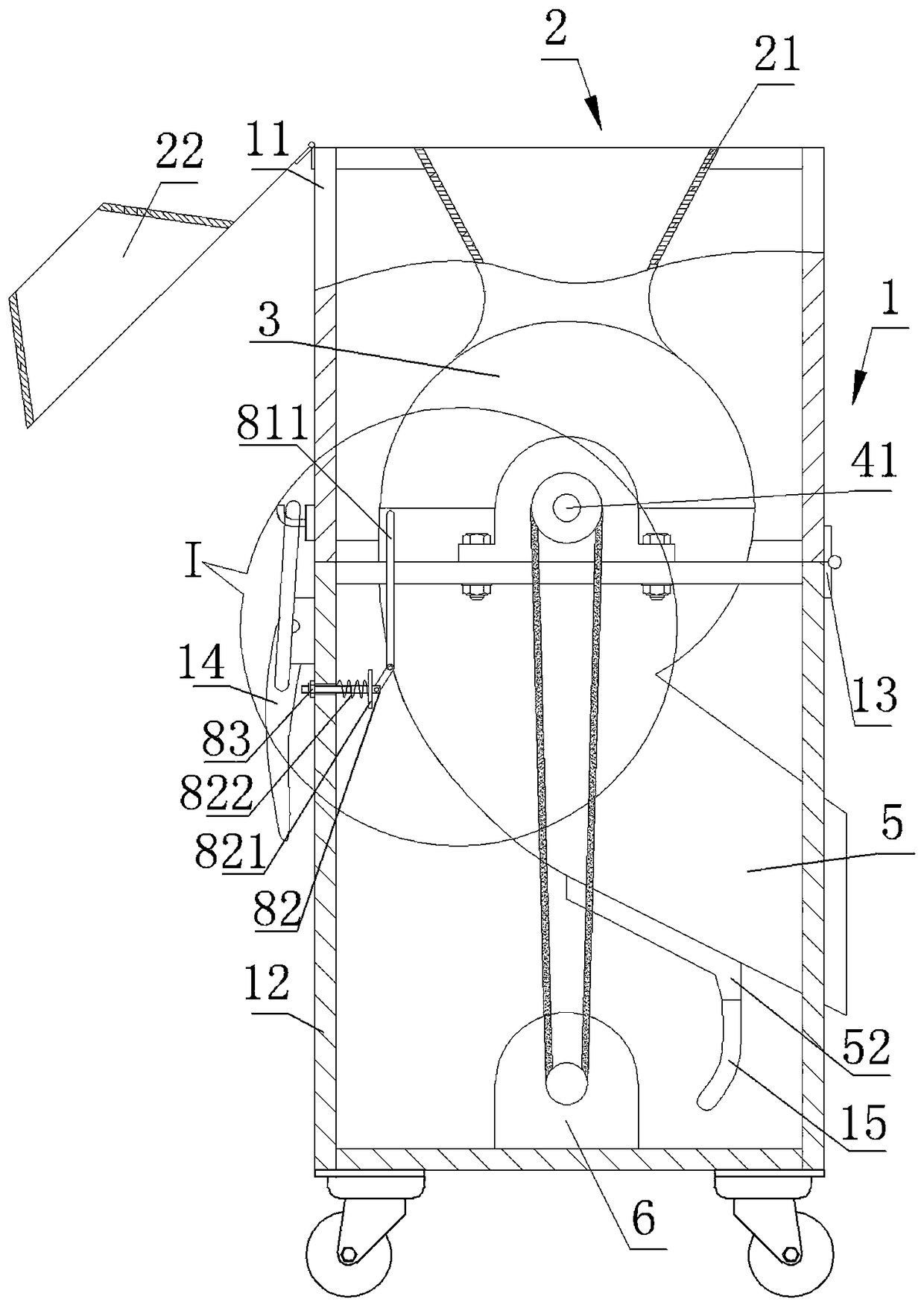

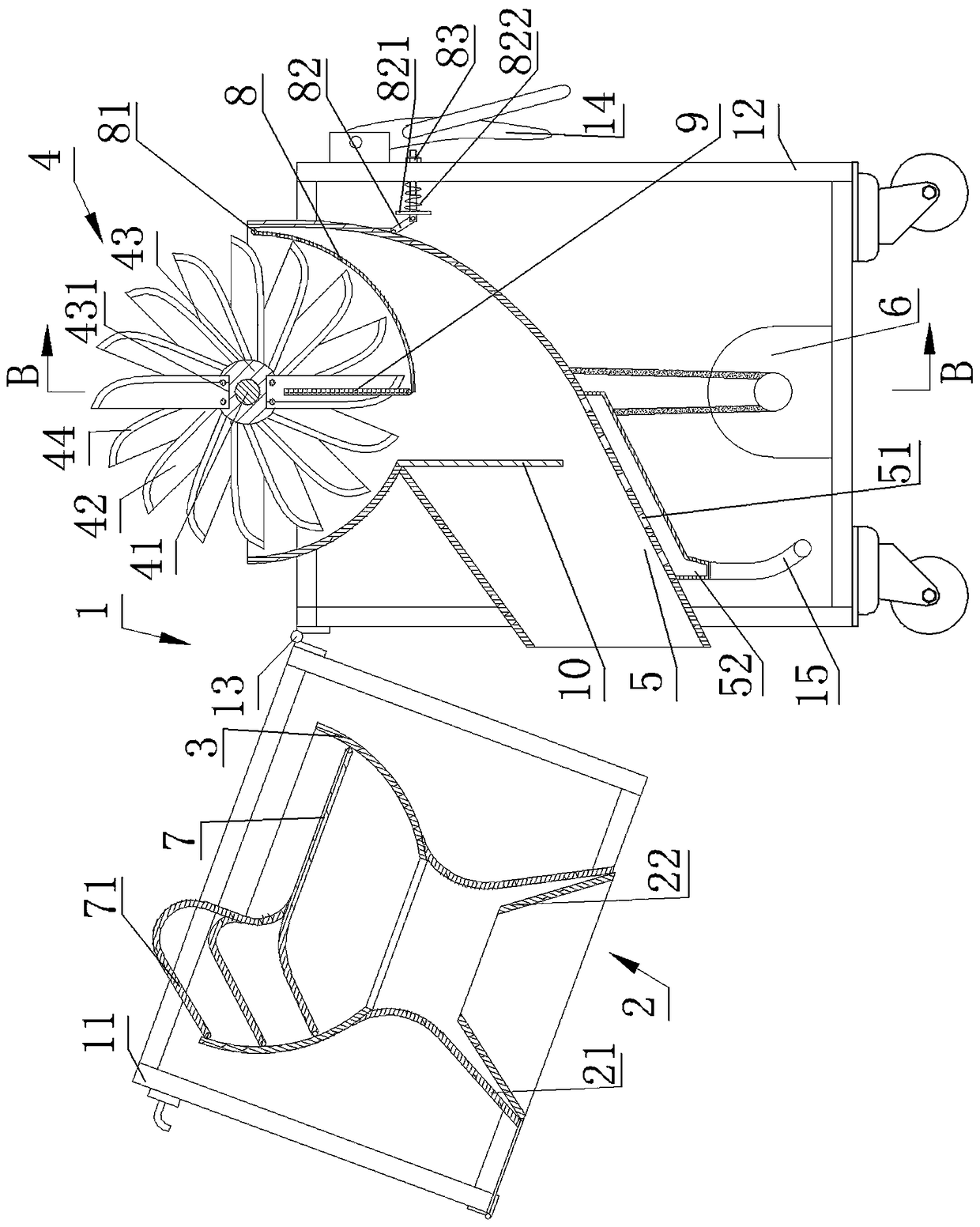

[0032] From Figure 1 to Figure 8It can be seen that this chopping machine of the present invention includes a casing 1, a feed hopper 2, a chopping cylinder 3, several combined cutters 4, a hopper 5, a motor 6, some auxiliary cutting rods 7, and arc adjustment Plate 8 and auxiliary cutting grid 9, wherein the chopping cylinder 3 is horizontally installed in the casing 1, each combined cutter 4 is installed on a rotating shaft 41 and is evenly arranged along the cylindrical helical line of the rotating shaft 41, and the rotating shaft 41 can rotate freely The axis of the penetrating chopping cylinder 3 is installed on the casing 1, each combined cutter 4 is installed in the chopping cylinder 3 through the rotating shaft 41, and each auxiliary cutting rod 7 is installed laterally in the chopping cylinder 3 above the rotating shaft 41, Each auxiliary cutting rod 7 is evenly arranged along the axial direction of the chopping cylinder 3, each auxiliary cutting rod 7 and the combin...

Embodiment 2

[0062] From Figure 9 It can be seen that the difference between the second embodiment and the first embodiment is that a roughing shell 16 is detachably installed on the upper shell 11 through bolts, and a rough-feeding shell 16 connected from top to bottom is provided in the roughing shell 16. Hopper 161 and coarsely chopping cylinder 162, the bottom of this coarsely chopping cylinder 162 is communicated with feed hopper 2, at the axial center of coarsely chopping cylinder 162 there are evenly installed some coarse combined cutters 163 along the helical line of the cylinder, A number of coarse auxiliary cutting rods 164 are evenly distributed in the coarse chopping cylinder 162 above the coarse combined cutter 163 along its axial direction, and each coarse combined cutter 163 and coarse auxiliary cutting rods 164 are arranged alternately along the coarse chopping cylinder 162 axial direction. , the thickness of the rough combination cutter 163 is greater than the combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com