Biodegradable high-barrier composite film material structure and packaging bag thereof

A composite film, biodegradable technology, applied in the field of degradable composite film materials, can solve the problems of insufficient barrier properties of degradable materials, non-degradable plastics polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

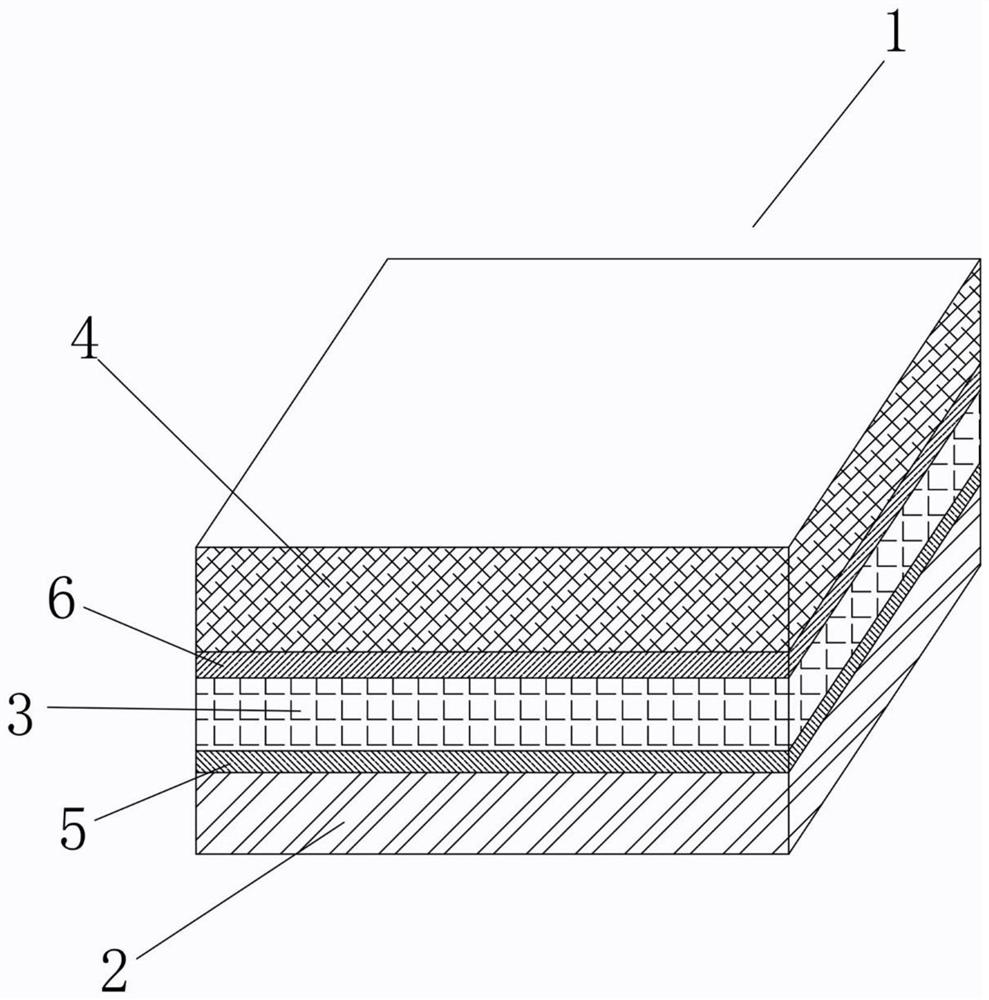

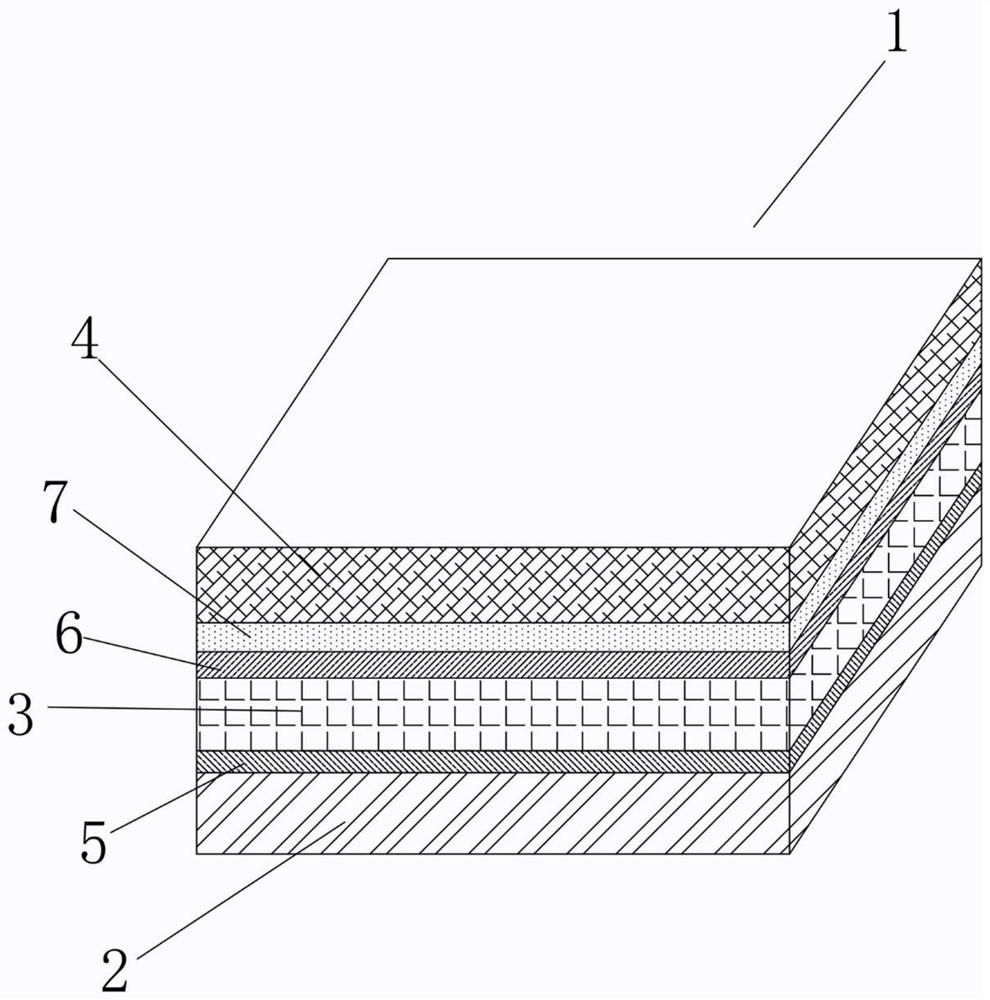

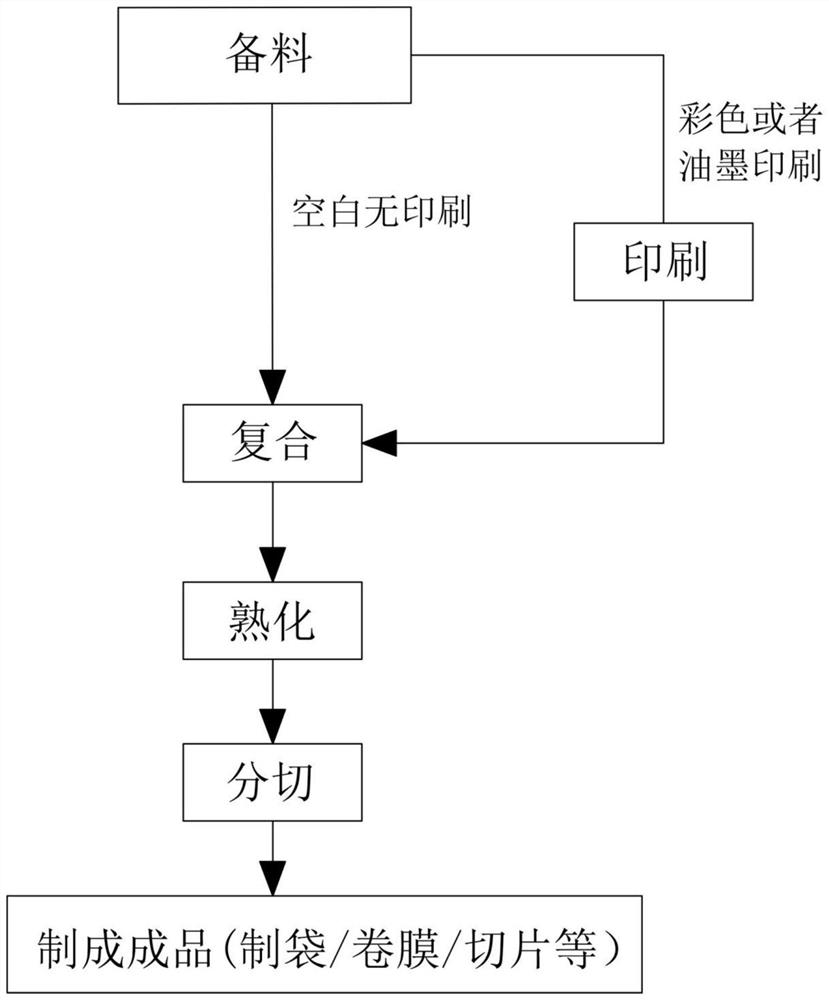

[0020] Such as figure 1 As shown, the structure of a biodegradable high-barrier composite film material 1 described in this embodiment, the composite film material 1 sequentially includes a cellulose layer 4, a pure aluminum layer 3, a PBAT layer 2 and a clamping The second adhesive layer 6 between the PBAT layer 2 and the first adhesive layer 5 of the pure aluminum layer 3, the pure aluminum layer 3 and the cellulose layer 4, the PBAT layer 2, the first adhesive layer 5, The pure aluminum layer 3, the second adhesive layer 6 and the cellulose layer 4 are bonded together through composite film-forming technology.

[0021] The PBAT layer 2 is a degradable material with good comprehensive performance, which can be made of starch, BTAT, PBS, PBSA, PCL, inorganic powder, PLA polylactic acid, PPC, PGA, etc. or a single material. Degradation of film materials. Among them, PLA is derived from corn / sugarcane / cassava to extract glucose and synthesize polylactic acid as biological org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com