A multi-material 3D printer

A 3D printer, multi-material technology, applied in the field of printers, can solve the problems of single printing material, difficulty, affecting printing speed, etc., to achieve the effect of accurate positioning, good load-bearing performance, and improved printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

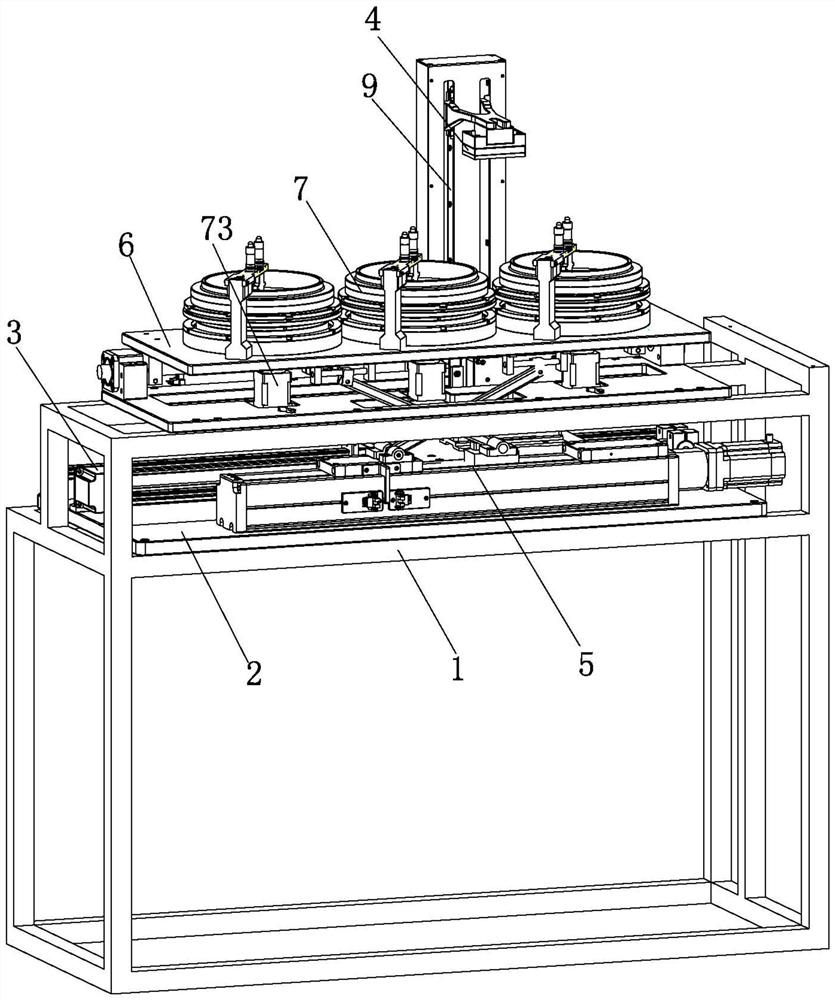

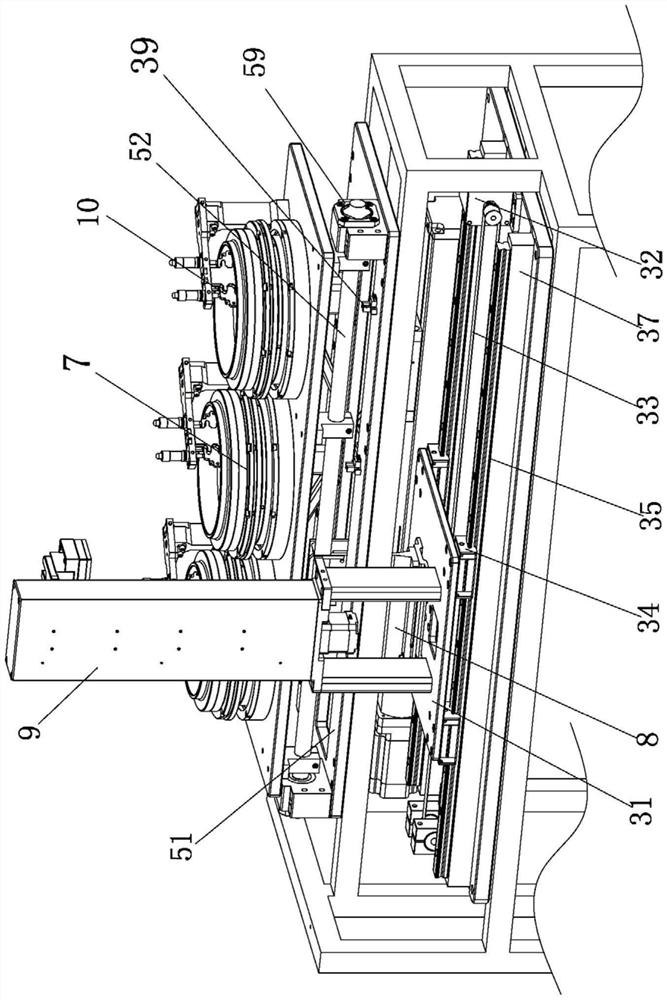

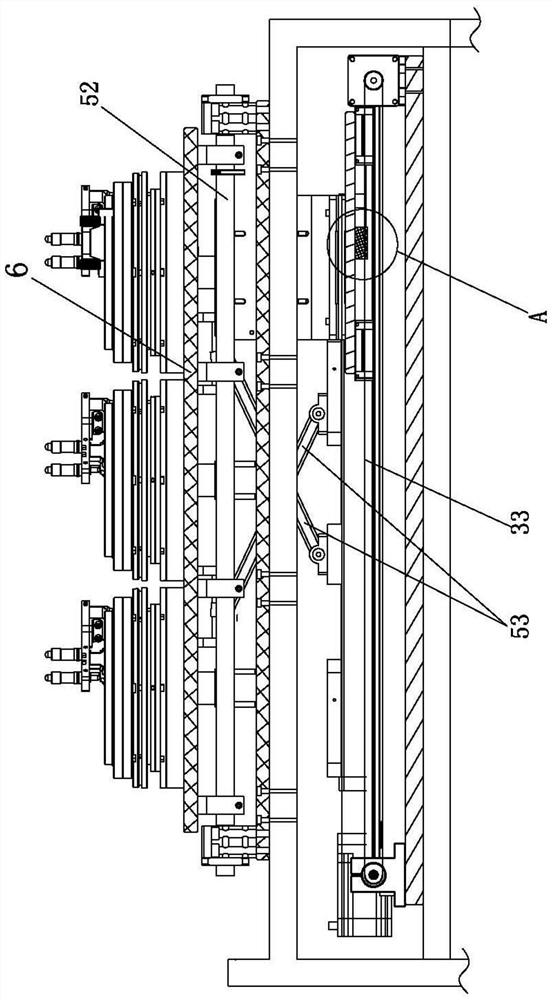

[0037] Please refer to the manual attached figure 1 to the attached Figure 9 As shown in the figure, the present invention is a multi-material 3D printer, which can print a variety of printing materials on one printed part, which consists of a frame 1, a bottom plate 2, a Z-axis translation mechanism 3, a printing platform 4, and an oblique pulling mechanism 5. , the mounting plate 6 and at least two material holding mechanisms 7 and other parts are assembled.

[0038] Wherein, the bottom plate 2 is fixedly installed on the rack 1 .

[0039] The Z-axis translation mechanism 3 is supported on the base plate 2 and can move relative to the base plate 2. An optical machine 8 is installed on the Z-axis translation mechanism 3, and the optical machine 8 can move with the Z-axis translation mechanism 3 to any position. The bottom of the material mechanism 7, which can cure the printing material, and only needs to be provided with a set of polishing machine 8, thereby greatly reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com