A kind of preparation method of low-temperature curing conductive copper paste

A copper paste, low temperature technology, used in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. The effect of reducing free space, increasing fluid volume, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method for low-temperature curing conductive copper paste, comprising the following steps:

[0024] (1) First add binder to the solvent to form a mixed solution, then add copper salt and nano-copper powder to the mixed solution, and finally add a reducing agent to form a mixed slurry, and control the viscosity of the mixed slurry to 10Pa·s~60Pa s;

[0025] (2) Add the above mixed slurry into a planetary mixer and stir for 20-60 minutes for a dispersion;

[0026] (3) Add the mixed slurry after the primary dispersion to the three-roll mill for secondary dispersion, and finally obtain the conductive copper paste.

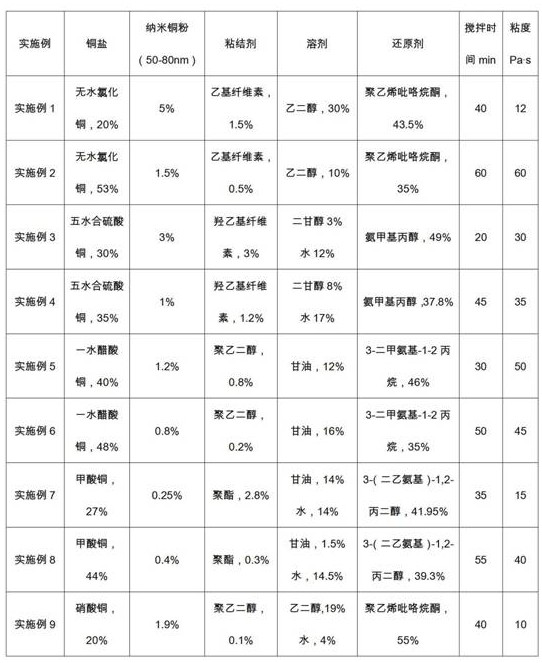

Embodiment 1-9

[0027] Embodiment 1-9, according to above-mentioned preparation steps, the raw material composition of each embodiment and process parameter see the following table:

[0028]

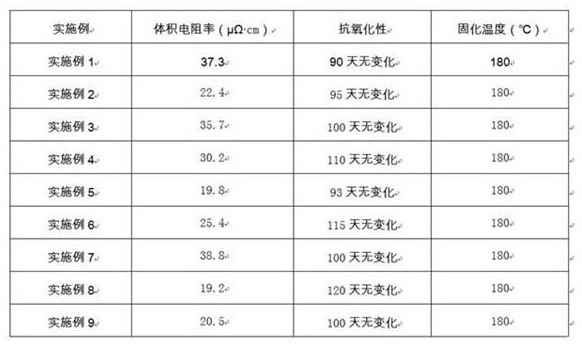

[0029] The performance of embodiment 1-9 conductive copper paste after solidification is as follows:

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com