Biodegradable composite film material, preparation method thereof and packaging bag thereof

A composite film and biodegradable technology, which is applied in the field of biodegradable composite film materials and its preparation method and packaging bags, and can solve the problems of non-degradable plastics polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

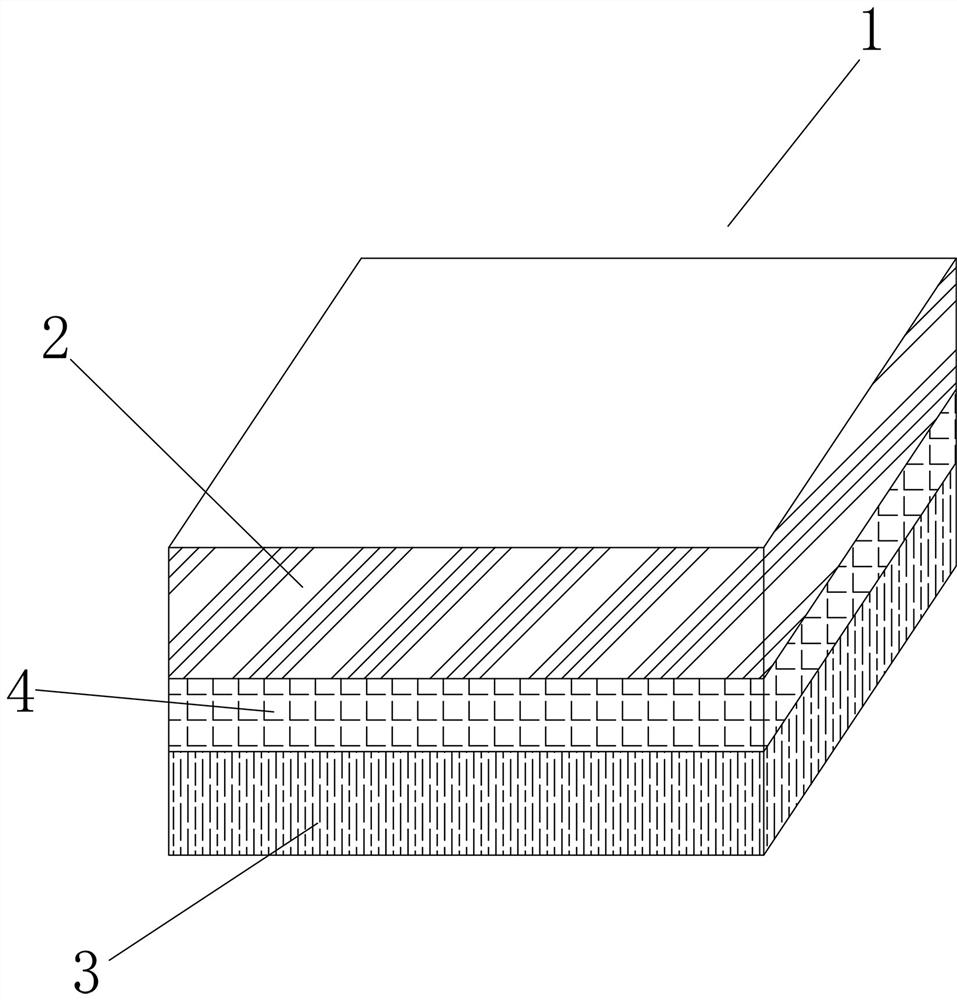

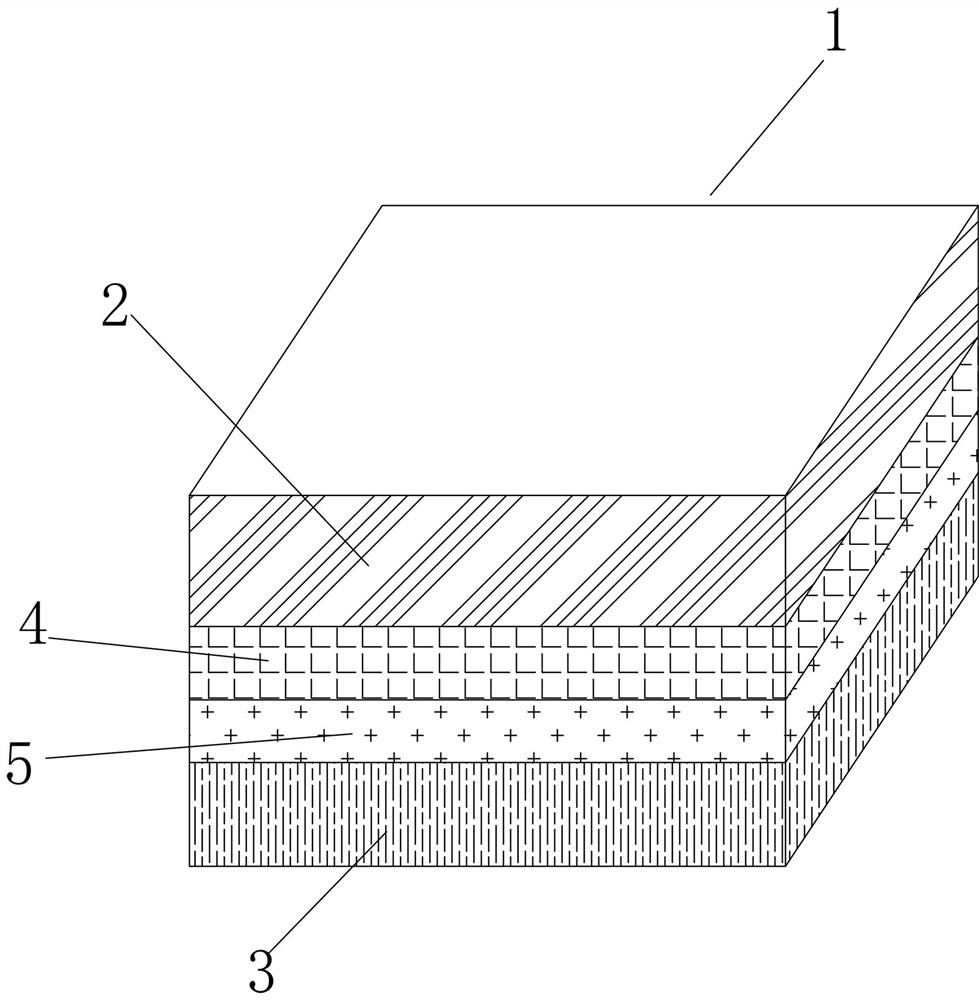

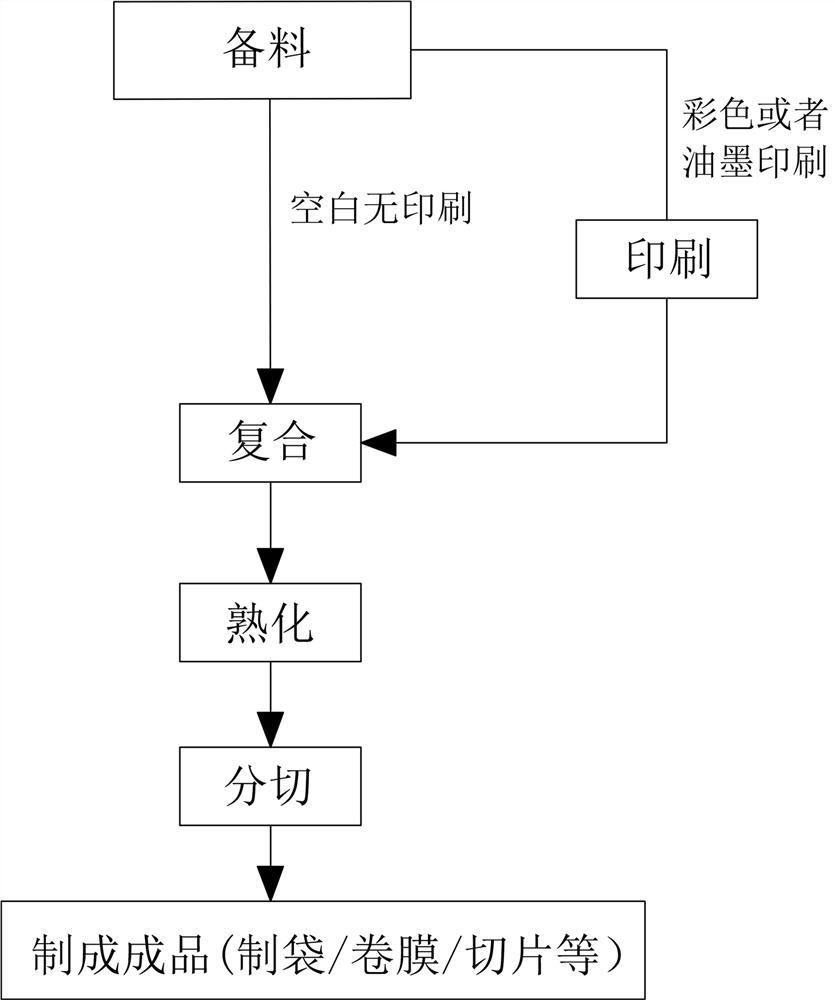

[0024] Such as figure 1 As shown, a biodegradable composite film material described in this embodiment, the composite film material 1 includes a PBAT layer 2, a natural cellulose layer 3 and is sandwiched between the PBAT layer 2 and the natural cellulose layer 3 The adhesive layer 4 between them, the PBAT layer 2, the adhesive layer 4 and the natural cellulose layer 3 are bonded together by dry compounding or solvent-free compounding film forming technology.

[0025] The PBAT layer 2 is a degradable material with good comprehensive performance, which can be a film material produced by the ratio of starch, BTAT, PBS and PLA polylactic acid or a single material. Among them, PLA is derived from corn / sugarcane / cassava to extract glucose to synthesize polylactic acid; BTAT and PBS are derived from coal resources to extract biomass fiber. The thickness of the above several natural materials as raw materials is between 15UM and 200UM, and they all have good properties. Heat sealabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com