Screen inner rupture-proof film, and preparation method thereof

A technology of explosion-proof film and screen, applied in the direction of film/flaky adhesives, coatings, adhesive additives, etc., can solve the problems of yellowing, waste, and shedding of protective films, and achieve the effect of protecting electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

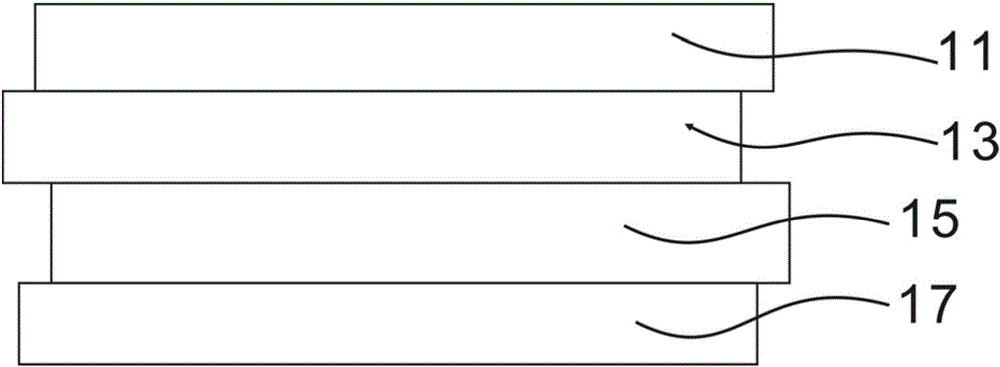

[0041] Choose a 50μm PET substrate 13, apply UV varnish glue on one side of the substrate 13 by dimple coating, and dry it in an oven at 50-130°C, 300-550mj / cm 2 Cured, the thickness is 2-3μm. UV varnish components: 30 parts of butanone, 30 parts of propylene glycol methyl ether acetate, 50 parts of hexanediol diacrylate, 30 parts of epoxy acrylic resin, 15 parts of polyurethane acrylic resin, 4 parts of benzophenone, and 1 part of triethanolamine share.

[0042] Coat the other side of the base material 13 with acrylic glue, apply it with a comma-type doctor blade, and cure it at 80-150° C. to obtain a 20 μm glue layer, and cover it with a release film 17 . Acrylic adhesive components: 50-60 parts of viscous monomer, 5-15 parts of internal polymeric monomer, 3-10 parts of modified monomer, and 0.1-1 part of crosslinking agent. The viscous monomer is 60 parts of butyl acrylate, the internal polymer monomer is 6 parts of vinyl acetate, 5 parts of methyl methacrylate, 5 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com