Peep-proof printable magnetic-resistant film and preparation method thereof

A technology of magnetic film and protective film, which is applied in the field of anti-peeping printable antimagnetic film and its preparation, which can solve the problems of single function and inability to meet the daily needs of customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing an anti-peep printable antimagnetic film, comprising the following steps:

[0060] A) one side of the substrate layer is coated with a micro-blind structure layer to obtain a substrate layer compounded with a micro-blind structure layer;

[0061] B) one side of the TPU film is coated with a UV hardening layer to obtain a TPU layer with a UV hardening layer;

[0062] C) OCA glue is coated on the other side of the base material layer, and the TPU layer with the UV hardening layer is bonded, and after curing, an OCA glue layer is obtained;

[0063] D) attaching a first protective film layer on the surface of the UV hardening layer, and attaching a second protective film layer on the surface of the micro-louver structure layer to obtain an anti-peeping printable antimagnetic film.

[0064] In the present invention, the micro-louver structure layer is first coated on one side of the base material layer to obtain the...

Embodiment 1

[0077] 1. On one side of a 50 μm PET film (substrate), a 25 μm micro-louver structure layer is coated with a doctor blade to obtain a PET film layer compounded with a micro-louver structure layer.

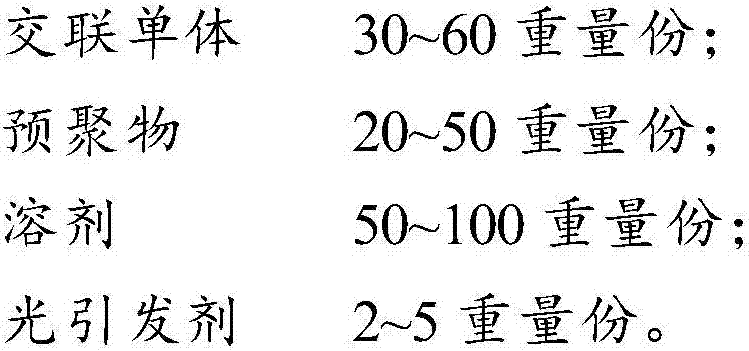

[0078] 2. With 12 parts by weight of silver powder and iron oxide, 6 parts by weight of carbon fiber, 45 parts by weight of hexanediol diacrylate, 25 parts by weight of epoxy acrylic resin, 80 parts by weight of toluene, 2 parts by weight of photoinitiated Agent (the mass ratio of benzophenone and triethanolamine is 2:1) was stirred and mixed for 5 minutes, dried in an oven at 90°C for 75 seconds, and then dried at 300-550mJ / cm 2 Under curing, a UV hardened layer with a thickness of 4 μm was obtained.

[0079] 3. On one side of the 100 μm TPU film, apply the above-mentioned UV curable layer by dimple coating to obtain a TPU layer with a UV curable layer.

[0080] 4. On the other side of the 50 μm PET film, apply a 30 μm OCA glue by means of drop glue coating, stick it with the TPU...

Embodiment 2

[0083] 1. On one side of a 50 μm PET film (substrate), a 30 μm micro-louver structure layer is coated with a doctor blade to obtain a PET film layer compounded with a micro-louver structure layer.

[0084] 2. With 10 parts by weight of silver powder and iron oxide, 4.5 parts by weight of graphite, 40 parts by weight of hexanediol diacrylate, 35 parts by weight of epoxy acrylic resin, 90 parts by weight of toluene, 3 parts by weight of photoinitiated Agent (the mass ratio of benzophenone and triethanolamine is 2:1) was stirred and mixed for 5 minutes, dried in an oven at 90°C for 75 seconds, and then dried at 300-550mJ / cm 2 Under curing, a UV hardened layer with a thickness of 4 μm was obtained.

[0085] 3. On one side of the 100 μm TPU film, apply the above-mentioned UV curable layer by dimple coating to obtain a TPU layer with a UV curable layer.

[0086]4. On the other side of the 50 μm PET film, apply a 25 μm OCA glue by means of drop glue coating, and stick it with the TP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com